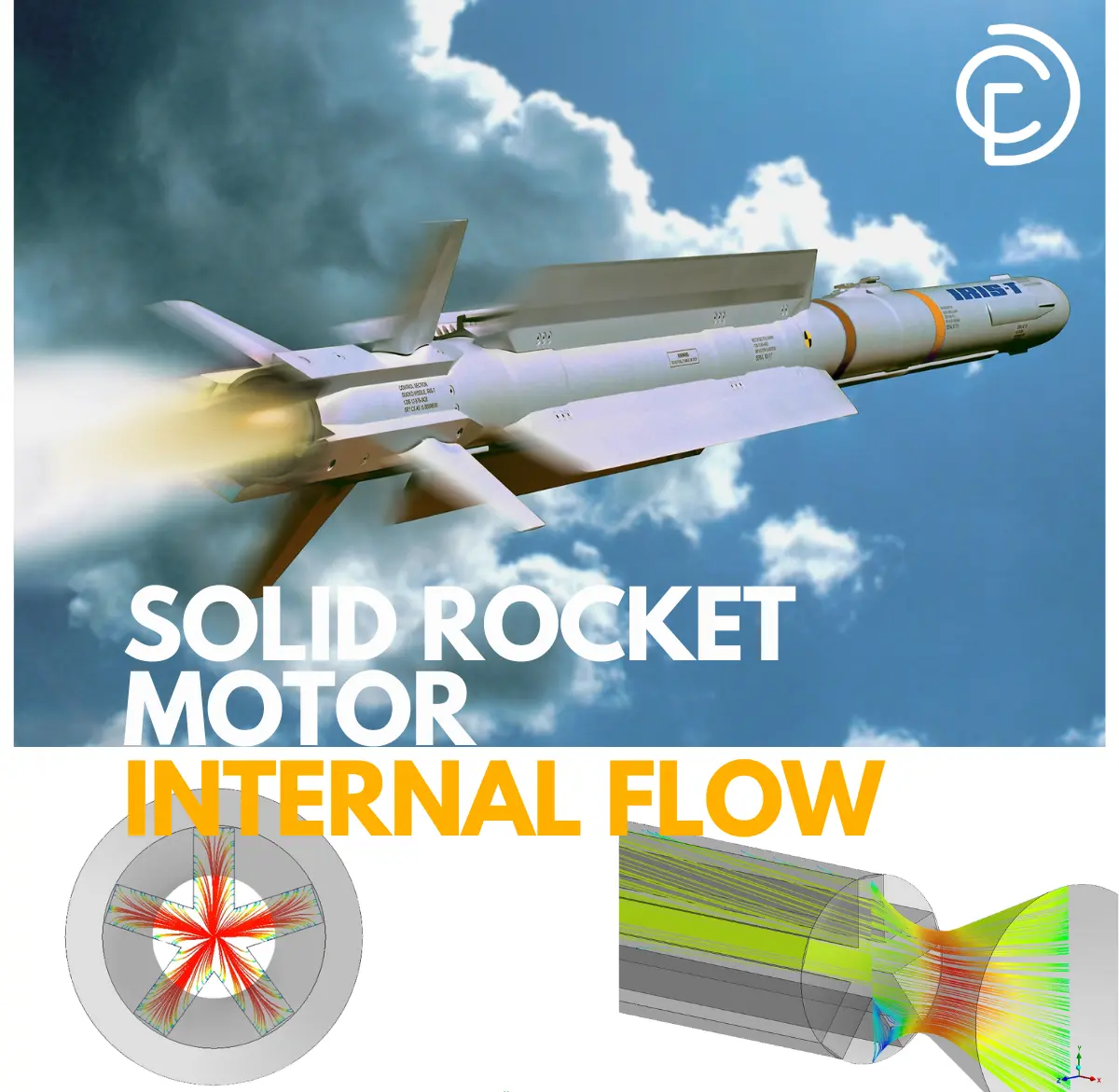

Solid Rocket Motor Internal Flow CFD: SRM Simulation in Fluent

Solid Rocket Motor Internal Flow CFD: SRM Simulation in Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€125Current price is: €125.

A Solid Rocket Motor (SRM) is a powerful and reliable propulsion system that forms the backbone of many launch vehicles and tactical missiles. The engineering principle is elegantly simple: a solid block of propellant, known as the grain, burns rapidly to produce a massive volume of high-pressure, high-temperature gas. This stored energy is then converted into kinetic energy and immense thrust by passing it through a specially shaped nozzle. However, the internal flow dynamics are incredibly complex, involving turbulent, high-speed compressible flow. A Solid Rocket Motor Internal Flow CFD simulation is the single most important engineering tool for designing and optimizing these systems for safety and performance. This SRM CFD tutorial uses ANSYS Fluent to conduct a detailed analysis of the entire process, from the initial combustion-driven flow to the final supersonic exhaust, which is the heart of a Solid rocket engine CFD investigation.

- Reference [1]: Shimada, Toru, Nobuhiro Sekino, and Mihoko Fukunaga. “Numerical investigation of roll torque induced by solid rocket motor internal flow.” Journal of Propulsion and Power6 (2009): 1300-1310.

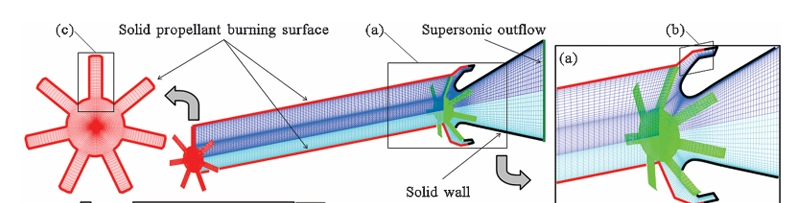

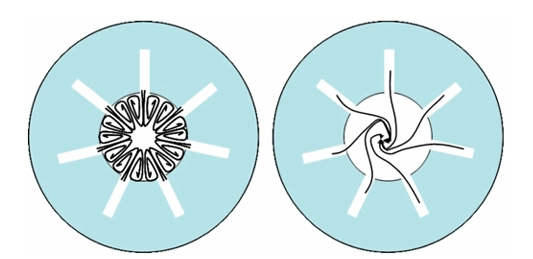

Figure 1: Illustration of the vortic

al flow patterns that can form inside an SRM [1]

