Hybrid Nanofluid In Cavity CFD: A Fluent Validation Tutorial

Hybrid Nanofluid In Cavity CFD: A Fluent Validation Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€195 Original price was: €195.€145Current price is: €145.

Improving heat transfer in enclosed spaces, or cavities, is vital for many technologies, like cooling electronics and designing energy systems. A powerful way to do this is to use a special fluid called a hybrid nanofluid. A Hybrid Nanofluid In Cavity CFD simulation allows engineers to see exactly how these advanced fluids improve performance. This report details a CFD simulation performed to validate the results of the research paper, “Effect of boundary conditions on heat transfer and entropy generation during two-phase mixed convection hybrid Al2O3-Cu/water nanofluid flow in a cavity [1]”.

- Reference [1]: Kashyap, Dhrubajyoti, and Anoop K. Dass. “Effect of boundary conditions on heat transfer and entropy generation during two-phase mixed convection hybrid Al2O3-Cu/water nanofluid flow in a cavity.” International Journal of Mechanical Sciences157 (2019): 45-59.

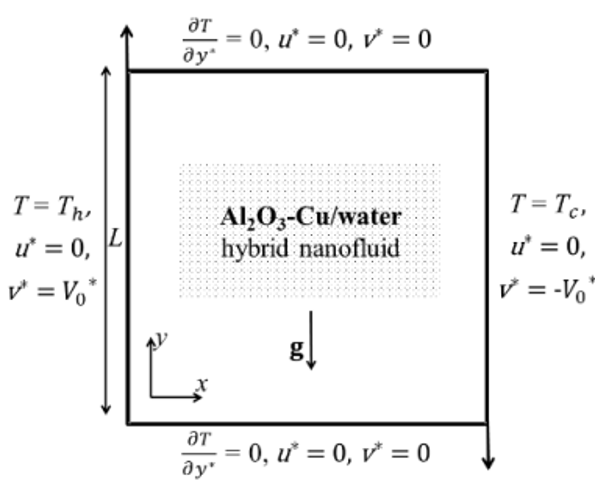

Figure 1: The schematic diagram of the computational model with its boundary conditions [1].

Simulation Process: Modeling the Hybrid Nanofluid In Cavity Fluent Simulation

The simulation was performed in ANSYS Fluent on a simple 2D square cavity. Because of the simple shape, a high-quality structured grid was used to ensure the results are accurate. The cavity is filled with a hybrid Al2O3-Cu/water nanofluid with a nanoparticle volume fraction of 2%. This advanced fluid was modeled using the efficient single-phase approach, where the nanofluid is treated as a single fluid with enhanced properties. A key parameter for this Hybrid Nanofluid Fluent simulation is the Richardson number, which was set to 1. This means the forces from the moving lid (forced convection) and the forces from temperature differences (natural convection) are equally strong.

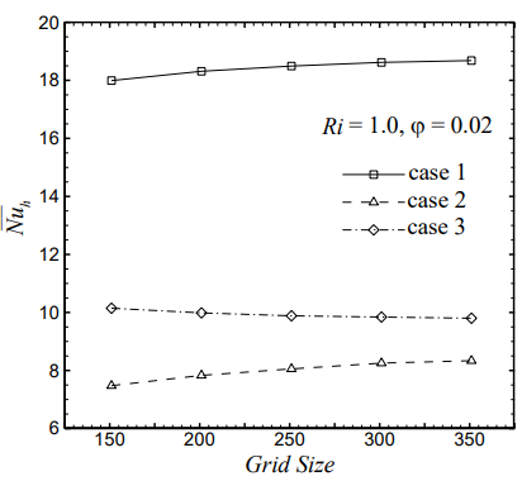

Figure 2: Nusselt number as the main objective for validation purpose [1]

Post-processing: CFD Analysis, How Mixed Convection and Nanoparticles Drive Heat Transfer

