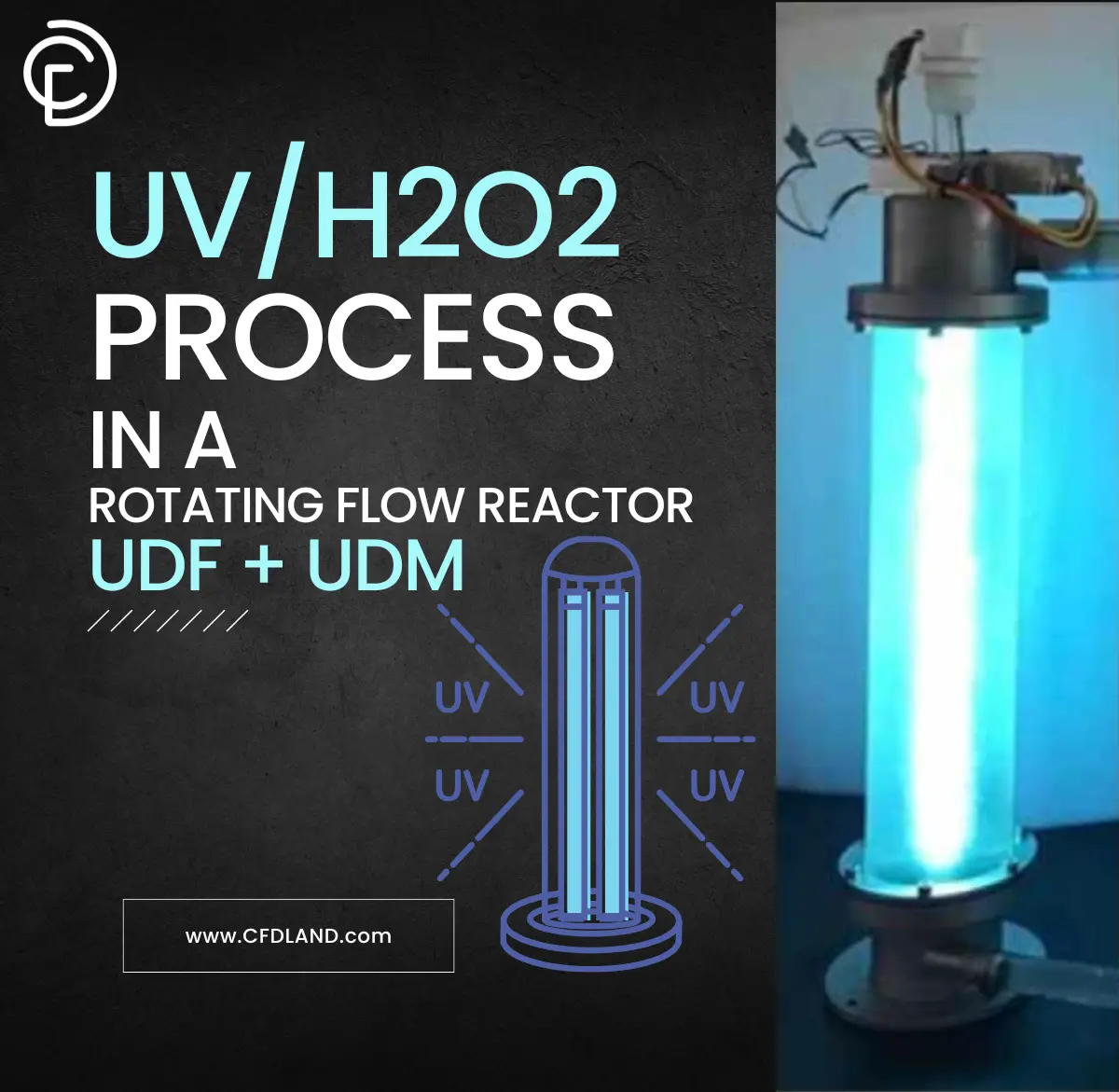

UV-H2O2 Process CFD: A Fluent Tutorial on Rotating Flow Reactors with UDF-UDM

UV-H2O2 Process CFD: A Fluent Tutorial on Rotating Flow Reactors with UDF-UDM

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€230 Original price was: €230.€199Current price is: €199.

