Miniature Steam Ejector CFD Simulation, ANSYS Fluent Training

Miniature Steam Ejector CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140 Original price was: €140.€115Current price is: €115.

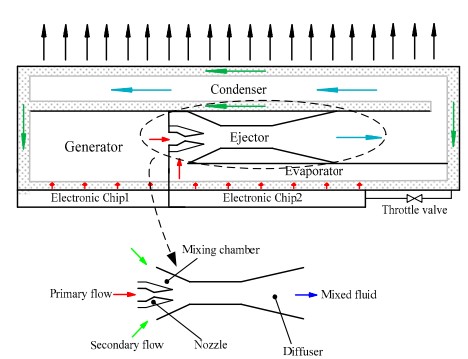

Thermal management of electronic components presents significant challenges in modern engineering applications, particularly as devices continue to miniaturize while computational demands increase. Miniature steam ejectors offer a compelling solution for efficient electronics cooling by utilizing the principles of thermodynamic cycles without requiring mechanical compression. These compact refrigeration systems operate through the integration of capillary pump loops, wherein the primary flow accelerates to supersonic velocities within a specialized nozzle, consequently generating a low-pressure region that induces secondary flow from the evaporator. Furthermore, computational fluid dynamics (CFD) represents an essential tool for analyzing the complex flow characteristics within these miniaturized devices where physical measurements remain challenging. The intricate fluid dynamics within the ejector mixing chamber involve sophisticated momentum transfer mechanisms that ultimately determine the overall performance coefficient of these systems. The reference paper “Numerical Investigation of Miniature Ejector Refrigeration System Embedded with a Capillary Pump Loop “ is our valid guidance through the current CFD study.

- Reference [1]: Dong, Jing-Ming, et al. “Numerical investigation of miniature ejector refrigeration system embedded with a capillary pump loop.” Micromachines8 (2017): 235.

