Shock Wave In Single-stage Ejector-diffuser (SSED) CFD Simulation

Shock Wave In Single-stage Ejector-diffuser (SSED) CFD Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170.00 Original price was: €170.00.€135.00Current price is: €135.00.

The single-stage ejector-diffuser works like a magical fluid pump that needs no electricity or moving parts to do its job! This amazing device uses a high-speed primary stream to pull in a slower secondary stream through pure fluid motion alone. Inside the ejector system, the fast-moving fluid creates a low-pressure zone that acts like a vacuum cleaner, sucking in the nearby fluid through a special opening. Then, both fluids mix together in the mixing chamber where they share energy and momentum before flowing into the widening diffuser section. Furthermore, the pressure recovery that happens in the diffuser makes these devices perfect for many important jobs in factories and cooling systems. Additionally, the special shape of the converging-diverging nozzle creates fascinating flow patterns that engineers can control to make the system work better. Most importantly, the ejector-diffuser can move fluids using only the energy from another flowing fluid, making them extremely energy-efficient solutions for modern industrial problems where saving power and reducing costs matter more than ever before. According to the reference paper entitled “Analytical and computational studies on the performance of a two-stage ejector–diffuser system”, the current numerical study over a single-stage ejector-diffuser system is conducted.

- Reference [1]: Kong, Fanshi, and H. D. Kim. “Analytical and computational studies on the performance of a two-stage ejector–diffuser system.” International Journal of Heat and Mass Transfer85 (2015): 71-87.

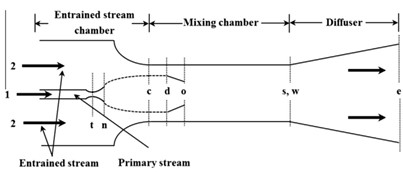

Figure 1: Schematic of SSED from reference paper [1]

