Toroidal Propeller Aeroacoustics Simulation Using Broadband Noise Sources Model – ANSYS Fluent Tutorial

Toroidal Propeller Aeroacoustics Simulation Using Broadband Noise Sources Model – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170

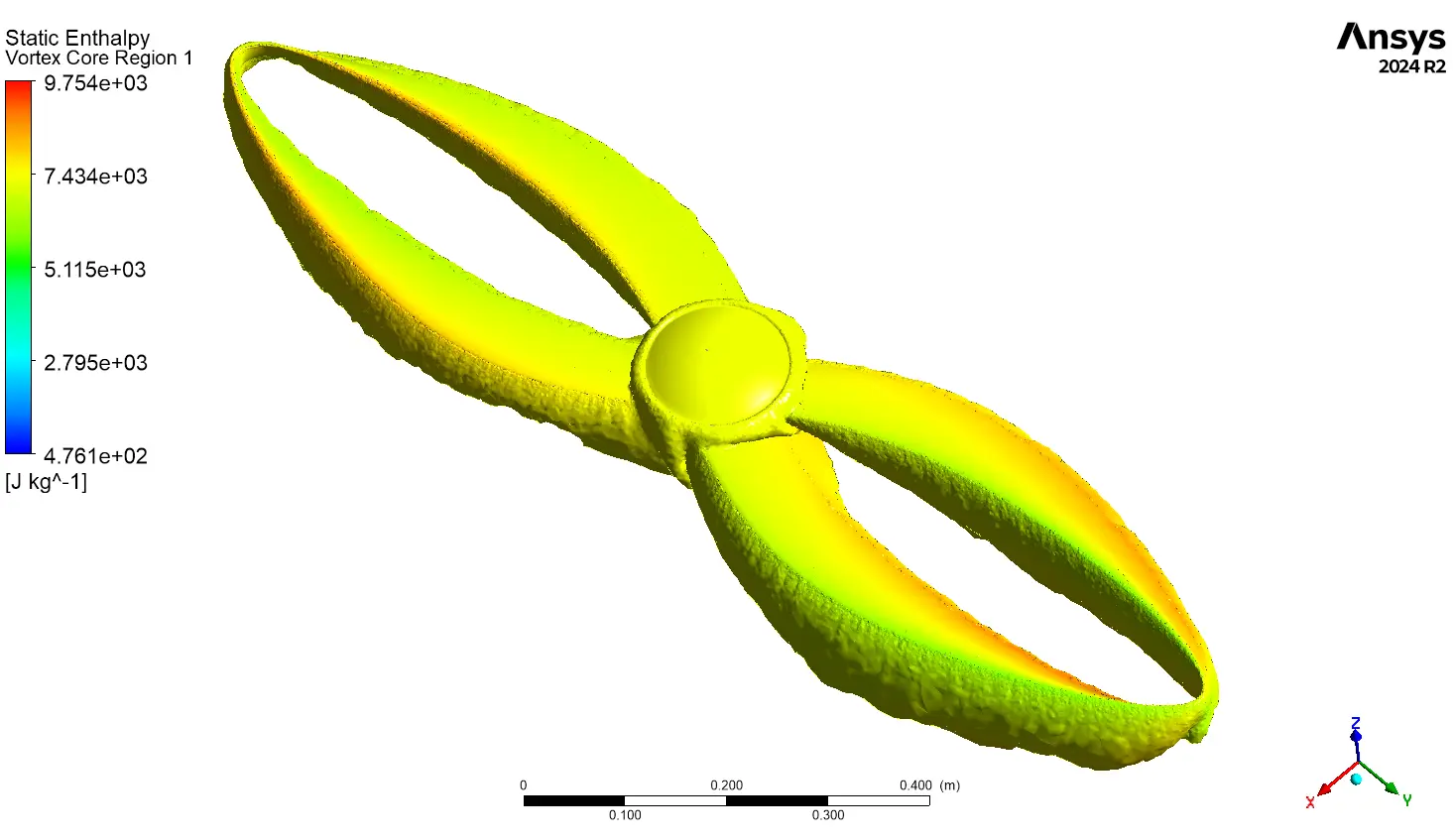

The innovative ring-shaped blade configuration of a toroidal propeller has the ability to greatly reduce noise for general aviation aircraft such as the Cessna 172. Based on the approaches provided in the reference paper “Numerical Aerodynamic and Aeroacoustics Analysis of Toroidal Propeller Designs,” this tutorial shows how to construct the Broadband Noise Sources Model in ANSYS Fluent to accurately forecast acoustic performance. These propellers solve the age-old problem of propeller efficiency vs. noise by reducing sound pressure levels by 4 to 6 dB and increasing aerodynamic efficiency through the use of a ring structure that contains vorticity. To assess turbulence-generated noise across different frequency bands, the simulation methodology integrates computational aeroacoustics (CAA) with optimized acoustic analogy approaches. This methodology provides a strong tool for creating propulsion technology that is quieter, more economical, and still performs well. Its applications range from reducing UAV noise to improving passenger comfort in general aviation.

- Reference [1]: Vu, Xuan-duc, et al. “Numerical Aerodynamic and Aeroacoustics Analysis of Toroidal Propeller Designs.” International Journal of Aviation Science and Technology01 (2024): 20-33.