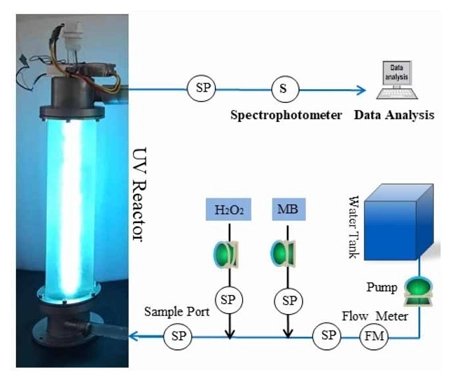

The UV-H2O2 process is a powerful method for cleaning contaminated water. It uses a combination of ultraviolet (UV) light and hydrogen peroxide (H2O2) to create highly reactive particles called hydroxyl radicals. These radicals are excellent at destroying harmful pollutants. When this process happens inside a Rotating Flow Reactor, the mixing is much better, which helps the UV light and H2O2 work more effectively. A UV-H2O2 Process CFD simulation is the only way to accurately see and predict how this complex system works. The main goal of this project is to simulate the performance of this reactor, paying special attention to how we can model the custom chemical reactions. Our work is guided by the methods in the reference papers by Luo, et al. [1, 3] and Mohajerani, et al. [2].

- Reference [1]: Luo, Minghan, Wenjie Xu, and Taeseop Jeong. “Development and numerical modelling of a novel UV/H2O2 rotating flow reactor for water treatment.” Water Science and Technology5 (2021): 1217-1229.

- Reference [2]: Mohajerani, Masroor, Mehrab Mehrvar, and Farhad Ein‐ “Photoreactor design and CFD modelling of a UV/H2O2 process for distillery wastewater treatment.” The Canadian Journal of Chemical Engineering90.3 (2012): 719-729.

- Reference [3]: Luo, Minghan, et al. “Computational fluid dynamics modeling of rotating annular VUV/UV photoreactor for water treatment.” Processes1 (2020): 79.

Figure 1: The schematic diagram of the UV-H2O2 Process in the reactor system [1].

