Oxygen Effect on Combustion CFD, A Fluent Simulation Tutorial

Oxygen Effect on Combustion CFD, A Fluent Simulation Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€190 Original price was: €190.€95Current price is: €95.

Oxygen is the most critical ingredient for combustion. The amount of oxygen supplied directly affects how efficiently fuel burns, the temperature of the flame, and the type of pollution it creates. If there isn’t enough oxygen, the combustion is incomplete and releases harmful gases like carbon monoxide. On the other hand, too much oxygen can make the combustion better, but it can also create more pollution called NOx. Because of this, a detailed Oxygen Effect on Combustion CFD simulation is essential to find the perfect balance. This project aims to compare two cases: a standard combustion case and a case with 10% excess air, to see the difference.

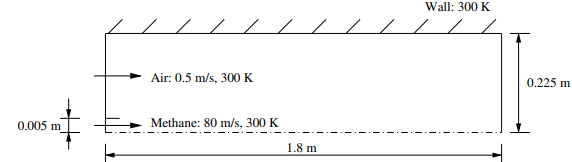

Figure 1: The 2D axisymmetric model of the methane-air combustion chamber.

Simulation process: Modeling Combustion with Excess oxygen in Fluent

To start the simulation, we used a clever trick. Because the combustion chamber is a cylinder, we can model it in 2D using an Axisymmetric setup. This saves a lot of computer time. A high-quality, structured mesh was then created to ensure the results are accurate. Next, we set up the physics in ANSYS Fluent. We used the Species Transport model to simulate the chemical reaction of methane and air. The interaction between the turbulence and the chemistry was handled by the Eddy Dissipation model. In this Oxygen Effect on Combustion fluent simulation, fuel and air enter through two separate inlets. We ran the simulation for two different scenarios: one with the normal amount of air, and a second one with 10% more air than needed.

Post-processing: The Trade-off Between Efficiency and NOx Risk

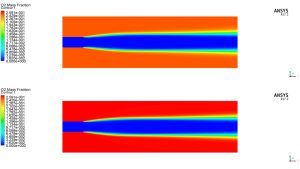

A detailed look at the results shows a critical engineering trade-off. The oxygen contours in Figure 2 tell the first part of the story. In the base case, the oxygen mass fraction drops from about 0.23 to zero, which means all the available oxygen is used up in the reaction. In the 10% excess air case, however, we can see that there is still leftover oxygen at the outlet. This proves that the extra air passed through the chamber without reacting, ensuring that every last bit of fuel was burned completely.

Figure 2: Oxygen mass fraction comparison, clearly showing the leftover oxygen in the excess air case.

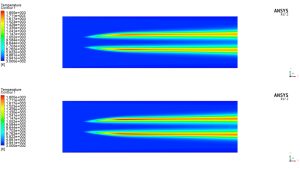

Figure 3: Temperature contours for both cases, highlighting the higher peak temperature with excess air.

However, the temperature contours in Figure 3 reveal the dangerous downside of this approach. While ensuring complete combustion is good, the excess air also causes the flame to become hotter. The peak temperature in the base case is around 1805 K. In the excess air case, this peak temperature increases significantly. This increase in peak temperature is the most critical result of the simulation, as temperatures above 1800 K dramatically increase the rate of thermal NOx formation—a major pollutant. This simulation perfectly demonstrates the challenge engineers face: adding more oxygen can improve combustion efficiency, but it comes at the cost of higher temperatures and a much greater risk of creating unwanted pollution. This is why precisely controlling the Oxygen Effect on Combustion is essential for designing clean and efficient energy systems.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€110Current price is: €110.

€360 Original price was: €360.€185Current price is: €185.

€360 Original price was: €360.€185Current price is: €185.

€200 Original price was: €200.€115Current price is: €115.

€120 Original price was: €120.€65Current price is: €65.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.