Baffled Shell & Tube Heat Exchanger CFD Simulation: A Fluent Tutorial

Baffled Shell & Tube Heat Exchanger CFD Simulation: A Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160 Original price was: €160.€110Current price is: €110.

A Shell & Tube Heat Exchanger is the workhorse of industrial cooling and heating. However, a simple shell with tubes often isn’t enough because the fluid flows too smoothly and doesn’t mix well. To fix this, engineers add baffles. These are metal plates placed inside the shell that block the straight path of the fluid. They force the water to flow up and down in a zigzag pattern. This extra movement creates turbulence, which helps move heat much faster.

This project is a baffled Shell & Tube Heat Exchanger CFD simulation designed to show you exactly how these internal plates improve performance. It is important to clarify that this is a CFD simulation. We use ANSYS Fluent to visualize the flow inside the shell and measure the temperature changes. For more learning resources on thermal systems, please visit our Heat exchanger tutorials.

Simulation Process: Modeling a Shell & Tube Heat Exchanger with Baffle

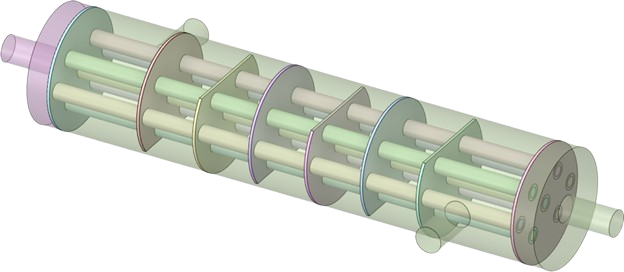

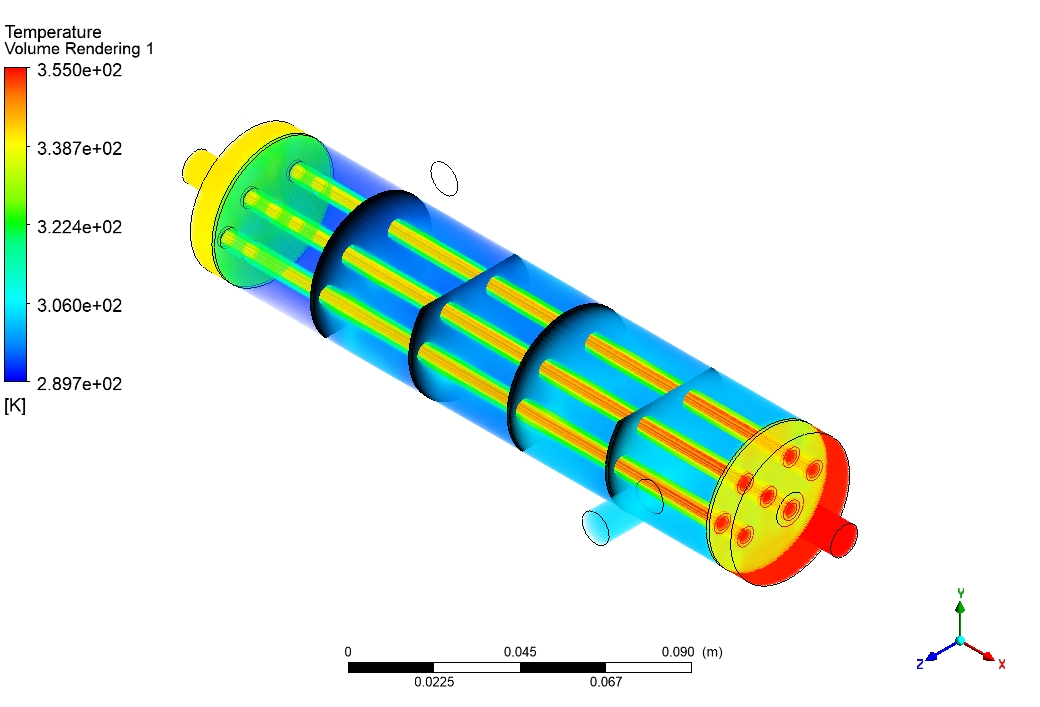

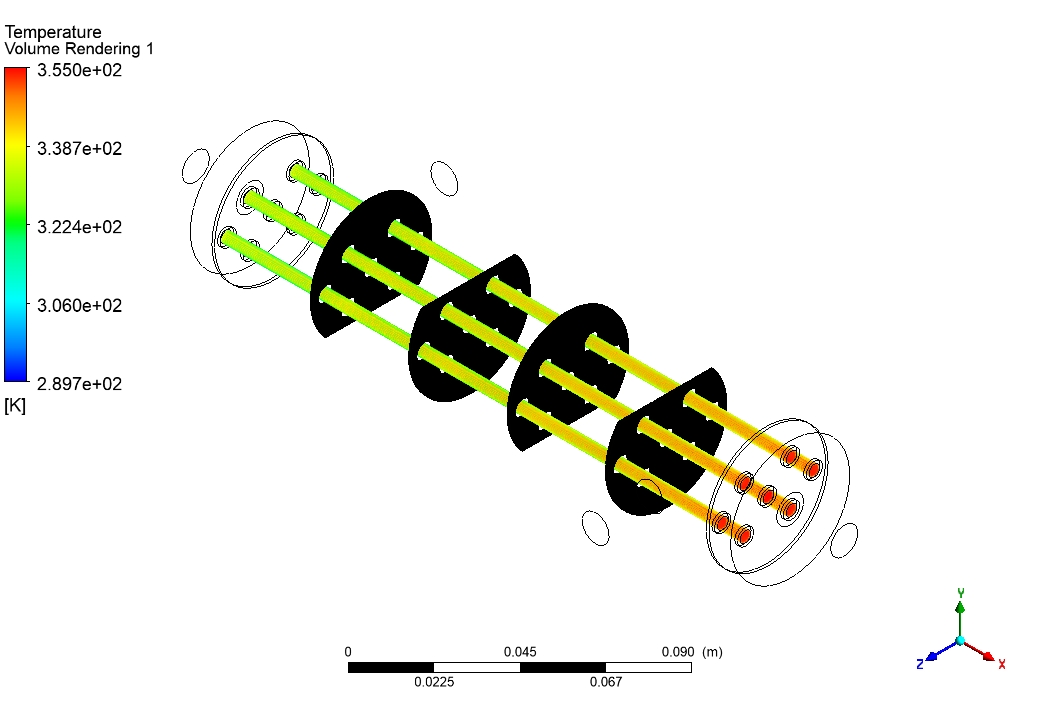

The first step in this Shell & Tube Heat Exchanger Simulation was to create a precise 3D model. We included the shell, the tubes, the new end caps, and most importantly, the baffles. We then generated a very fine mesh with over 2,280,000 tetrahedral cells. A mesh this large is necessary to capture the swirling details of the flow around the sharp edges of the baffles.

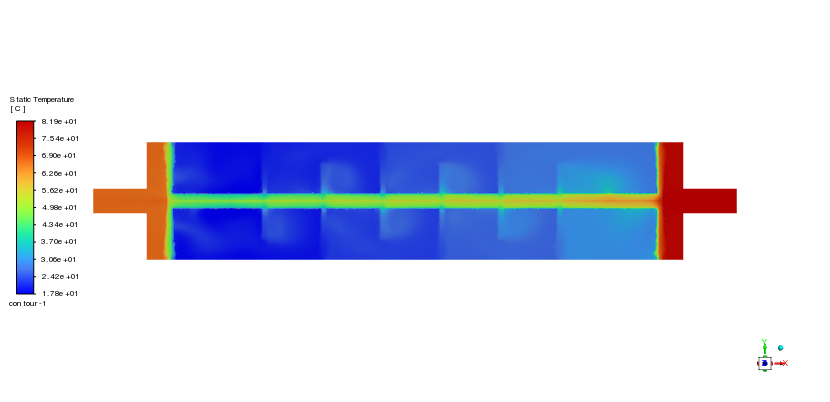

In the ANSYS Fluent setup, we chose the k-epsilon turbulence model. This model is perfect for this type of baffle in Shell & Tube Heat Exchanger fluent study because it accurately predicts the chaotic eddies created by the zigzag flow. We also turned on the Energy equation to calculate the temperature changes. The boundary conditions were defined to match a real-world case: extremely hot water enters the tubes at 82°C, while cold water enters the shell at 16.85°C to cool it down.