Simulation Process

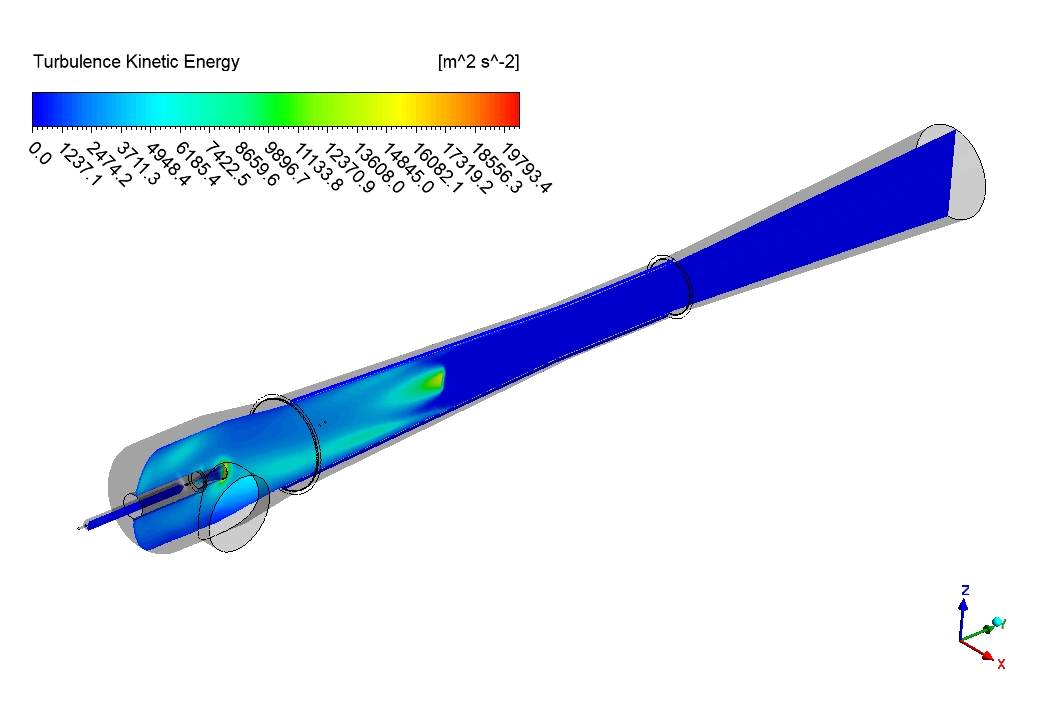

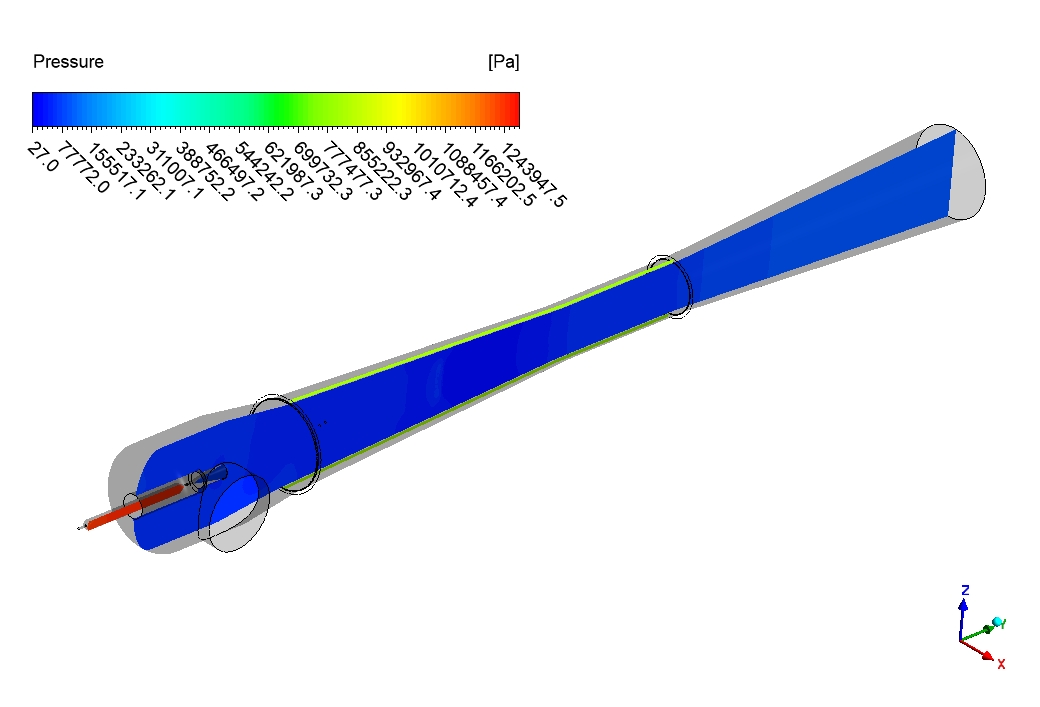

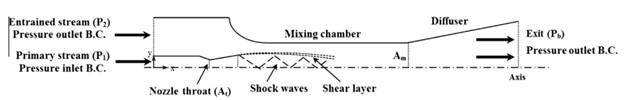

The ejector–diffuser flows are numerically studied by using the axisymmetric domains. The schematic of it is given in the reference paper and illustrated below. 586192 polyhedral cells are produced. A mixture of air, nitrogen and water vapor modeled by the Species Transport model enters SSED system. The compressibility is inevitable in ejectors, so the ideal-gas approach is adopted.

Figure 2: Schematic of SSED system with an axisymmetric view [1]

