Tube Heat Exchanger With Helical Groove CFD: A Fluent Analysis Tutorial

Tube Heat Exchanger With Helical Groove CFD: A Fluent Analysis Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160 Original price was: €160.€85Current price is: €85.

Heat exchangers are vital components in countless industrial and domestic systems, from power plants to refrigerators. The primary engineering goal is always to transfer the maximum amount of heat with the minimum amount of energy and space. One of the most effective passive methods for improving performance is to modify the internal geometry of the tubes. A Tube Heat Exchanger with Helical Groove is a perfect example of this design philosophy. The internal spiral grooves are not just for decoration; they fundamentally alter the fluid flow, forcing it into a swirling or vortex motion. This “swirl flow” dramatically improves the heat transfer process. A Tube Heat Exchanger CFD simulation is the most powerful tool for engineers to visualize these complex flow patterns and accurately quantify the performance gains. The present CFD study is guided by the valuable research paper, “CFD Study of Tube in Tube Heat Exchanger with Helical Insert of Different Height and Helical Groove [1].”

- Reference [1]: Tiwari, Anshuman, Parag Mishra, and Ajay Singh. “CFD Study of Tube in Tube Heat Exchanger with Helical Insert of Different Height and Helical Groove.” International Journal of Applied Engineering Research 13.18 (2018): 13566-13573.

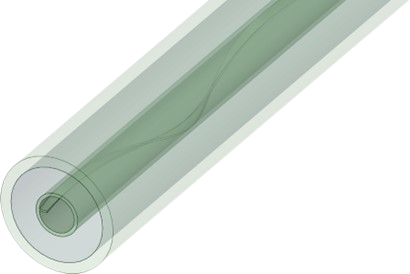

Figure 1: Schematic of the Tube Heat Exchanger With Helical Groove, the subject of this CFD analysis.

Simulation Process: Modeling the Helical Groove Fluent Simulation

The first step in this Helical groove fluent simulation was to accurately model the geometry, which consists of four distinct parts: two fluid domains (one for the hot fluid, one for the cold) and two solid domains for the copper tube walls. The complex, curving geometry of the helical groove presents a significant meshing challenge. To accurately capture the flow physics in this region, a very fine mesh is required. Therefore, a high-density grid containing 14,423,295 cells was generated.

Within ANSYS Fluent, the energy equation was enabled to solve for heat transfer. The material for the tube walls was set to copper, known for its excellent thermal conductivity. The simulation was set up as a counter-flow heat exchanger, where the hot and cold fluids move in opposite directions to maximize thermal efficiency. The boundary conditions were defined with an inlet temperature of 328 K for the hot fluid and 305 K for the cold fluid, with both entering at a velocity of 1.3 m/s.

