Phase Change Material (PCM) In Solar Panel CFD Simulation, Experimental Paper Validation

Phase Change Material (PCM) In Solar Panel CFD Simulation, Experimental Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€185Current price is: €185.

Phase Change Materials (PCMs) offer a novel approach to improving the performance and efficiency of solar panels. High operating temperatures lead to efficiency losses in solar panels, making integrating phase change materials into the panel structure beneficial for better thermal regulation. The materials capture surplus heat during the highest sunlight periods, transitioning from solid to liquid, and subsequently release this accumulated thermal energy as temperatures decrease. This process aids in keeping the solar panel’s temperature nearer to ambient conditions, reducing the adverse impacts of overheating on photovoltaic efficiency. Research indicates that the integration of phase change materials can lead to a temperature increase in solar panels of over 30°C for prolonged durations, thereby enhancing their total energy efficiency. Additionally, PCMs present further advantages, including providing heat for building integration and serving as insulation material during colder periods. It is noteworthy that the present CFD simulation over PCMs in Solar panels is conducted to validate the experimental data of the reference paper entitled “ Phase-change materials to improve solar panel’s performance”.

- Reference [1]: Biwole, Pascal Henry, Pierre Eclache, and Frédéric Kuznik. “Phase-change materials to improve solar panel’s performance.” Energy and Buildings62 (2013): 59-67.

![Schematic of PCM in solar panel problem [1]](https://cfdland.com/wp-content/uploads/2024/10/Schematic-of-PCM-in-solar-panel-problem-1-273x300.png)

Figure 1: Schematic of PCM in solar panel problem [1]

