Steam Methane Reforming (SMR) CFD Simulation: Hydrogen Production Validation in ANSYS Fluent

Steam Methane Reforming (SMR) CFD Simulation: Hydrogen Production Validation in ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€310 Original price was: €310.€185Current price is: €185.

Steam Methane Reforming (SMR) is the most common industrial method for Hydrogen production. In this chemical process, Methane (CH4) reacts with Steam (H2O) inside a reactor. With the help of a catalyst, they transform into Hydrogen (H2) and Carbon Monoxide (CO). This reaction is endothermic, which means it absorbs a massive amount of heat to work. Industries rely on this process for oil refining and manufacturing electronics.

In this Steam Methane Reforming CFD simulation, we perform a numerical validation study. We aim to replicate the results of a specific scientific paper by Lao et al. (2016). By using ANSYS Fluent, we validate the physics of the reactor to ensure our settings match real-world data. This tutorial demonstrates how to model complex chemical reactions using advanced CFD techniques.

CH4 + H2O → CO + 3H2

- Reference [1]: Lao, Liangfeng, et al. “CFD modeling and control of a steam methane reforming reactor.” Chemical Engineering Science148 (2016): 78-92.

SMR Simulation Setup: Mesh, UDF, and Physics in ANSYS Fluent

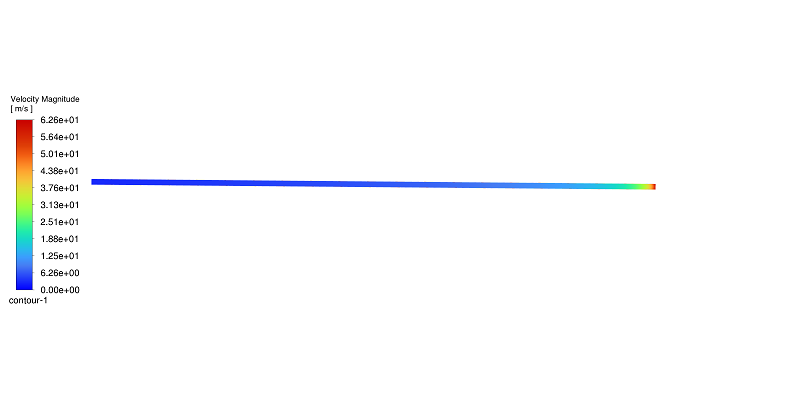

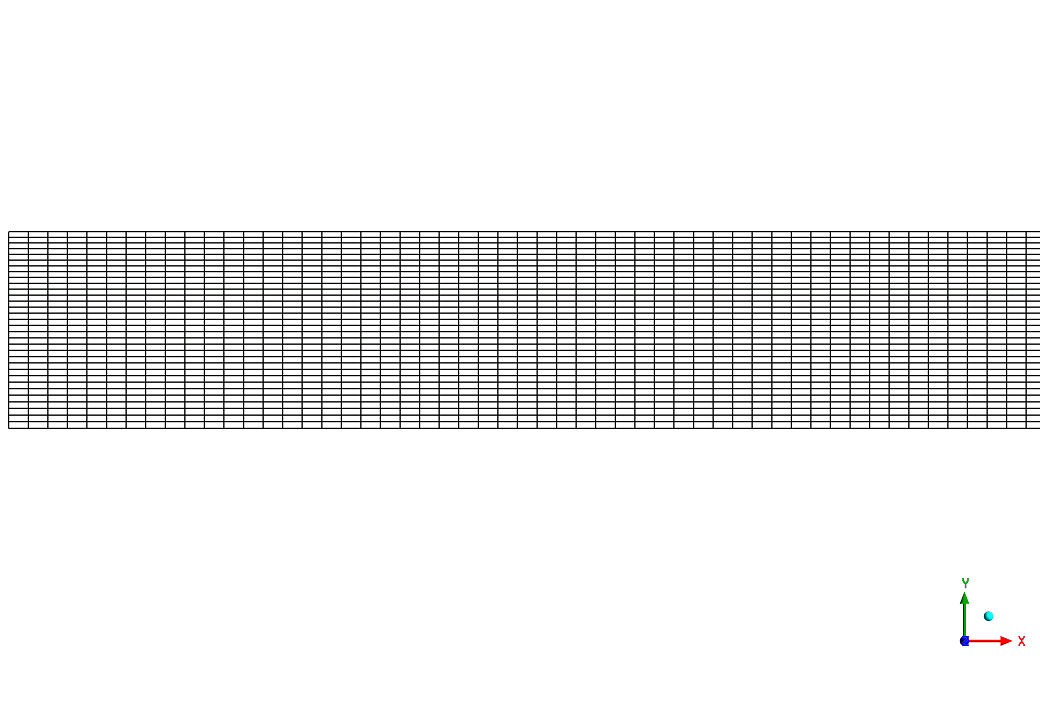