Figure 1: 3D Toroidal Propeller model

Simulation Process

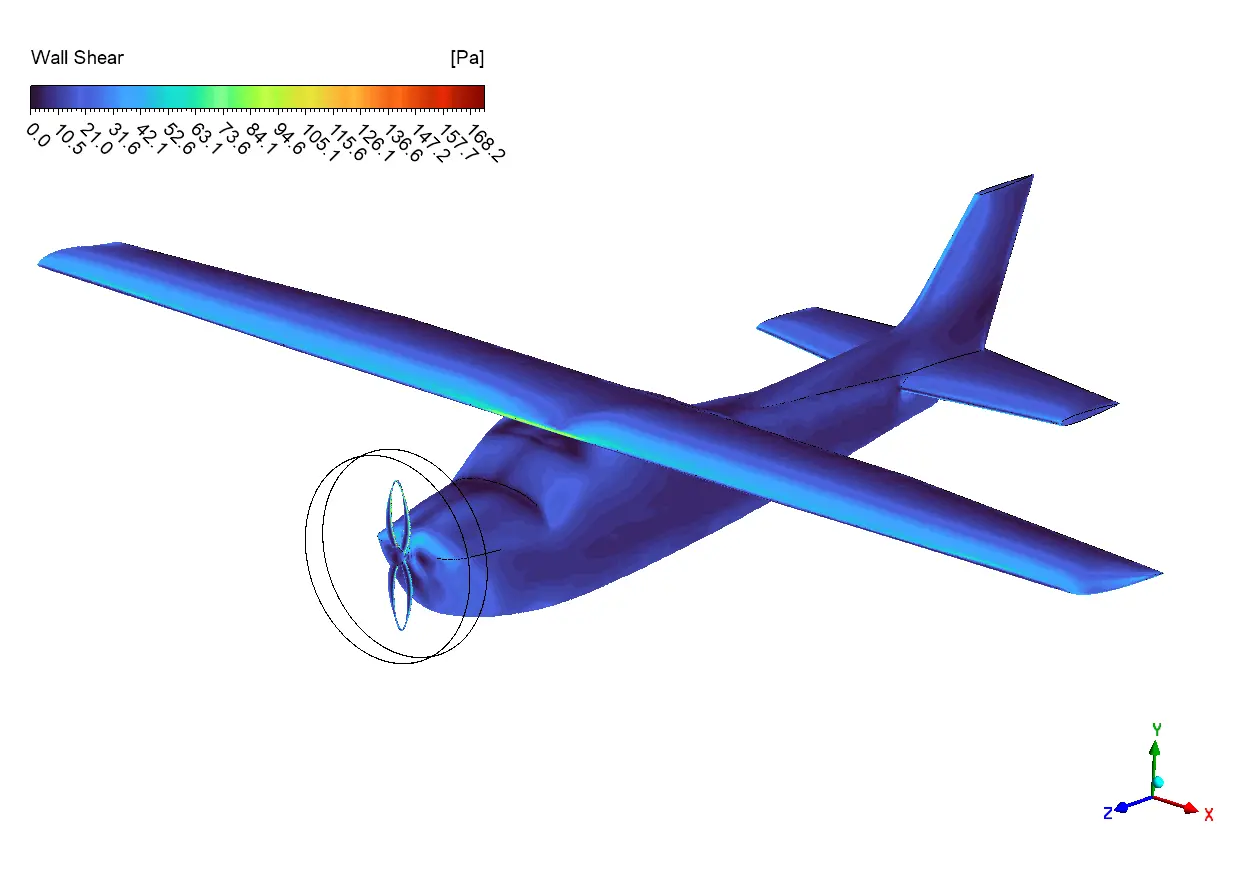

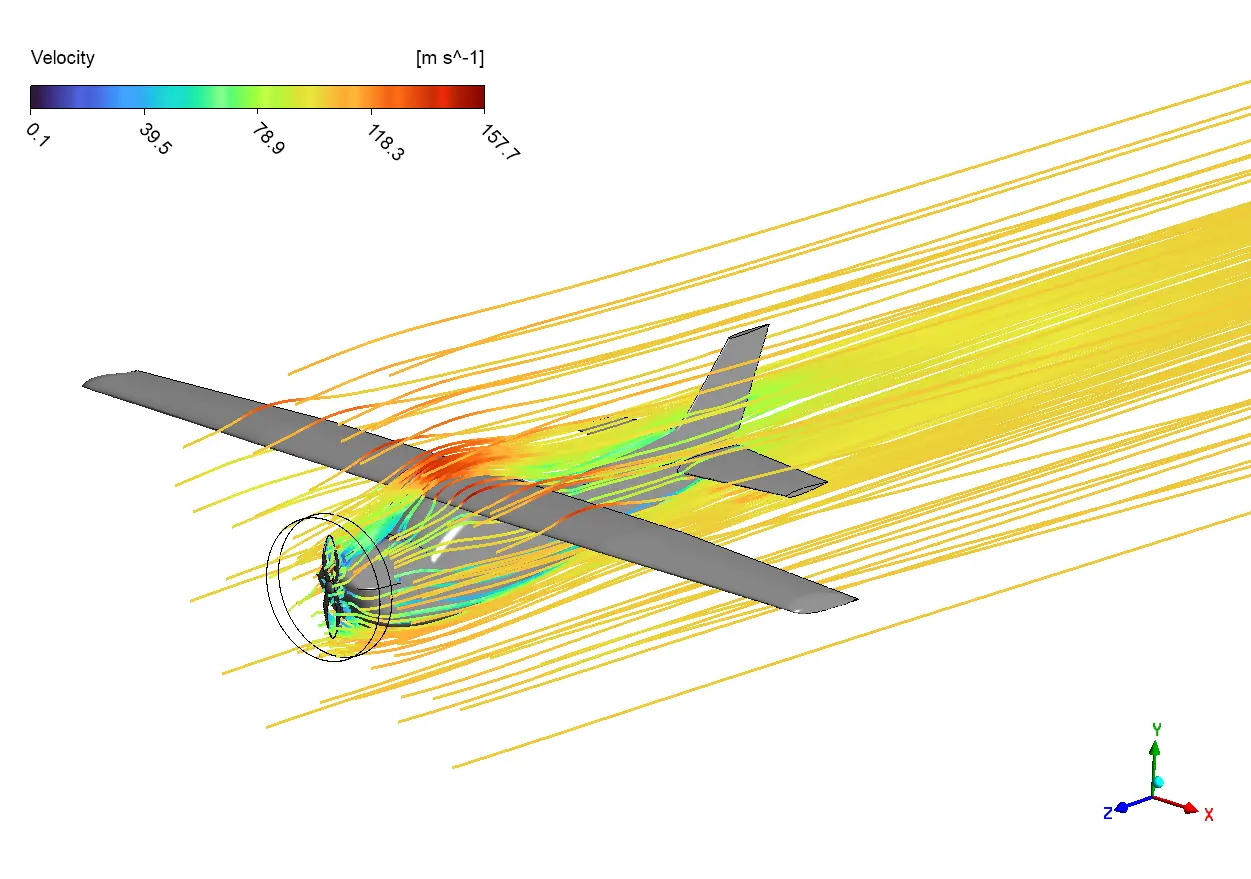

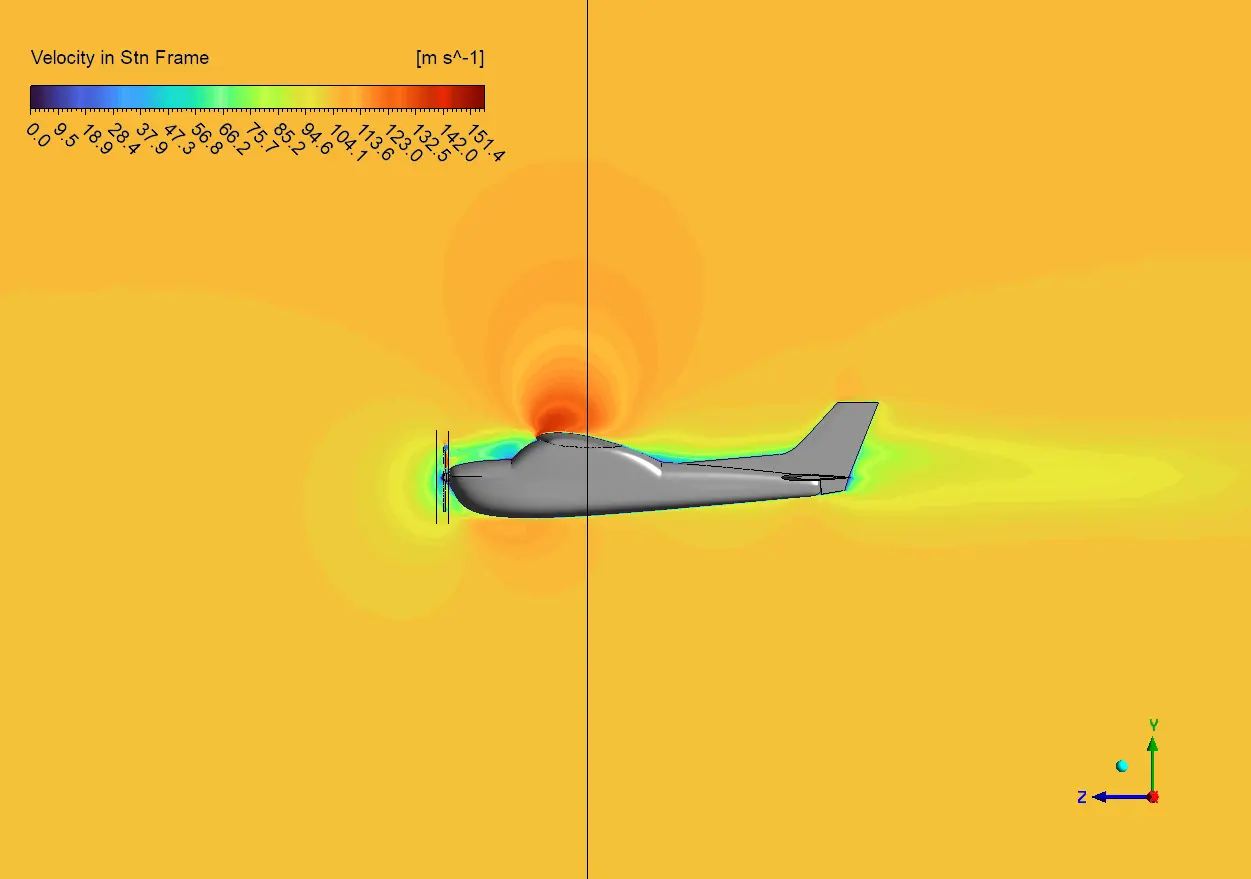

Our aeroacoustics simulation of the Cessna 172’s toroidal propeller uses a 3D domain created in ANSYS Design Modeler with separate regions for the aircraft body and propeller rotation. The unstructured mesh contains 9.8 million elements with refinement around the propeller tips where turbulence-generated noise is most significant. The simulation follows a two-stage workflow: first, a steady-state RANS solution establishes the flow field, followed by enabling the Broadband Noise Sources Model to identify acoustic hotspots. The Sliding Mesh (Mesh Motion) method simulates propeller rotation while the Broadband Noise Sources Model calculates noise distribution throughout the domain, allowing visualization of noise source regions rather than propagating to far-field receivers. This approach provides immediate insight into where and why noise is generated, enabling efficient acoustic signature optimization of the toroidal propeller design compared to conventional configurations.

