Refrigerator Evaporator CFD Simulation – ANSYS Fluent Tutorial

Refrigerator Evaporator CFD Simulation – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€180 Original price was: €180.€155Current price is: €155.

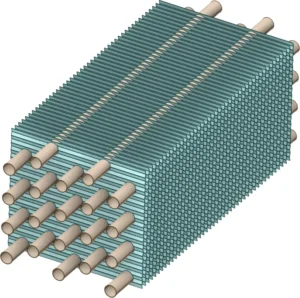

Evaporators in open display refrigerators are a great engineering issue that needs to be solved in commercial refrigeration systems that are used in grocery stores and convenience shops all over the world. These special heat exchangers are what keep open merchandisers running smoothly. They keep exact temperature zones without doors, which is important for both keeping products fresh and letting customers in. The attached model shows a finned-tube design with several copper or aluminum tubes going through closely spaced parallel fins that make the heat transfer surface area bigger while lowering the airflow resistance.

Within this complex structure, the changes from a liquid to a gas. It then absorbs heat from the air around it and cools the display area to the best temperature for food storage, which is between 2 and 4°C. Furthermore, these evaporators have to work well even though they are constantly faced with tough conditions such as changing humidity levels, shoppers walking around and disturbing the air curtain, and the possibility of frost formation, which can greatly lower heat performance.

