Pin Fin In Microchannel Ansys Fluent CFD Simulation – Numerical Paper Validation

Pin Fin In Microchannel Ansys Fluent CFD Simulation – Numerical Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€190 Original price was: €190.€155Current price is: €155.

Pin fin microchannels are becoming extremely popular in modern electronic cooling systems because they work better than regular flat microchannels. This VALIDATION study uses Ansys Fluent to confirm how accurately we can predict the way pin fins improve heat transfer in tiny channels. When properly designed, these small pin fin arrays can boost cooling performance by 40-120% compared to smooth channels, while only increasing pressure drop by 15-45%. Our pin fin CFD model checks these claims against real lab tests. The microchannel heat sink design uses rows of tiny pins that disturb the flow and create more cooling efficiency where it’s needed most. Different pin fin shapes (like circles, squares, or diamonds) affect both heat transfer coefficient and pressure loss in different ways. The thermal-hydraulic performance of these systems depends heavily on the pin fin spacing and arrangement pattern. Using Ansys Fluent microchannel simulations allows engineers to optimize these complex trade-offs without expensive testing. The pin fin Fluent approach accurately captures how these tiny structures enhance turbulent mixing and interrupt thermal boundary layers, which are the main reasons for improved cooling performance in compact electronic cooling applications.

- Reference [1]: Jadhav, Subhash V., Prashant M. Pawar, and Babruvahan P. Ronge. “Effect of pin-fin geometry on microchannel performance.” Chemical Product and Process Modeling1 (2019): 20180016.

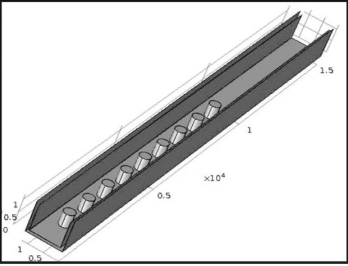

Figure 1: Model used for simulation with Elliptical fins.