Simulation Process: Modeling Custom UV Reactions with UDF & UDM

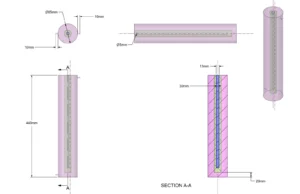

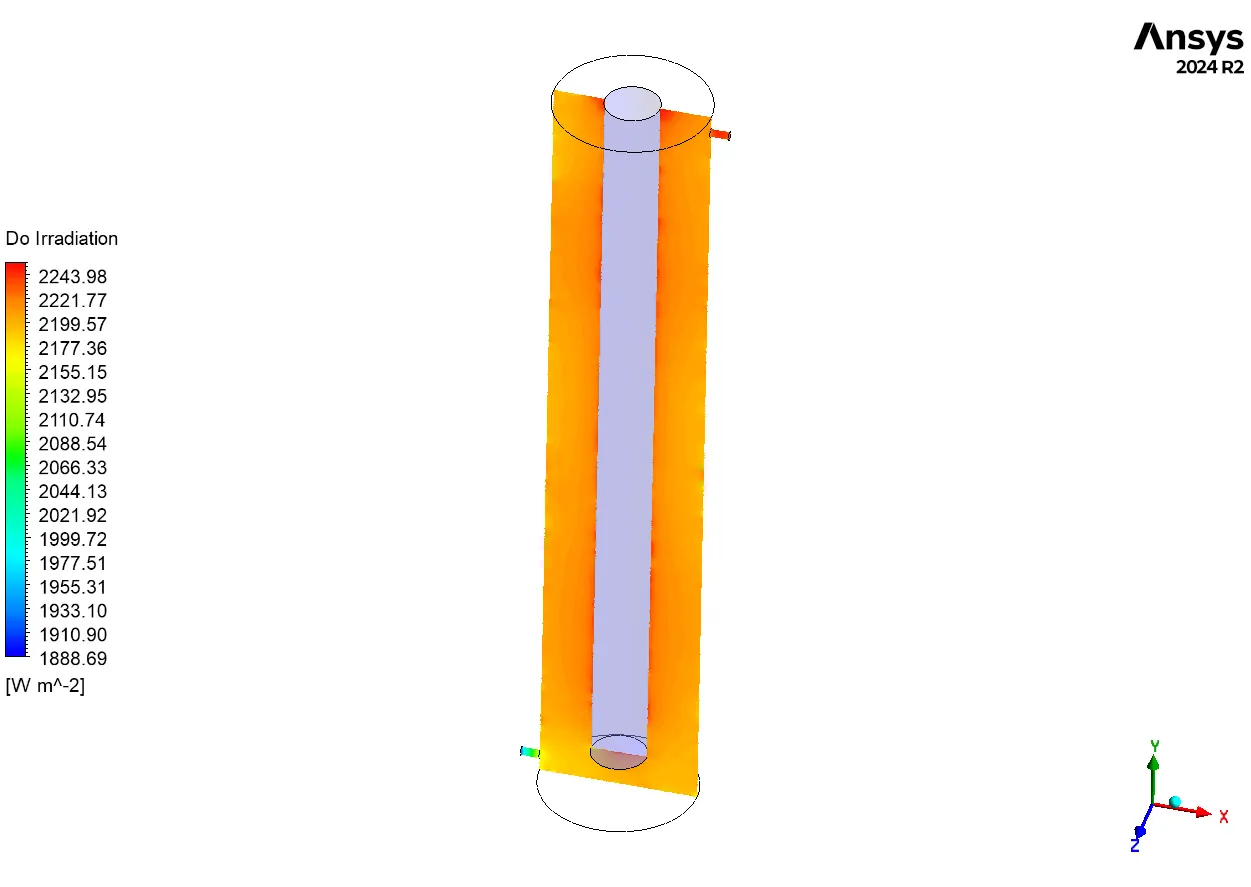

To simulate a UV-H2O2 Process in Fluent, we must teach the software how to handle the special chemistry. First, the 3D geometry of the rectangular chamber and its two UV lamps was designed. Then, a high-quality mesh was created, with very fine cells near the lamps where the UV radiation is strongest. The most critical part of this simulation was programming the reactions. ANSYS Fluent does not have a built-in model for photochemical reactions. Therefore, we had to write our own custom code.

This was done using a User-Defined Function (UDF) and User-Defined Memory (UDM). The UDF contains the mathematical equations that calculate how much local irradiation each cell in the reactor receives from the UV lamps. The UDM is like a special memory slot for each cell that stores this calculated UV light intensity. The Species Transport model in Fluent then uses these stored UV values to calculate the reaction rates for H2O2, hydroxyl radicals, and the pollutants. This powerful combination of UDF & UDM in Fluent allows us to perform a very accurate and realistic simulation.

Table 1: Reactions Used in the UV/H₂O₂-COD Model

| Reaction Equation | Description | Rate Expression | Rate Constant / Parameters |

| H₂O₂ + hν → 2·OH | Photolysis of H₂O₂ under UV | R₁ = (Φ · ε · [H₂O₂] · E₀)/ln(10) | Φ = 0.5, ε = 19.6 m⁻¹, E₀ = UV irradiance |

| CH₂O (COD) + ·OH → CO₂ + H₂O | Oxidation of COD by OH radicals | R₂ = k · [OH] · [COD] | k = 4.9 × 10⁹ M⁻¹s⁻¹ |

| H₂O₂ + ·OH → HO₂· + H₂O | Radical scavenging | R₃ = k₂ · [H₂O₂] · [OH] | k₂ = (1.4-4.5) × 10⁷ M⁻¹s⁻¹ |

