Steam Methane Reforming CFD Validation (SMR Reaction), ANSYS Fluent Tutorial

Steam Methane Reforming CFD Validation (SMR Reaction), ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€310 Original price was: €310.€185Current price is: €185.

Steam Methane Reforming (SMR) is the most dominant and economically important industrial process for producing hydrogen (H2) gas. Hydrogen is a crucial clean energy carrier and a vital raw material in industries like petroleum refining and ammonia production. The SMR process works by reacting methane (CH4), the main component of natural gas, with high-temperature steam (H2O) inside a reactor filled with a catalyst. This chemical reaction is highly endothermic, meaning it requires a constant and significant input of external heat to work.

CH4 + H2O → CO + 3H2

Due to the high temperatures and complex interplay between fluid flow, heat transfer, and chemical reactions, accurately predicting and optimizing reactor performance is a major engineering challenge. This is why a Steam Methane Reforming CFD simulation is so valuable. It allows engineers to see inside the reactor, understand temperature distribution, and predict chemical species concentrations without expensive and difficult physical experiments. This project details a Steam Methane Reforming CFD VALIDATION study. We aim to replicate the results of the reference paper, “CFD modeling and control of a steam methane reforming reactor [1]”, using ANSYS Fluent to prove the accuracy of our simulation setup.

- Reference [1]: Lao, Liangfeng, et al. “CFD modeling and control of a steam methane reforming reactor.” Chemical Engineering Science148 (2016): 78-92.

