Nanofluid in Spiral Tube CFD Simulation ANSYS Fluent Training

Nanofluid in Spiral Tube CFD Simulation ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€190.00 Original price was: €190.00.€99.00Current price is: €99.00.

Nanofluid in spiral tube heat exchangers is a cutting-edge thermal management technique. Engineers can boost thermal conductivity by spreading metallic or oxide-based nanoparticles in a fluid. In the detailed channels of a spiral tube heat exchanger, this nanofluid actively interacts with tube walls to speed heat exchange. The spiral shape maximizes nanofluid-tube surface area interaction and heat transfer. These spiral coils are usually used in Solar Ponds. There are many studies conducted regarding this topic. However, in the present project, the paper entitled “ Application of nanofluid to improve the thermal performance of horizontal spiral coil utilized in solar ponds: Geometric study [1]” is selected as the reference, published in Renewable Energy journal of Elsevier.

- Reference [1]: Khodabandeh, Erfan, et al. “Application of nanofluid to improve the thermal performance of horizontal spiral coil utilized in solar ponds: geometric study.” Renewable Energy122 (2018): 1-16.

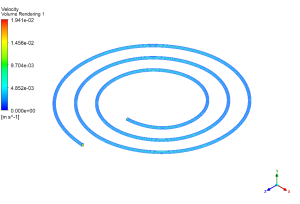

Figure 1: Geometry of Spiral Tube solar pond

Simulation Process

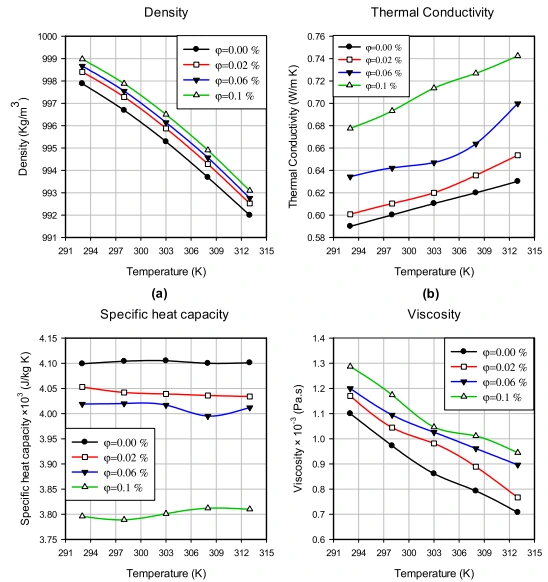

The geometry complex geometry may seem difficult to design. However, with the help of SpaceClaim software, it is modelled. The curvature of the model makes it challenging to generate a fine grid. It is actually meshed using Fluent Meshing software with 5704311 elements. Given the low Reynolds number, the flow regime remains Laminar through the spiral coil. The nanofluid enters the spiral coil with a total temperature of 34°C while the coil wall is 60°C. The properties of nanofluid is highly dependent on temperature. In other words, the nanofluid properties are not constant. It is worth mentioning that, the nanofluid is modeled regarding single-phase approach. As given in the reference paper, the properties should be applied:

Figure 2: . Thermophysical properties of water-graphene nanoplatelet/platinum hybrid nanofluid (a) Density (b) Thermal conductivity (c) Specific heat capacity (d) Viscosity [1]

Post-processing

After the CFD simulation was completed, it was analyzed to find important temperature gradients and flow patterns inside the spiral tube heat exchanger. The temperature curves show a clear rise from the starting point of 307.1K (34°C) to the highest point of 333.2K (60°C), which means that heat is moving effectively from the tube walls to the nanofluid. The volume rendering image shows that the temperature distribution follows the shape of a spiral, with the highest temperatures (shown in red) found along the outer coils, where the nanofluid has absorbed the most heat. This proves that the design works well at keeping things cool.

Figure 3: a) Temperature b) velocity field inside the spiral coil using nanofluid

The velocity field analysis shows a well-developed laminar flow pattern, with velocities ranging from 0 to 0.01941 m/s through the spiral geometry. The velocity contours remain relatively uniform across the coil cross-section, suggesting stable flow conditions without significant secondary flows or separation. This flow behavior, combined with the temperature distribution, confirms that the spiral configuration effectively promotes gradual heating of the nanofluid while maintaining steady flow characteristics essential for solar pond applications. The simulation results demonstrate that the combination of spiral geometry and nanofluid properties achieves the desired thermal enhancement without compromising flow stability.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170.00 Original price was: €170.00.€99.00Current price is: €99.00.

€280.00 Original price was: €280.00.€185.00Current price is: €185.00.

€295.00 Original price was: €295.00.€175.00Current price is: €175.00.

€360.00 Original price was: €360.00.€185.00Current price is: €185.00.

€120.00 Original price was: €120.00.€65.00Current price is: €65.00.

€205.00 Original price was: €205.00.€155.00Current price is: €155.00.

Reviews

There are no reviews yet.