Two-Phase In-line Separator CFD Simulation: Swirling Generator Analysis in ANSYS Fluent

Two-Phase In-line Separator CFD Simulation: Swirling Generator Analysis in ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€195 Original price was: €195.€135Current price is: €135.

In the oil industry, oil and water often mix together in pipes. Separating them quickly is very important. Old tanks are too big and slow. The best solution is an In-line Separator. This is a device inside the pipe that spins the fluid. It uses a part called an “Axial-Flow Swirl Generator.” When the fluid spins, the heavy water flies to the outside, and the light oil stays in the middle.

Designing the blades for this spinner is hard. If the shape is wrong, the fluids won’t separate. To fix this, engineers use In-line Separator CFD Simulation. In this tutorial, we use ANSYS Fluent to simulate this process. We look at a mix of water and oil. We use the Eulerian Multiphase Model to track both fluids at the same time. This helps us see if the design works before we build it. For more examples of mixing and separating fluids, please check our Multiphase CFD tutorials.

- Referennce [1]: Je, Yeong-Wan, Jong-Chul Lee, and Youn-Jea Kim. “Performance characteristics of in-line oil separator with various airfoil vane configurations of the axial-flow swirl generator.” Processes5 (2022): 948.

Figure 1- 3D Geometry of the In-line Separator showing the complex Swirl Generator blades designed in SolidWorks and SpaceClaim.

Simulation Process: Eulerian Multiphase and RSM Turbulence Setup

For this In-line Separator CFD Simulation, the geometry is complex. The blades have a special twisted shape (airfoil). We designed them in Solidworks and prepared the domain in ANSYS SpaceClaim. The mesh is the most critical part. We used Fluent Meshing to create Poly-Hexacore elements. This gives us a total of 3,310,421 cells. We needed this many cells to capture the small details of the flow around the blades.

For the physics, we used the Reynolds Stress Model (RSM). Standard models like k-epsilon are not good for spinning flows. RSM is much more accurate for “Swirling Flow.” We set up the Eulerian Multiphase Model with two phases:

- Primary Phase: Water (Heavy)

- Secondary Phase: Oil (Light). We also set specific rules for “Drag” and “Surface Tension” to make sure the oil droplets behave realistically in the water.

Figure 2- Mesh generation details showing the high-quality Poly-Hexacore elements around the swirl generator blades.

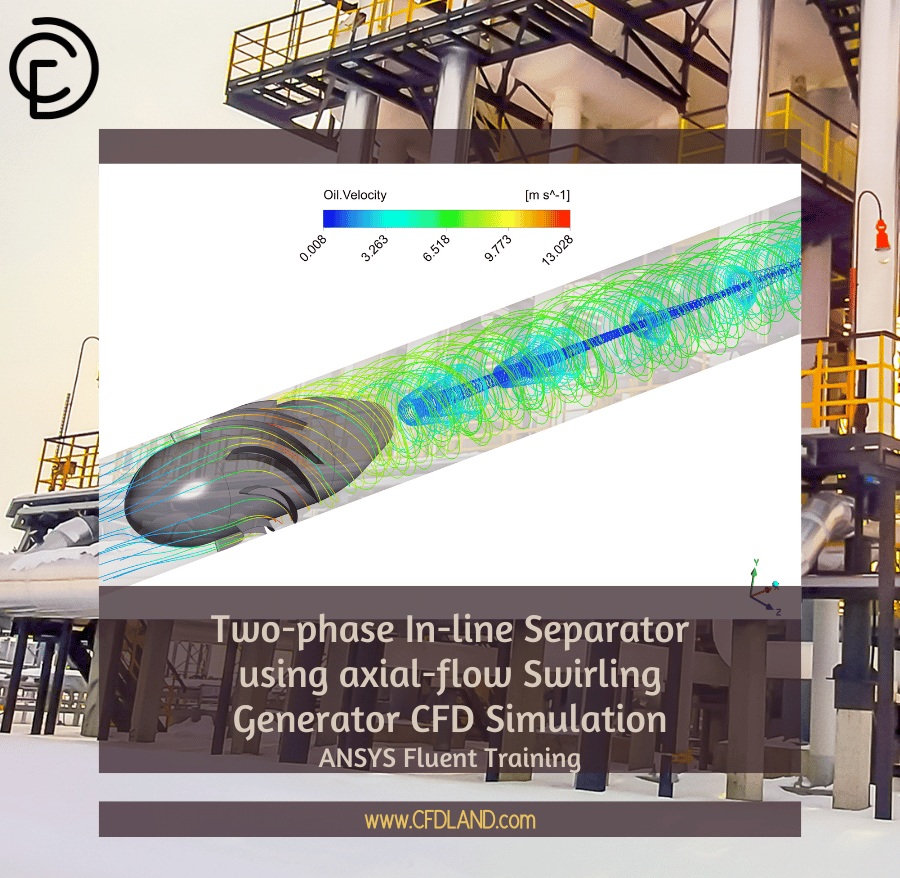

Post-processing: Velocity and Phase Separation Analysis in In-line Separator

Now we analyze the images to see if the separator works. We look at the speed and the location of the oil and water. First, let’s look at the Velocity Streamlines in Figure 3. The lines show the path of the fluid. As the fluid hits the blades, it starts to spin. The legend in the image shows the velocity reaches a maximum of 13.028 m/s (Red color) right as it passes through the swirl generator. This high speed is necessary. It creates a strong “Centrifugal Force.” This force acts like a washing machine spin cycle. It pushes heavy things outward.

Next, we look at the Water Volume Fraction Contour in Figure 4. This image shows us where the water is.

- The Walls (Red): The scale shows red is 0.987. This means the walls are almost 100% water. The centrifugal force has successfully pushed the heavy water to the outside.

- The Center (Blue): The center of the pipe is blue, which means there is almost no water here.

Figure 3- Velocity Streamlines colored by magnitude. The image shows the fluid spinning and reaching speeds of 13 m/s inside the generator.

This result is confirmed by the Oil Distribution Chart. The chart shows a peak in the center (rD=0). The oil collects in the core of the pipe. This proves the Eulerian Multiphase setup was correct. The density difference causes the separation. The heavy water pushes out, squeezing the light oil into a clean core. This design is highly effective for cleaning oil from wastewater or refining petroleum.

Figure 4- Volume fraction of a) water b) oil phase

Figure 5: Oil volume fraction graph at the outlet

Key Takeaways & FAQ

- Q: Why do we use the Reynolds Stress Model (RSM)?

- A: Simple turbulence models cannot calculate twisting flows accurately. RSM solves 7 equations to track the complex swirling motion inside the separator.

- Q: How does the separator work?

- A: It uses density difference. The blades spin the fluid. Centrifugal force pushes heavy water to the outside walls, forcing lighter oil to the center.

- Q: How do we know the separation worked?

- A: The contours show a clear “Red” ring of water on the outside and a “Blue” core in the middle. This means the two liquids have separated completely.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€160Current price is: €160.

€170 Original price was: €170.€155Current price is: €155.

€205 Original price was: €205.€165Current price is: €165.

€205 Original price was: €205.€169Current price is: €169.

€205 Original price was: €205.€135Current price is: €135.

€240 Original price was: €240.€155Current price is: €155.

Reviews

There are no reviews yet.