Mold Filling CFD: A Fluent VOF Simulation of the Teeming Process

Mold Filling CFD: A Fluent VOF Simulation of the Teeming Process

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€99Current price is: €99.

The teeming process, also known as mold filling, is a critical step in making high-quality metal parts. A Mold Filling CFD simulation is a powerful tool that helps engineers see how liquid metal flows inside a mold. Using ANSYS Fluent, we can perform a Mold Filling (Teeming Process) Fluent analysis to study the multiphase flow of molten steel and air. This is very important for preventing defects like bubbles that can weaken the final product. This casting simulation CFD uses the Volume of Fluid (VOF) model to track the free surface, which is the line between the hot metal and the air. This study is based on the reference paper, “Mathematical Modeling of Initial Filling Moment of Uphill Teeming Process Considering a Trumpet” [1], to ensure our model is accurate.

- Reference [1]: Tan, Zhe, Mikael Ersson, and Pär G. Jönsson. “Mathematical modeling of initial filling moment of uphill teeming process considering a trumpet.” ISIJ international9 (2011): 1461-1467.

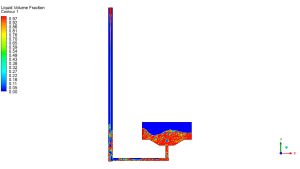

Figure 1: The uphill teeming system geometry used for this Teeming Process CFD analysis [1].

Simulation Process: Fluent Setup, Transient VOF Model for Two-Phase Flow

For this Uphill Teeming CFD simulation, we modeled the geometry from the reference paper [1], which includes a trumpet, runner, and mold. We used ANSYS Meshing to create a structured grid with 84,198 quadrilateral cells. A structured grid provides very accurate results for this type of flow. Because the filling process happens over time, we set up a transient simulation. The most important physics model we used was the Volume of Fluid (VOF) multiphase model. The VOF model is perfect for tracking the interface between two fluids that do not mix, in this case, the liquid molten steel and the air inside the mold.

Post-processing: CFD Analysis, Visualizing Free-Surface Behavior and Turbulence

The volume fraction contour provides a professional visual of the dynamic free-surface flow as the mold fills. This professional visual is not just a picture; it’s a diagnostic tool. We can analyze how the initial high-velocity jet of molten steel enters the runner system, creating significant splashing. As the molten steel flows up the vertical runner and makes the sharp 90-degree turn into the horizontal section, the flow becomes highly turbulent. From an engineering standpoint, this corner is a critical point of wear. The high-speed, swirling metal will erode the refractory lining over time, which can lead to maintenance problems and introduce impurities into the steel.

Figure 2: A professional visual of the liquid volume fraction from the Mold Filling (Teeming Process) CFD analysis, showing air entrapment.

This metallurgical process simulation allows us to predict final product quality. The turbulent flow seen in the runner directly causes the wavy, uneven flow front entering the mold from the trumpet. This uneven filling is a major concern because it can trap air and slag, creating defects like porosity and non-metallic inclusions in the final steel ingot. The simulation clearly shows areas of almost pure liquid steel (volume fraction of 0.97) right next to large pockets of trapped air. By identifying these problem zones, engineers can redesign the runner system to create a calmer, more stable flow. The most important achievement of this simulation is its ability to precisely predict the locations of high turbulence and air entrapment, giving engineers the exact data needed to optimize the teeming process, reduce material defects, and improve the final quality of the steel ingot without costly and time-consuming physical trials.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€175Current price is: €175.

€155 Original price was: €155.€135Current price is: €135.

€195 Original price was: €195.€150Current price is: €150.

€195 Original price was: €195.€135Current price is: €135.

€330 Original price was: €330.€199Current price is: €199.

Reviews

There are no reviews yet.