Simulation Process: Modeling the SRM CFD Simulation in ANSYS Fluent

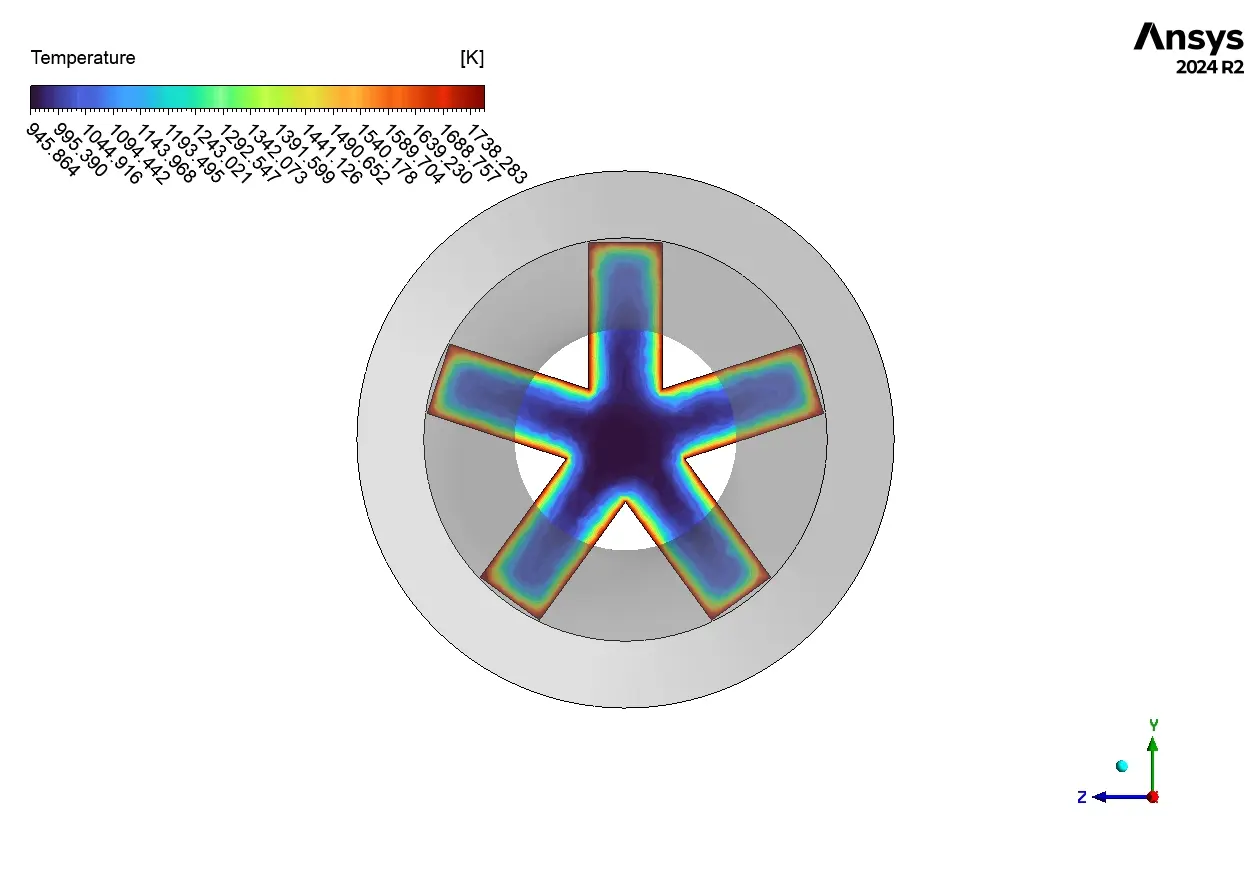

The first step in this Solid Rocket Motor Internal Flow Fluent simulation was to create an accurate 3D geometry of the SRM, featuring its characteristic star-shaped propellant grain. This star shape is a critical design feature used to control the burn rate by providing a large, consistent surface area. Using the ANSYS Fluent Meshing tool, a high-quality unstructured grid of 1,668,980 tetrahedral cells was generated. This dense mesh is essential for accurately capturing the complex flow patterns.

Inside the ANSYS Fluent solver, the simulation was configured to handle the extreme conditions of a rocket motor. The Density-based solver was selected, as it is specifically designed for high-speed, compressible flow where gas density changes dramatically. To simplify the analysis and focus on the core gas dynamics of pressure and velocity change, the Inviscid flow model was used. This is a common and effective approach for the initial analysis of the primary thrust generation mechanism in a supersonic nozzle.

Figure 2: The geometry of the Solid Rocket Motor CFD model with its star-shaped grain.

