Solar Collector CFD Simulation: Non-Uniform Heat Flux Analysis with UDF in ANSYS Fluent

Solar Collector CFD Simulation: Non-Uniform Heat Flux Analysis with UDF in ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185 Original price was: €185.€135Current price is: €135.

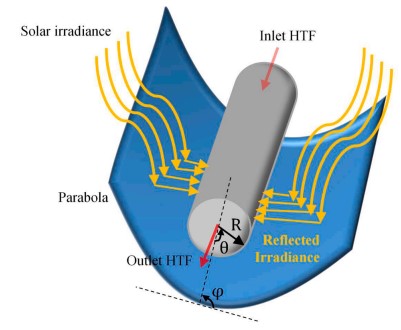

A solar collector is a device designed to capture energy from the sun and transfer it to a fluid. While simple models assume the sunlight hits the surface evenly, in reality, the heat distribution is often irregular. This is called “non-uniform heat flux.” Accurately predicting this uneven distribution is critical because high concentrations of heat can create hot spots that might damage the receiver or improve efficiency depending on the design.

In this Solar Collector Non-Uniform Flux project, we perform a detailed numerical analysis using ANSYS Fluent. We reference a study by Siavashi et al. (2021) to use as guidance for our approach. The main goal of this CFD training is to demonstrate how to simulate real-world conditions where solar intensity varies across the absorber surface. By using a User-Defined Function (UDF), we can apply a specific heat profile to the collector and analyze the resulting thermal gradients.

- Reference [1]: Siavashi, Majid, Mehdi Vahabzadeh Bozorg, and Mohammad Hesam Toosi. “A numerical analysis of the effects of nanofluid and porous media utilization on the performance of parabolic trough solar collectors.” Sustainable Energy Technologies and Assessments45 (2021): 101179.

Figure 1- Schematic diagram of the solar collector geometry used for the simulation.

