U-tube Shell and Tube Heat Exchanger CFD Simulation, ANSYS Fluent Training

U-tube Shell and Tube Heat Exchanger CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160 Original price was: €160.€80Current price is: €80.

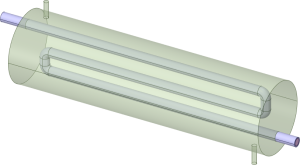

A U-tube Shell and Tube Heat Exchanger is a smart and efficient device used to transfer heat between two fluids without letting them mix. Inside a large cylindrical shell, there is a bundle of tubes bent into a U-shape. One fluid, like cold water, flows through these tubes, while another hot fluid circulates in the shell around them. This design is very popular in industries like power generation and HVAC systems because it provides a large surface area for heat exchange in a compact space. Using a U-tube Shell and Tube Heat Exchanger CFD simulation is the best way to see the complex flow patterns and accurately predict its thermal performance.

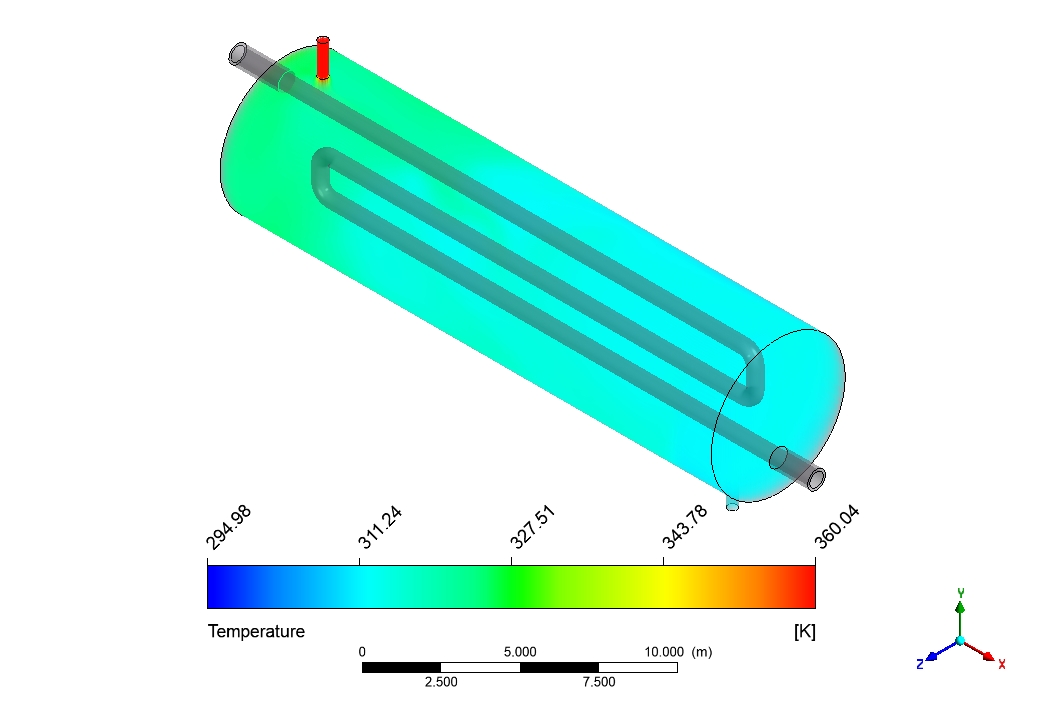

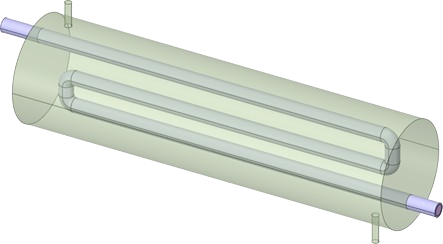

Figure 1: The 3D geometry design of the U-tube Shell and Tube Heat Exchanger.

Simulation Process: Modeling Conjugate Heat Transfer in the U-tube STHE

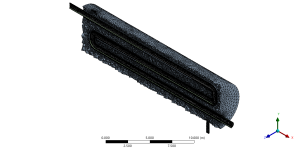

To begin our simulation, we first created the 3D geometry. This model has three main zones: the cold fluid inside the tubes, the hot fluid inside the shell, and the solid copper walls of the tubes themselves. Modeling all three zones allows us to perform a Conjugate Heat Transfer (CHT) analysis, which is very accurate. Next, we created a high-quality mesh with 1,035,902 tetrahedral cells to capture the details of the flow and heat transfer.

After that, we set up the physics for our U-tube Shell and Tube Heat Exchanger fluent simulation. We defined the boundary conditions based on a typical industrial use case. Cold water at a temperature of 290 K enters the U-tubes. At the same time, a hot fluid at 360 K enters the shell. The simulation then calculates how heat moves from the hot shell fluid, through the copper tube walls, and into the cold tube fluid.