Post-processing: CFD Analysis of SRM Internal Flow

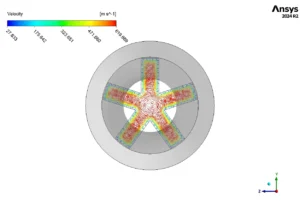

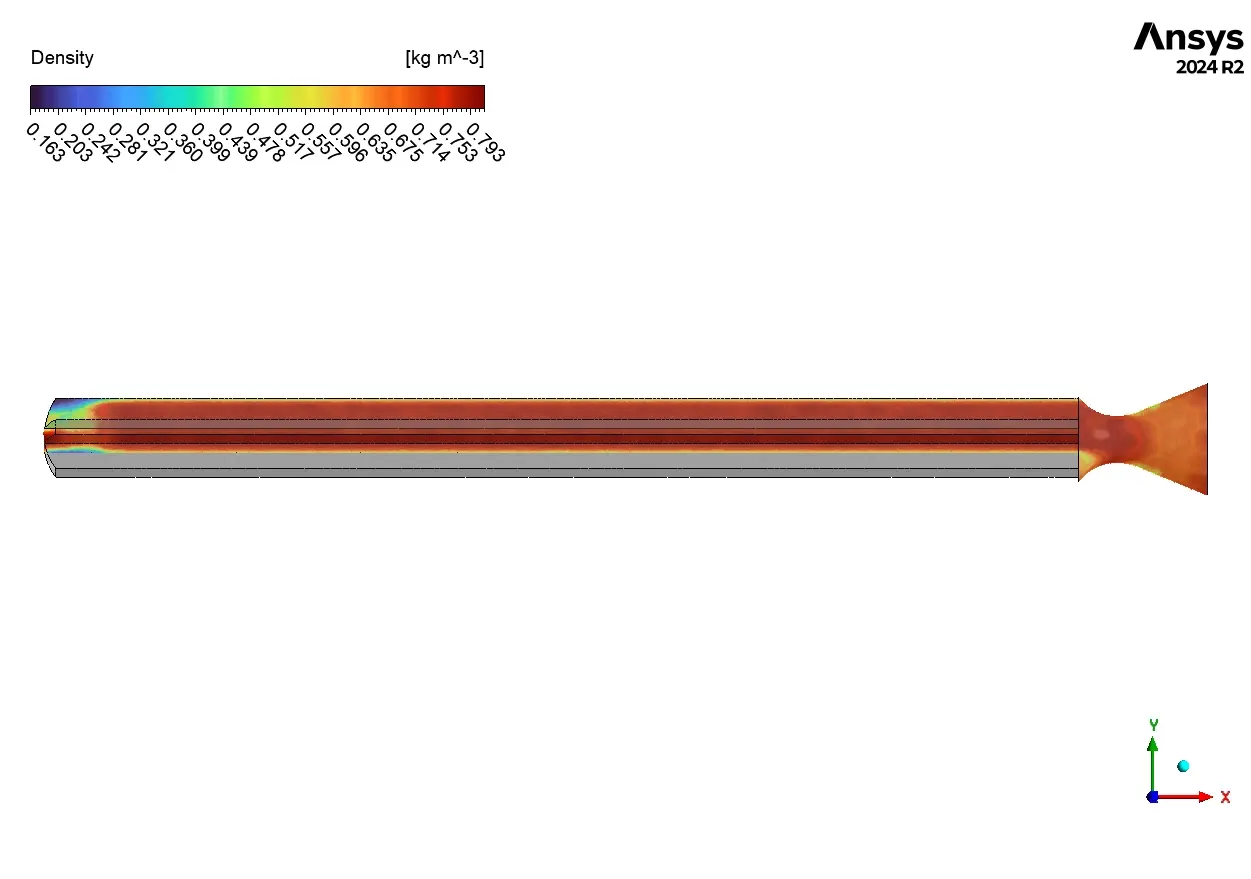

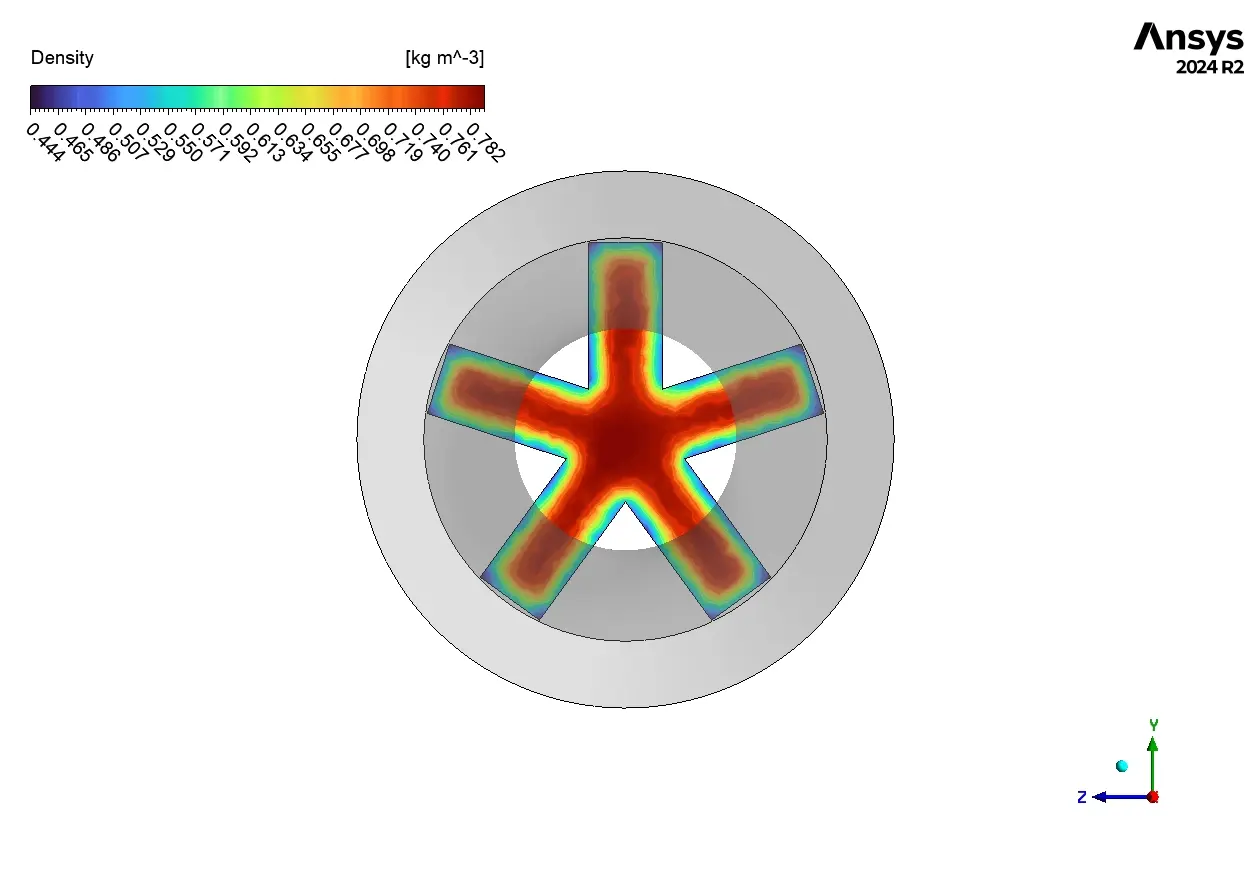

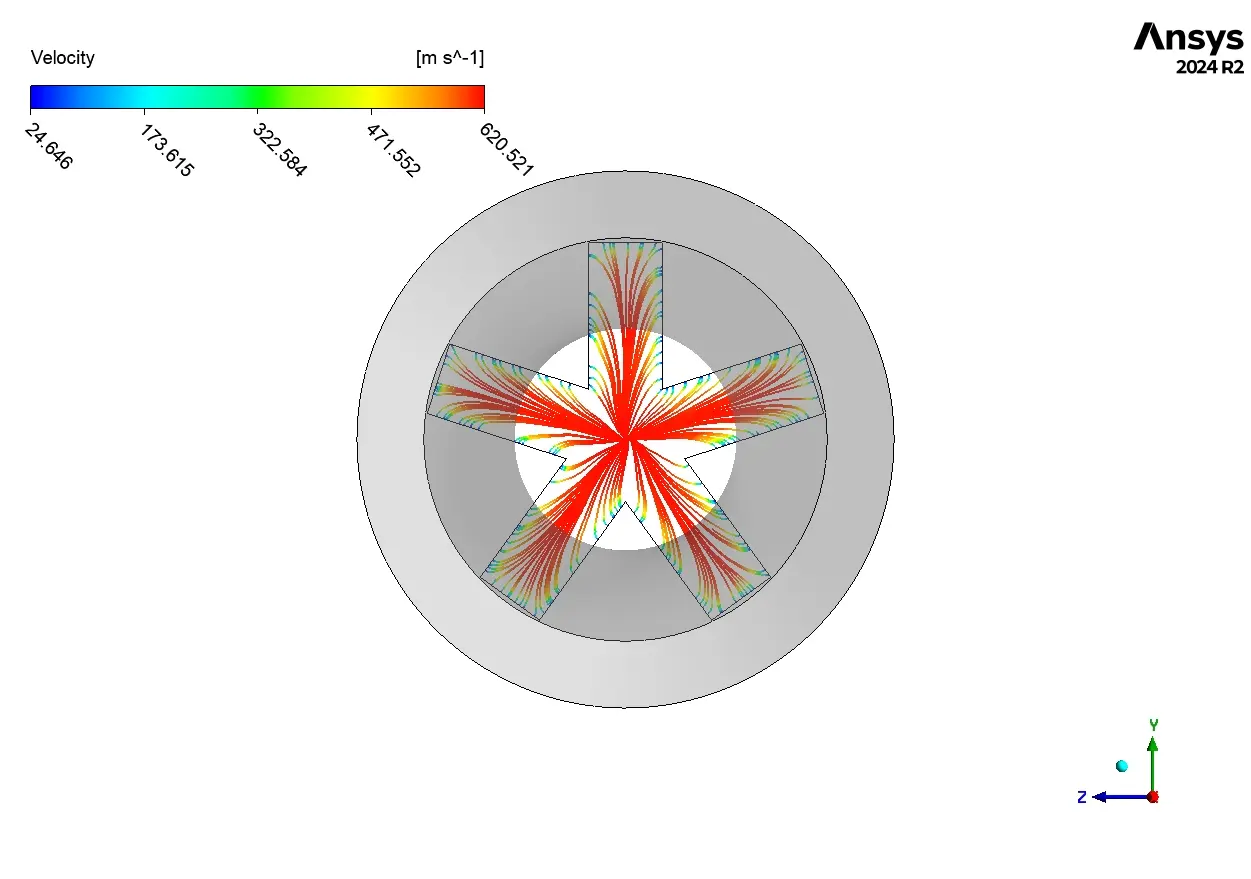

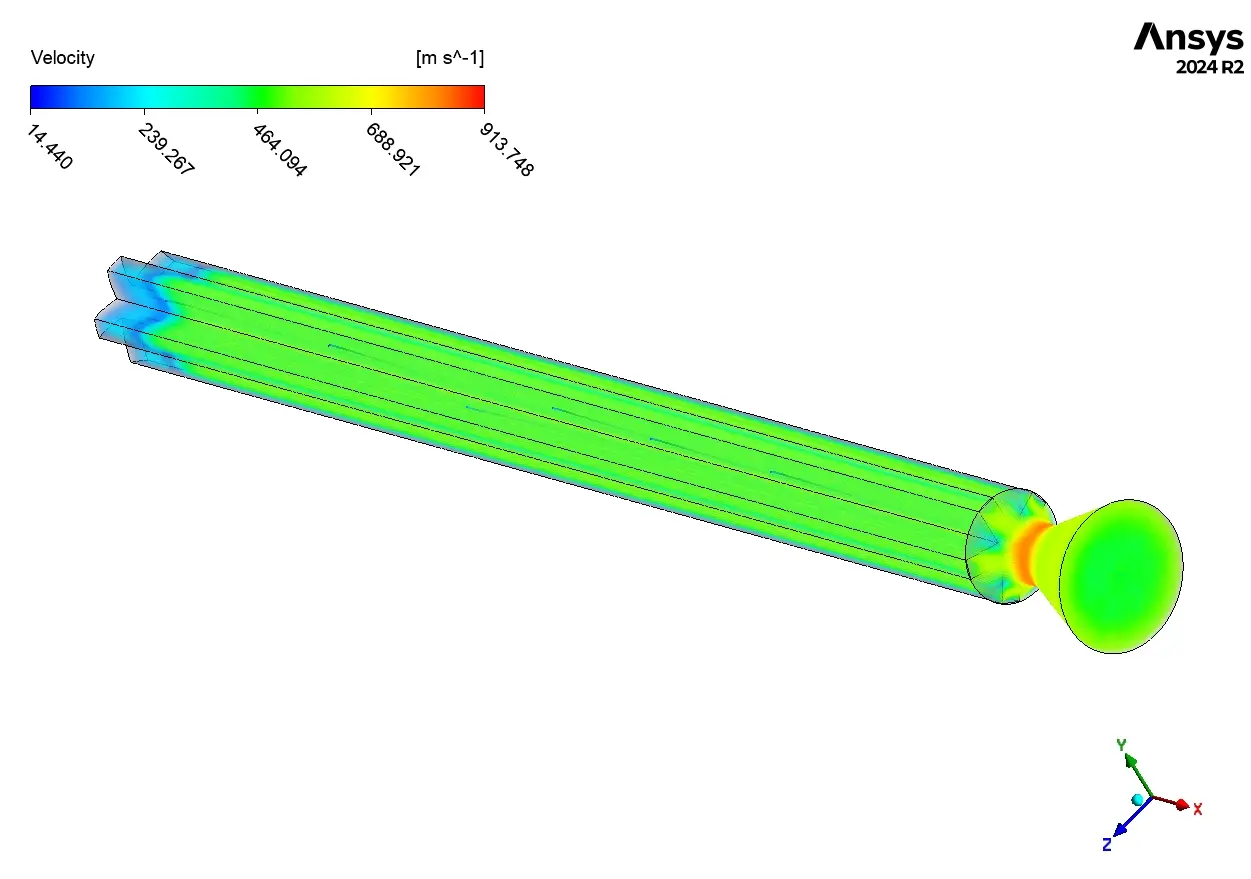

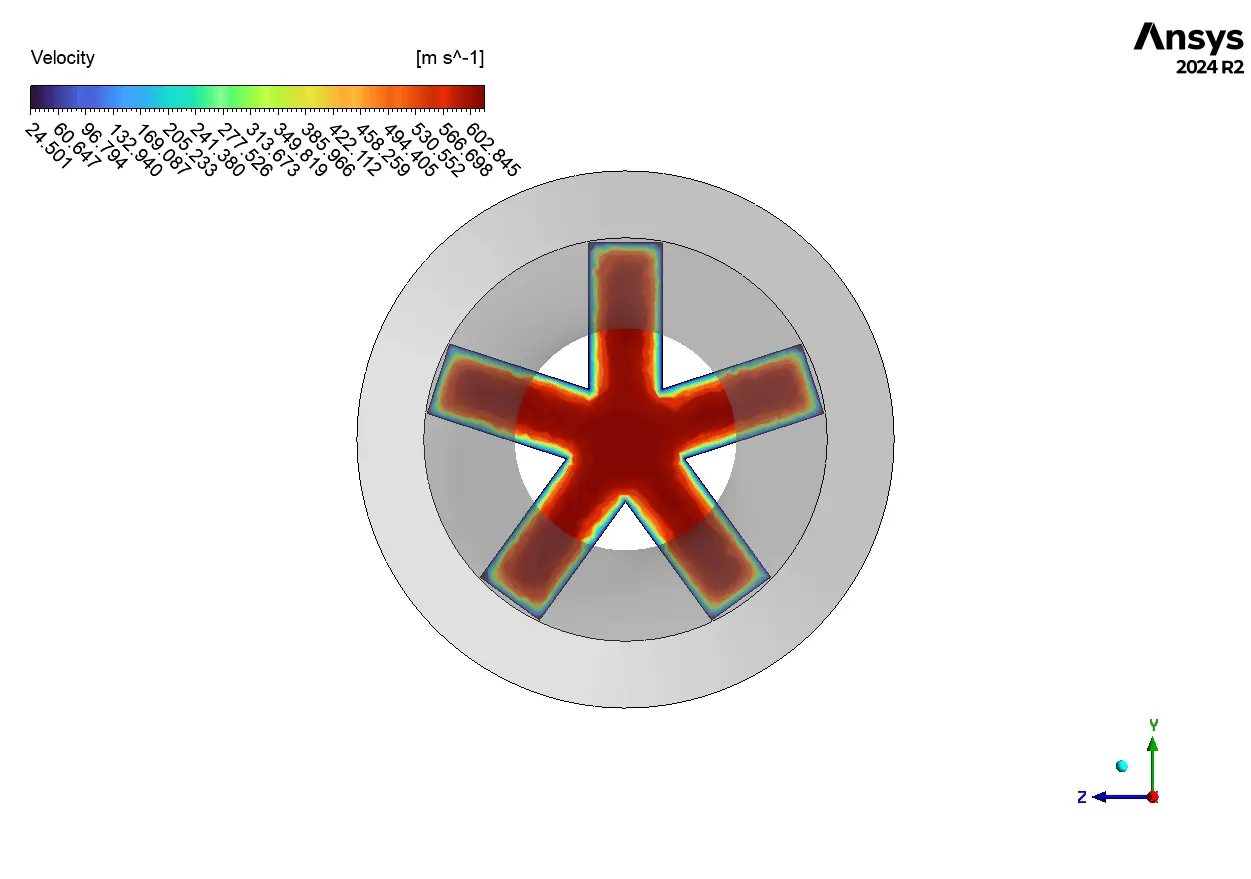

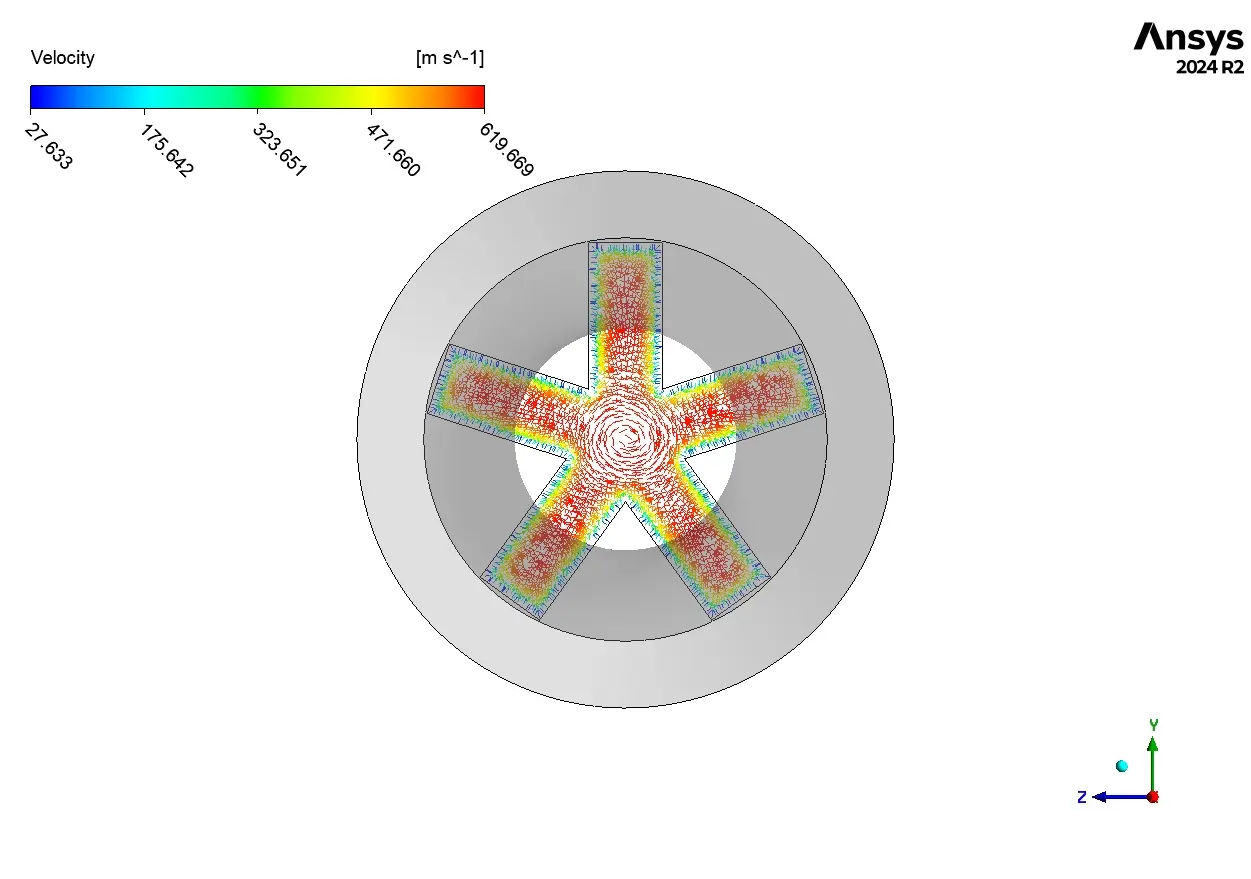

The simulation results provide a clear and detailed story of the energy conversion process inside the rocket motor, beginning in the combustion chamber. The velocity vectors in Figure 3 reveal the complex flow pattern originating at the star-shaped grain. The flow moves from the propellant walls toward the center, and because of this geometry, the converging streams induce a powerful swirling motion, or vortex, along the motor’s central axis. This is a critical insight, as this rotational flow can lead to unwanted roll torque on the vehicle. In this high-pressure chamber, the gas density is at its peak (~0.7 kg/m³), acting as a reservoir of stored potential energy before the gas enters the nozzle. This initial flow condition, with its characteristic swirl and high pressure, is the direct input that governs the performance of the entire propulsion system.

