Indirect Solar Dryer CFD: A Fluent Tutorial on Drying and DPM Simulation

Indirect Solar Dryer CFD: A Fluent Tutorial on Drying and DPM Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185 Original price was: €185.€135Current price is: €135.

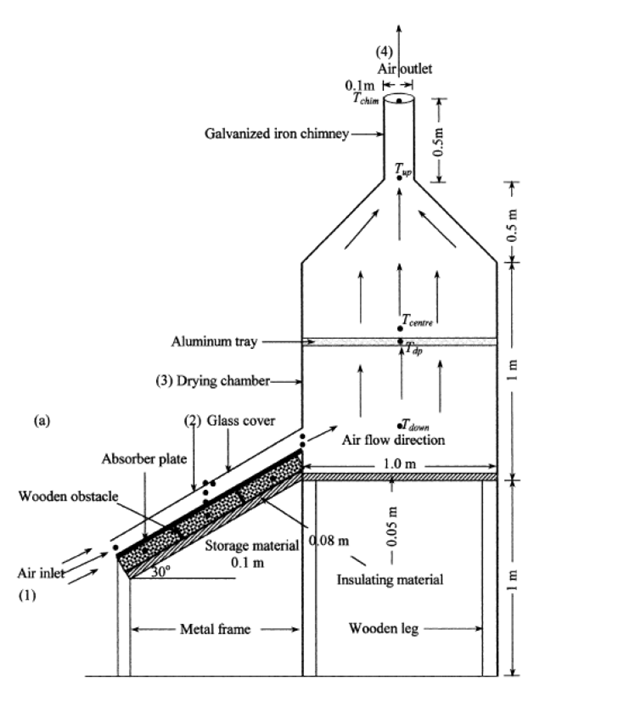

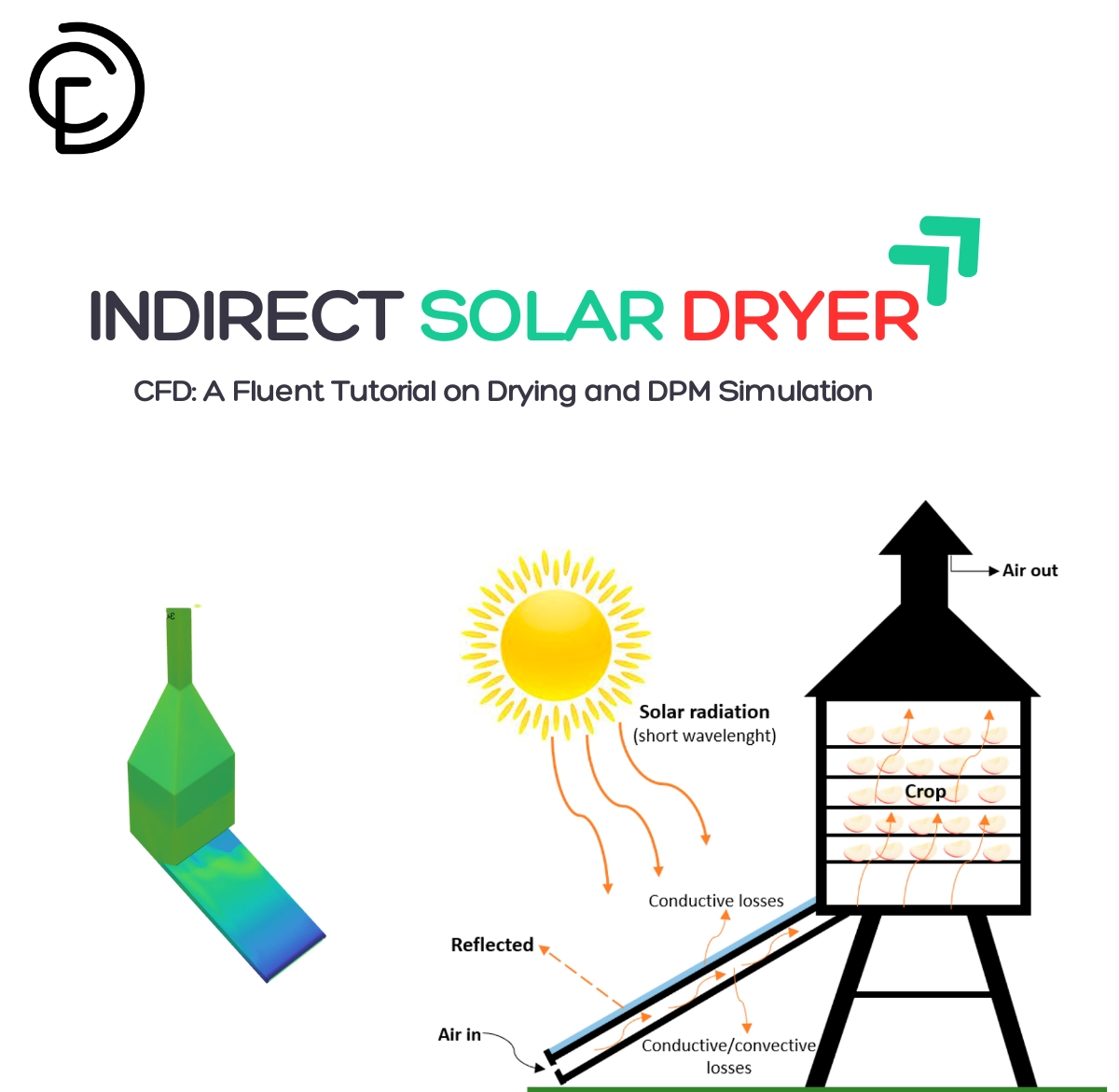

An Indirect Solar Dryer is an advanced and highly efficient technology for preserving agricultural products like fruits, vegetables, and grains. Unlike simple direct dryers where products are exposed to the sun, an indirect system uses a separate solar collector to heat air first. This hot air is then channeled into a protected drying chamber, ensuring a more uniform, controlled, and hygienic drying process. The engineering goal is to maximize the heat transfer from the collector to the air and then from the air to the products, removing moisture as quickly as possible without degrading the product’s quality. A Solar Dryer CFD simulation is the most powerful tool available to engineers for visualizing airflow, predicting temperature distribution, and optimizing the overall design for peak performance. This Indirect Solar Dryer CFD simulation is guided by the principles and methods found in the important research paper by Romero, V. M., et al. [1].

- Reference [1]: Romero, V. M., et al. “Simulation and validation of vanilla drying process in an indirect solar dryer prototype using CFD Fluent program.” Energy Procedia57 (2014): 1651-1658.

Figure 1: The solar dryer prototypes that inspired the Solar Dryer Fluent model [1]

Simulation Process: Modeling Heat Transfer and Airflow in the Indirect Solar Dryer CFD Simulation