| 2·OH → H₂O₂ | Radical recombination | R₄ = k₃ · [OH]² | k₃ = (5.0-8.0) × 10⁹ M⁻¹s⁻¹ |

| 2HO₂· → H₂O₂ + O₂ | Peroxyl radical reaction | R₅ = k₄ · [HO₂]² | k₄ = (0.8-2.2) × 10⁶ M⁻¹s⁻¹ |

| HO₂· + ·OH → H₂O + O₂ | Radical termination | R₆ = k₅ · [HO₂] · [OH] | k₅ = 6.6 × 10⁹ M⁻¹s⁻¹ |

Figure 2: The 3D model used for the Rotating Flow Reactor CFD simulation.

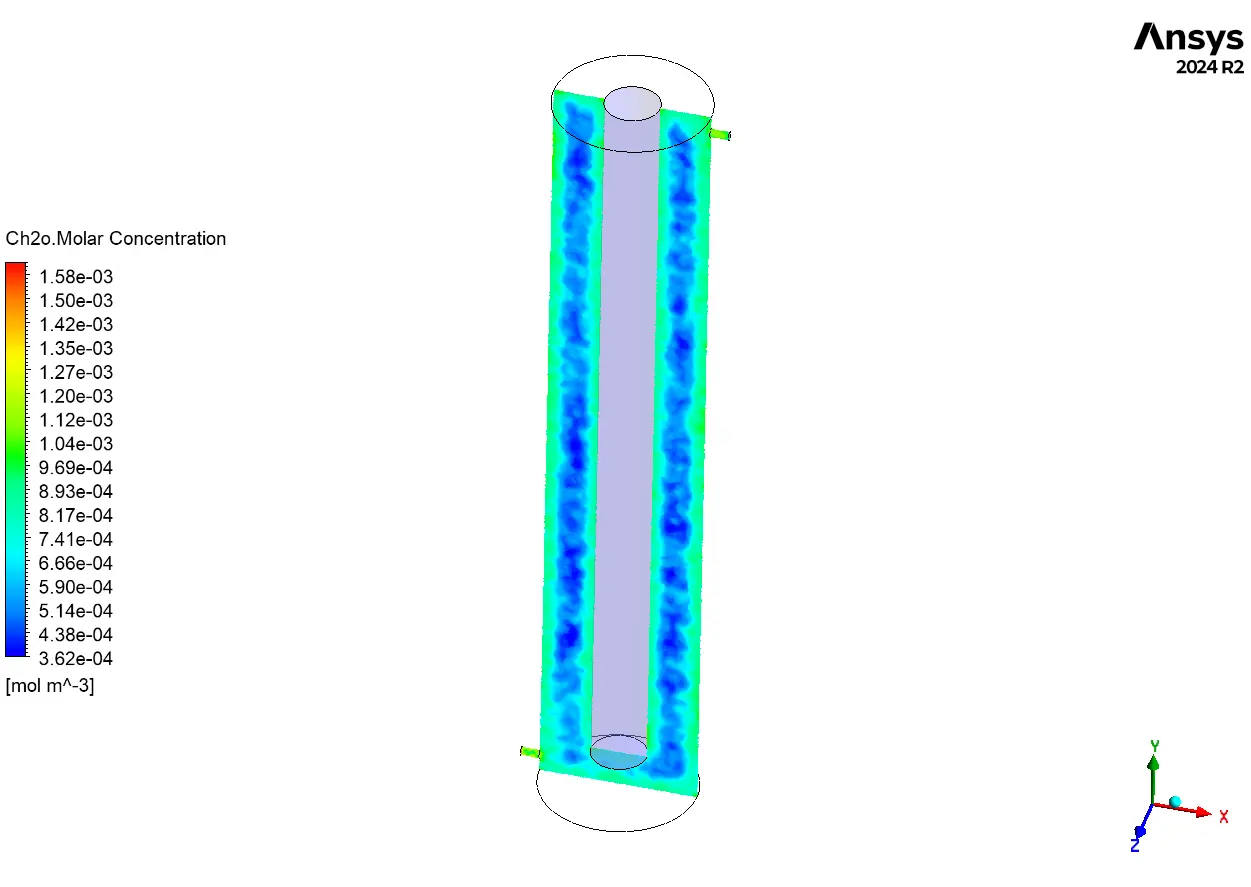

