Pulsating Fluidized Bed CFD Simulation: A UDF Tutorial in ANSYS Fluent

Pulsating Fluidized Bed CFD Simulation: A UDF Tutorial in ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€205 Original price was: €205.€155Current price is: €155.

Pulsating Fluidized Beds (PFBs) are advanced reactors where the gas flow is not steady but pulses periodically. This pulsation, alternating between high and low flow rates, causes the bed of solid particles to expand and contract cyclically. This dynamic behavior offers significant advantages over conventional fluidized beds, especially for processes like combustion, gasification, and drying. The main benefits are improved particle mixing, enhanced heat and mass transfer, and better control over reaction times.

This tutorial demonstrates a Pulsating Fluidized Bed CFD simulation focused on the complex behavior of particle mixing and segregation. Such simulations are challenging but provide invaluable insights for chemical and mechanical engineers. For more examples of this technology, you can explore our full range of Fluidized Bed CFD Simulation projects. Our work is based on the findings in the reference paper by Lim et al. [1].

- Reference [1]: Lim, Leonard Jing Jie, and Eldin Wee Chuan Lim. “Mixing and segregation behaviors of a binary mixture in a pulsating fluidized bed.” Powder Technology345 (2019): 311-328.

- Reference [2]: Liu, G-Q., et al. “Experimental studies of particle flow dynamics in a two-dimensional spouted bed.” Chemical Engineering Science4 (2008): 1131-1141.

- Reference [3]: Zhang, Kai, et al. “Prediction of segregation behavior of binary mixture in a pulsed fluidized bed.” Advanced Powder Technology11 (2019): 2659-2665.

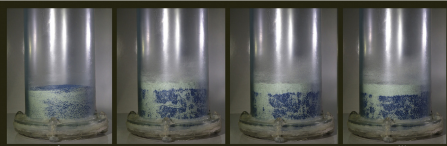

Figure 1: Snapshots showing the particle segregation process in a Pulsating Fluidized Bed.