To create an accurate digital twin of the dryer, we first built the geometry and generated a high-quality structured mesh using ICEM. A structured grid is essential for providing the most precise results in this type of thermal-fluid simulation. The core of this Solar Dryer Fluent model is the physics setup. To simulate the sun’s energy, we used a combination of the DO radiation model and Solar Ray Tracing. This allows us to accurately track how solar energy is absorbed by the collector surface.

Because the sun’s intensity changes throughout the day, a transient simulation was critical. We wrote a custom User-Defined Function (UDF) to apply a realistic, variable solar heat flux that changes over time, mimicking the sun’s path from morning to evening. To model the moisture leaving the products, the 2-way Discrete Phase Model (DPM) was activated with unsteady particle tracking. This allows us to inject water droplets and see how they evaporate and are carried away by the hot air, which is a key part of any Drying CFD analysis.

Post-processing: Linking Solar Flux, Airflow, and Drying Potential

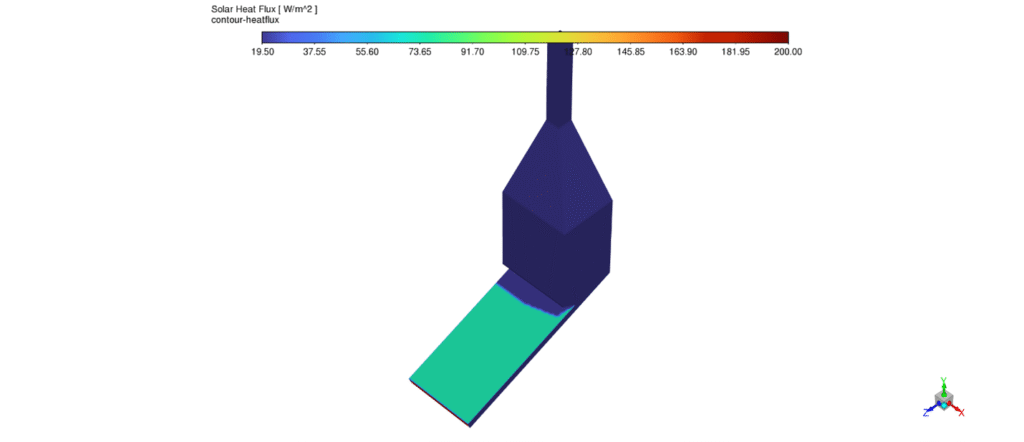

The simulation results provide a clear and detailed story of how the solar dryer functions as an integrated system, starting with the energy source. The solar heat flux contour in Figure 3 shows the system’s engine at work. The collector surface is intensely heated by the sun, absorbing energy at a peak rate of 200 W/m², while other shaded surfaces receive as little as 19.50 W/m². This non-uniform heating is precisely what the Solar Ray Tracing model is designed to capture. This absorbed solar energy is the direct cause of the temperature rise within the system. It is the fuel that powers the entire drying process.