Post-processing

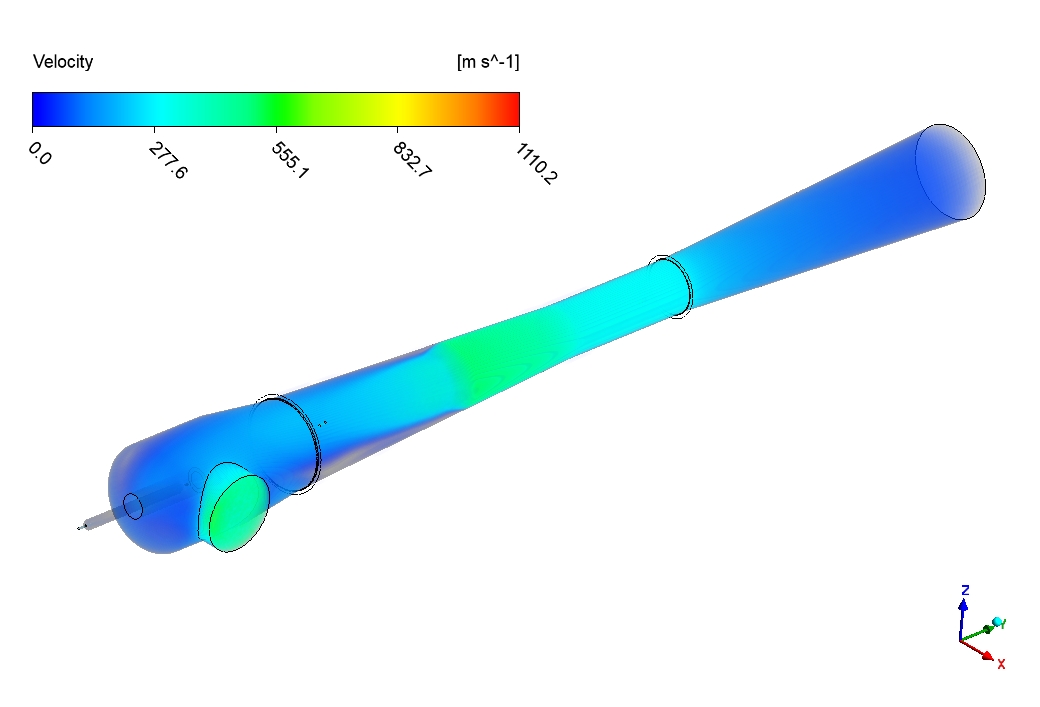

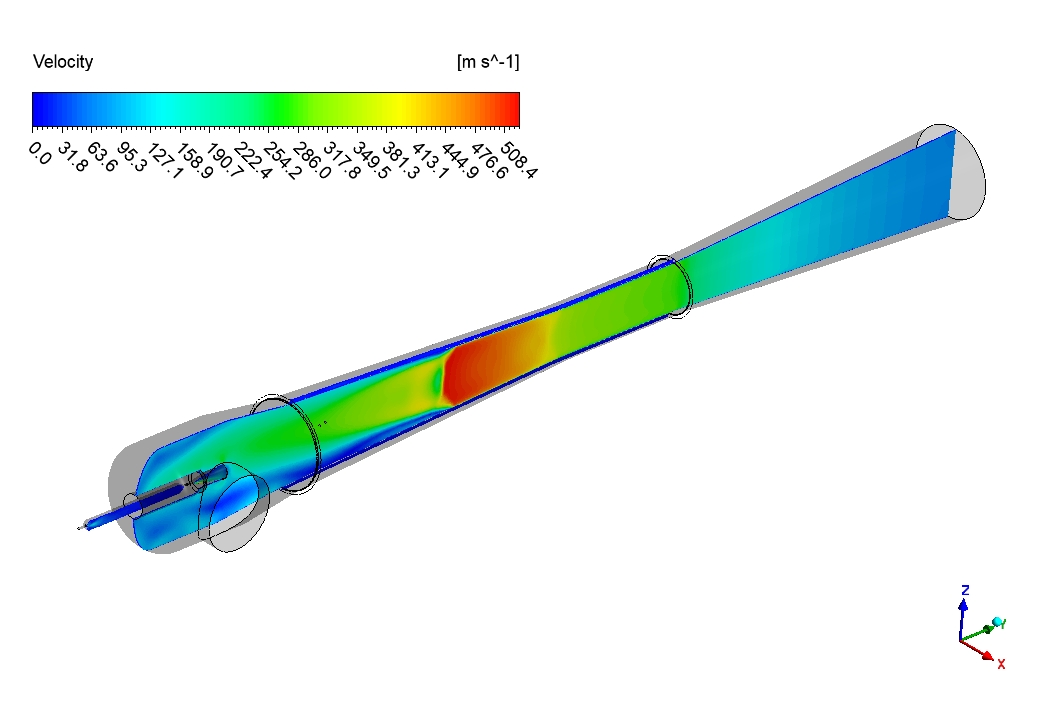

The velocity patterns in our single-stage ejector tell an amazing story of how fluids move through this special device! In the narrow part of the tube, the primary flow speeds up dramatically, reaching maximum speeds of 508.4 m/s. We successfully created supersonic flow conditions where the fluid moves faster than sound! After this super-fast section, notice how the speed gradually decreases as the tube gets wider in the diffuser section. What makes this even more interesting is how the fast-moving jet pulls in the slower secondary flow from the small side opening, just like how a fast-moving train creates a vacuum that pulls things toward it. The highest speeds happen exactly where the tube is narrowest, and this creates a powerful suction effect. Then as the mixed fluids move through the widening tube, they slow down in a very specific pattern that helps convert their speed energy back into pressure energy – this is the main job of any ejector-diffuser system!

Figure 3: Velocity magnitude distribution throughout the single-stage ejector-diffuser system