Simulation Process: Multiphase PFB Modeling in ANSYS Fluent

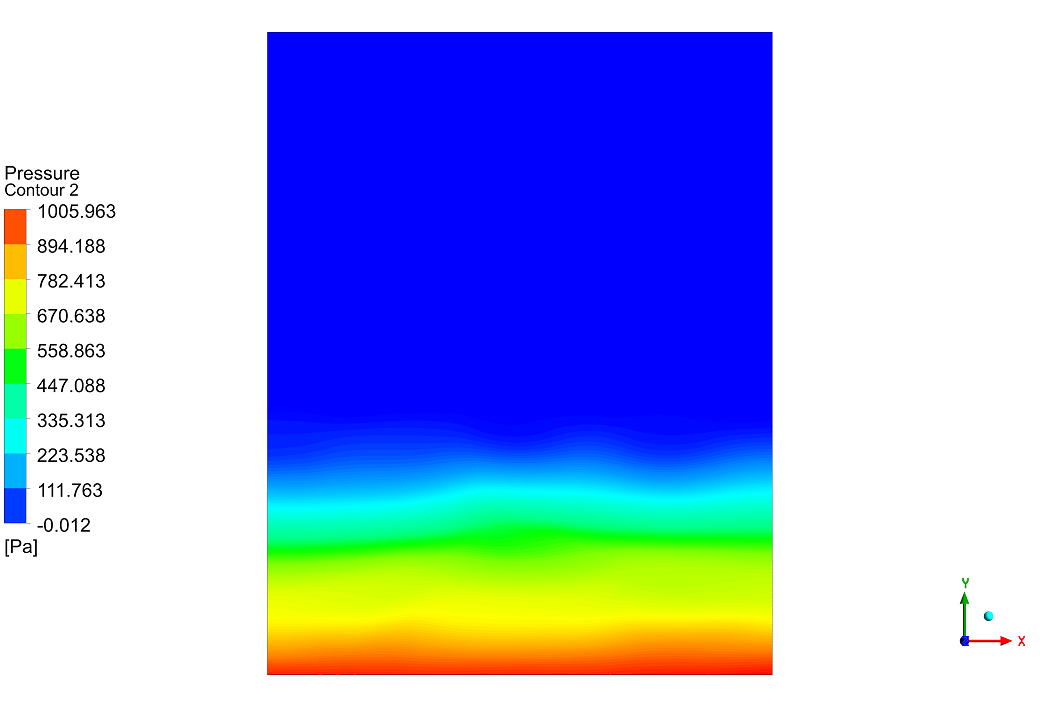

The simulation process for this project began with a straightforward geometry and mesh generation. We created a simple 2D rectangular domain and applied a properly structured grid using ANSYS Meshing, resulting in a total of 5695 elements. The main challenges were in the solver setup within ANSYS Fluent. This Pulsating Fluidized Bed simulation involves three phases: one gas phase and two different solid granular phases. To handle this, the Eulerian multiphase model was activated. This model is essential because it treats each phase as an interpenetrating continuum, allowing us to track the volume fraction of each solid particle type.

The most critical part of the setup was defining the pulsating inlet flow. Standard Fluent settings do not allow for a time-varying, pulsating velocity. Therefore, a User-Defined Function (UDF) was written in the C programming language. This UDF instructs the solver to vary the inlet gas velocity over time, creating the pulsating effect that gives the PFB its name.

Post-processing: Particle Segregation in the Pulsating Fluidized Bed Fluent Simulation

