Spiral Heat Exchanger CFD, A Fluent Tutorial to Heat Transfer Coefficient

Spiral Heat Exchanger CFD, A Fluent Tutorial to Heat Transfer Coefficient

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160 Original price was: €160.€75Current price is: €75.

A Spiral Heat Exchanger is a very clever device used for thermal management. Unlike other designs, it uses two long, spiral-shaped channels wrapped around each other. This smart design gives it a very large surface area for heat exchange in a very small and compact shape. Because of this, it is excellent at its job and saves a lot of energy. A Spiral Heat Exchanger CFD simulation is the best way to see and measure how well it works. The main goal of this project is to model the heat transfer between a hot and a cold fluid and to calculate the heat transfer coefficient CFD to understand its efficiency. Our work is guided by the important methods described in the reference paper by Bahiraei, et al. [1].

- Reference [1]: Bahiraei, Mehdi, Hamid Kiani Salmi, and Mohammad Reza Safaei. “Effect of employing a new biological nanofluid containing functionalized graphene nanoplatelets on thermal and hydraulic characteristics of a spiral heat exchanger.” Energy conversion and management180 (2019): 72-82.

- Reference [2]: Zhang, Yanfeng, et al. “Numerical study on heat transfer enhancement in capsule-type plate heat exchangers.” Applied Thermal Engineering108 (2016): 1237-1242.

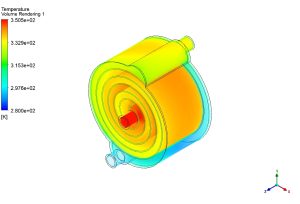

Figure 1: The 3D geometry used for the Spiral Heat Exchanger CFD simulation.

Simulation Process: CFD Modeling of the Spiral Heat Exchanger

To begin the Spiral Heat Exchanger fluent simulation, we first prepared the geometry. The model has three parts: one spiral channel for the hot fluid, a second channel for the cold fluid, and a solid copper wall that separates them. Next, a very good mesh with about 1 million elements was created to fill the entire space. A high-quality mesh is crucial for getting accurate results.

The physics were then set up in ANSYS Fluent. The simulation was defined as a heat transfer problem between fluids and a solid. The hot fluid enters at a temperature of 350 K, and the cold fluid enters at 280 K. Because the wall separating them is made of copper, which is very good at conducting heat, we expect to see excellent performance.

Two important output parameters, including Delta(T-LMTD) and heat transfer coefficient, are calculated based on the given equations:

![]()

![]()

![]()

Post-processing: From LMTD to Heat Transfer Performance

A detailed analysis of the results proves the exceptional performance of the spiral design. The temperature contour in Figure 2 shows a very smooth and efficient heat transfer process. The hot fluid enters at 350 K and gradually cools down to an outlet temperature of 333 K. At the same time, the cold fluid enters at 280 K and warms up to 296.5 K as it flows through its channel. This shows that a large amount of heat was successfully transferred from the hot side to the cold side. Using these four temperature values, we calculated the Log Mean Temperature Difference (LMTD) to be 53.42 K. This number represents the average driving force for heat transfer across the entire exchanger, and it is a key value for thermal design.

Figure 2: Temperature field showing the efficient heat exchange within the Spiral Heat Exchanger.

Furthermore, the simulation allowed us to calculate the single most important metric for performance: the heat transfer coefficient. The most significant achievement of this study is the calculation of the heat transfer coefficient, which was found to be 102.8 W/m²K. This value is a direct measurement of how effectively heat moves from the copper wall into the fluids. A higher number means better performance. This excellent result confirms that the spiral design, with its large contact area, and the highly conductive copper wall work together perfectly. This heat transfer coefficient fluent simulation successfully proves why spiral heat exchangers are a top choice for applications that need high efficiency in a small space.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€145 Original price was: €145.€95Current price is: €95.

€185 Original price was: €185.€125Current price is: €125.

€200 Original price was: €200.€115Current price is: €115.

€185 Original price was: €185.€135Current price is: €135.

€245 Original price was: €245.€199Current price is: €199.

€240 Original price was: €240.€115Current price is: €115.

Reviews

There are no reviews yet.