Nanofluid in Microchannel Heat Sink CFD Simulation: Single-Phase Fluent Tutorial

Nanofluid in Microchannel Heat Sink CFD Simulation: Single-Phase Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160 Original price was: €160.€95Current price is: €95.

Modern electronics are becoming smaller and faster, but this creates a huge problem: heat. If we cannot remove the heat quickly, the devices will fail. To solve this, engineers use Microchannel Heat Sinks. These are small blocks of silicon with tiny channels cut into them. They have a very large surface area, which helps transfer heat. To make them even better, we use Nanofluids instead of plain water. A nanofluid is a liquid mixed with tiny solid particles (nanoparticles) that boost its ability to conduct heat.

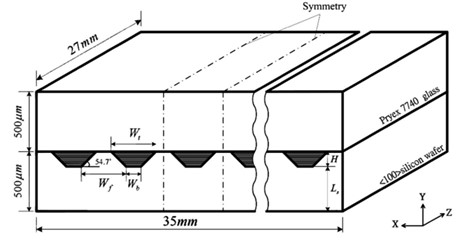

This project is a Nanofluid in Microchannel Heat Sink CFD simulation designed to demonstrate how this advanced cooling technology works. We use ANSYS Fluent to model the flow and heat transfer. In this tutorial, we use the “Single-Phase” method, which treats the nanofluid as one uniform liquid with enhanced properties. For more examples of small-scale flow analysis, please visit our Microfluid & Nanofluid tutorials. The geometry and physics setup are based on the research of Yang et al. [1].

- Reference [1]: Yang, Yue-Tzu, et al. “Numerical study of microchannel heat sink performance using nanofluids.” International Communications in Heat and Mass Transfer57 (2014): 27-35.

Figure 1: Schematic of the microchannel geometry used in the Single-Phase Nanofluid CFD simulation.[1].

Simulation Process: Single-Phase Nanofluid Model in Fluent

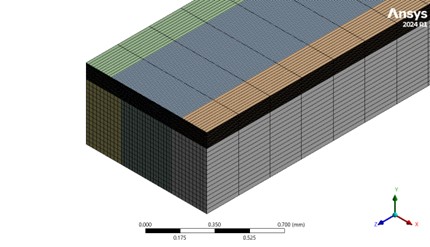

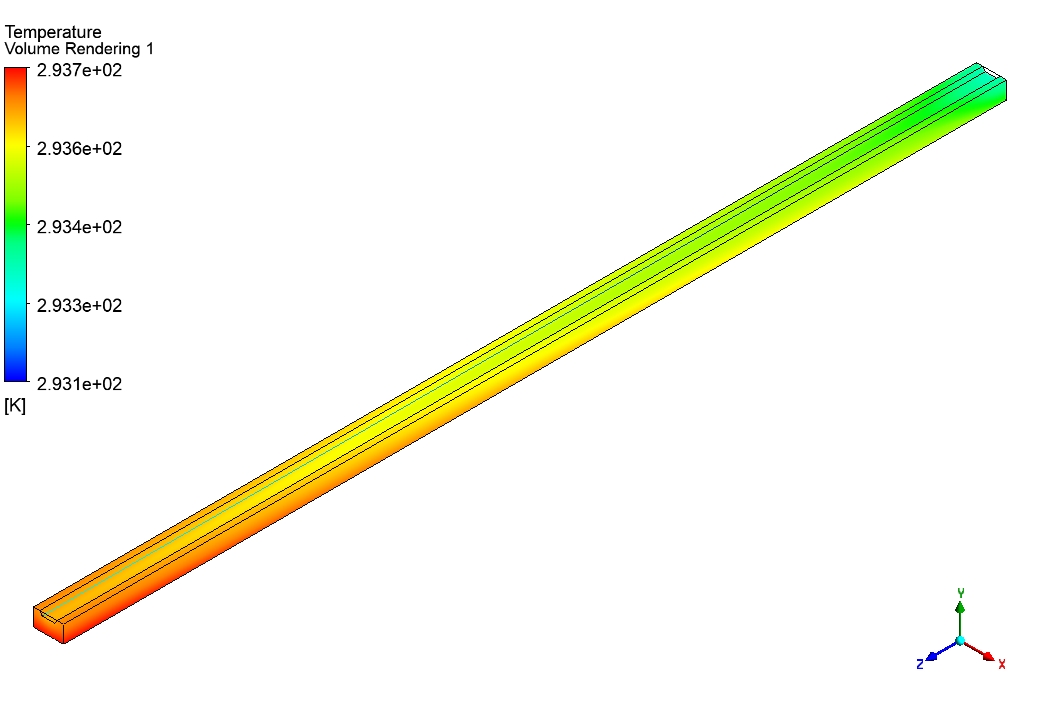

To start this Nanofluid in Microchannel Heat Sink fluent tutorial, we created a 3D model of a single channel. We used a symmetric design to save simulation time. The mesh generation was a critical step. We utilized ANSYS Meshing to build a high-quality structured grid with hexagonal cells. As shown in Figure 2, these brick-shaped cells align perfectly with the straight channel, which ensures the calculation is very accurate.