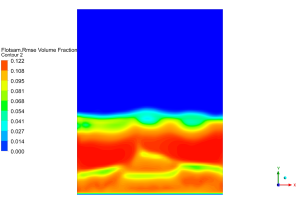

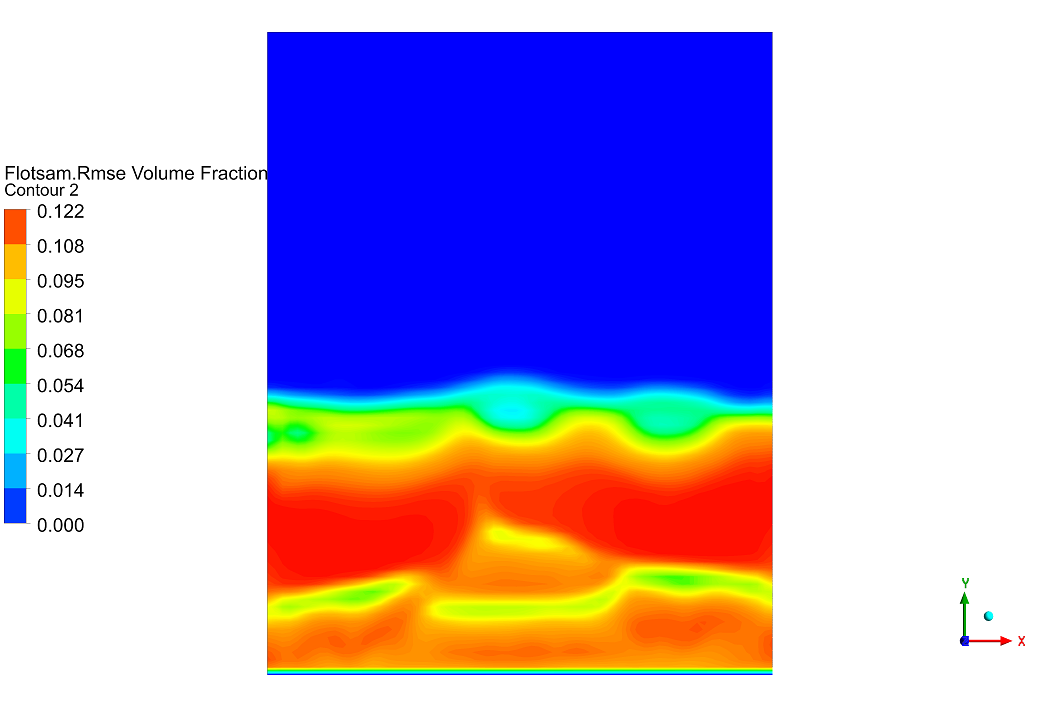

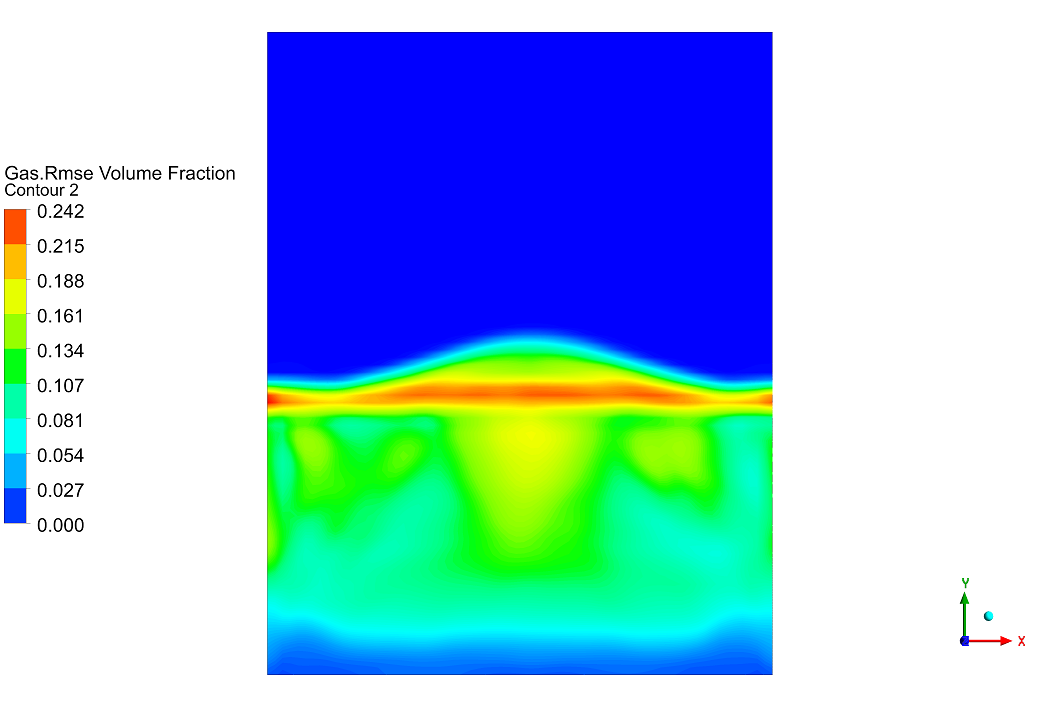

The post-processing focuses on analyzing the volume fraction of the two granular phases, known as “flotsam” (lighter particles) and “jetsam” (heavier particles), to understand their mixing and segregation behavior. The volume fraction contour for the flotsam phase, shown in Figure 2, reveals clear segregation. The flotsam volume fraction ranges from 0 to 0.122. The highest concentrations are consistently found in the lower part of the bed. This indicates that as the pulsating gas flow weakens during its cycle, these lighter particles settle down, creating a distinct stratified layer. The upward movement of the gas is not always strong enough to keep them fully mixed throughout the entire volume.

Figure 2: Flotsam granular volume fraction, showing segregation at the bottom of the Pulsating Fluidized Bed.