Simulation Process

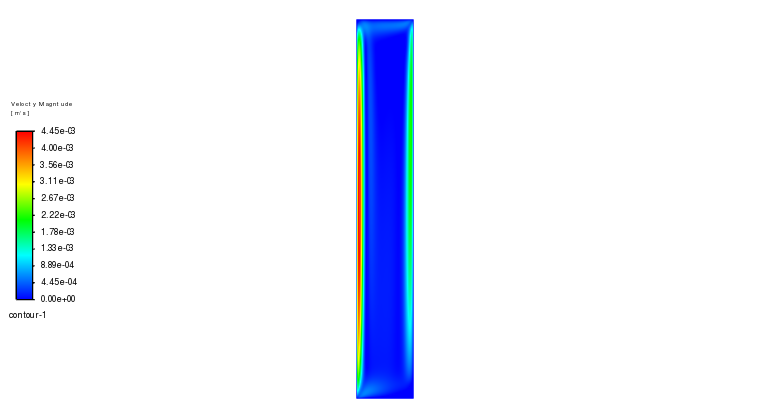

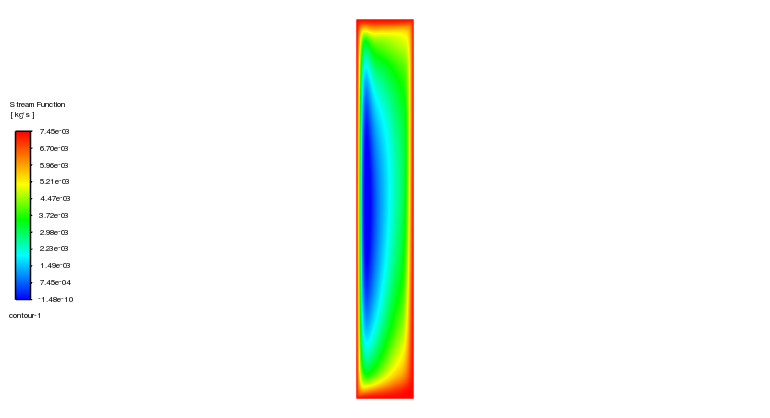

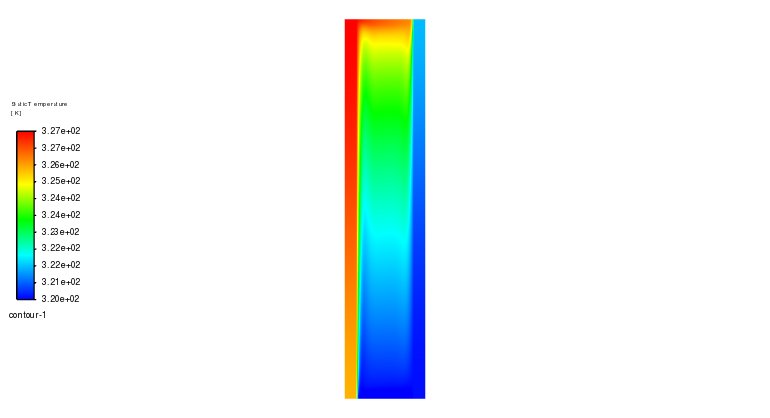

A fluid region containing phase change material is surrounded by two aluminum solid zones. The geometry model is primarily created using Design Modeler. Unlike the reference paper, we adopted a structured 21780-cell grid to describe the domain. The thermophysical properties of the simulated materials are presented in Table 1[1]. As noted, the PCM`s specific heat and thermal conductivity are temperature-dependent; thus, a unique User-defined function (UDF) is written. On the left plate, an inward heat flux E = 1000W/m2 is applied to mimic solar radiation. The same plate also receives a convection heat flux.