Figure 2: A cross-sectional view of the mesh created for the U-tube STHE CFD simulation.

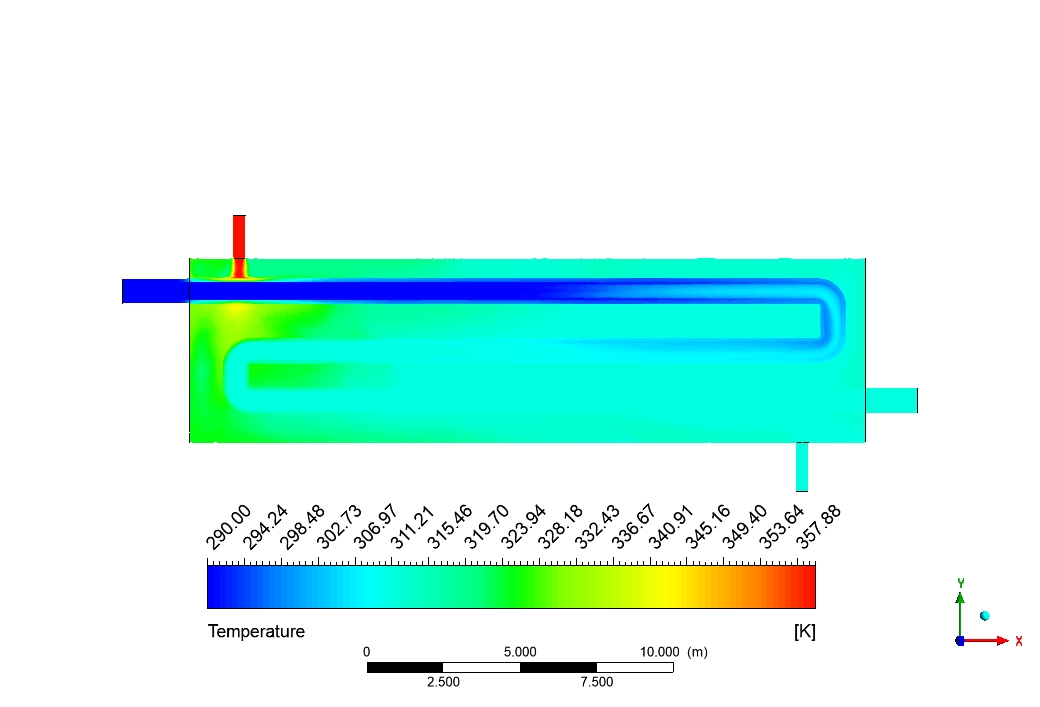

Post-processing: How U-bend Vortices Drive Heat Transfer

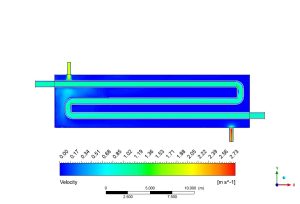

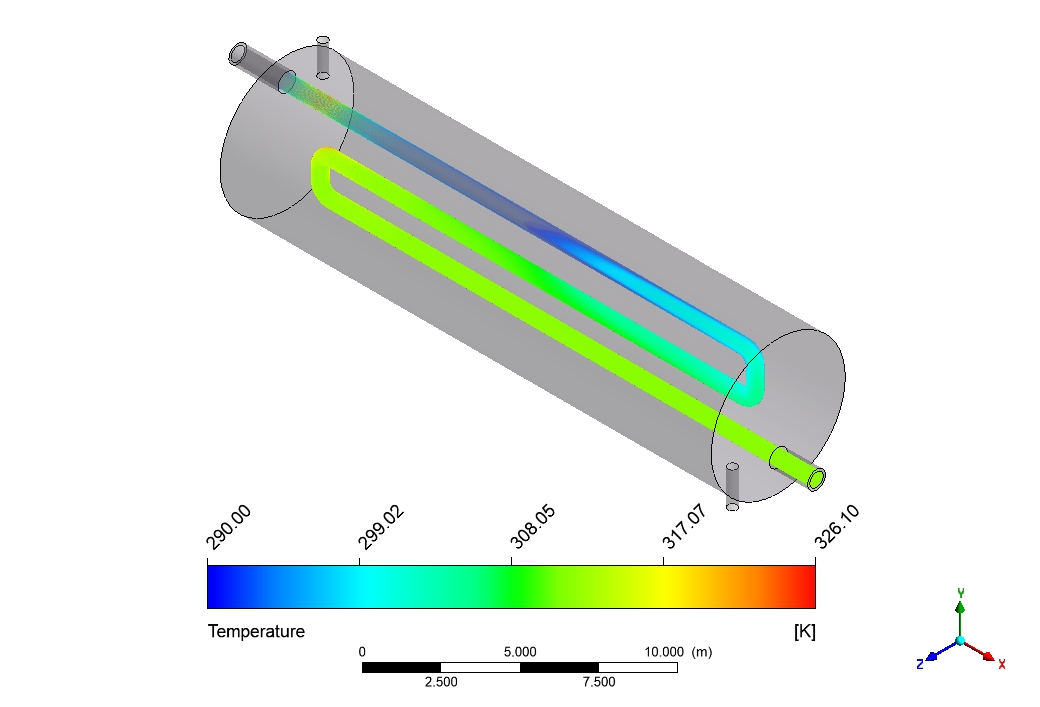

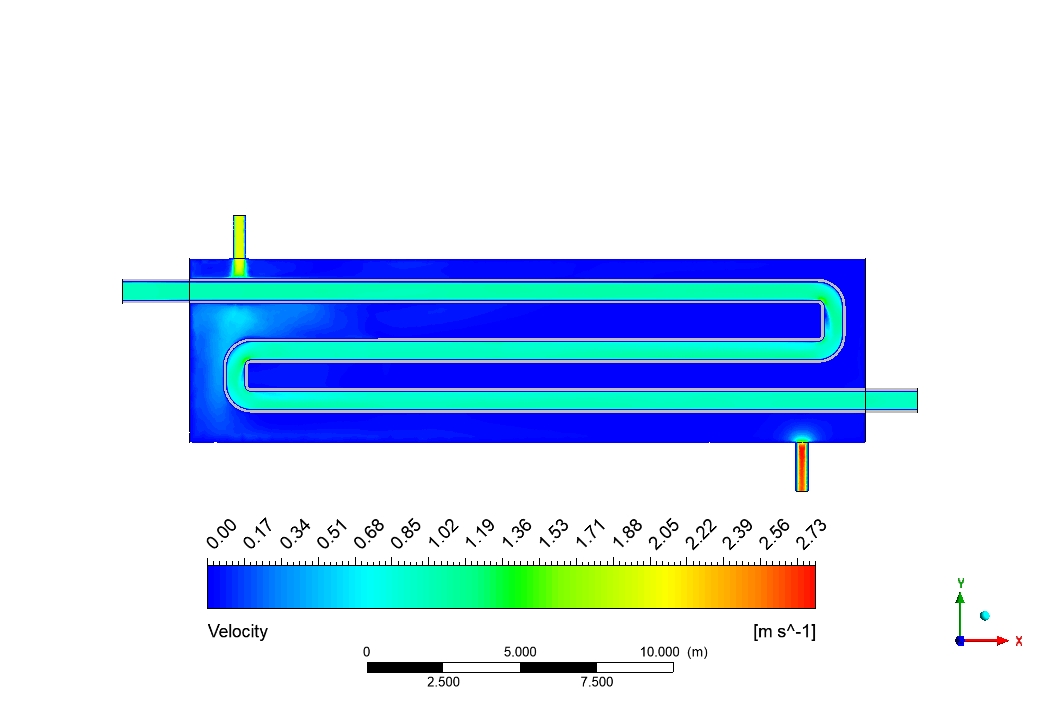

A deep analysis of the results reveals exactly how the U-bend design creates such effective heat transfer. The velocity contour in Figure 4 shows that the fluid reaches a maximum speed of 2.73 m/s, mostly near the inlets and outlets. However, the most important action happens in the curved U-bend section. As the fluid flows around this bend, it creates special rotating flow patterns called Dean Vortices. These vortices are critical because they cause the fluid to mix radially, from the center of the pipe to the walls. This mixing action breaks up the stable thermal boundary layers, forcing the colder fluid from the core to come into contact with the hot tube walls.

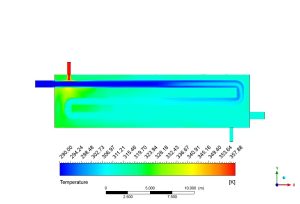

Figure 3: Temperature distribution in the U-tube Shell and Tube Heat Exchanger.

This enhanced mixing directly leads to the excellent thermal performance seen in the temperature contours. The cold water entering the tube at 290 K gets heated up by an impressive 21.48 K, leaving the exchanger at 311.48 K. Simultaneously, the hot fluid in the shell gives away its heat, and its temperature drops by a massive 48.35 K, from 360 K to 311.65 K. This large, two-way temperature change is the most significant achievement of the simulation, and it is a direct consequence of the Dean vortices created by the U-tube design. This detailed U-tube STHE CFD analysis successfully proves that the geometry is not just a simple pipe; it is a highly engineered system that uses fluid dynamics to maximize thermal efficiency.

Figure 4: Velocity distribution, showing how the U-bend creates the flow patterns responsible for high performance.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€130 Original price was: €130.€65Current price is: €65.

€185 Original price was: €185.€125Current price is: €125.

€160 Original price was: €160.€85Current price is: €85.

€245 Original price was: €245.€199Current price is: €199.

€360 Original price was: €360.€180Current price is: €180.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.