Simulation Process: Mesh Generation and Non-Uniform Flux UDF Setup

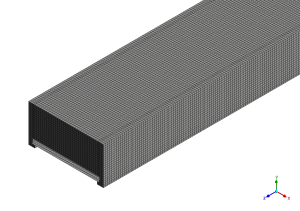

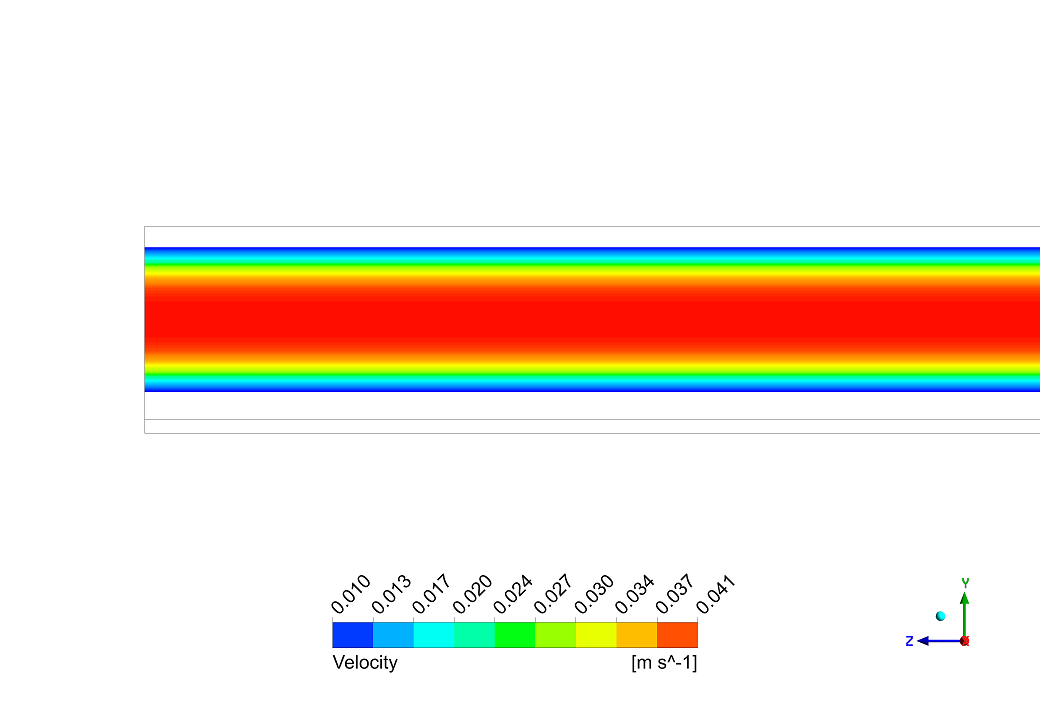

To begin this CFD simulation, we designed the geometry in ANSYS Design Modeler. The model includes distinct zones for the opaque insulation and the glass cover, as each requires specific radiative properties. A critical step in any thermal analysis is meshing. We used ICEM software to generate a high-quality “structured grid.” This grid consists of exactly 1,144,005 quadrilateral elements. We chose a structured mesh because it aligns the cells with the flow direction, which significantly improves the accuracy of the heat transfer calculations.

For the physics setup in ANSYS Fluent, standard constant heat flux settings were not sufficient. To capture the realistic behavior of the solar collector, we needed to model the varying intensity of the sun. Therefore, we wrote a User-Defined Function (UDF). This script tells the solver exactly how much heat to apply at every specific point on the absorber layer. Furthermore, to account for how radiation travels through the glass and heats the fluid, we activated the Discrete Ordinates (DO) radiation model. This combination of a fine mesh, the DO model, and a custom UDF allows for a precise simulation of the non-uniform thermal environment.

Figure 2: tructured grid generated in ICEM with 1,144,005 elements.

Post-processing: Thermal Analysis and Flux Distribution

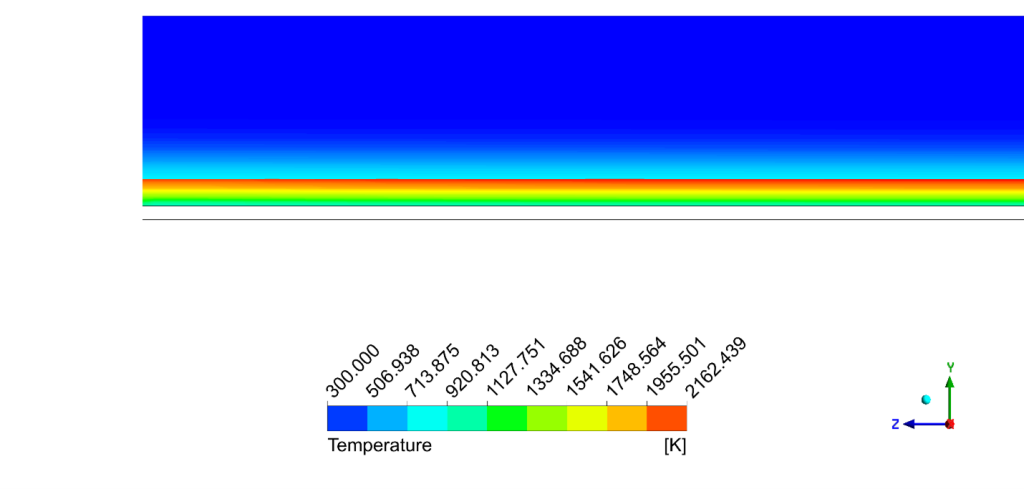

In this section, we analyze the impact of the Non-Uniform Heat Flux on the thermal performance of the collector. The results provide a deep insight into how the concentrated solar energy affects the working fluid. First, we examine the Heat Flux Contour (Figure 3), which visualizes the profile applied by our UDF. The contour shows a distinct peak in the center region. This indicates that the UDF is working correctly, concentrating the solar radiation onto a specific focal line rather than spreading it evenly. This “non-uniformity” is the key factor in this simulation. It creates isolated zones of high intensity that a standard uniform model would miss completely.