Figure 3: Velocity vectors and density contour, showing the swirling flow and high-pressure gas in the Solid Rocket Motor combustion chamber

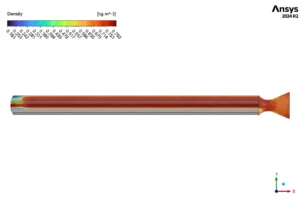

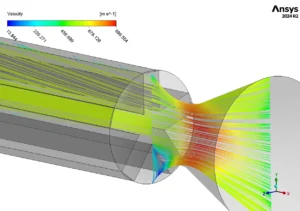

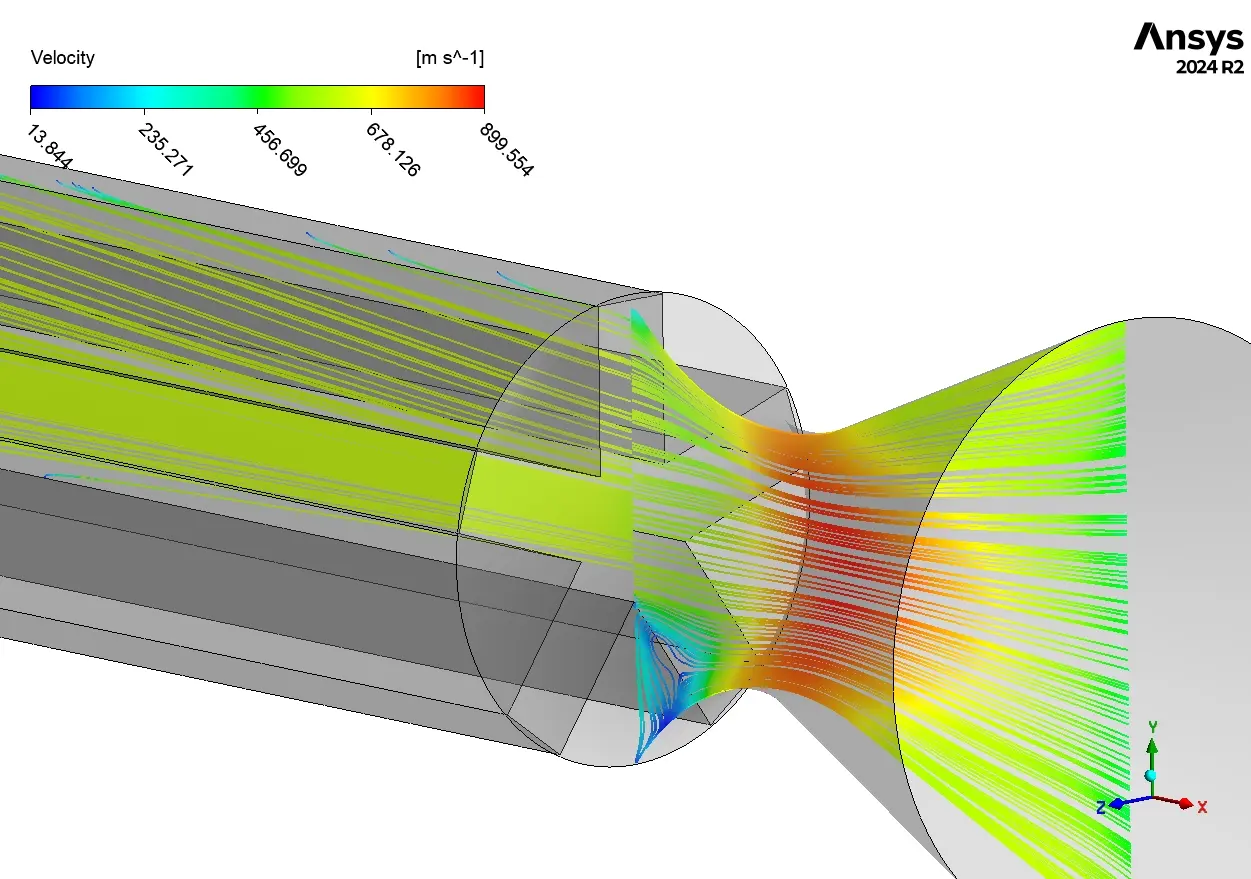

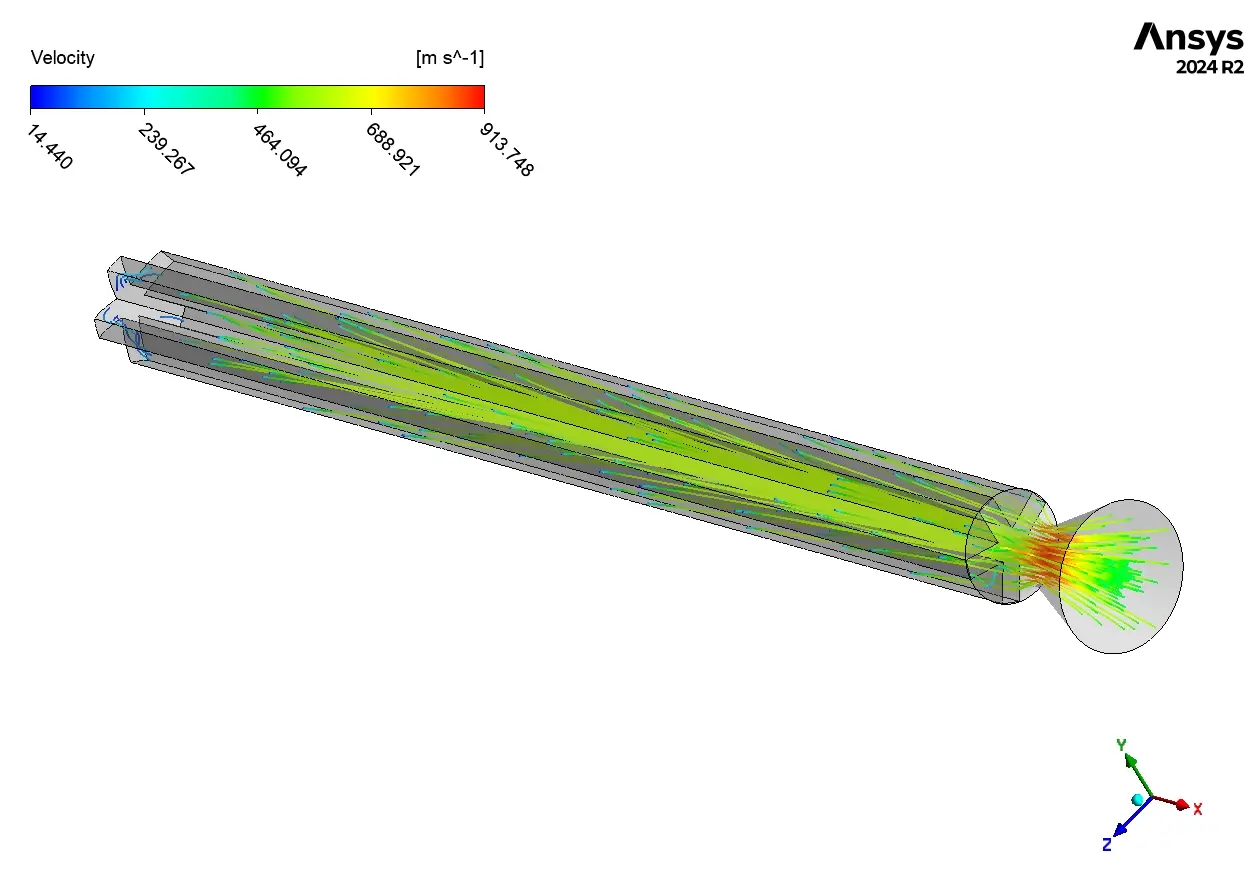

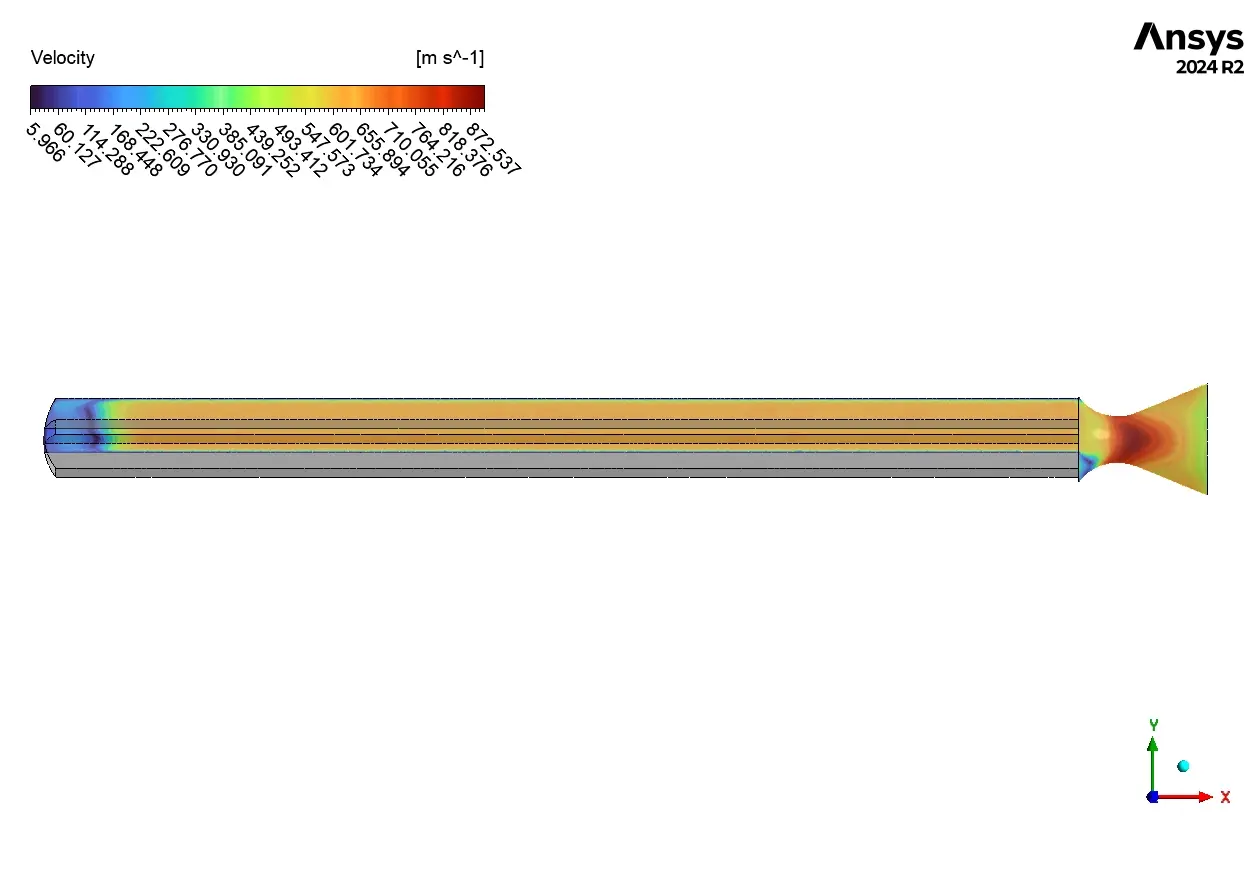

Figure 4: Velocity streamlines showing the gas accelerating through the nozzle in the Solid Rocket Motor Internal Flow Fluent simulation