To begin this CFD validation study, we first prepared the geometry in ANSYS Design Modeler. We created a 2D rectangular domain with dimensions of 12.5 meters by 0.063 meters. Although the drawing is 2D, we set the solver to “axisymmetric.” This is a crucial step because it allows the software to simulate a cylindrical combustion chamber efficiently without creating a heavy 3D model. Next, we focused on the grid generation in ANSYS Meshing. A high-quality mesh is essential for capturing chemical reactions. We generated a structured grid containing exactly 64,000 cells. As shown in Figure 1, the mesh is fine and uniform, which helps in calculating the gradients of temperature and species accurately.

Figure 1- Close-up view of the structured mesh grid (64,000 cells) generated for the SMR combustion chamber.

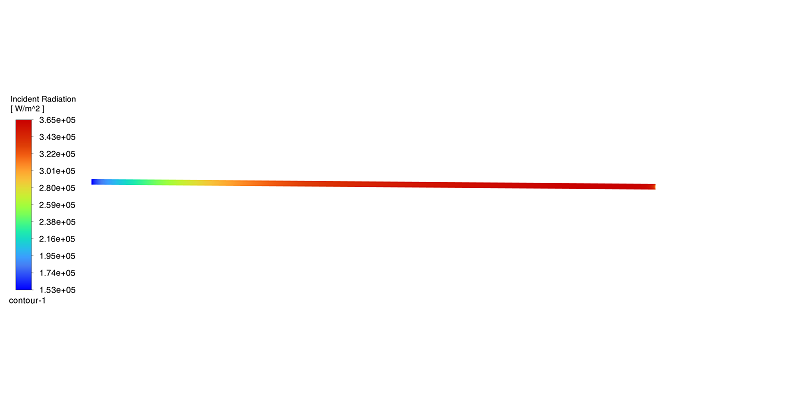

For the physics setup in ANSYS Fluent, we selected the k-epsilon turbulence model combined with “Enhanced Wall Treatment.” This ensures the flow near the reactor walls is calculated correctly. Because the SMR reaction involves high temperatures, radiation plays a major role. Therefore, we activated the Discrete Ordinates (DO) radiation model. To simulate the chemistry, we used the Species Transport model. However, the standard Arrhenius kinetic model was not sufficient for this specific case. To solve this, we wrote and compiled a User-Defined Function (UDF) to control the volume reaction rate precisely. Finally, we enabled the Porous Media module to simulate the resistance of the catalyst bed inside the chamber.