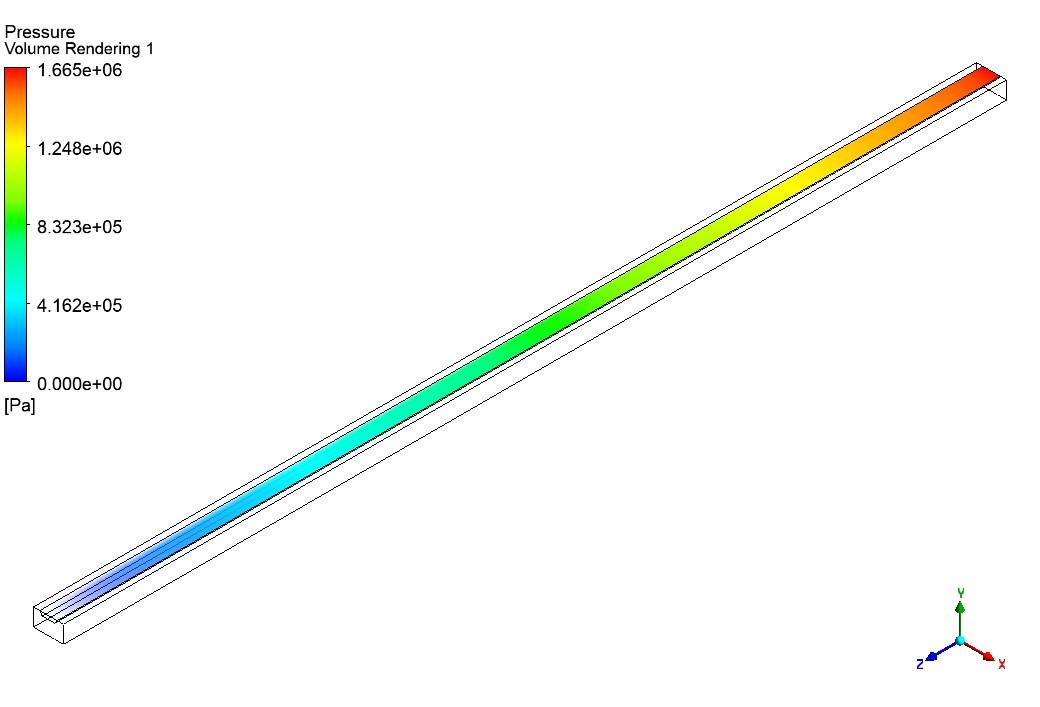

In the ANSYS Fluent setup, we chose the Single-Phase Nanofluid approach. This means we did not track every individual nanoparticle. Instead, we calculated the “effective” properties (like density, viscosity, and thermal conductivity) of the mixture and applied them to the fluid material. The solid part of the heat sink was defined as Silicon, with thermal conductivity that changes with temperature. Finally, we applied a Heat Flux of 26800 W/m² to the bottom of the sink. This number represents the intense heat coming from a computer chip that needs to be cooled.

Figure 2: Structured mesh generation for the microchannel heat sink.

Post-processing: Analysis of Thermal Resistance and Heat Removal

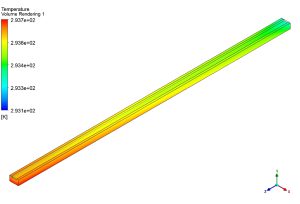

A real, in-depth analysis of the simulation results allows us to understand exactly how the Nanofluid in Microchannel Heat Sink ANSYS fluent model performs under load. The temperature contour in Figure 3 tells the story of energy transfer. The process starts at the bottom wall, where the constant heat flux of 26800 W/m² is applied. This energy conducts through the solid silicon and reaches the channel walls. The most critical data point is the temperature change of the fluid itself. The nanofluid enters the inlet at a cool 293.15 K. As it flows through the channel, it “scrubs” the heat from the silicon walls. By the time it reaches the outlet, the temperature has risen to 293.35 K. This increase of 0.20 K might seem small, but in the world of micro-cooling, it is significant. It proves that the fluid is actively absorbing thermal energy and carrying it away from the chip.

The effectiveness of this cooling process is mathematically defined by the Thermal Resistance, which came out to be 0.011698 K/W. In simple terms, this low number is the score of the heat sink. A lower resistance means the heat sink is very efficient. It tells us that for every Watt of heat power we put in, the temperature of the chip only rises by a tiny fraction (0.011 degrees). This high performance is directly caused by the single phase nanofluid in fluent properties. Because the nanofluid has a higher thermal conductivity than pure water, it reduces the “barrier” to heat flow at the wall. The simulation clearly shows that the combination of the high surface area of the microchannel and the enhanced properties of the nanofluid results in a system that can handle high power loads while keeping the electronics safe and cool. The uniform temperature distribution seen in the silicon confirms that there are no dangerous “hot spots” that could damage the device.

Figure 3: Temperature contour showing the heat transfer from the silicon to the nanofluid.

Key Takeaways & FAQ

- Q: What is a Single-Phase Nanofluid model?

- A: In this Nanofluid in Microchannel Heat Sink CFD simulation, the Single-Phase model treats the fluid and nanoparticles as one mixed material. We calculate new properties (like higher thermal conductivity) for this mixture and simulate it as a single liquid in ANSYS Fluent.

- Q: Why is Thermal Resistance important?

- A: Thermal resistance measures how hard it is for heat to escape. The calculated value of 0.011698 K/W is very low, which means the heat flows easily from the chip to the fluid. This indicates a high-performance cooling system.

- Q: How does the heat flux affect the simulation?

- A: The heat flux of 26800 W/m² simulates the power of the electronic chip. It is the source of energy that drives the temperature gradients seen in the contours.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€360 Original price was: €360.€185Current price is: €185.

€130 Original price was: €130.€85Current price is: €85.

€190 Original price was: €190.€95Current price is: €95.

€240 Original price was: €240.€125Current price is: €125.

€200 Original price was: €200.€115Current price is: €115.

€245 Original price was: €245.€185Current price is: €185.

Reviews

There are no reviews yet.