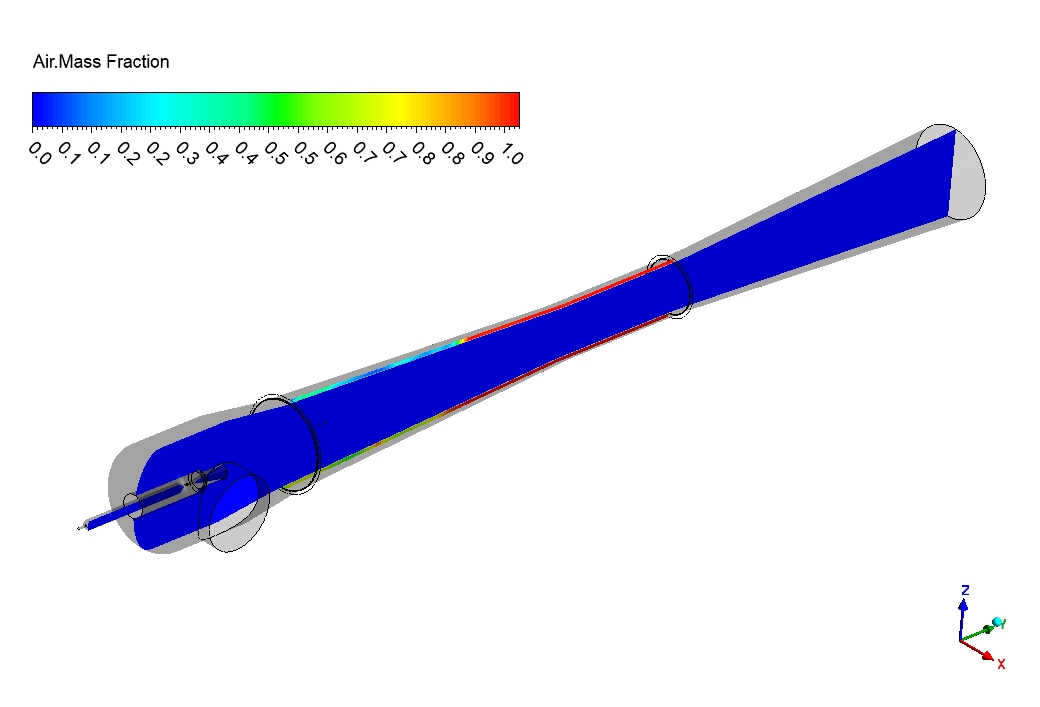

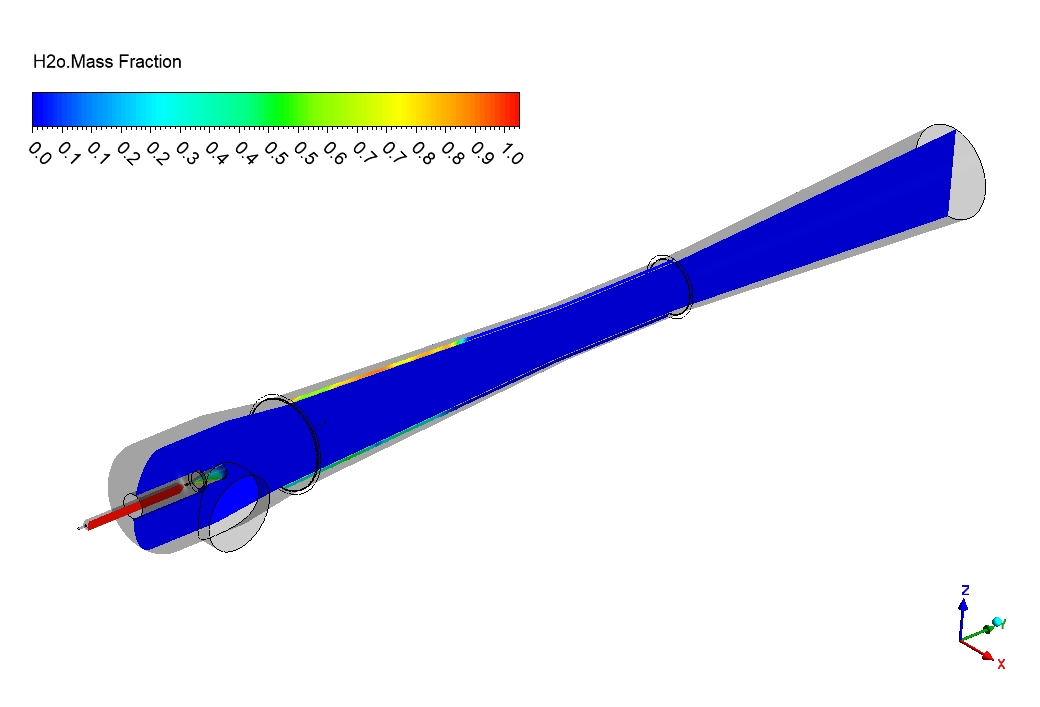

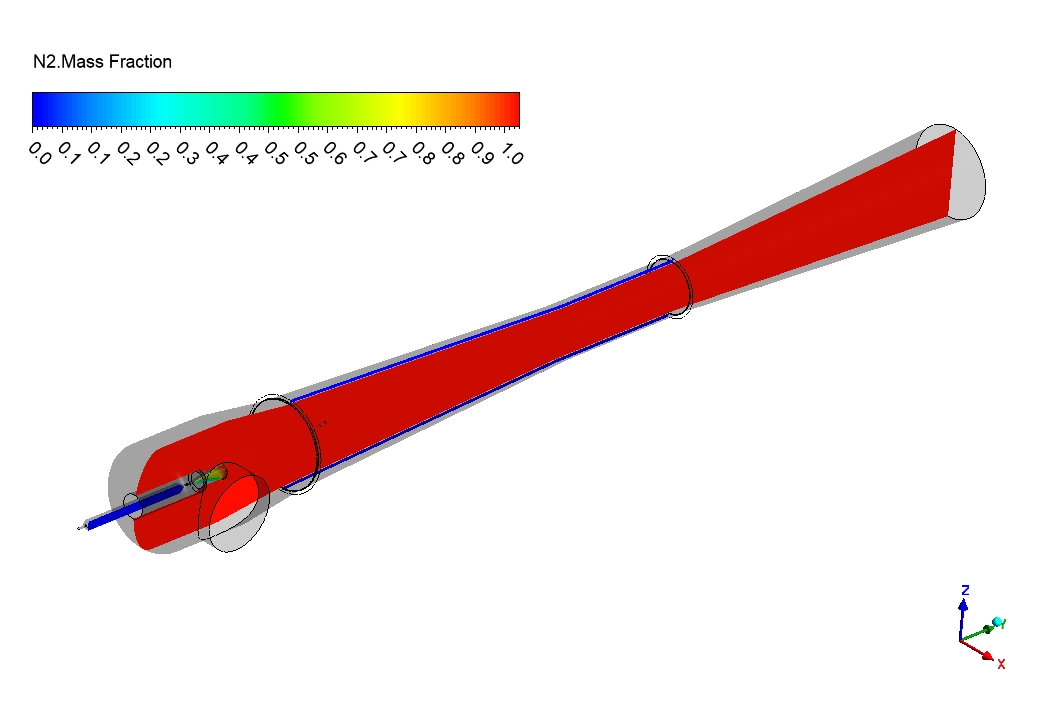

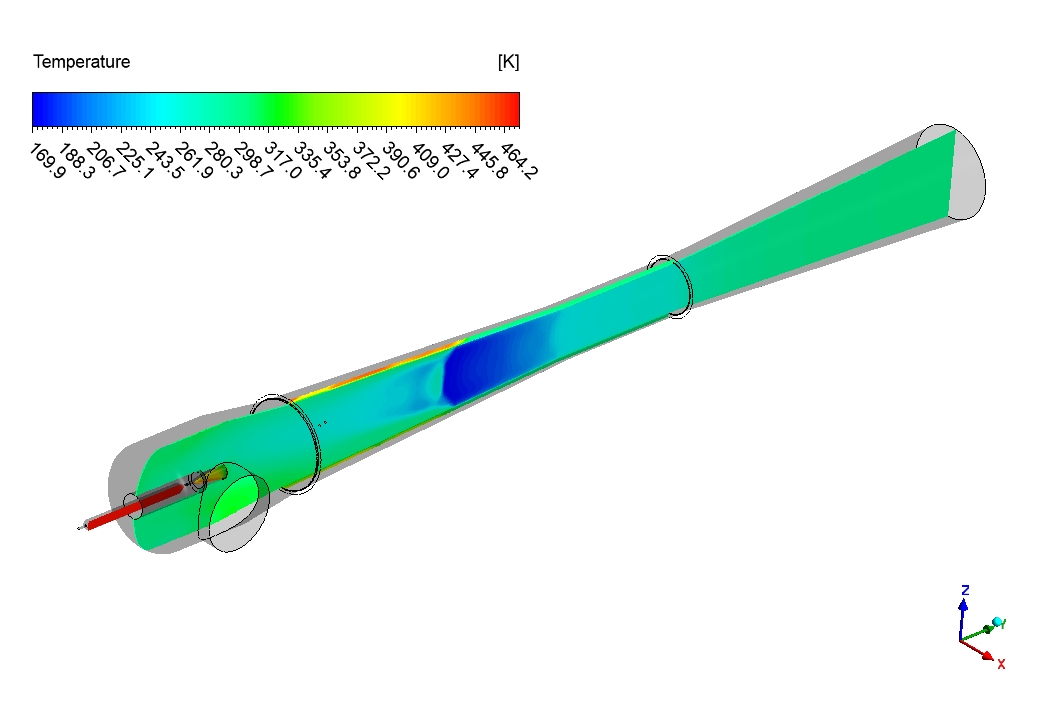

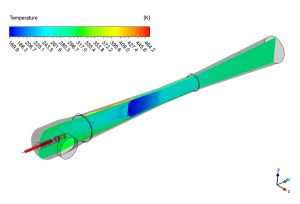

Looking at the temperature and air mass fraction results makes this even more fascinating! The temperature drops to as low as 169.9 K (that’s -103°C!) in the mixing region where the fast and slow flows come together. We accurately captured the cooling effect that happens when high-speed fluids expand rapidly – the same principle that makes refrigerators work! Meanwhile, the air mass fraction shows exactly where the different fluids mix together throughout the ejector. Most of the system contains almost pure working fluid (low air mass fraction values near 0), but right at the edges of the jet and near the secondary inlet, we see higher values as air mixes in. The most important mixing happens right after the narrowest part where the speedy primary stream gives some of its energy to the slower secondary stream. This energy transfer is what makes ejector-diffusers so useful in refrigeration systems, vacuum pumps, and many other important machines – all without any moving parts!

Figure 4: Temperature distribution showing values from 169.9 K to 464.2 K across the ejector, highlighting the significant cooling effect in the expansion region where rapid acceleration occurs

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€150.00 Original price was: €150.00.€130.00Current price is: €130.00.

€165.00 Original price was: €165.00.€135.00Current price is: €135.00.

€175.00 Original price was: €175.00.€145.00Current price is: €145.00.

€185.00 Original price was: €185.00.€115.00Current price is: €115.00.

€380.00 Original price was: €380.00.€185.00Current price is: €185.00.

€320.00 Original price was: €320.00.€175.00Current price is: €175.00.

Reviews

There are no reviews yet.