SMR CFD Post-Processing: Thermal Analysis and Hydrogen Yield Validation

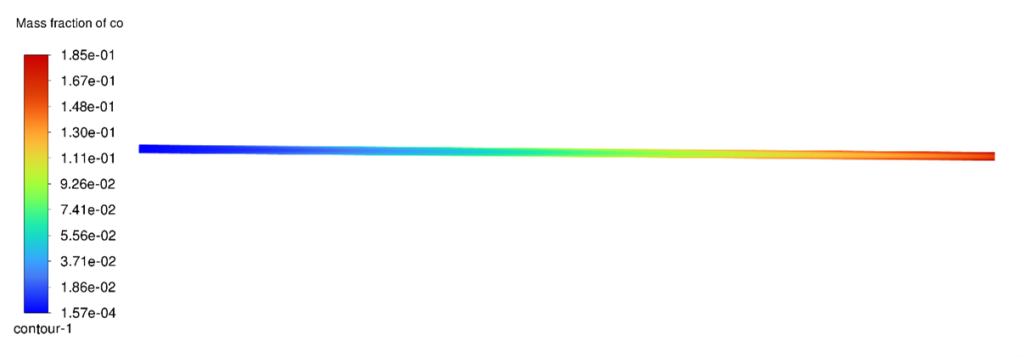

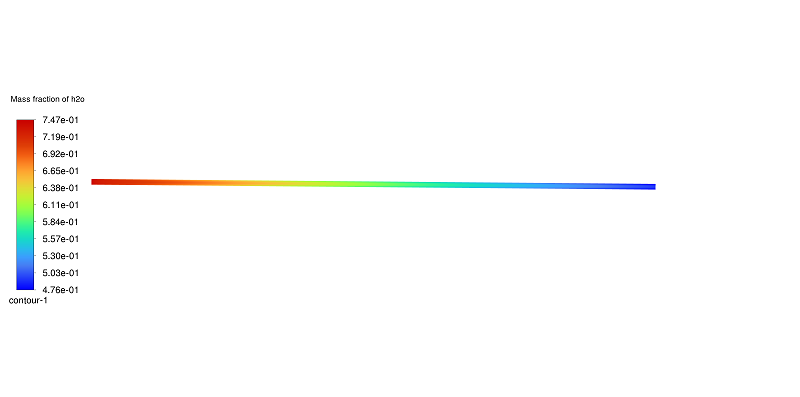

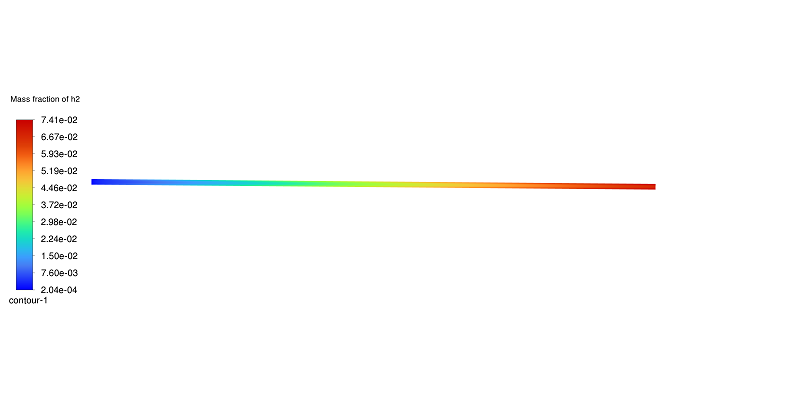

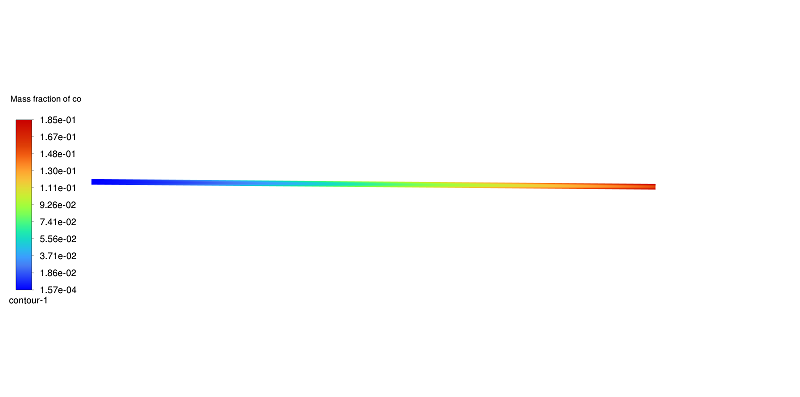

In this section, we analyze the results of the Steam Methane Reforming CFD. We examine the chemical behavior and thermal distribution to confirm the accuracy of our UDF and boundary conditions. First, we analyze the production of Carbon Monoxide (CO), which indicates the reaction progress. The Mass Fraction contour (Figure 2) reveals the reaction zone. When the Methane enters the inlet, it does not react immediately. We can observe a clear entry length where the Methane mixes with the Water Vapor. Once the mixing is sufficient, the reaction ignites, and CO is produced. The contour shows that the reaction stabilizes further down the tube. This visual evidence confirms that our UDF is correctly controlling the reaction kinetics, as the delay matches the physical expectations of mixing time.

