Swirl Burner Combustion CFD Simulation: Non-premixed Analysis in Ansys Fluent

Swirl Burner Combustion CFD Simulation: Non-premixed Analysis in Ansys Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€240 Original price was: €240.€125Current price is: €125.

A Swirl Burner is a sophisticated device widely used in gas turbines and industrial furnaces. Its main purpose is to mix fuel and air efficiently and to keep the flame stable so it does not blow out. It achieves this by using special vanes that force the incoming air to spin rapidly. This swirling motion creates complex aerodynamic structures that are difficult to see with the naked eye. Therefore, engineers rely on Swirl Burner CFD simulation to visualize these internal flows.

In this project, we perform a comprehensive Swirl Burner simulation focusing on Non-premixed combustion. This means the fuel and air enter the chamber separately and mix inside. We use ANSYS Fluent to predict the mixing, the chemical reactions, and the resulting temperature field. This CFD study allows us to understand the physics of flame anchoring without the cost of building a physical prototype. For those interested in mastering these techniques, we highly recommend exploring our combustion tutorials. The methodology for this Swirl Burner combustion ANSYS fluent project is based on the research by Mansouri et al. [1].

- Reference [1]: Mansouri, Zakaria, and Toufik Boushaki. “Experimental and numerical investigation of turbulent isothermal and reacting flows in a non-premixed swirl burner.” International Journal of Heat and Fluid Flow72 (2018): 200-213.

Figure 1: The geometry of the combustion chamber showing the air and fuel inlets.

Simulation Process: Modeling Turbulence and Chemistry

The success of a Swirl Burner combustion simulation depends on the accurate setup of the physics models. First, we created a high-quality 3D structured mesh. As seen in Figure 2, the mesh is very fine near the inlet vanes and the mixing zone. This is crucial because the flow gradients in these areas are very steep. A coarse mesh would miss the details of the swirl and lead to incorrect results.

In ANSYS Fluent, we selected the Non-premixed Combustion model. This model is ideal for diffusion flames where the mixing rate controls how fast the fuel burns. To handle the interaction between the turbulent flow and the chemistry, we used the Eddy Dissipation Concept (EDC). The EDC model is more detailed than standard models and is highly recommended for Swirl Burner combustion fluent studies. Finally, since the flame temperature is very high, we activated the P1 Radiation model to account for the heat lost through radiation to the walls.

Figure 2: The high-quality mesh used for the computational domain.

Post-processing: Flame Stabilization and Recirculation Physics

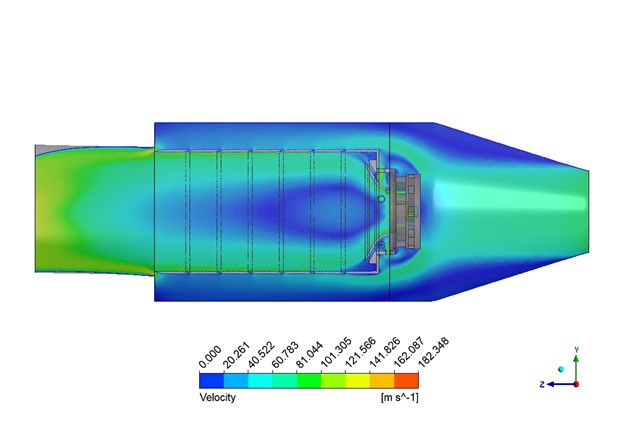

The results of the Swirl Burner combustion ANSYS fluent simulation provide a deep insight into the mechanism of flame stabilization. The velocity streamlines in Figure 3 reveal the formation of a large toroidal structure known as the Central Recirculation Zone (CRZ). This zone is the heart of a swirl burner. It forms because the swirling air moves outward due to centrifugal force, creating a low-pressure region in the center of the burner. This low pressure sucks the fluid downstream back towards the inlet. This reverse flow is critical because it carries hot combustion products back to the root of the flame. By bringing these hot gases back, the CRZ continuously ignites the fresh fuel and air mixture entering the burner. Without this recirculation, the high-speed incoming air would simply blow the flame out of the chamber.

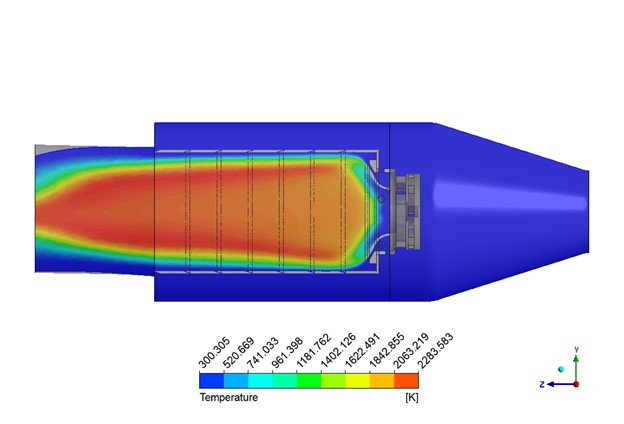

Figure 3: Velocity streamlines illustrating the formation of the critical Central Recirculation Zone (CRZ). Temperature contour showing the high-temperature flame front anchored by the recirculation zone.

The temperature contour in Figure 4 further confirms this behavior and visualizes the shape of the flame. We observe a distinct V-shaped high-temperature region that matches the shear layer of the airflow. The simulation predicts a peak temperature of approximately 2100 K. This intense heat is concentrated along the boundaries of the Central Recirculation Zone. The V-shape indicates that the flame is anchored at the burner outlet and expands outwards as the swirling flow spreads. The temperature is lowest in the center where the fuel is injected and highest where the fuel fully mixes with the swirling air. This detailed mapping of the temperature field demonstrates that the Non-premixed Combustion model in ANSYS Fluent are successfully capturing the complex physics of the Swirl Burner. The simulation proves that the swirl intensity is sufficient to create a robust CRZ, which effectively stabilizes the flame at high temperatures.

Key Takeaways & FAQ

- Q: Why is the Central Recirculation Zone (CRZ) important?

- A: The Central Recirculation Zone (CRZ) is essential for Flame Stabilization. It acts as a aerodynamic anchor. By recirculating hot burnt gases back to the nozzle, it provides a constant source of heat to ignite the fresh fuel and air. This prevents the flame from blowing off, even at high flow rates.

- Q: Why use the k-epsilon Realizable model for Swirl Burners?

- A: Standard turbulence models assume the flow is isotropic (the same in all directions). However, in a Swirl Burner CFD simulation, the flow has strong rotation and curvature. The k-epsilon Realizable model contains special mathematical terms that account for this rotation, providing much more accurate predictions of the swirl strength and the size of the CRZ.

- Q: What is Non-premixed Combustion?

- A: In Non-premixed combustion, the fuel and oxidizer (air) enter the chamber through separate inlets. They must mix before they can burn. In this type of simulation, the rate of combustion is controlled by how fast the turbulence mixes the two streams, rather than how fast the chemical reaction itself is.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€130 Original price was: €130.€85Current price is: €85.

€265 Original price was: €265.€135Current price is: €135.

€295 Original price was: €295.€175Current price is: €175.

€360 Original price was: €360.€185Current price is: €185.

€185 Original price was: €185.€135Current price is: €135.

€240 Original price was: €240.€115Current price is: €115.

Reviews

There are no reviews yet.