Figure 1: Full schematic of Refrigerator Evaporator

Simulation Process

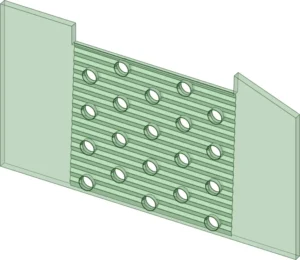

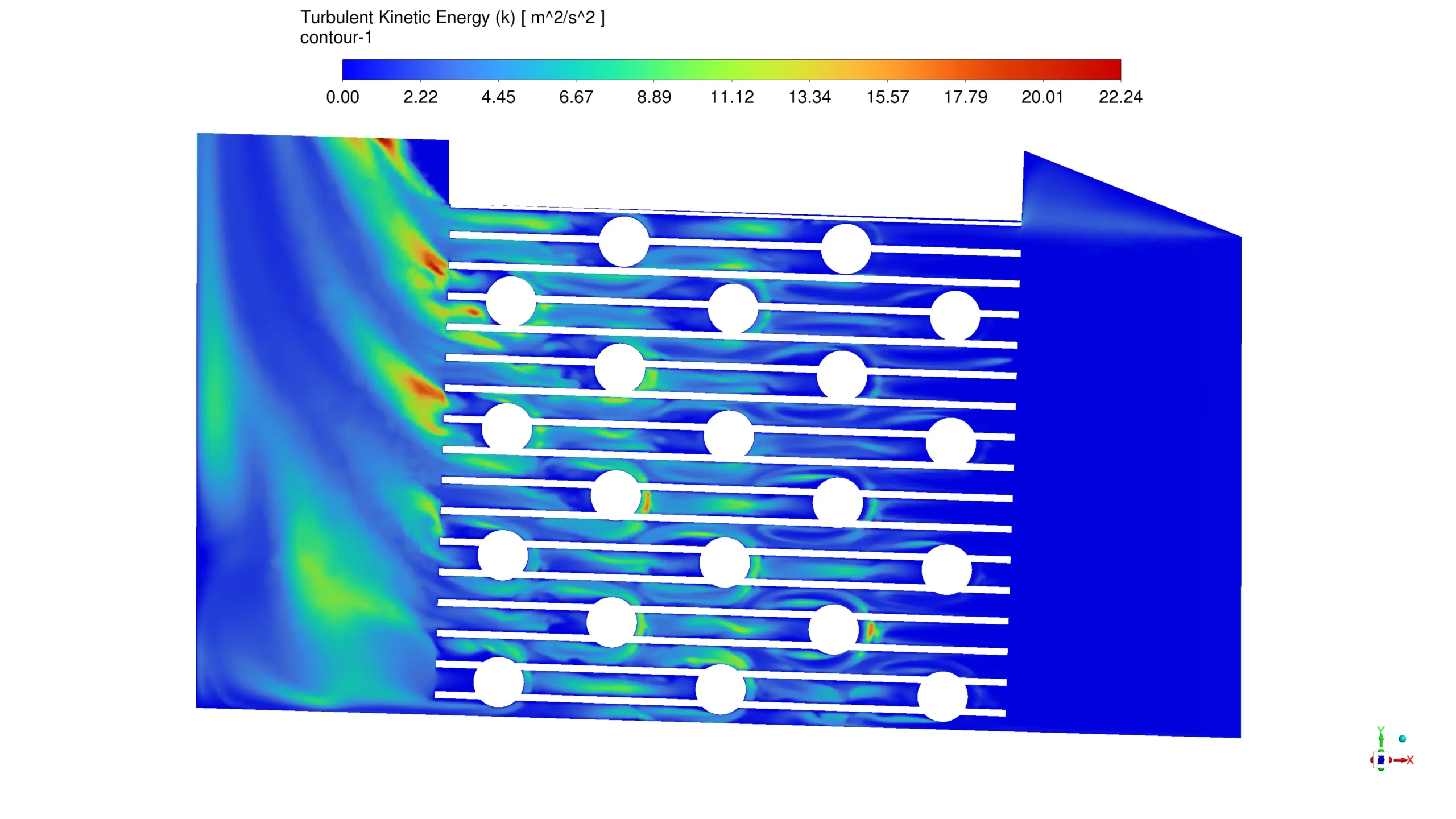

To make the refrigerator evaporator simulation work, a model of a section of the whole evaporator assembly was used to find an appropriate balance between accuracy and speed. The picture shows that the model has many refrigerant tubes set up in a random pattern through parallel fins that make the surface area for heat transfer bigger. Using Fluent Meshing to break up this geometry created a high-resolution mesh with 11,637,928 cells that correctly captured the complex flow patterns around the fins and tubes. The species transport model is used in the simulation to track the motion of both air and water vapor (H2O). This is important for figuring out how much vapor and frost might form on cold surfaces. The boundary conditions were set to reflect normal working conditions. For example, the evaporator wall surfaces were kept at -10°C to simulate the temperature of the refrigerant, and the humid air coming in was kept at 24°C to reflect normal store conditions.