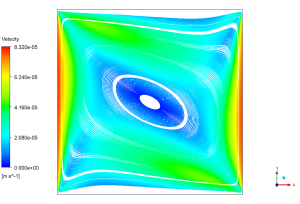

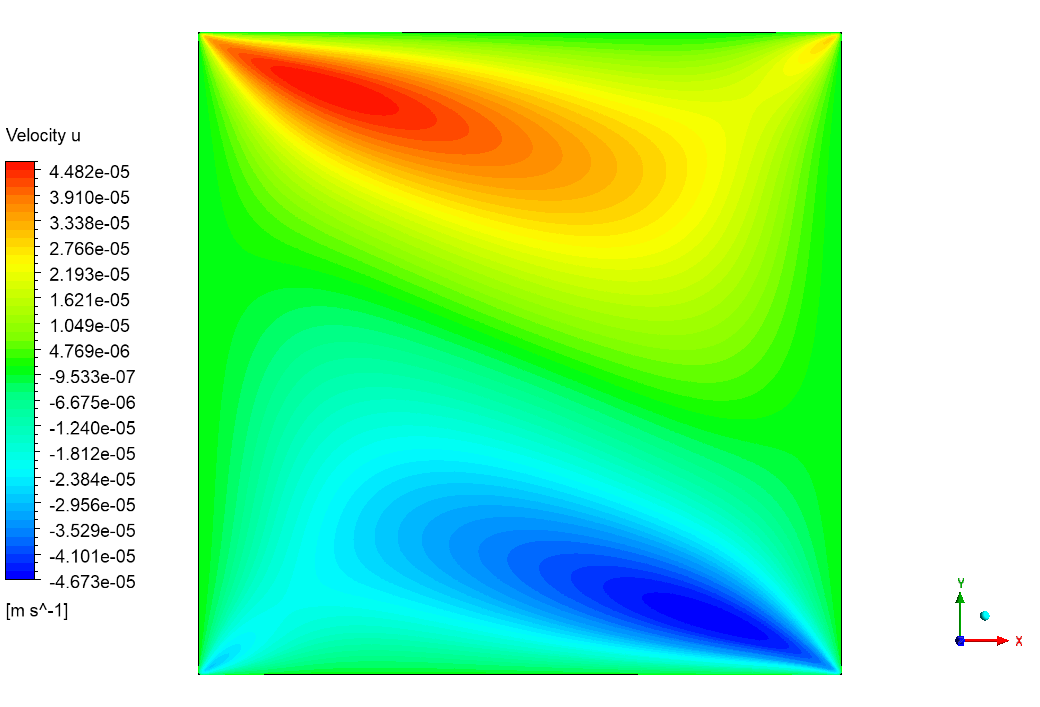

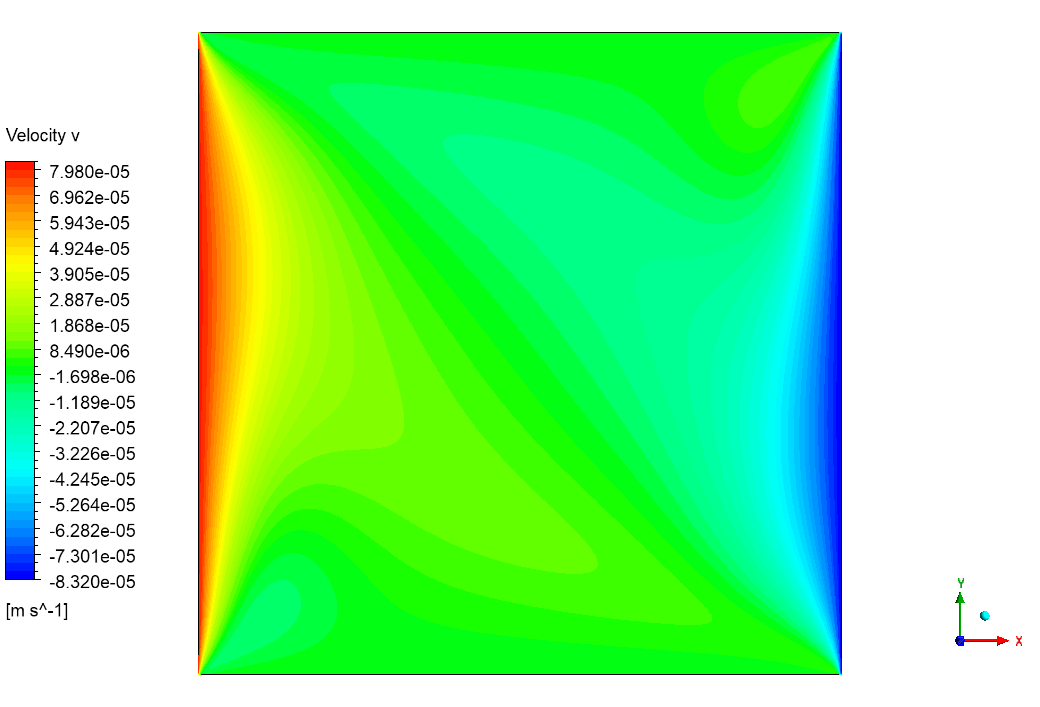

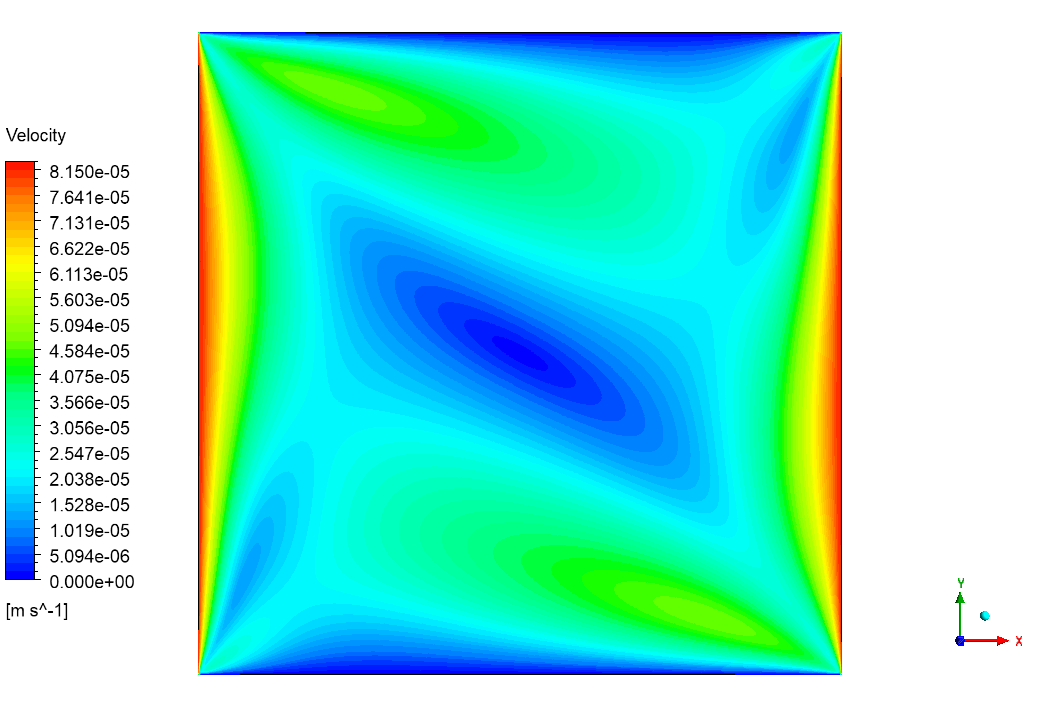

The simulation results provide a clear and fully substantiated story that begins with the fluid motion, which is the “cause” of the enhanced heat transfer. In this Hybrid Nanofluid CFD model, with a Richardson number of 1, two forces work together. First, the moving top lid drags the fluid, forcing it into a large-scale circulation. Second, the hot left wall heats the nanofluid, making it lighter and causing it to rise, while the cold right wall cools it, making it denser and causing it to sink. The velocity contour in Figure 2 is the visual proof of these combined forces, showing a large, dominant vortex in the center of the cavity. This vortex, with speeds up to 8.32×10⁻⁵ m/s, acts like a powerful mixing engine. This effect is amplified by the Al2O3-Cu nanoparticles, which have much higher thermal conductivity than water, turning the entire rotating fluid into a highly efficient heat carrier.