Post-processing

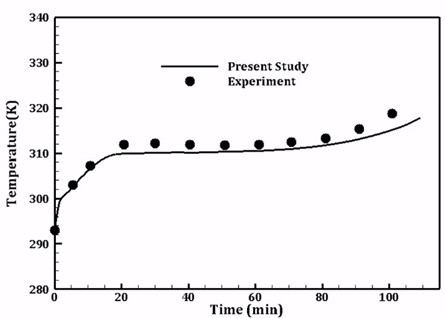

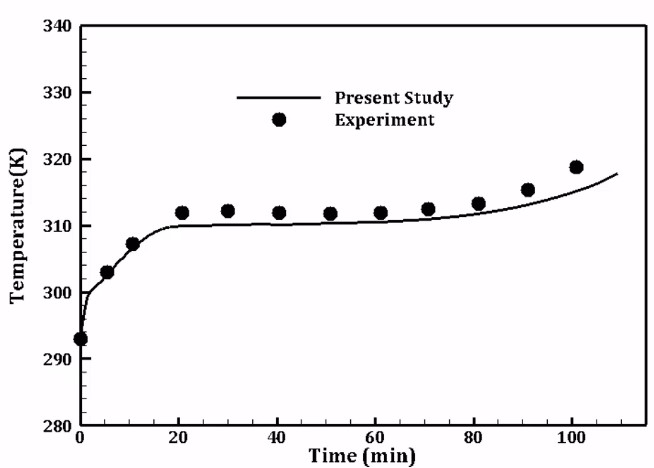

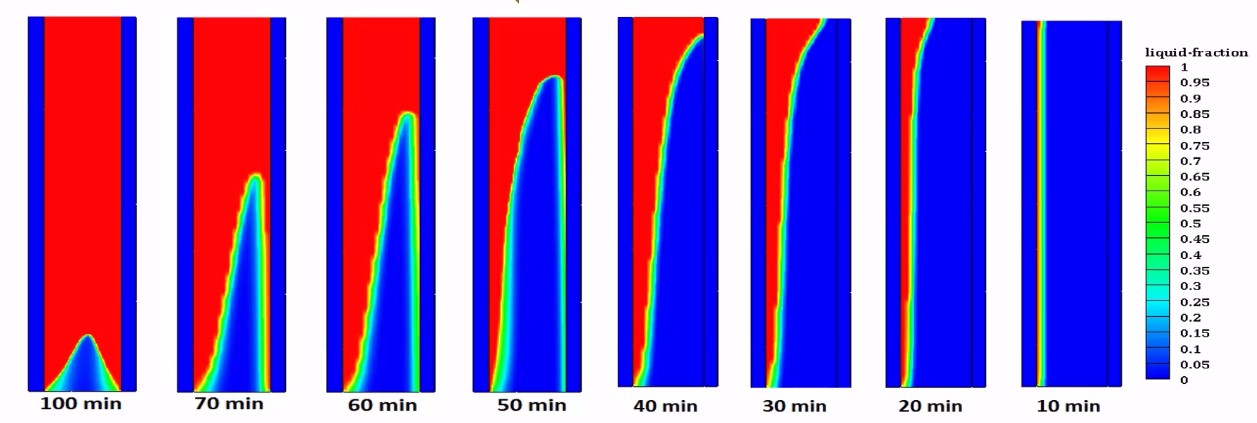

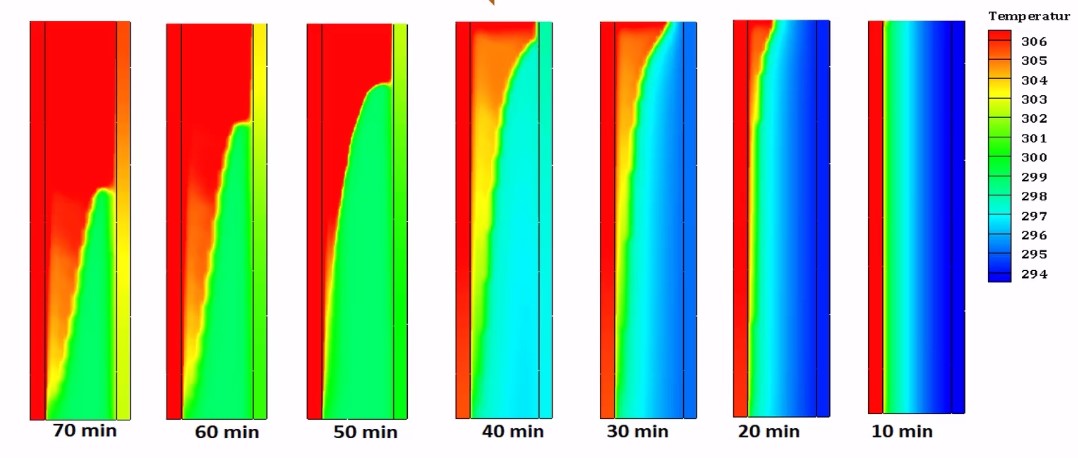

The simulation results of Phase Change Materials (PCMs) in solar panels show an immense increase in controlling temperature. This backs up the theoretical predictions and is very close to data from previous research that used experiments. The main result shows that the peak working temperature of solar panels dropped by about 30°C, which is in line with how PCMs were supposed to work. This change in temperature is directly linked to higher photovoltaic performance, since the panels work better when they are cooler. The simulation was very accurate at predicting how the PCM would react to heat; the changes in temperature and efficiency were very close to what was seen in the experiments (Fig.2).

Figure 2: Temperature comparison between CFD Simulation and Experimental data of the reference paper – Phase change material in Solar energy CFD Simulation

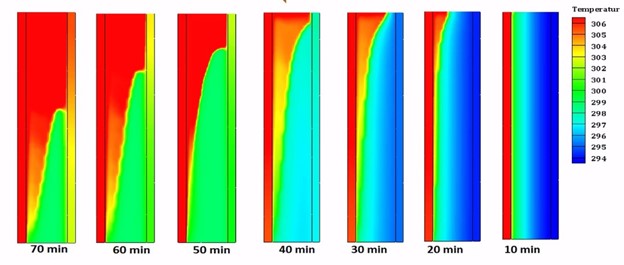

The temperature contour plots show how well the PCM works over time. They show how the temperature drops gradually from 70 minutes to 10 minutes. These graphs show that the PCM could absorb and spread heat, which kept the temperature profile more stable during the simulation time. Besides the main confirmation, the study looked into other things, like how PCM thickness and material choice affect the efficiency of solar panels. Getting the right PCM thickness was found to make thermal control even better without making the solar panel system much heavier or more expensive. Also, picking the right PCM material, especially ones with higher latent heat capacity, was very important for getting the most out of the energy store and release. By bridging the gap between modeling and real-world use, these results not only prove the theoretical benefits of PCMs but also show how they can be used in real-world solar panel systems.

Figure 3: Temperature distribution of PCM in Solar Panel CFD Simulation

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€190 Original price was: €190.€99Current price is: €99.

€360 Original price was: €360.€185Current price is: €185.

€160 Original price was: €160.€80Current price is: €80.

€265 Original price was: €265.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.