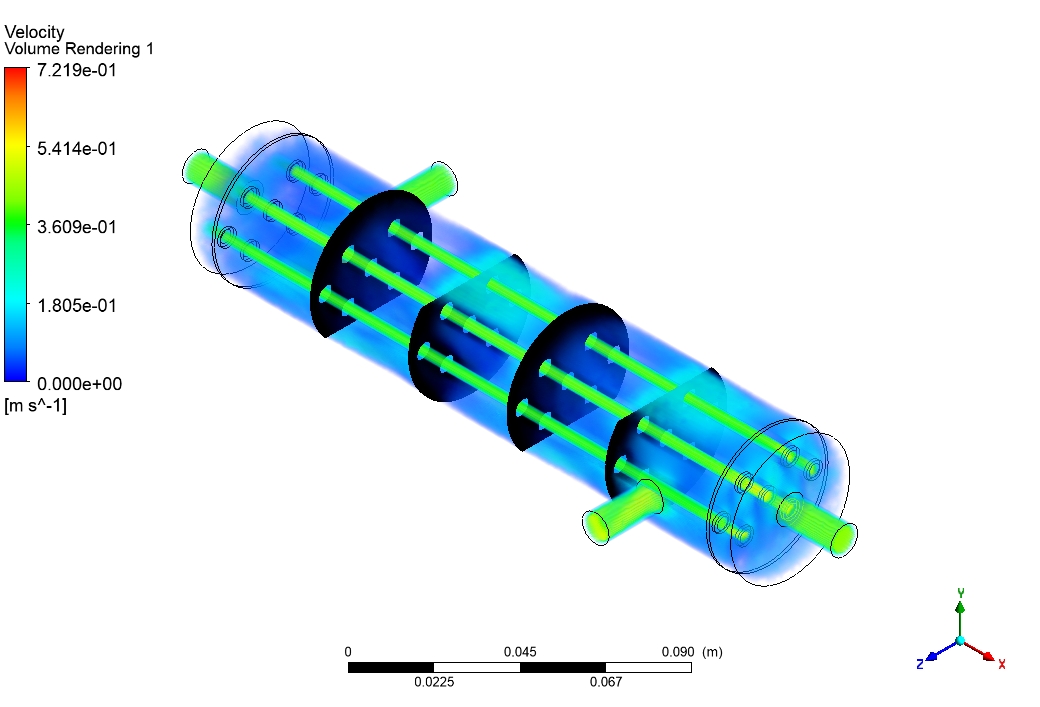

Figure 1: The 3D geometry of the Shell & Tube Heat Exchanger with baffles and end caps.