Table1: Validation of hybrid nanofluid in cavity CFD simulation problem

| Reference Paper | CFD Simulation | Error (%) | |

| Nusselt Number | 18 | 16.92 | 6 |

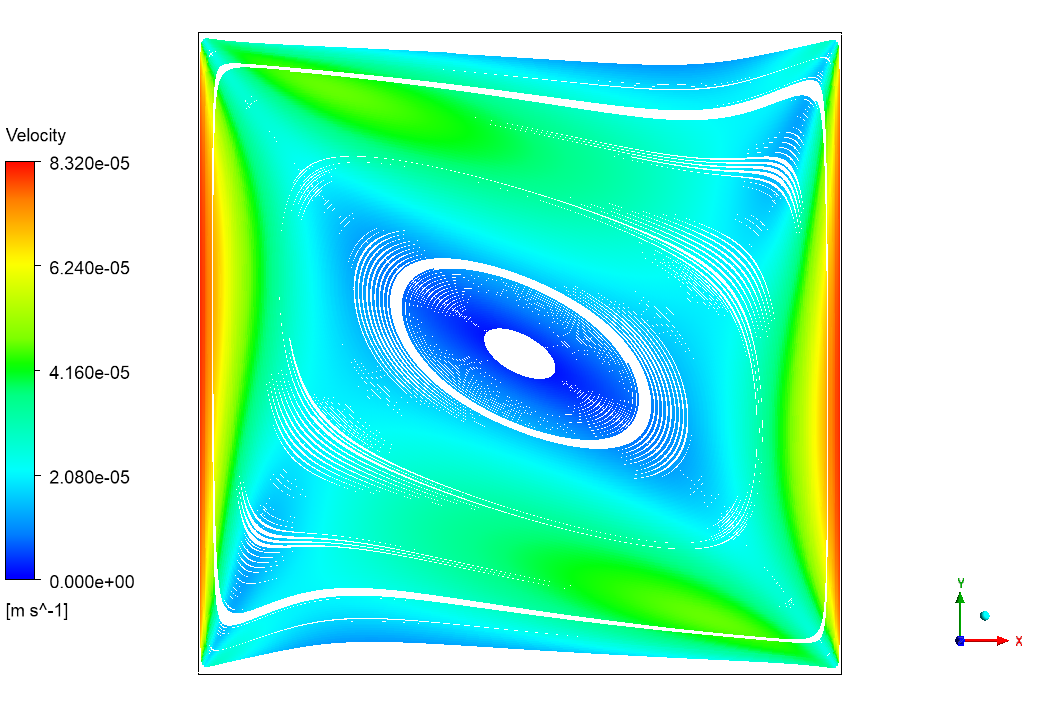

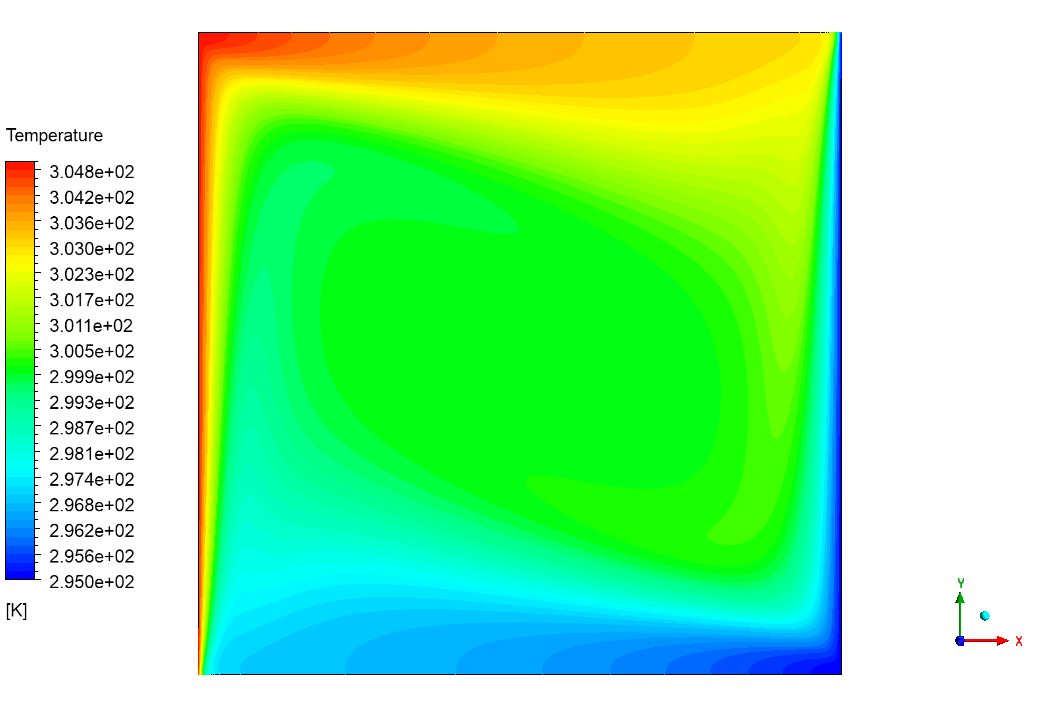

Figure 3: Temperature contour showing the effective heat transport and thermal gradient established by the hybrid nanofluid flow.

This powerful, nanoparticle-enhanced vortex has a direct and measurable “effect” on the cavity’s thermal performance. The temperature contour in Figure 3 shows this clearly. The vortex grabs heat from the hot left wall (red, 304.8K) and efficiently carries it across the cavity toward the cold right wall (blue, 295K), creating the distinct diagonal temperature gradient. The excellent mixing in the vortex’s core creates a large, uniform temperature zone (green, ~301K), preventing hot spots and distributing the thermal energy evenly. The ultimate proof of this effect is the high rate of heat transfer, which is measured by the Nusselt number. As the table below shows, our simulation’s calculated Nusselt number of 16.92 is extremely close to the reference paper’s value of 18. This incredibly small error of only 6% confirms our simulation is accurate.

The most significant achievement of this Hybrid Nanofluid VALIDATION CFD study is the clear demonstration of how the combined forces of mixed convection create a powerful vortex (the cause) that, when amplified by the nanofluid’s superior properties, results in a validated, high rate of heat transfer across the cavity (the effect).

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€265 Original price was: €265.€145Current price is: €145.

€140 Original price was: €140.€85Current price is: €85.

€265 Original price was: €265.€135Current price is: €135.

€165 Original price was: €165.€125Current price is: €125.

€195 Original price was: €195.€135Current price is: €135.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.