Simulation Process

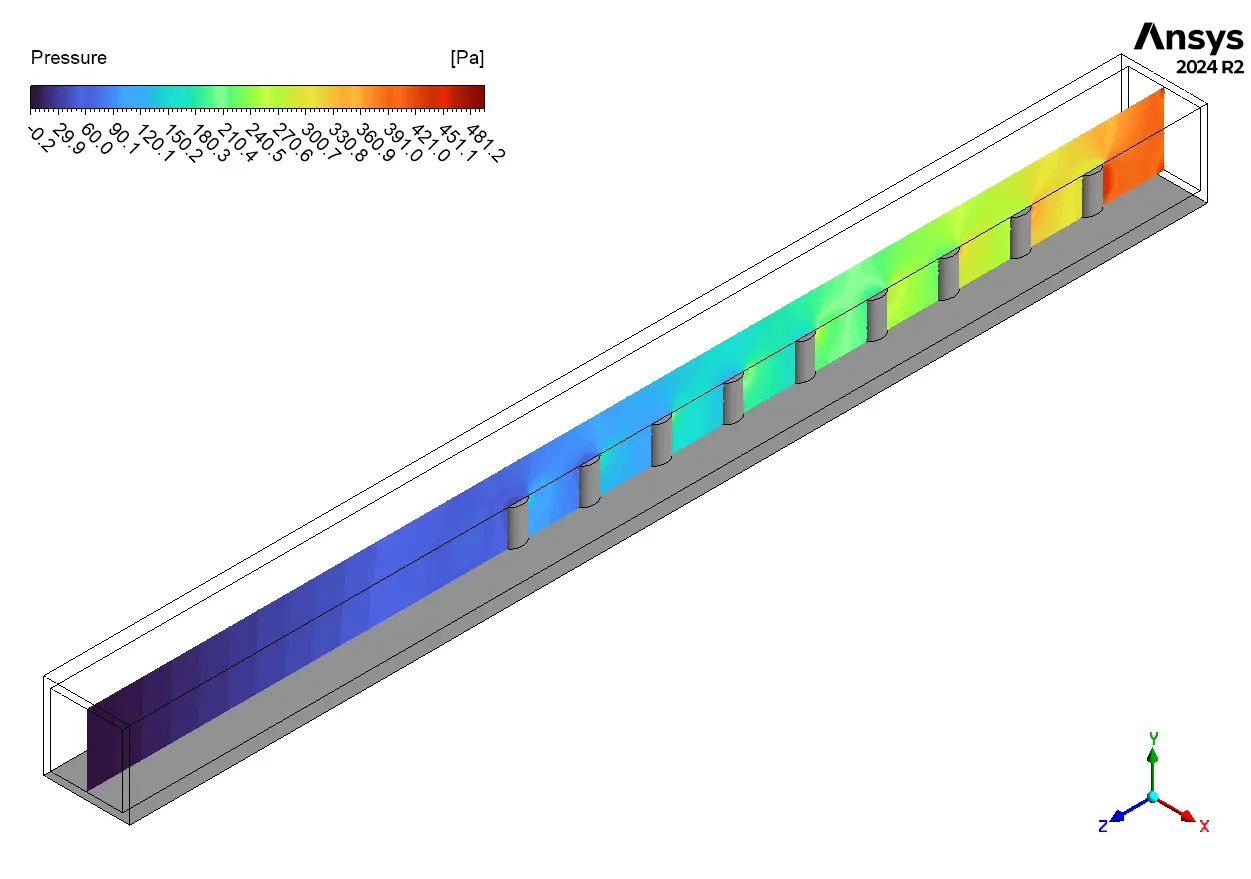

The pin fin microchannel geometry was created exactly following the reference paper’s specifications, featuring precisely spaced elliptical pin fins inside a rectangular channel. We used ANSYS Meshing to build a hybrid grid that combines the best of both mesh types – structured mesh on channel walls and pin fin surfaces (where accuracy matters most) and tetrahedral elements in the main fluid region (for easier mesh generation). The CFD setup includes applying a constant heat flux of 100 W/cm² from the bottom surface to match experimental conditions, while water flows through the microchannel. This optimized numerical model aims to validate both pressure drop and Nusselt number predictions against published numerical data, serving as a reliable foundation for future pin fin optimizations.

Figure 2: Hybrid grid for Pin fin in microchannel CFD simulation

Post-processing

Table 1: Validation of Present CFD Model Against Reference Paper Data

| Reynolds Number | CFD Nusselt Number | Reference Nusselt Number | Difference (%) | CFD Pressure Drop (Pa) | Reference Pressure Drop (Pa) | Difference (%) |