Post-Processing

The acoustic post-processing of our Broadband Noise Sources Model simulation proves significant noise reduction benefits of the toroidal propeller design compared to conventional propellers on the Cessna 172. The pressure contour visualization clearly shows the propagation of pressure waves around the aircraft, with concentrations of high-pressure regions (red/orange areas) directly surrounding the propeller and lower pressure zones (green/blue) extending outward in characteristic patterns. This pressure distribution directly corresponds to the acoustic wave generation mechanism captured by our computational aeroacoustics approach.

Figure 2: Pressure gradient around Toroidal Propeller

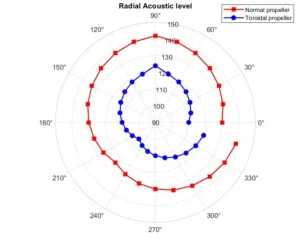

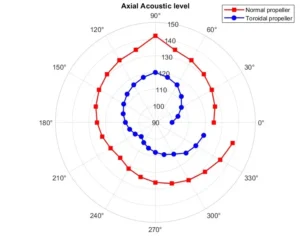

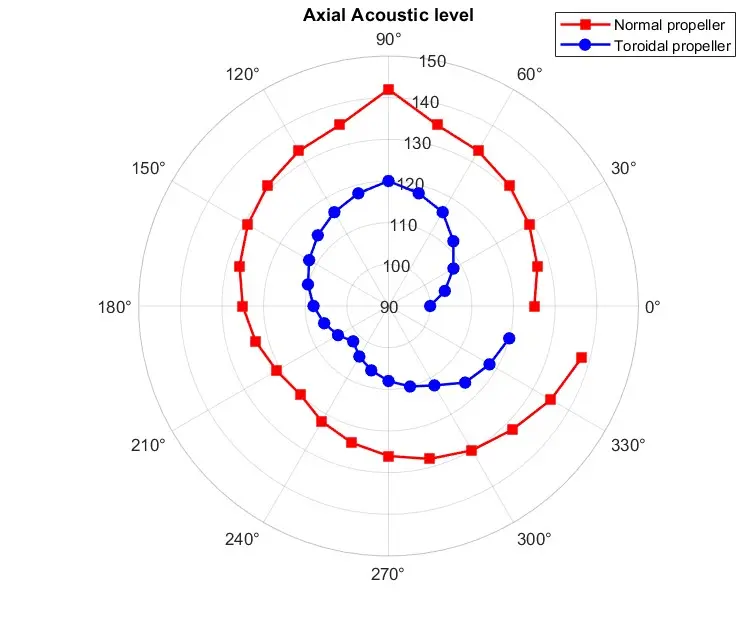

Figure 3:Radial and axial acoustic level

The polar diagrams present compelling evidence of the toroidal propeller’s acoustic advantages. The radial acoustic level measurements demonstrate an average sound pressure level reduction of 15-20 dB compared to the conventional propeller across all directional angles. While the conventional propeller generates noise levels consistently above 140 dB (red line), the toroidal design maintains levels around 120-125 dB (blue line). Similarly, the axial acoustic level plot confirms these findings with comparable noise reduction benefits observable in all directions. This uniform noise reduction pattern indicates that the ring propeller technology effectively minimizes both tip vortex noise and broadband noise components by fundamentally altering the blade tip flow characteristics.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€195 Original price was: €195.€165Current price is: €165.

€235 Original price was: €235.€155Current price is: €155.

€220 Original price was: €220.€115Current price is: €115.

€380 Original price was: €380.€185Current price is: €185.

Reviews

There are no reviews yet.