Figure 1: Schematic of ejector system

Simulation Process

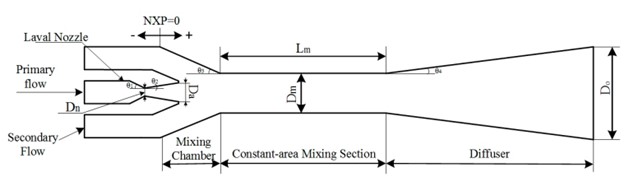

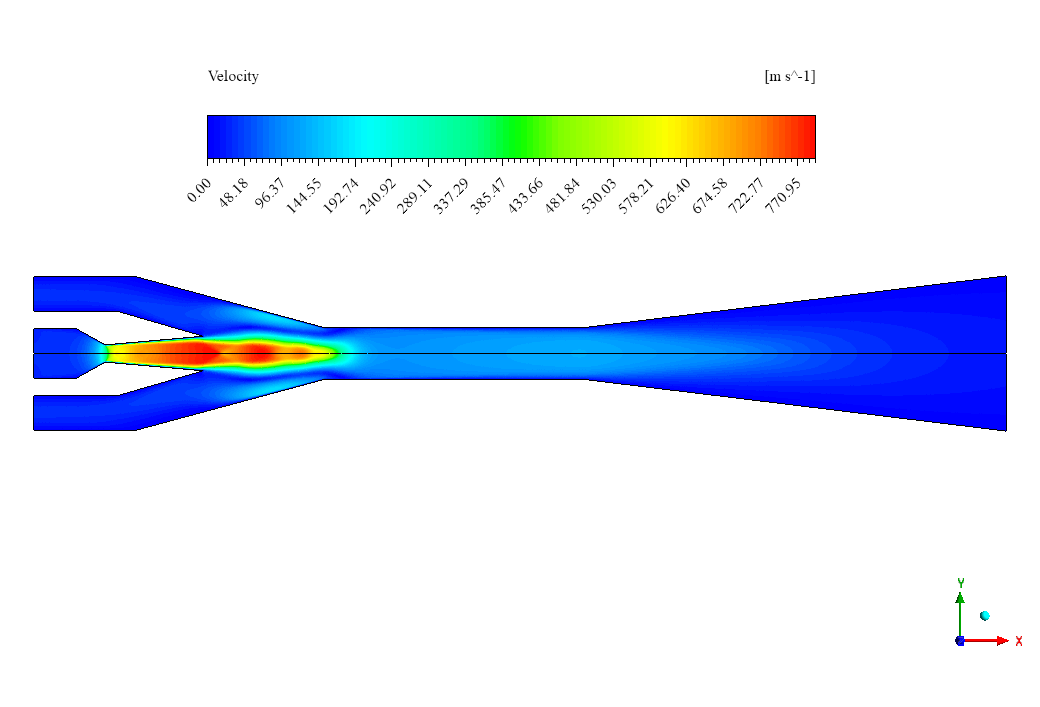

Ejector schematic is presented below as well as the reference paper. In the absence of exact dimensions, construction points are recognized using Plotdigitizer software. This study features from 57088 structured cells that are produced using ANSYS Meshing. Axisymmetric swirl can be used in the current simulation to model swirling flow patterns in cylindrical or symmetrically shaped systems. The ideal-gas assumption of water vapor provides preliminaries to follow the compressibility theory.

Figure 2: Geometry of the ejector [1]

Post-processing

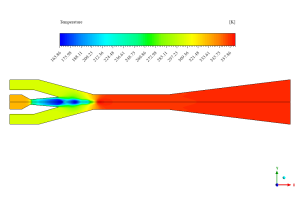

The temperature distribution within the miniature steam ejector exhibits significant thermal gradients characteristic of supersonic flow phenomena. Figure 3 presents the spatial temperature contours ranging from 163.86K to 362.08K across the ejector geometry. The simulation successfully captured the dramatic temperature reduction in the converging-diverging nozzle region, where values decrease from approximately 300K at the inlet to minimum temperatures of 163-185K at the throat. This pronounced cooling effect results from the rapid expansion of water vapor as it accelerates through the nozzle, converting thermal energy into kinetic energy according to fundamental thermodynamic principles. Notably, the temperature field downstream of the throat demonstrates a distinct recovery pattern, with values progressively increasing to 340-362K in the diffuser section. This thermal recovery corresponds to the expected behavior in ejector systems where shock wave formation and flow mixing processes induce temperature rise through conversion of kinetic energy back to thermal energy. The temperature gradient between the central flow region and wall boundaries further indicates the complex interaction of primary and secondary flows characteristic of refrigeration ejectors.

Figure 3: Temperature contour showing distribution across the miniature steam ejector

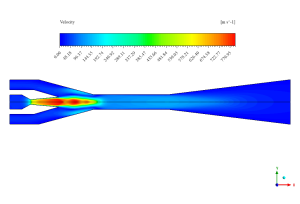

The velocity contour presented in Figure 4 provides complementary evidence of the flow behavior within the miniature steam ejector. The analysis quantitatively confirmed the development of supersonic flow conditions with maximum velocities approaching 787.75 m/s in the throat region. This velocity distribution correlates inversely with the temperature profile, demonstrating classical gas-dynamic behavior where regions of minimum temperature coincide with maximum velocity. The formation of high-velocity jets (600-700 m/s) extending from the nozzle creates the essential low-pressure region that drives the entrainment process fundamental to ejector operation. As flow progresses through the mixing chamber and diffuser, velocity magnitudes decrease substantially to approximately 150-200 m/s, facilitating pressure recovery necessary for refrigeration cycle efficiency. The blue regions (0-100 m/s) adjacent to wall boundaries indicate boundary layer development, while the central high-velocity core (shown in yellow-red) illustrates the primary flow pathway. This velocity structure, combined with the temperature distribution, confirms that the miniature ejector design achieves the necessary flow conditions for effective secondary fluid entrainment required in capillary pump loop cooling applications for electronics.

Figure 4: Velocity magnitude contour displaying flow acceleration through the ejector

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€330 Original price was: €330.€175Current price is: €175.

€280 Original price was: €280.€145Current price is: €145.

€140 Original price was: €140.€85Current price is: €85.

€280 Original price was: €280.€145Current price is: €145.

€165 Original price was: €165.€125Current price is: €125.

€195 Original price was: €195.€135Current price is: €135.

Reviews

There are no reviews yet.