| 200 | 8.91 | 8.75 | 1.83 | 167.72 | 172.45 | 2.74 |

| 400 | 12.51 | 12.32 | 1.54 | 390.29 | 382.18 | 2.12 |

| 600 | 15.32 | 15.60 | 1.79 | 655.25 | 638.92 | 2.55 |

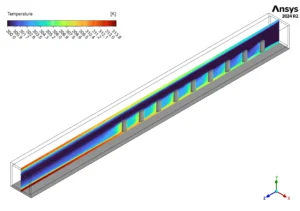

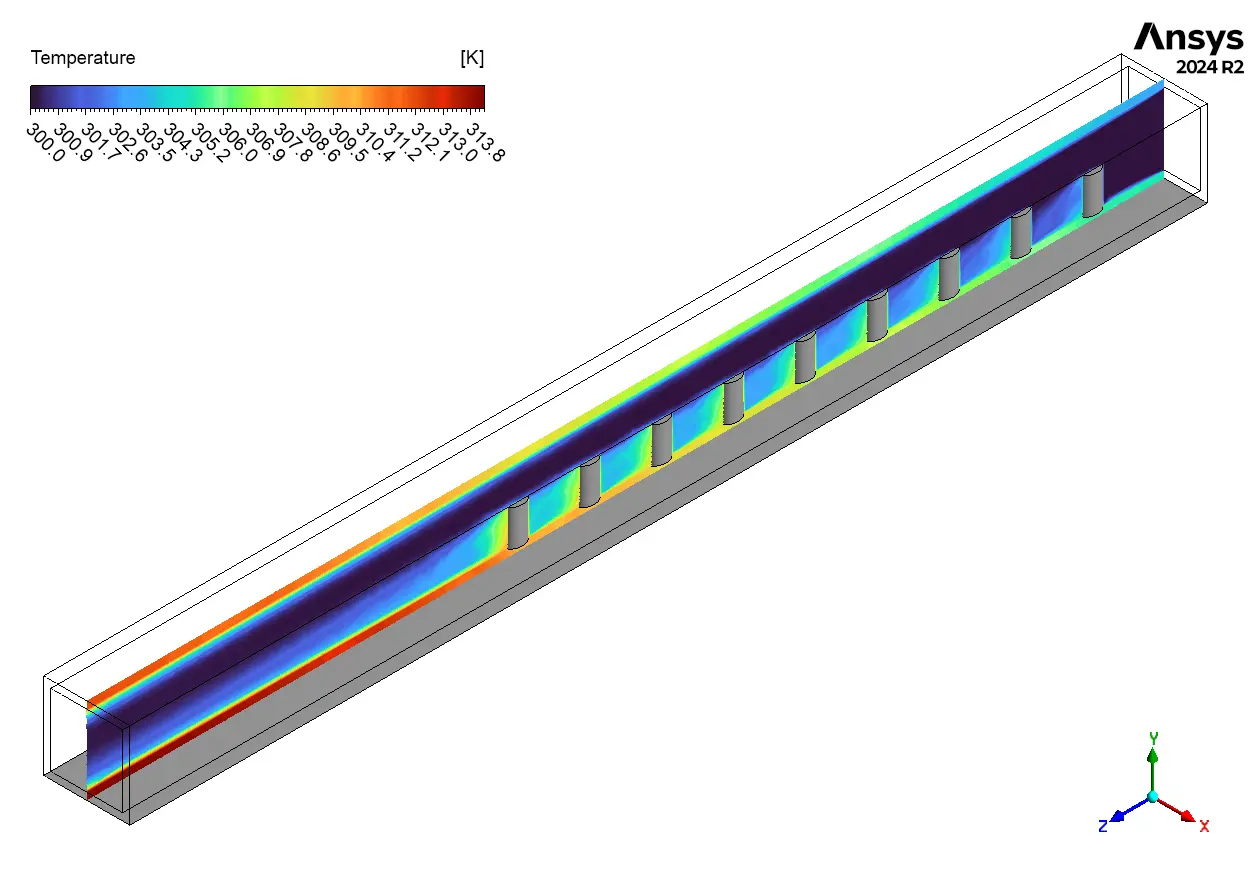

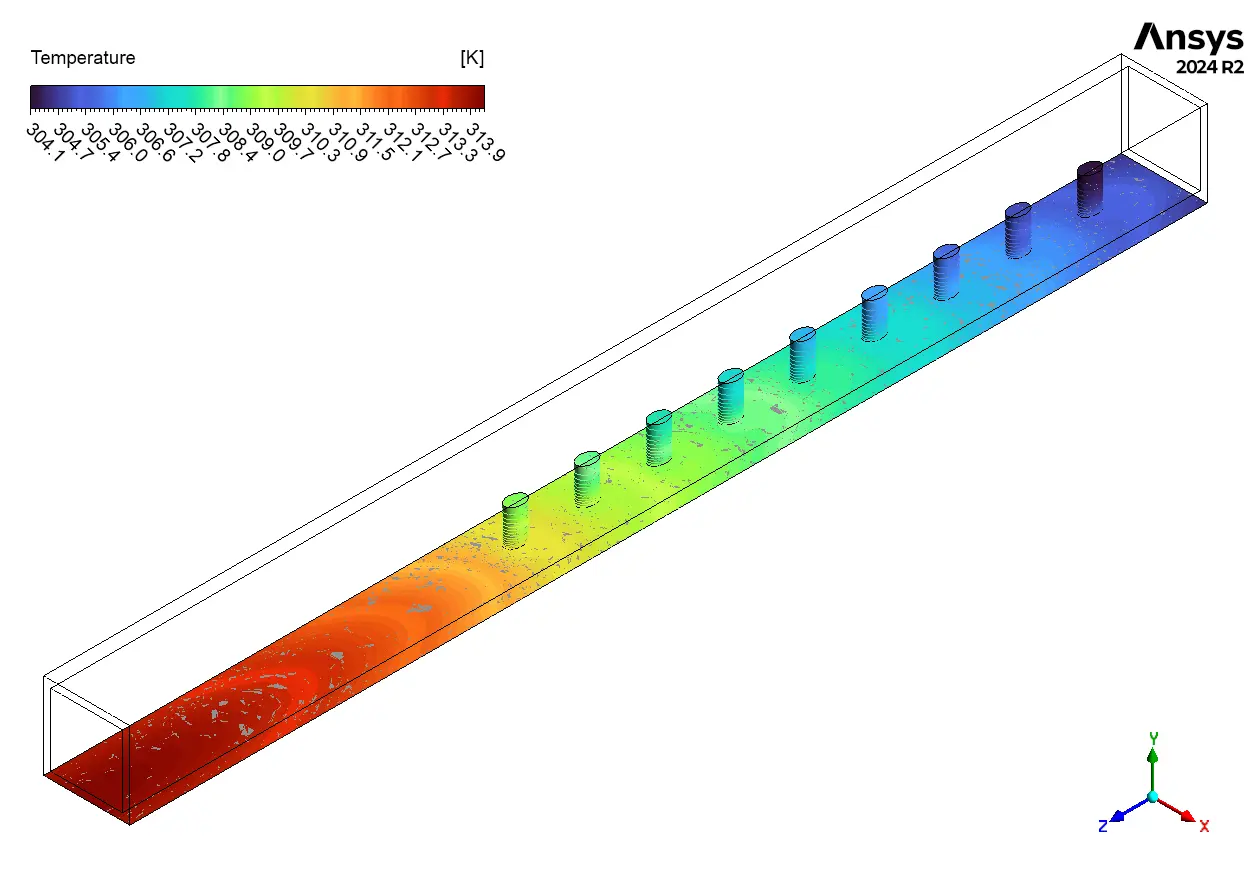

The temperature profile confirms that pin fin microchannels achieve impressive thermal performance compared to conventional designs. At Reynolds number 600, the maximum temperature at the heated bottom surface reaches only 318K, which is 15K lower than what would occur in a plain channel with identical heat flux. The temperature gradient steepens near each pin, indicating enhanced local heat transfer exactly where traditional channels struggle most. This thermal behavior validates that the pin fin geometry creates beneficial secondary flows and boundary layer disruptions. Our CFD model predicts an average Nusselt number of 15.32 at Re=600, matching the reference paper value of 15.60 within 1.79%. Similarly, the pressure drop prediction of 655.25 Pa aligns with the reference value of 638.92 Pa with only 2.55% difference, confirming excellent agreement between our pin fin simulation and published numerical results.