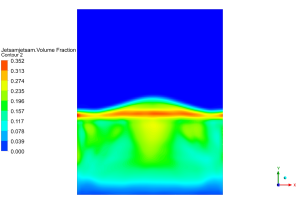

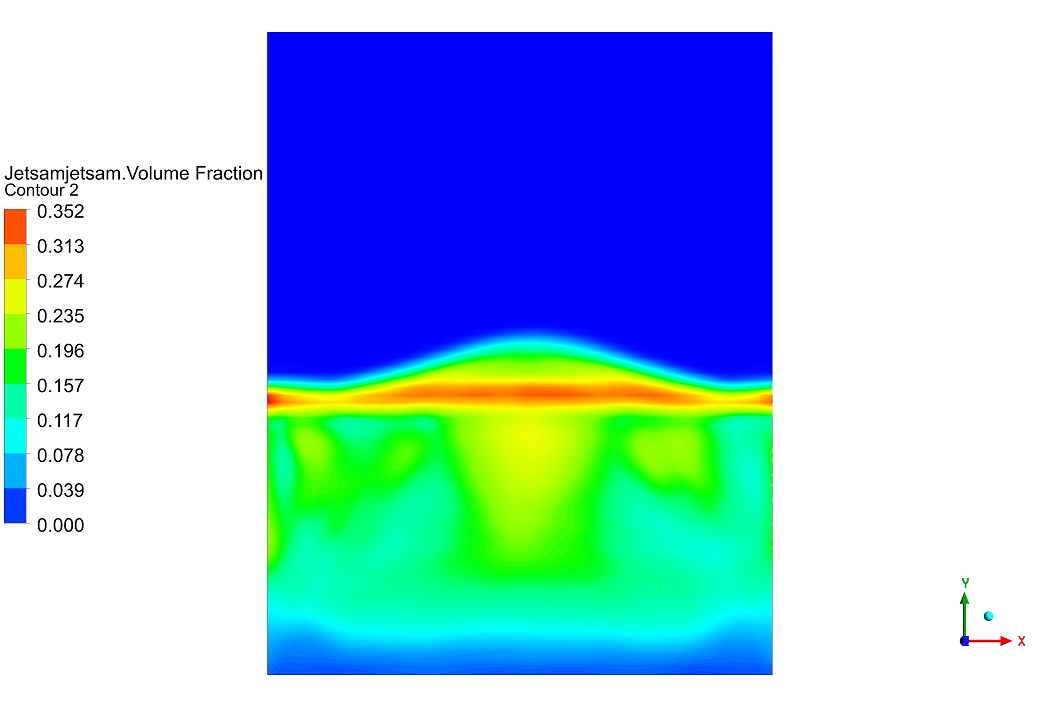

In contrast, Figure 3 shows the jetsam phase, which has a higher maximum volume fraction, ranging from 0 to 0.352. This indicates that the jetsam particles are the more dominant solid phase in the mixture. These heavier particles exhibit a more complex pattern. While some segregation is visible, they are also more actively mixed in the central region of the bed. The pulsating flow is strong enough to lift and circulate these heavier particles, but as the pulse fades, they begin to settle, creating dynamic concentration bands. The animation of this Pulsating Fluidized Bed Fluent simulation clearly shows this cyclic process: the strong pulse mixes the particles, and the weak pulse allows for partial segregation. This dynamic equilibrium is what enhances the overall performance compared to a standard, non-pulsating bed.

Figure 3: Jetsam volume fraction, showing a dynamic mixing pattern in the Pulsating Fluidized Bed.

Key Takeaways & FAQ

- Q: Why do you need a UDF for a Pulsating Fluidized Bed CFD simulation in Fluent?

- A: Standard inlet boundary conditions in Fluent are typically set to a constant velocity or pressure. A Pulsating Fluidized Bed requires the inlet gas velocity to change over time in a specific pattern (e.g., a sine wave). A User-Defined Function (UDF) is a custom script that allows you to program this time-dependent behavior, which is essential for accurately modeling the pulsation.

- Q: What is particle segregation in a fluidized bed?

- A: Particle segregation is the separation of a mixture of particles based on their physical properties, such as size or density. In this simulation, the lighter “flotsam” particles tend to settle at the bottom, while the heavier “jetsam” particles are more actively mixed, demonstrating this phenomenon.

- Q: What is the Eulerian multiphase model used for in ANSYS Fluent?

- A: The Eulerian model is used for multiphase flows where the different phases mix and interact, but are treated as continuous fluids that share the same space. It is ideal for fluidized beds where you need to track the volume fraction (concentration) of different solid particle types within a gas, rather than tracking each individual particle.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170 Original price was: €170.€159Current price is: €159.

€160 Original price was: €160.€145Current price is: €145.

€160 Original price was: €160.€145Current price is: €145.

€140 Original price was: €140.€85Current price is: €85.

€265 Original price was: €265.€155Current price is: €155.

€210 Original price was: €210.€155Current price is: €155.

Reviews

There are no reviews yet.