Post-processing: How Baffles Drive Heat Transfer

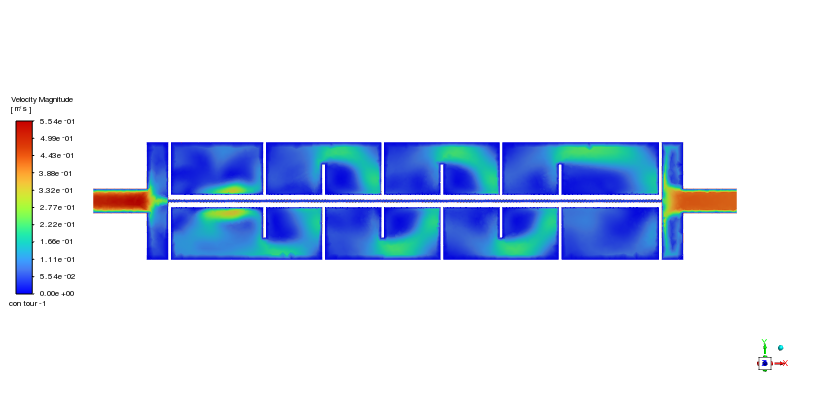

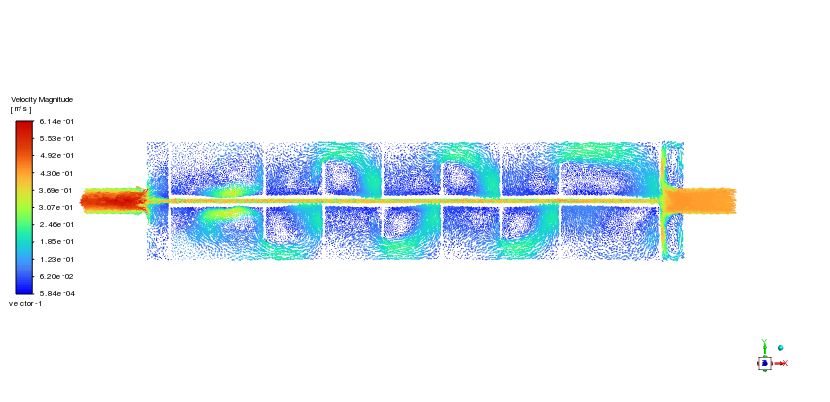

A real analysis of the simulation results allows us to see the physics in action. The velocity contours are the first thing we check. In a standard exchanger, the water would just slide along the tubes. But here, the Shell & Tube Heat Exchanger baffle ANSYS fluent results show something very different. The baffles act like dams, forcing the water to speed up as it squeezes through the gaps. The contour shows the velocity hitting a maximum of 0.54 m/s in these narrow regions. This speed is critical. It creates a “serpentine” or snake-like flow path. As the water rushes around each baffle, it becomes turbulent. This turbulence is the key secret; it scrubs the walls of the tubes, stripping away the stagnant layer of fluid and allowing fresh, cold water to touch the hot surface.

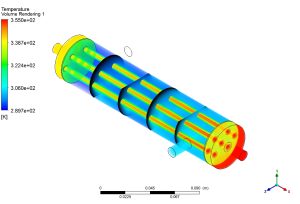

The temperature contours prove that this mechanical chaos leads to thermal success. We can see the hot water entering the tubes at a bright red 82°C. As it travels through the exchanger, the color shifts to green and then to blue, indicating rapid cooling. By the time the hot water reaches the outlet, it has cooled down to 67°C. This is a massive temperature drop of 15°C, which represents an 18% improvement in cooling performance. This result confirms that the baffles are doing their job. They didn’t just direct the flow; they engineered a high-energy environment that forced the heat to move from the hot liquid to the cold liquid much more efficiently than a straight tube ever could.

Figure 2: Velocity contours showing the zigzag flow and temperature distribution showing cooling.

Key Takeaways & FAQ

- Q: Why are baffles used in a Shell & Tube Heat Exchanger?

- A: Baffles serve two main purposes: they support the tubes structurally, and more importantly, they force the shell-side fluid into a cross-flow pattern. As shown in this baffled Shell & Tube Heat Exchanger CFD simulation, this creates turbulence (up to 0.54 m/s) which significantly increases the heat transfer rate.

- Q: What is the k-epsilon model?

- A: The k-epsilon turbulence model is a mathematical formula used in ANSYS Fluent to simulate mean flow characteristics for turbulent flow conditions. It is the industry standard for modeling the complex, swirling flow patterns found in a baffled heat exchanger.

- Q: How do we measure the performance improvement?

- A: We measure it by the temperature drop of the hot fluid. In this CFD simulation, the hot water dropped from 82°C to 67°C. This substantial difference proves that the heat is being effectively transferred to the cold fluid.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€130Current price is: €130.

€160 Original price was: €160.€145Current price is: €145.

€145 Original price was: €145.€95Current price is: €95.

€200 Original price was: €200.€125Current price is: €125.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.