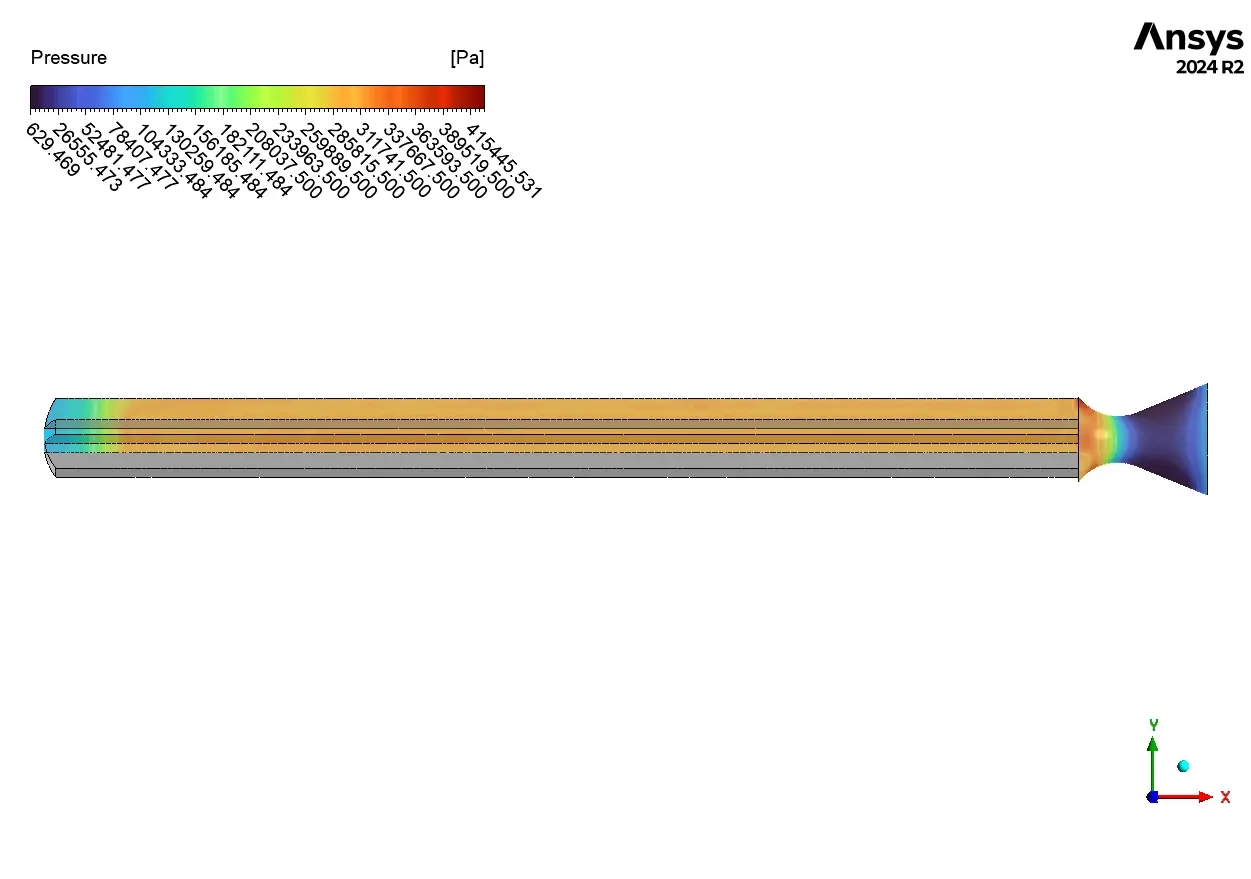

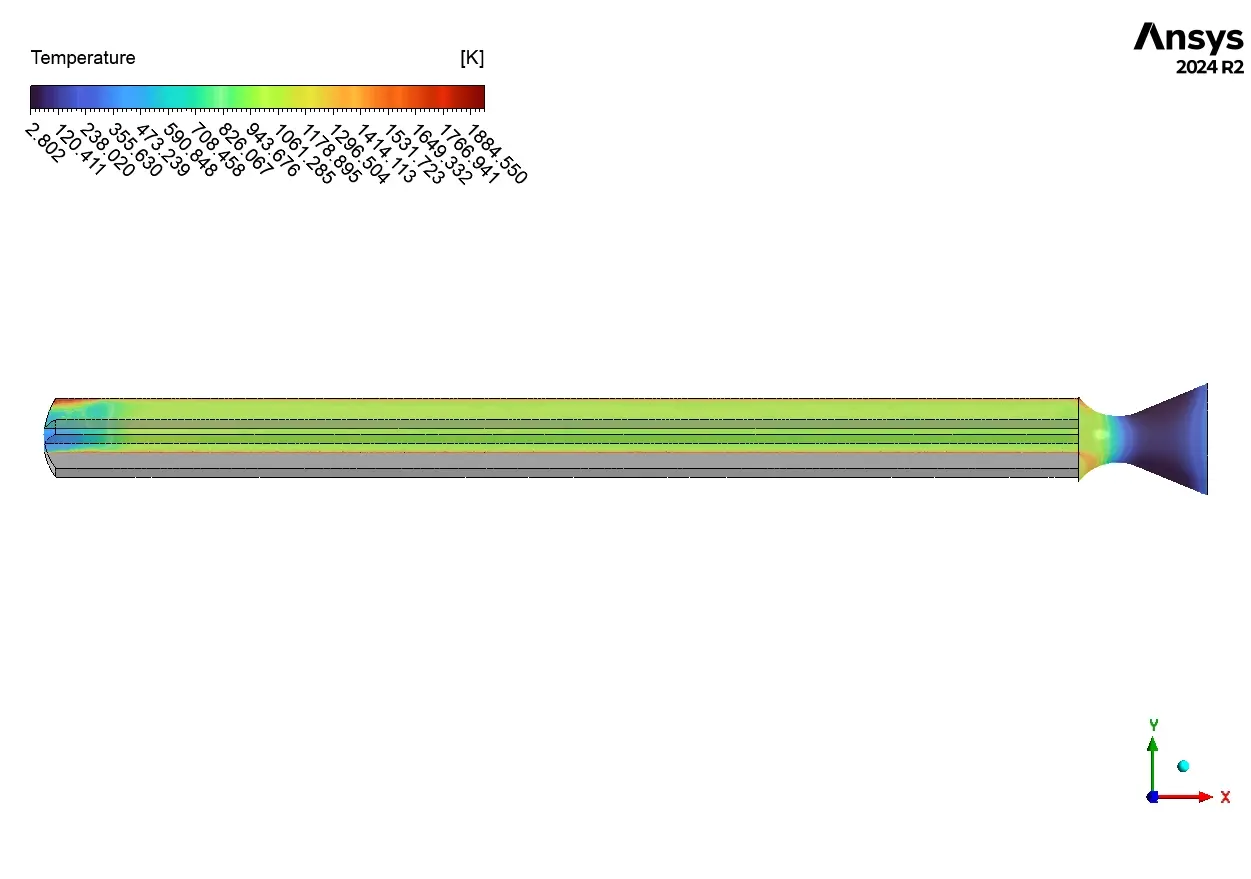

This pressurized, swirling gas then enters the converging-diverging de Laval nozzle, where the energy conversion takes place. The velocity streamlines in Figure 4 beautifully illustrate this process. In the converging section, the subsonic flow is squeezed, accelerating until it reaches precisely sonic speed (Mach 1) at the narrowest point, the throat. As the flow enters the diverging (expanding) section, the now-supersonic flow behaves counter-intuitively: as the area increases, the gas expands rapidly, causing a massive drop in pressure and a corresponding massive increase in velocity. The simulation shows the velocity skyrocketing from subsonic speeds in the chamber to a peak of 899 m/s in the exhaust plume. The most significant achievement of this SRM CFD simulation is the clear visualization of this fundamental principle of rocket propulsion: the successful conversion of high-pressure, low-velocity potential energy in the chamber into low-pressure, high-velocity kinetic energy at the exit. This high-velocity exhaust, by Newton’s third law, is what generates the powerful thrust that propels the rocket.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€155Current price is: €155.

€170 Original price was: €170.€115Current price is: €115.

€155 Original price was: €155.€95Current price is: €95.

€140 Original price was: €140.€85Current price is: €85.

Reviews

There are no reviews yet.