Head Loss In Pipe Fitting CFD Simulation, ANSYS Fluent Training

Head Loss In Pipe Fitting CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140 Original price was: €140.€85Current price is: €85.

Head loss happens when water flows through pipes and loses some of its energy – this is super important for engineers to understand! When water moves through different types of pipe fittings like elbows, tees, and valves, it slows down and changes direction, causing energy to disappear. First of all, proper calculation of head loss coefficients helps engineers build water systems that work well without wasting power. Additionally, different shapes of pipe fittings create unique flow patterns that affect how much energy gets lost along the way. Moreover, the pressure drop in piping systems directly impacts how big pumps need to be and how much they cost to run! Furthermore, understanding head loss helps prevent problems like noisy pipes, water hammer, and equipment damage in real buildings and factories. Most importantly, modern engineers use powerful CFD simulation tools like ANSYS Fluent to see exactly where energy dissipation happens inside complicated pipe networks! To further examine this topic, we performed a CFD simulation using ANSYS Fluent, taking inspiration from the research paper titled “Teaching turbulent flow through pipe fittings using computational fluid dynamics approach.”

- Reference [1]: Gajbhiye, Bhavesh D., et al. “Teaching turbulent flow through pipe fittings using computational fluid dynamics approach.” Engineering Reports1 (2020): e12093.

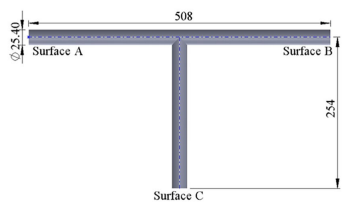

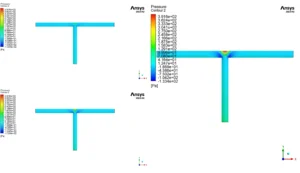

Figure 1: Tee junction pipe fit

Simulation process

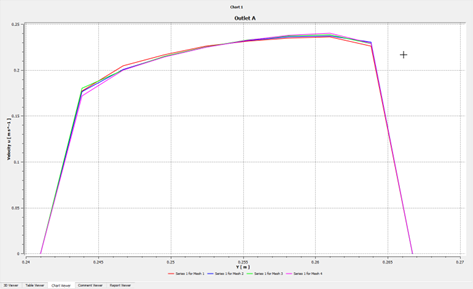

To study head loss in pipe fittings, we used a special computer program called ANSYS Fluent! First of all, we got all the measurements for our T-junction pipe from a research paper that teaches about fluid flow. Then, we did something smart called a grid independence study to make sure our results would be accurate. Also, we tried four different mesh sizes with 72,532, 162,918, 261,270, and 494,266 tiny pieces (called elements). Most importantly, we picked grid #3 with exactly 261,270 mesh cells because it gave us the most reliable head loss coefficient values without wasting computer power! Furthermore, we ran the simulation three times using different Reynolds numbers to see how speed affects the results. Additionally, we calculated the head loss coefficient using a simple formula: pressure drop divided by 0.5 times fluid density times velocity squared. This careful CFD approach helps engineers understand exactly how much energy gets lost when water flows through pipe fittings in real systems!

Figure 2: Mesh independence study

Post-processing

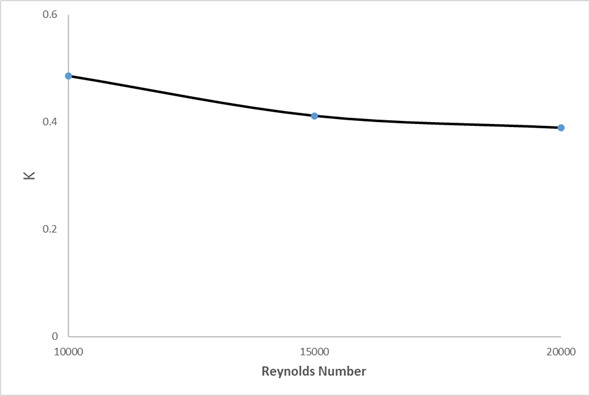

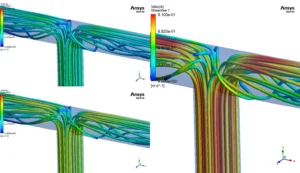

The streamlines in our T-junction pipe show exactly how water moves through this tricky fitting! First of all, when water enters the main pipe, it flows smoothly until it hits the junction point. At this spot, the flow patterns get super complicated as some water continues straight and some turns downward. Our measurements show that water reaches its highest speed of 0.91 meters per second in the straight sections of the pipe! Additionally, we can see that right at the junction, water slows down a lot and creates spinning movements called vortices. Most importantly, these spinning water patterns cause energy loss that engineers must plan for. Furthermore, our careful analysis shows that the head loss coefficient gets smaller as water moves faster! The exact values we measured are 0.486 for Reynolds number 10000, 0.412 for Reynolds number 15000, and 0.389 for Reynolds number 20000. This cool pattern means that faster-moving water (higher Reynolds number) actually loses less energy at the junction than slower water!

Figure 3: Head loss coefficient Vs. Reynolds number

Figure 4: Velocity streamlines through the T-junction pipe fitting

The pressure distribution in the T-junction clearly shows where energy disappears in our pipe system! At the corner where the pipes meet, there’s a dramatic pressure drop that engineers need to watch out for. Our detailed measurements reveal a maximum pressure of 391.6 pascals at the entry points and a minimum pressure of -133.4 pascals in certain areas! Also, this big change in pressure happens because water has to suddenly change direction, creating turbulence and friction. Moreover, this pressure drop is exactly what causes the head loss that makes pumps work harder in real buildings. The relationship between pressure and velocity follows a clear pattern – where water speeds up, the pressure drops, and where water slows down, pressure increases! Our calculations show that even changing the Reynolds number from 10000 to 20000 reduces the head loss coefficient by 19.95%! Most importantly, this information helps engineers design better pipe systems that save energy and money in real-world applications like water supply systems and industrial cooling networks!

Figure 5: Pressure distribution in the T-junction pipe

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€75Current price is: €75.

€265 Original price was: €265.€155Current price is: €155.

€265 Original price was: €265.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

€220 Original price was: €220.€155Current price is: €155.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.