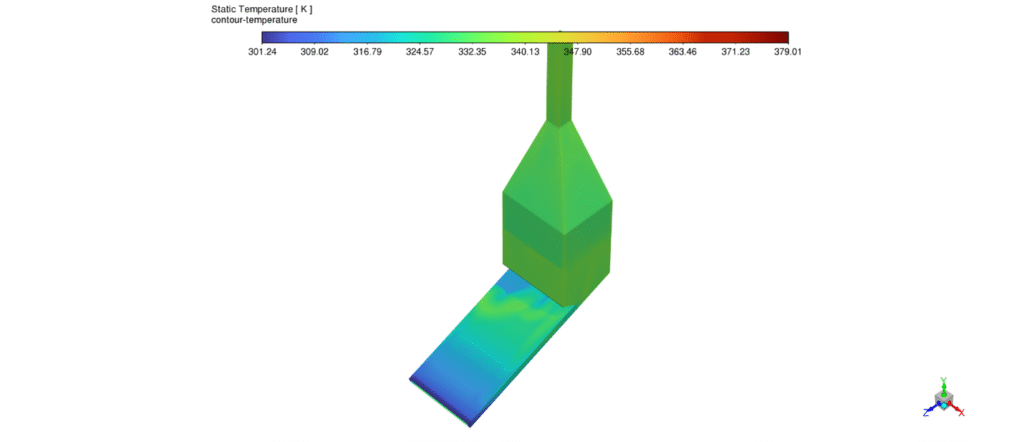

Figure 3: Contours of temperature and velocity vectors, showing how thermal gradients drive the airflow in the Indirect Solar Dryer Fluent simulation.

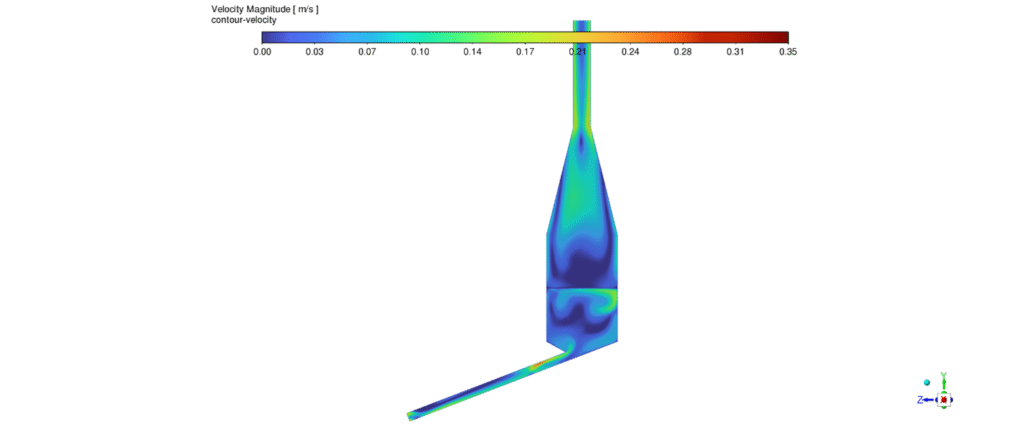

This thermal energy input immediately creates a powerful fluid dynamic response. The temperature contour in Figure 4 shows that the air heats up dramatically, with temperatures ranging from a cool 302.31 K at the inlet to a hot 356.68 K in the solar collector. This large temperature difference creates a strong buoyancy force. The hot, less dense air naturally rises, creating a self-sustaining airflow loop that moves at up to 0.35 m/s. This natural convection is the transport mechanism, carrying the thermal energy from the collector into the drying chamber where the products are located. The most significant achievement of this Solar Dryer CFD simulation is the clear visualization of this fundamental link: the solar flux creates a specific temperature gradient, which in turn drives the exact airflow pattern needed to initiate drying.The final step is the moisture removal itself. While we have successfully established the thermal and fluid dynamic conditions, the simulation has only been run for a few seconds. This is long enough to see the initial airflow patterns but is too short to observe significant evaporation. The Drying DPM CFD analysis requires more time. For the moisture particles to be released from the products and carried away by the hot air stream, the simulation must continue until the system reaches a stable operating temperature and the products themselves have been heated sufficiently. The current results perfectly validate the initial setup, confirming that the dryer will generate the necessary hot airflow. The next stage of the simulation will focus on tracking the DPM particles over a longer period to quantify the moisture removal rate and determine the overall drying efficiency.

Figure 4: Solar heat flux distribution showing the intense energy absorption on the collector surface in the Solar Collector CFD model.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€240 Original price was: €240.€175Current price is: €175.

€200 Original price was: €200.€115Current price is: €115.

€185 Original price was: €185.€135Current price is: €135.

€245 Original price was: €245.€199Current price is: €199.

€360 Original price was: €360.€180Current price is: €180.

€240 Original price was: €240.€135Current price is: €135.

Reviews

There are no reviews yet.