Post-processing: CFD Analysis of Thermal Performance and Swirl Flow Dynamics

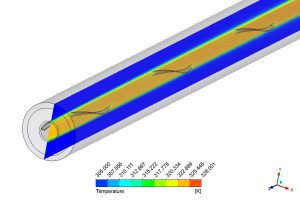

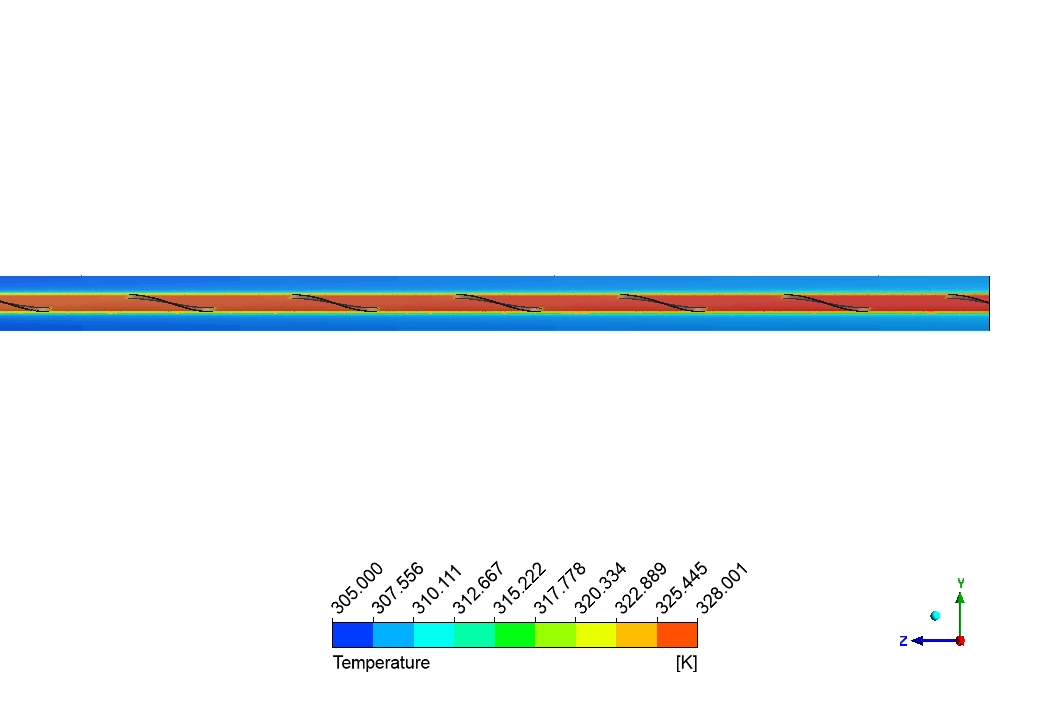

The simulation results provide a clear, substantiated story of enhanced thermal performance, which is directly visible in the temperature contours in Figure 2. The core function of the helical groove is to act as a turbulence promoter. As the fluid is forced to follow the spiral path, it develops a strong swirling motion. This swirl aggressively disrupts the formation of the thermal boundary layer—a thin, slow-moving layer of fluid near the tube wall that acts as the primary resistance to heat transfer. By constantly mixing the fluid from the core of the flow with the fluid near the wall, the helical groove effectively thins this insulating layer. The result is a significant boost in convective heat transfer. This is quantitatively proven by the simulation data: the hot fluid successfully transfers its energy, cooling from 328 K to 324 K, while the cold fluid absorbs this energy, heating from 305 K to 309 K. This balanced 4K temperature change in both streams confirms the efficient and effective heat exchange promoted by the design.

Figure 2: Temperature field from the Tube Heat Exchanger CFD simulation, clearly showing the effective heat transfer between the hot and cold fluids.

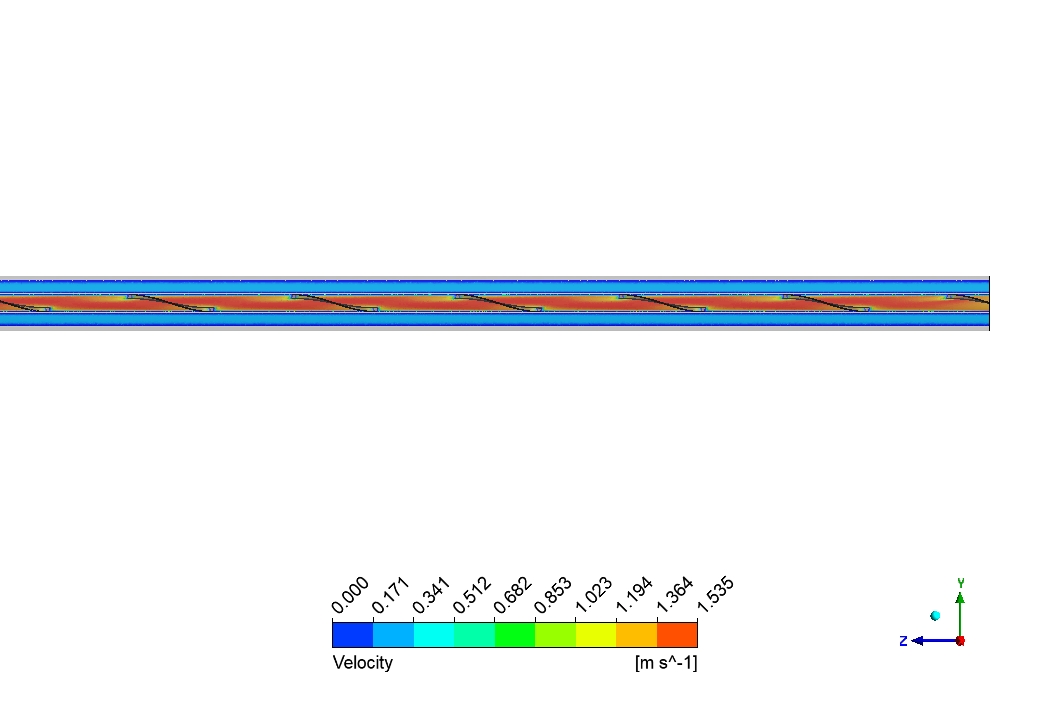

While the thermal benefits are clear, a complete engineering analysis must also consider the hydraulic penalty. The same swirling motion that enhances heat transfer also forces the fluid to travel a longer, more complex path and increases turbulence, which inevitably leads to a higher pressure drop compared to a simple smooth tube. The velocity analysis, which shows a slight increase from 1.3 m/s to 1.313 m/s, hints at the complex flow patterns and accelerations within the grooved geometry. This increase in pressure drop is the “cost” of the heat transfer enhancement. The most significant achievement of this Helical groove CFD simulation is the ability to quantify both sides of this engineering trade-off. It not only confirms the significant thermal improvement but also provides the data needed to assess the pressure drop, allowing engineers to make an informed decision about whether the performance gain justifies the increased pumping power required. This holistic view is essential for optimizing heat exchanger designs for real-world applications.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€185 Original price was: €185.€155Current price is: €155.

€185 Original price was: €185.€125Current price is: €125.

€190 Original price was: €190.€125Current price is: €125.

€185 Original price was: €185.€135Current price is: €135.

€200 Original price was: €200.€125Current price is: €125.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.