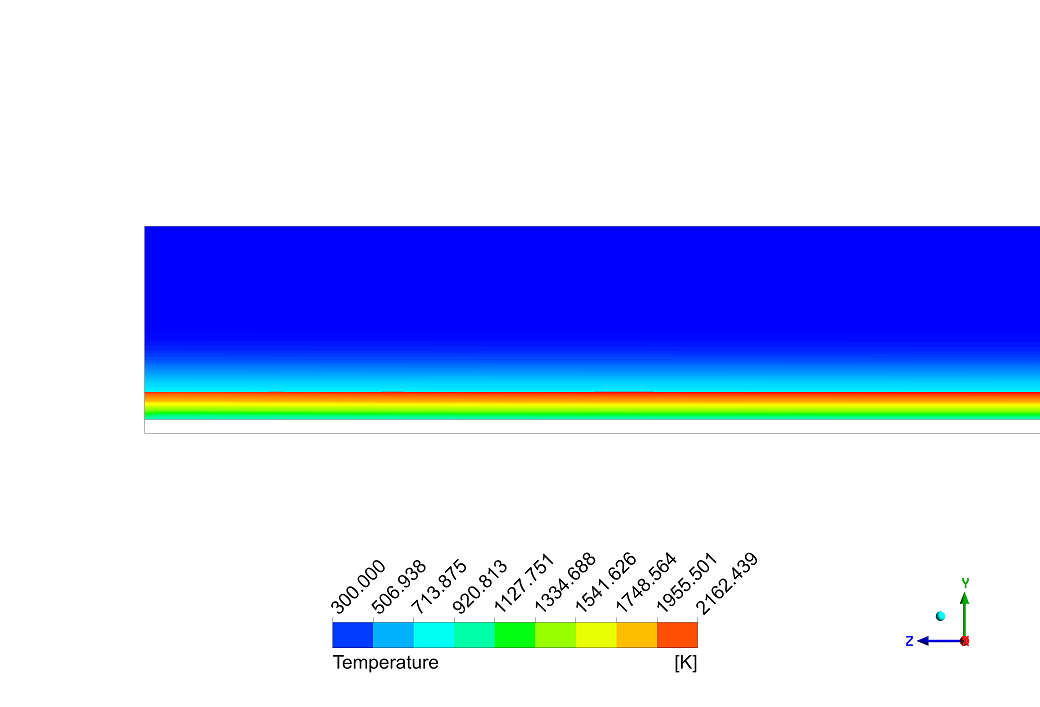

Consequently, this intense flux drives the temperature distribution shown in Figure 4. The thermal gradients are sharp and strategic. We can see that the highest temperatures are located exactly where the UDF applied the maximum flux. The heat transfer to the working fluid is highly effective. The data shows that the fluid enters the collector at 300 K. As it travels through the tube and absorbs the concentrated energy, its temperature rises to 367.13 K at the outlet. This represents a significant 22.3% increase in temperature.

Figure 3: Contour showing the Non-Uniform Heat Flux profile applied via UDF.

Figure 4: Temperature distribution contour showing the thermal gradient and fluid heating.

Moreover, the opaque top layer plays a vital role. The temperature contours near the boundary layers indicate that this layer effectively reduces heat loss to the environment. The detailed view provided by the 1,144,005 mesh elements allows us to see that the heat is being trapped and directed into the fluid, validating the thermal efficiency of the design. The simulation proves that using a non-uniform flux boundary condition is essential for predicting the true maximum temperatures and ensuring the material can withstand the thermal stress.

Key Takeaways & FAQ

- Q: Why use a User-Defined Function (UDF) for heat flux?

- A: Standard Fluent settings usually apply a constant heat value. In a real solar collector, the sunlight is focused and creates a non-uniform flux (higher in the center, lower at the edges). A UDF is the only way to mathematically map this real-world profile onto the geometry.

- Q: What is the advantage of using ICEM for meshing?

- A: ICEM is a powerful tool for creating structured grids with quadrilateral elements. These elements provide better control over the mesh quality and alignment, which is crucial for capturing accurate temperature gradients in complex heat transfer simulations.

- Q: How does the Discrete Ordinates (DO) model help?

- A: The DO model solves the radiative transfer equation for a finite number of discrete solid angles. It is essential for solar CFD simulations because it accurately calculates how sunlight passes through semi-transparent media (like glass) and heats up opaque surfaces.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€75Current price is: €75.

€130 Original price was: €130.€85Current price is: €85.

€240 Original price was: €240.€135Current price is: €135.

€245 Original price was: €245.€185Current price is: €185.

€210 Original price was: €210.€155Current price is: €155.

€240 Original price was: €240.€115Current price is: €115.

Reviews

There are no reviews yet.