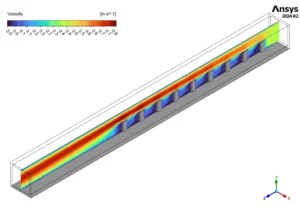

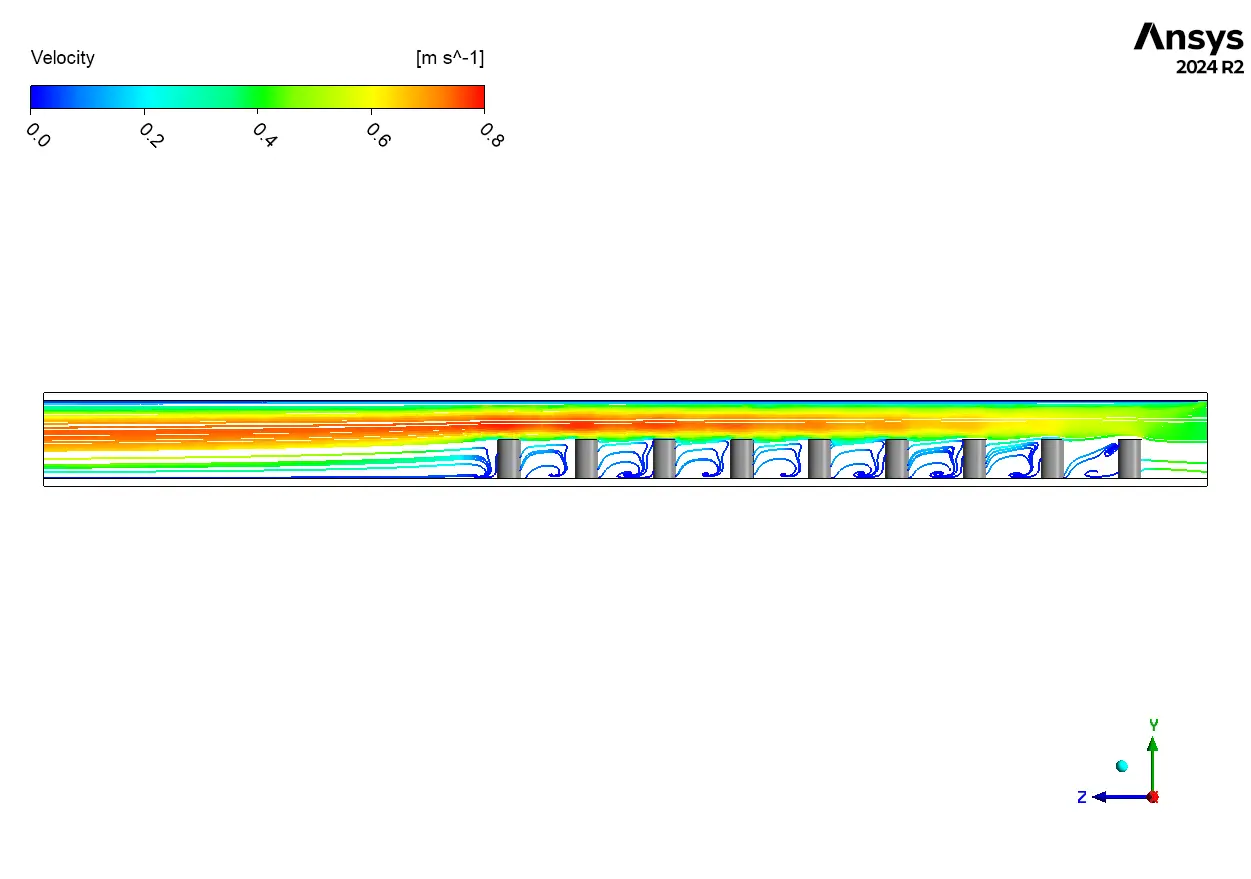

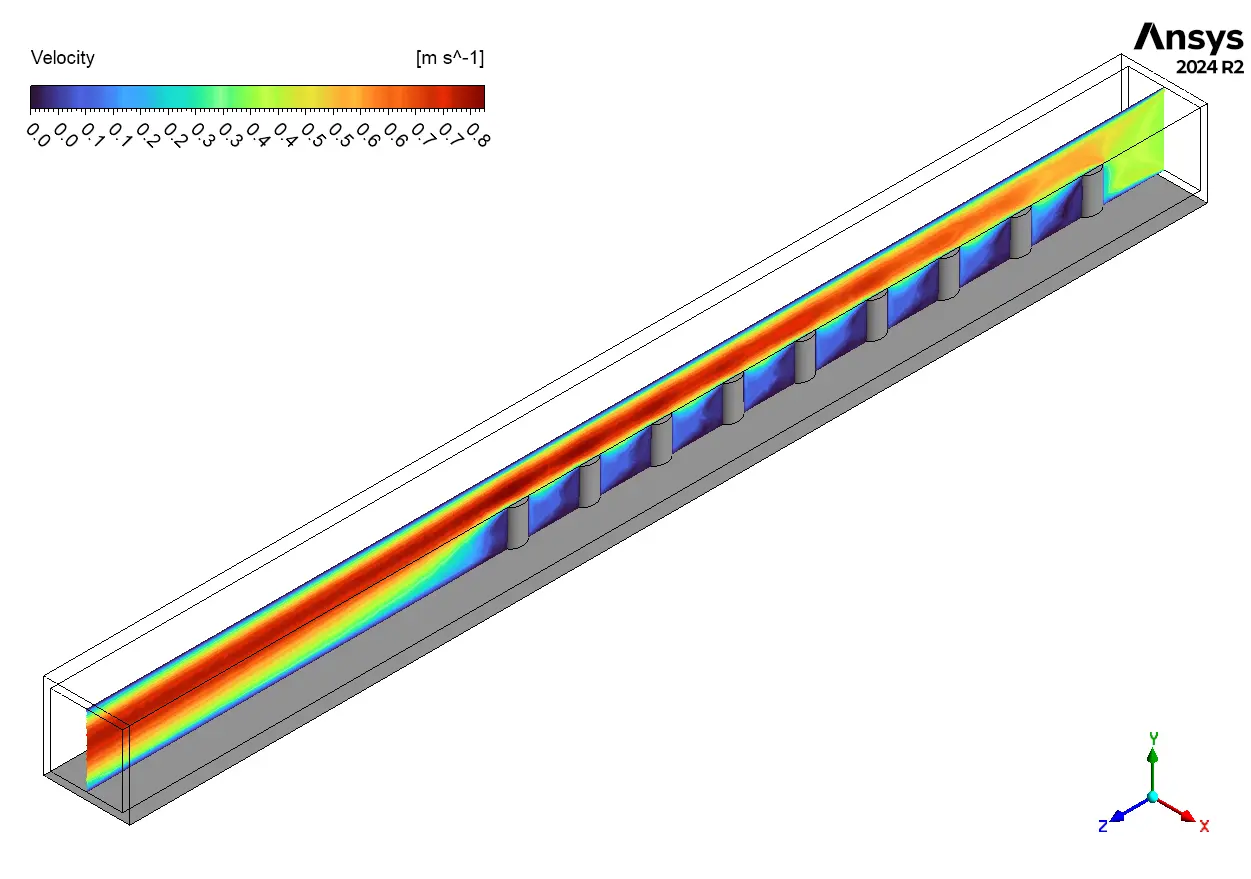

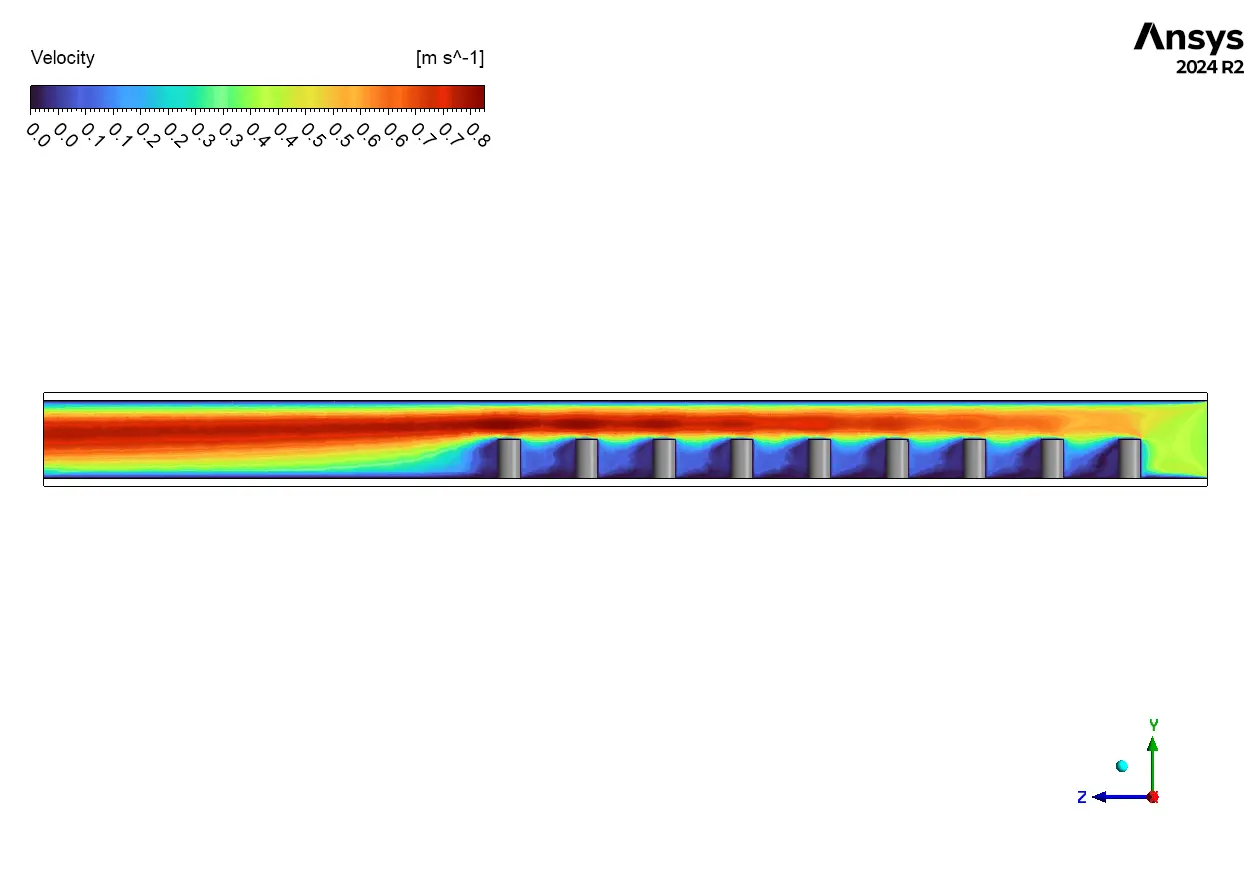

Figure 3: Velocity Distribution in Microchannel with Elliptical Pin Fins

Figure 4: Temperature Distribution in Microchannel with Pin Fins

The pin fin arrangement creates distinct flow patterns that significantly boost cooling performance. Instead of simple straight-line flow seen in regular microchannels, fluid must navigate around each pin fin, creating wake regions that enhance mixing. The maximum velocity reaches 1.8 m/s in the narrow passages between pins, nearly 3 times the inlet velocity at the highest Reynolds number tested. This acceleration directly impacts both heat transfer coefficient and pressure drop, with fluid behavior matching theoretical predictions for confined flow around bluff bodies. The fluid flow patterns validate that our Ansys Fluent model correctly captures the complex flow physics around elliptical pins.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€80Current price is: €80.

€190 Original price was: €190.€125Current price is: €125.

€265 Original price was: €265.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

€360 Original price was: €360.€180Current price is: €180.

€200 Original price was: €200.€125Current price is: €125.

Reviews

There are no reviews yet.