Simulation Process , CFD Modeling of the SMR Reaction

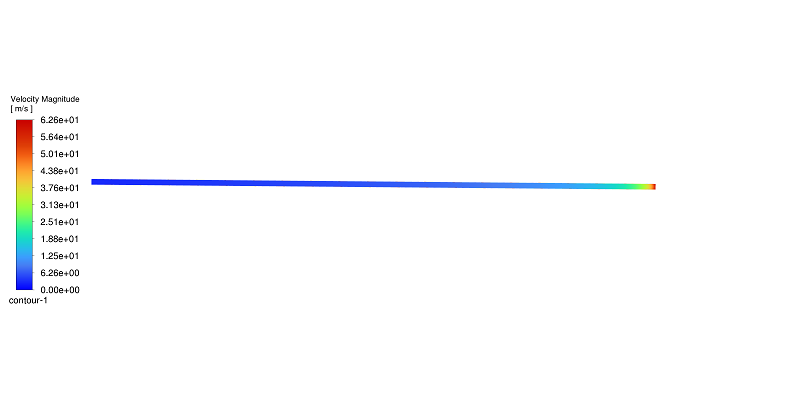

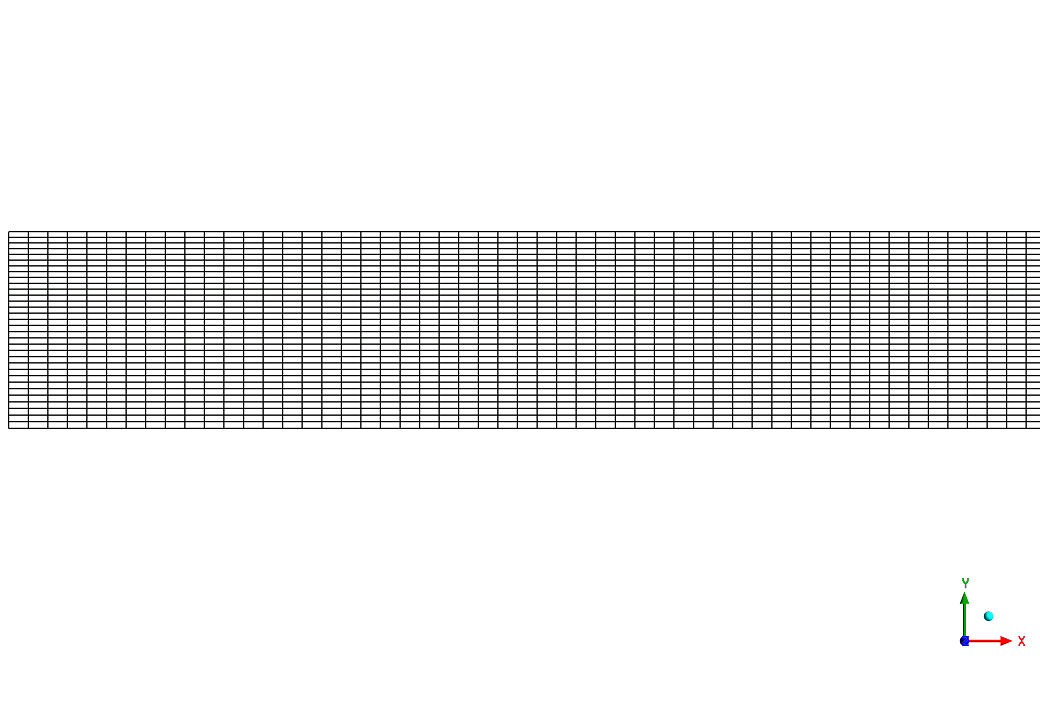

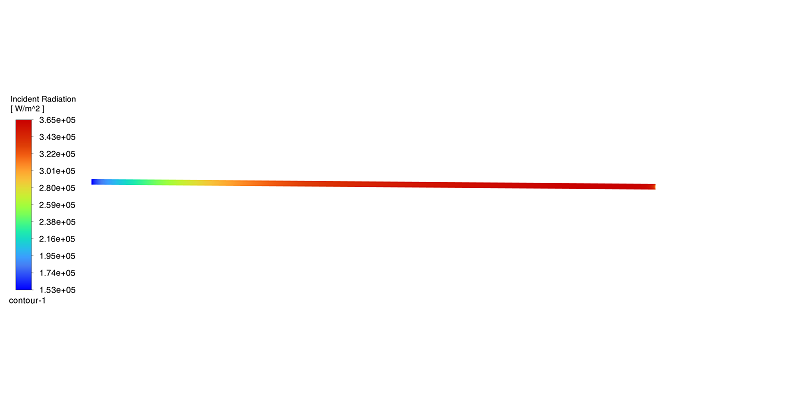

The simulation process began with creating the 2D axisymmetric geometry in ANSYS Design Modeler. A high-quality structured mesh with 64,000 cells was then generated in ANSYS Meshing to ensure the numerical accuracy of the results (Figure 1). Inside ANSYS Fluent, several key models were activated to build a realistic SMR CFD simulation. The k-epsilon turbulence model with Enhanced Wall Treatment was used to model the fluid flow. Because the reaction occurs at very high temperatures, the Discrete Ordinates (DO) radiation model was enabled to account for radiative heat transfer.

Figure 1- A close-up view of the structured mesh grid generated for the SMR CFD simulation.

To handle the chemical reaction itself, the Species Transport model was used. This model tracks each chemical component (CH4, H2O, CO, H2) throughout the reactor. A crucial part of this Steam Methane Reforming Fluent simulation was implementing a custom User-Defined Function (UDF). The reaction kinetics were too complex for standard models, so a UDF was written to control the reaction rate accurately. Finally, a porous zone was defined in the domain to represent the catalyst bed, which is fundamental to the SMR process