Figure 2: Our 3D model – section of the whole evaporator

Post-processing

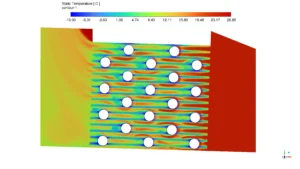

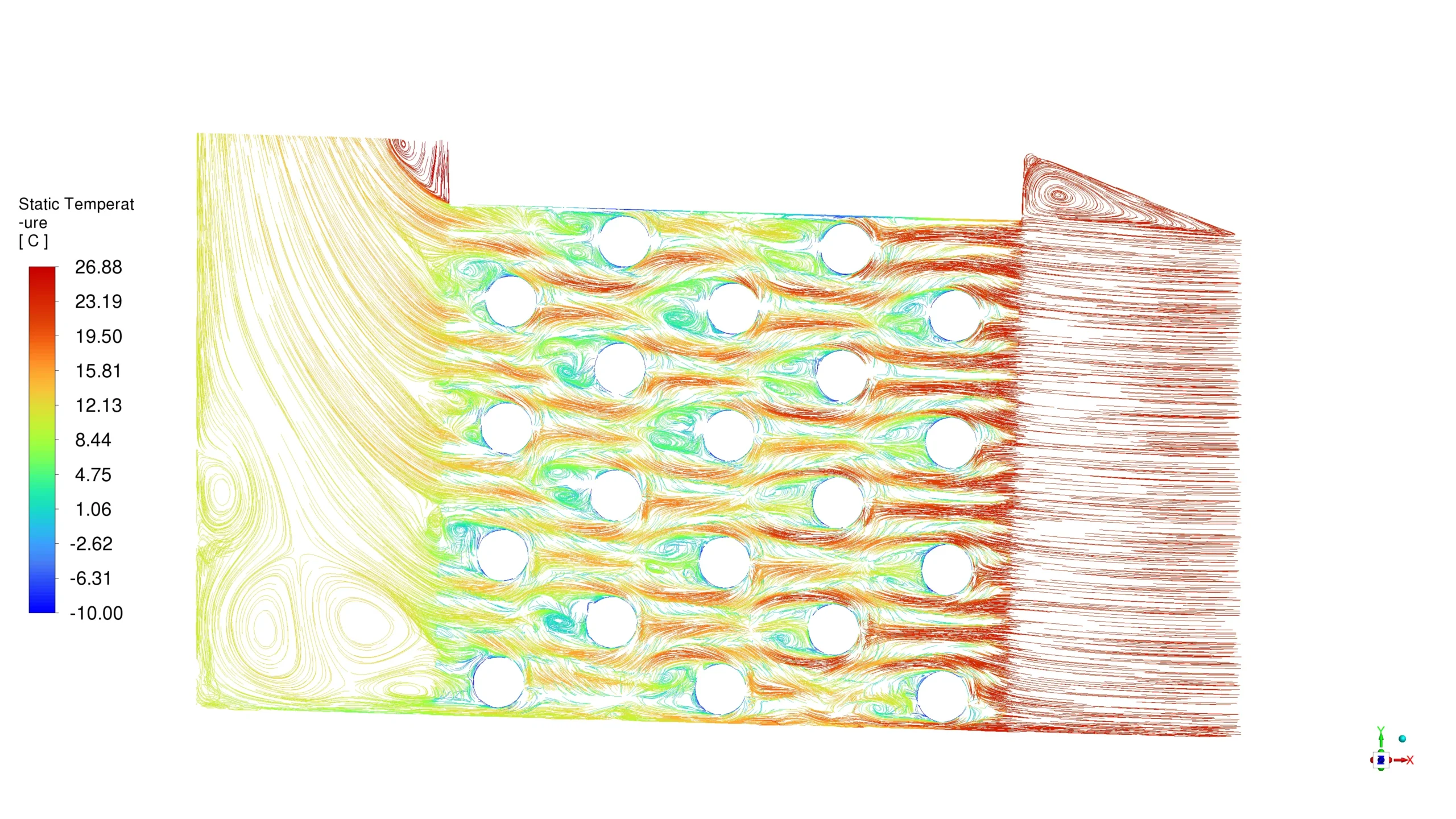

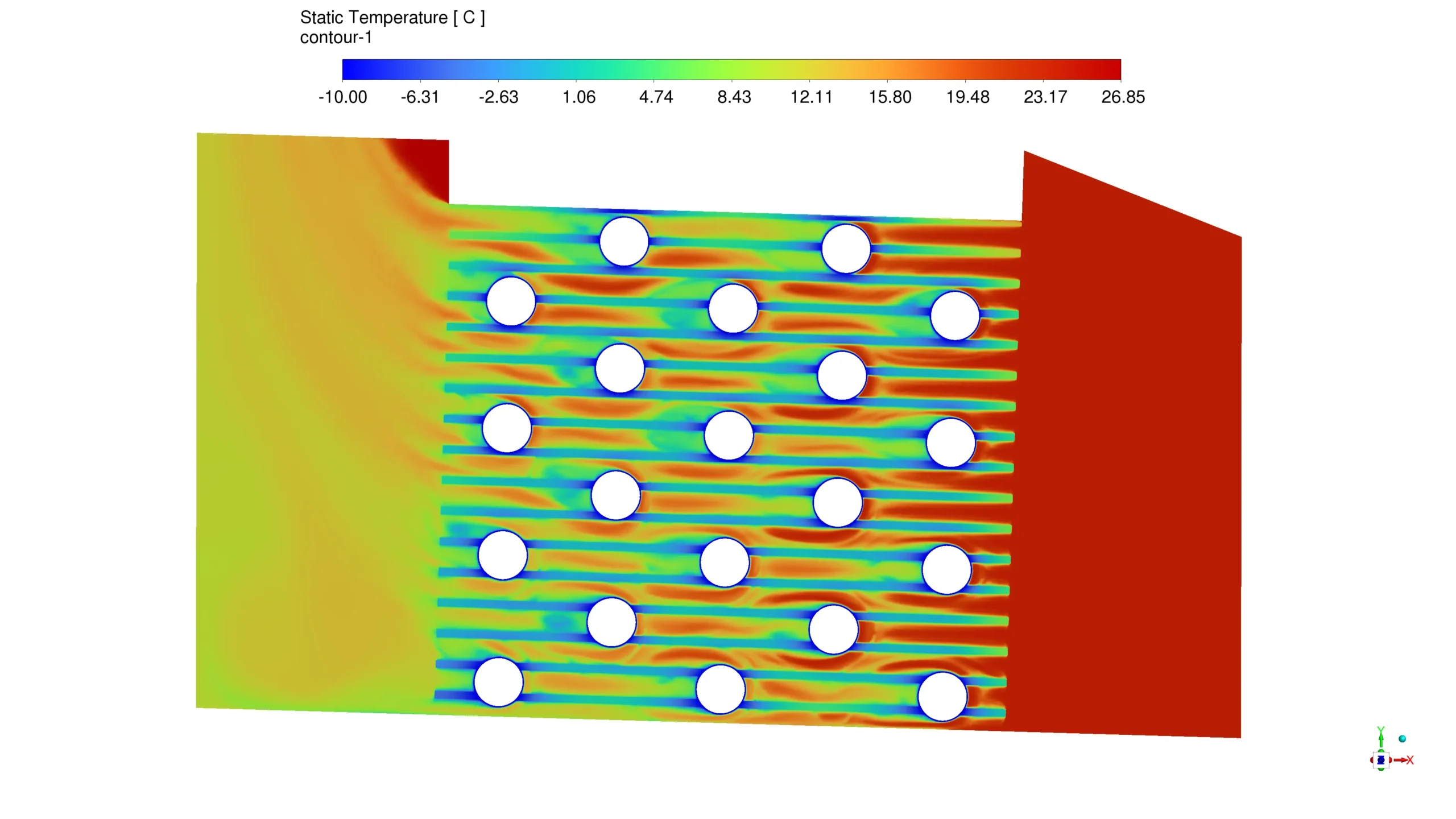

As warm air from the storage area moves through the evaporator coil assembly, the static temperature curve shows how the temperature drops over time. The illustration clearly shows that the 24°C air that comes in (shown by the red and orange areas at the intake) cools down a lot when it comes in touch with the -10°C evaporator tubes, making clear thermal boundary layers around each tube. The staggered tube design stands out because it creates a zigzag flow pattern that keeps air in place longer and transfers heat more efficiently. The difference in temperature between the rows shows the sequential cooling effect, where each row takes in more heat from the airstream than the previous row. This multi-row arrangement is very important for getting the end outlet temperature of 13.97°C, which is a big drop of 10.03°C in temperature across the evaporator. Also, the temperature distribution shows that there is localized warmth between tubes (visible as yellow-green areas). This suggests that the fin design could be improved to improve heat transfer in these areas and make the cooling more even throughout the evaporator section.