| In Reference Paper | Present CFD Simulation | Error | |

| Mole Fraction of H2 | 0.4645 | 0.4605 | 0.86% |

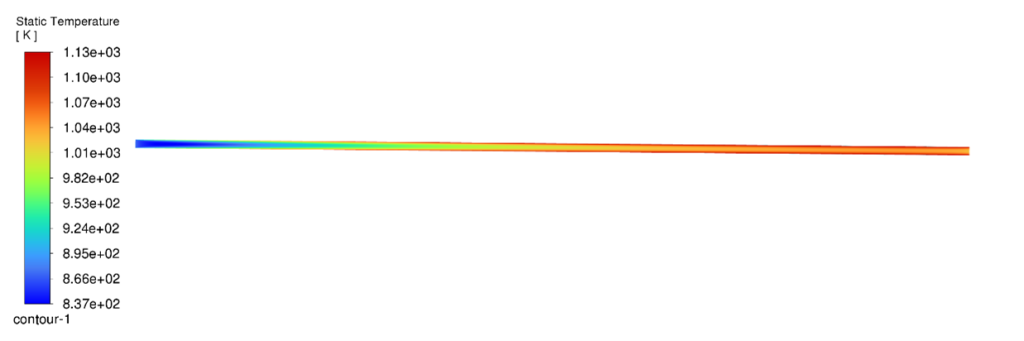

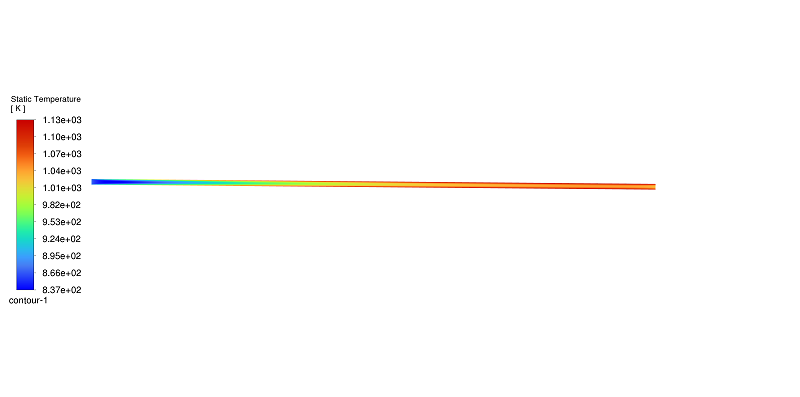

Furthermore, the temperature distribution is critical for this endothermic reaction. The Temperature Contour (Figure 3) depicts the thermal field inside the combustion chamber. The reference paper specified a particular temperature gradient for the upper wall, which we applied using an expression. The results show a temperature range between 837 K and 1130 K. The software reports an average chamber temperature of 1122 K. This high average temperature proves that the heat transfer is effective. Moreover, it justifies our use of the Discrete Ordinates (DO) model, as ignoring radiation at these temperatures would lead to significant errors in the energy balance.

Finally, we validate our CFD analysis by comparing our quantitative data with Table 5 from the reference paper. The key performance indicator is the Mole Fraction of Hydrogen (H2) at the outlet. The reference paper reports a value of 0.4645. Our ANSYS Fluent simulation achieved a value of 0.4605. Comparing these two numbers reveals an error of only 0.86%. This exceptionally low error rate confirms that the combination of the UDF, the Porous Media model, and the structured mesh has resulted in a highly accurate and validated model.

Figure 2- Mass fraction contour of Carbon Monoxide (CO) showing the reaction ignition zone.

Figure 3 – Temperature distribution contour showing the thermal gradient (837K – 1130K) across the reactor.

Key Takeaways & FAQ

- Q: What is Steam Methane Reforming (SMR)?

- A: SMR is a process used in industries to make Hydrogen. It mixes Methane and Steam over a catalyst to create Hydrogen and Carbon Monoxide.

- Q: Why use a User-Defined Function (UDF) in this simulation?

- A: We use a UDF because the specific chemical reaction rate in this study does not follow the standard library models in ANSYS Fluent. The code tells the software exactly how fast the reaction should happen.

- Q: Why is the Discrete Ordinates (DO) model important here?

- A: The reactor operates at very high temperatures (up to 1130 K). At this level, heat radiation is very strong. The DO model accurately calculates this radiation, ensuring the temperature results are correct.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€145Current price is: €145.

€105 Original price was: €105.€85Current price is: €85.

€240 Original price was: €240.€125Current price is: €125.

€240 Original price was: €240.€135Current price is: €135.

€245 Original price was: €245.€185Current price is: €185.

€185 Original price was: €185.€135Current price is: €135.

Reviews

There are no reviews yet.