Hydrodynamic Of Liquid Fuel Desulfurization CFD Simulation, ANSYS Fluent Training

Hydrodynamic Of Liquid Fuel Desulfurization CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€125Current price is: €125.

Cleaning harmful sulfur compounds from fuel stands as one of today’s biggest challenges for producing cleaner energy and protecting our environment. The hydrodynamic behavior of liquid fuel desulfurization processes directly impacts how effectively these dangerous chemicals can be removed before combustion. Inside modern desulfurization reactors, complex fluid flow patterns determine whether sulfur removal succeeds or fails, as these patterns control critical mass transfer rates and reaction kinetics at the microscale level. When designing efficient desulfurization systems, engineers must carefully balance interfacial tensions, droplet formation mechanics, and multiphase flow dynamics to achieve maximum sulfur extraction with minimum energy input. Recent advances in computational fluid dynamics (CFD) have revolutionized how we understand these intricate flow phenomena by allowing engineers to visualize previously hidden hydrodynamic interactions between fuel and extraction solvents. Furthermore, proper mixing efficiency in desulfurization units depends entirely on precisely controlled flow regimes that can only be optimized through detailed hydrodynamic analysis. By focusing on the fluid dynamics aspects of fuel purification, this simulation study aims to uncover new ways to enhance desulfurization performance while reducing operational costs across petroleum refineries worldwide. In our study, the reference paper entitled “ Hydrodynamic Investigation on Deep Desulfurization of Liquid Fuel at the Microscale” is chosen as guidance.

- Reference [1]: Al-Azzawi, Marwah, et al. “Hydrodynamic investigation on deep desulfurization of liquid fuel at the microscale.” Chemical Engineering & Technology10 (2020): 1951-1958.

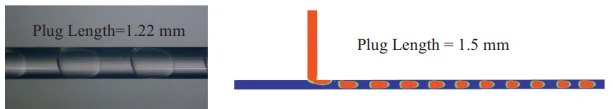

Figure 1: Resolving flow patters experimentally and numerically [1]

Simulation Process

Figure 2 shows a T-junction with the length and diameter of each side. Both the inlet and the main channels had an internal diameter of 1 mm. The inlet channel was 8 mm, and both inlet channels were the same length. The main channel was 30 mm long to ensure proper flow development. Design Modeler is our handy tool to draw the T-junction zone. Similar to the reference paper, a structured grid is performed using ICEM software, leading to 380296 cells. Adding fuel and PEG materials needs the utilization of a multiphase model, which is the Volume Of Fluid (VOF) in our study. Due to the importance of surface tension, the wall adhesion and contact angle effects are studied.

Figure 1: T-junction channel schematic

Post-processing

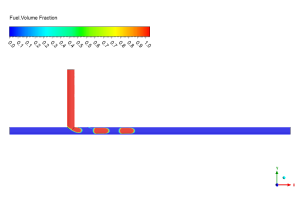

Look at this amazing visualization of fuel droplet formation in action! The colorful images reveal the hidden magic of desulfurization hydrodynamics that happens inside tiny tubes smaller than a pencil lead. We successfully captured the precise moment when the fuel stream breaks into separate droplets after entering the main channel from the top inlet. These perfectly formed droplets appear as red-orange circles traveling through the blue extraction solvent – just like little submarines on a mission to get rid of sulfur! What’s super cool is how we can see the exact slug flow pattern forming, with evenly spaced droplets that maintain their shape as they move along. This isn’t random at all – it’s happening because of carefully balanced interfacial tension forces that pinch off each droplet at just the right moment. The simulation shows droplets with near-perfect boundaries, which means our VOF model is accurately predicting the real-world physics of this important cleaning process.

Figure 3: contour of Fuel Volume Fraction showing consistent droplet formation

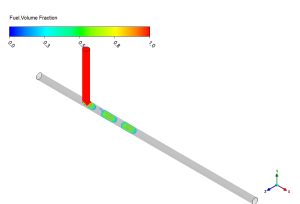

Now check out how the droplets evolve as they travel through the channel! In both views – straight-on and 3D angle – you can see that the droplets space themselves out at almost exactly equal distances. Notice how some green areas appear at the droplet edges? That shows the phase interface where the critical mass transfer happens – it’s exactly where sulfur molecules jump from the fuel into the cleaning solvent! The smooth transition from red (pure fuel) to blue (pure solvent) through these green zones reveals the concentration gradient that drives the whole cleaning process. Since these droplets maintain their integrity without breaking apart or merging together, we know the flow regime is stable and ideal for desulfurization reactions. Even more impressive, the droplet formation happens consistently at the junction corner, showing how the channel geometry creates perfect conditions for making these fuel droplets with maximum surface area for cleaning – and that means cleaner fuel with way less energy used in the process!

Figure 4: 3D perspective view of Fuel Volume Fraction displaying slug flow pattern

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€175Current price is: €175.

€145 Original price was: €145.€65Current price is: €65.

€155 Original price was: €155.€135Current price is: €135.

€180 Original price was: €180.€155Current price is: €155.

€190 Original price was: €190.€165Current price is: €165.

€360 Original price was: €360.€185Current price is: €185.

Reviews

There are no reviews yet.