Figure 3: Temperature field around Refrigerator Evaporator

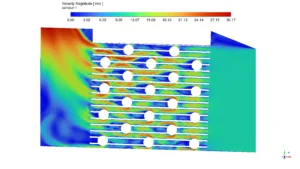

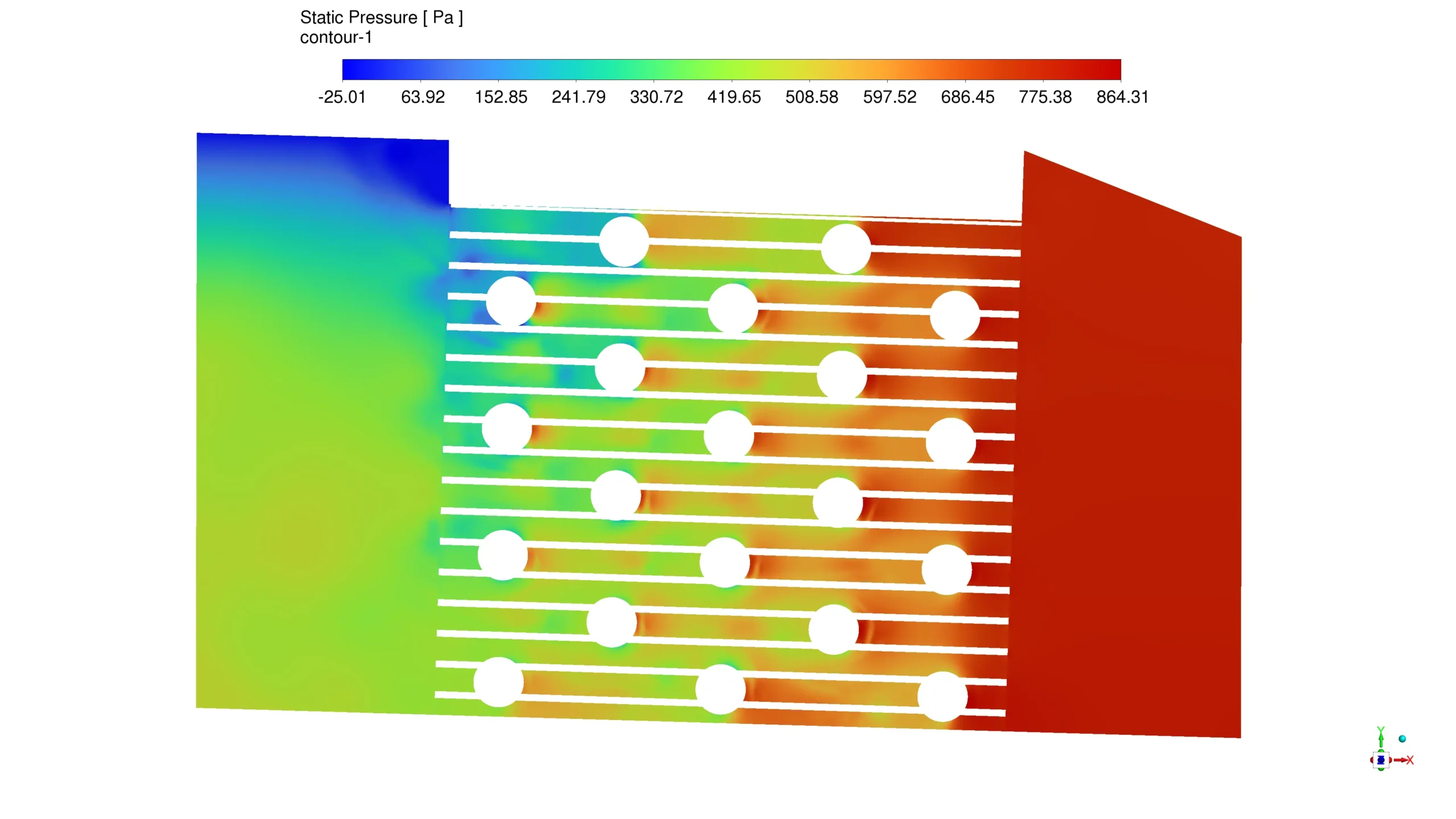

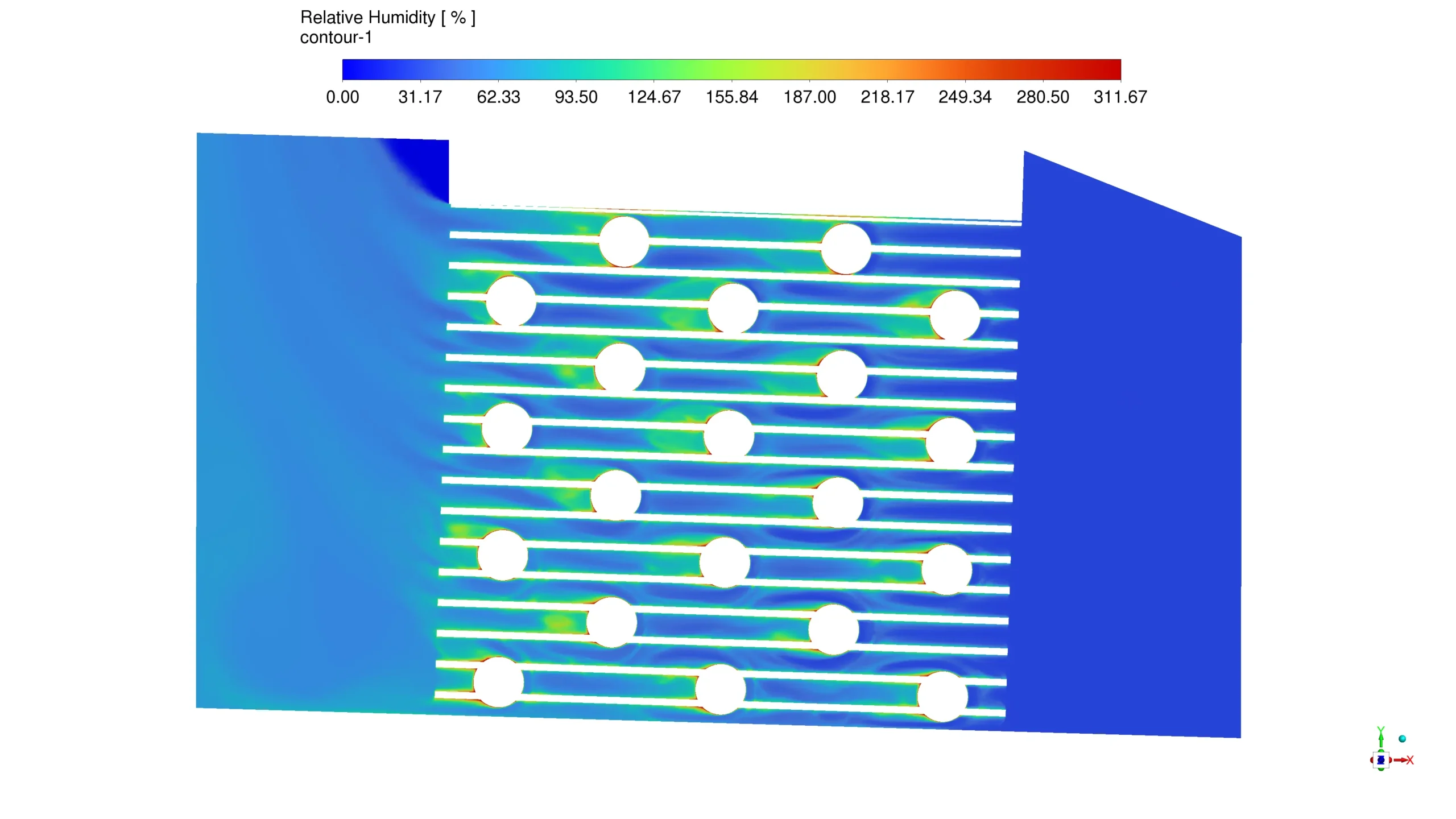

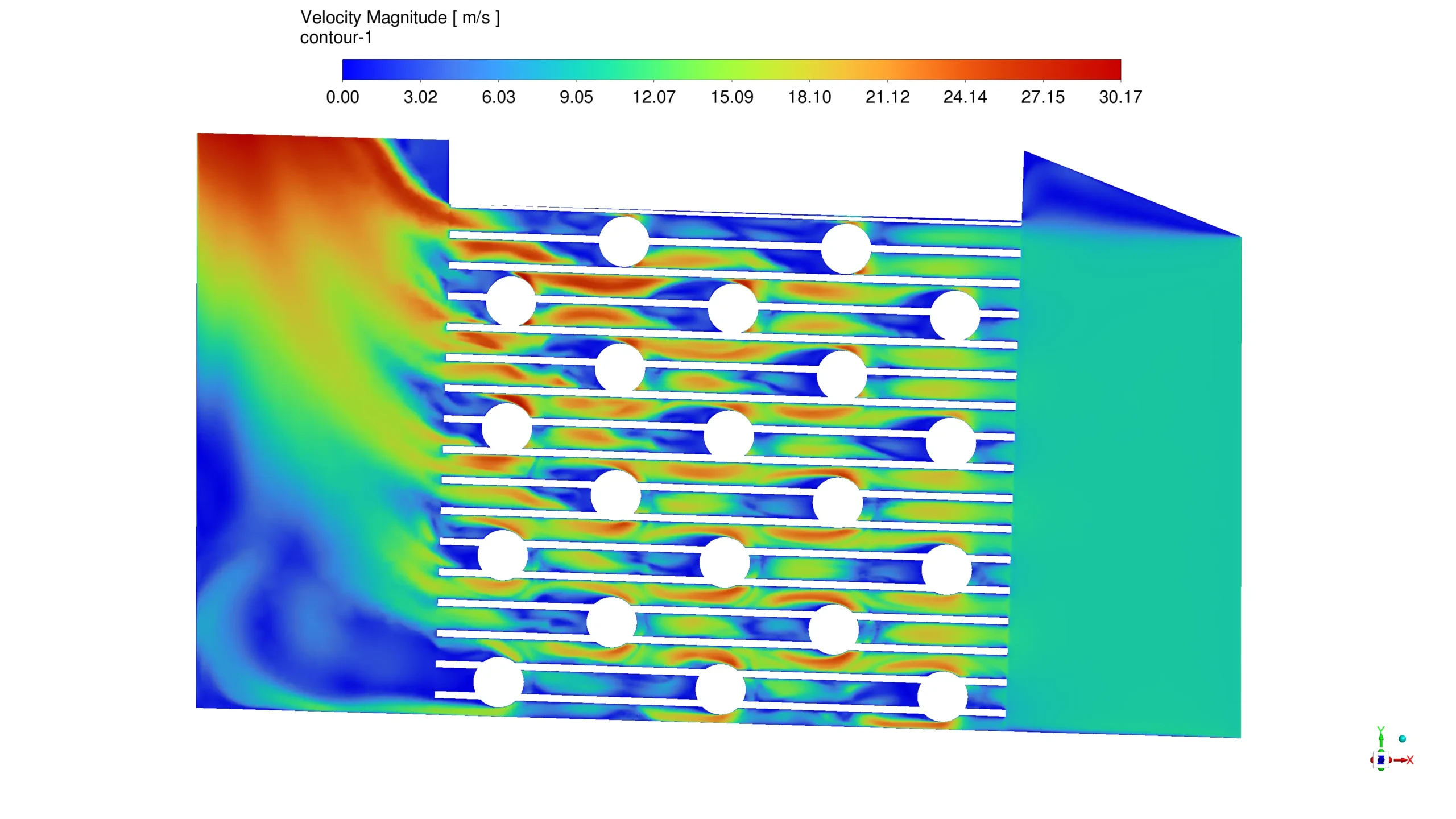

The screenshots of the coupled velocity magnitude and relative humidity give us more information about how the evaporator works. The velocity curve shows that the flow is speeding up a lot between the tubes, reaching peak speeds of around 30 m/s in the narrowest passages and staying at slower speeds of 3–9 m/s in the wider flow areas. This speeding up of the flow greatly improves the convective heat transfer coefficients right where the most cooling is needed. The relative humidity curve, on the other hand, shows how well the evaporator removes moisture; the incoming humid air experiences a big drop from its starting point to the measured 56.25% relative humidity at the exit. The areas with the highest humidity levels (in green) are mostly near the coldest surfaces, where water vapor condenses when it hits surfaces below the dew point. This dehumidification feature is very important for open display freezers because it keeps product packaging from fogging up and keeps moisture from getting into the display area. According to these results, the staggered tube configuration effectively balances airflow resistance with heat transfer enhancement. Also, the evaporator’s ability to maintain proper food preservation environments in open refrigerated merchandisers is proven by the fact that it can reach the right outlet conditions (13.97°C at 56.25% RH).

Figure 4: Velocity field around Refrigerator Evaporator

Figure 5: RH around Refrigerator Evaporator

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€115Current price is: €115.

€195 Original price was: €195.€135Current price is: €135.

€105 Original price was: €105.€65Current price is: €65.

€130 Original price was: €130.€115Current price is: €115.

€160 Original price was: €160.€135Current price is: €135.

€140 Original price was: €140.€65Current price is: €65.

Reviews

There are no reviews yet.