Post-processing , SMR CFD Validation – Reaction & Thermal Results

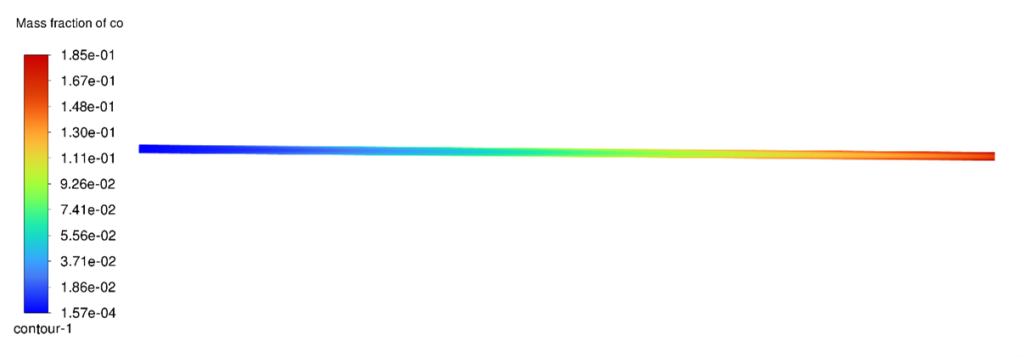

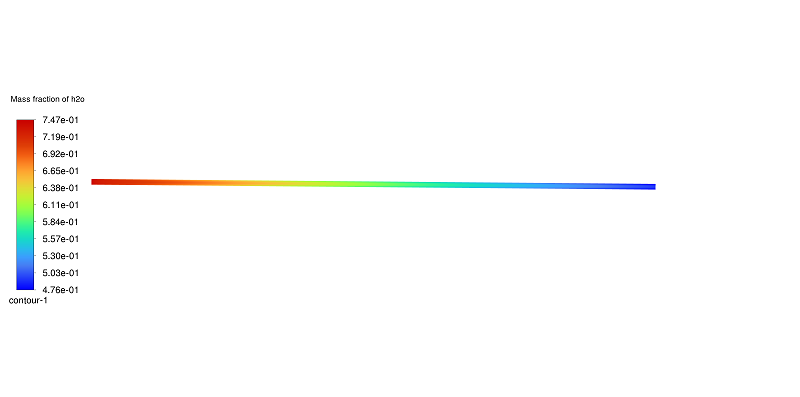

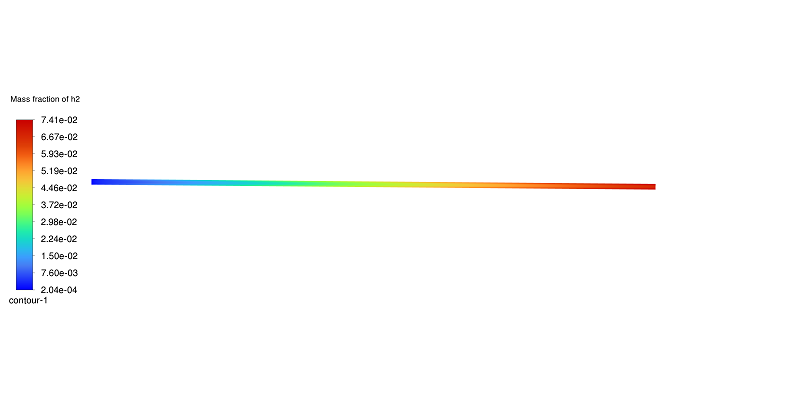

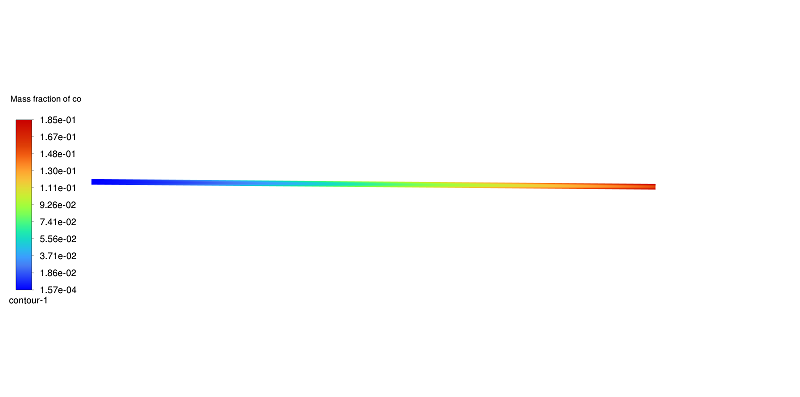

The simulation results provide a clear window into the reactor’s performance. The mass fraction of carbon monoxide (CO) in Figure 2 is a direct indicator of where the reforming reaction is happening. We can see that the reaction does not begin immediately at the inlet. Instead, there is a development region where the methane and steam mix and heat up as they enter the porous catalyst bed. Once the mixture reaches the required activation temperature within the catalyst zone, the reaction, governed by our custom UDF, initiates rapidly, leading to the production of CO and, most importantly, hydrogen gas.

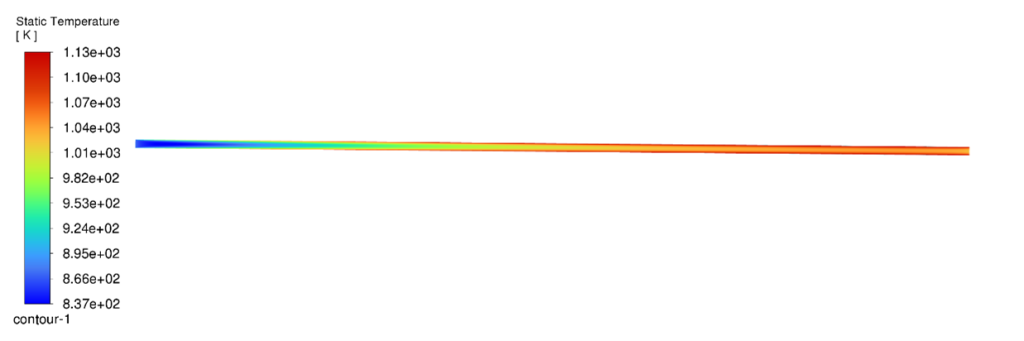

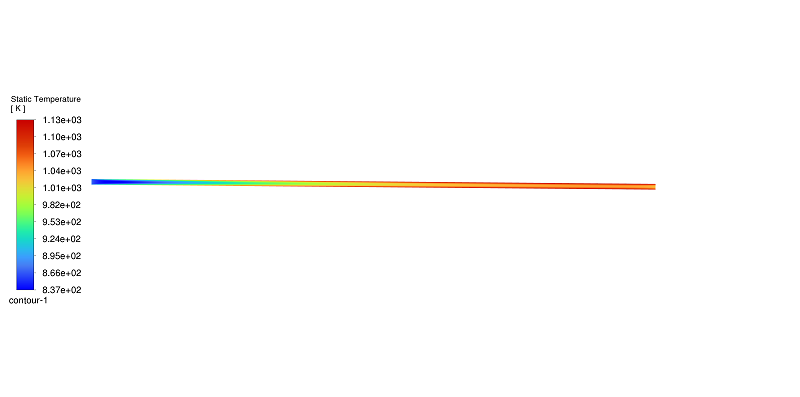

The temperature distribution, shown in Figure 3, is critical for this endothermic process. The contour shows that the temperature ranges from 837K to a maximum of 1130K, which is consistent with the high-energy requirements of SMR. A specific temperature gradient was applied to the upper wall using an expression to supply the necessary heat for the reaction. The final and most important goal of this project was the Steam Methane Reforming CFD Validation. Our simulation predicted a final hydrogen (H2) mole fraction of 0.4605 at the outlet. When compared to the reference paper’s value of 0.4645, our result is incredibly close. This represents a calculation error of only 0.86%, which is an excellent agreement and successfully validates our entire CFD model and its complex setup.

Figure 2- Contour of carbon monoxide mass fraction, indicating the region where the SMR reaction occurs in the Steam Methane Reforming Fluent simulation

Figure 3 – Temperature distribution within the combustion chamber from the Steam Methane Reforming CFD analysis.

| In Reference Paper | Present CFD Simulation | Error | |

| Mole Fraction of H2 | 0.4645 | 0.4605 | 0.86% |

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170 Original price was: €170.€135Current price is: €135.

€175 Original price was: €175.€145Current price is: €145.

€175 Original price was: €175.€145Current price is: €145.

€130 Original price was: €130.€115Current price is: €115.

€195 Original price was: €195.€145Current price is: €145.

€360 Original price was: €360.€185Current price is: €185.

Reviews

There are no reviews yet.