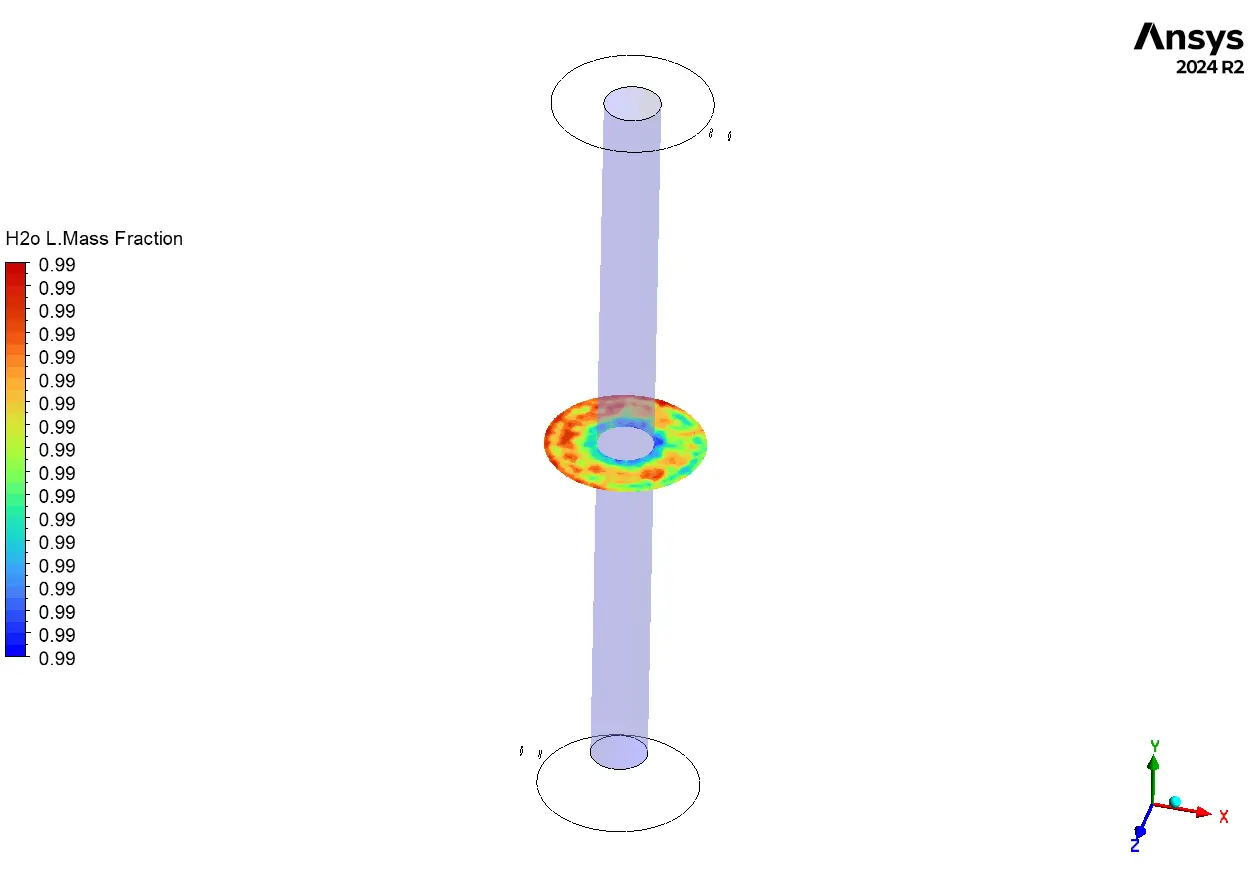

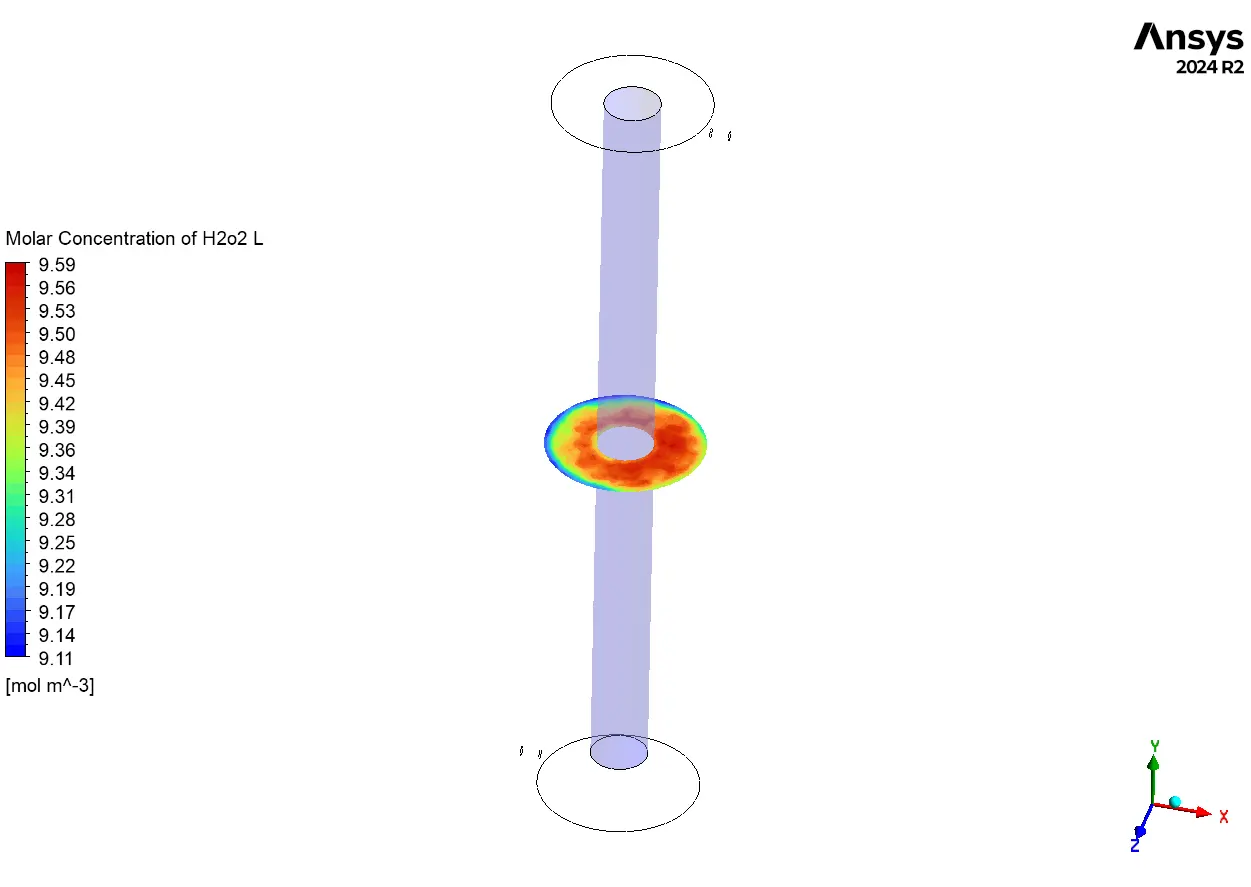

Post-Processing: Analyzing Reactor Efficiency and Thermal Performance

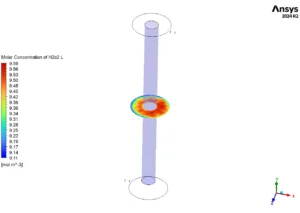

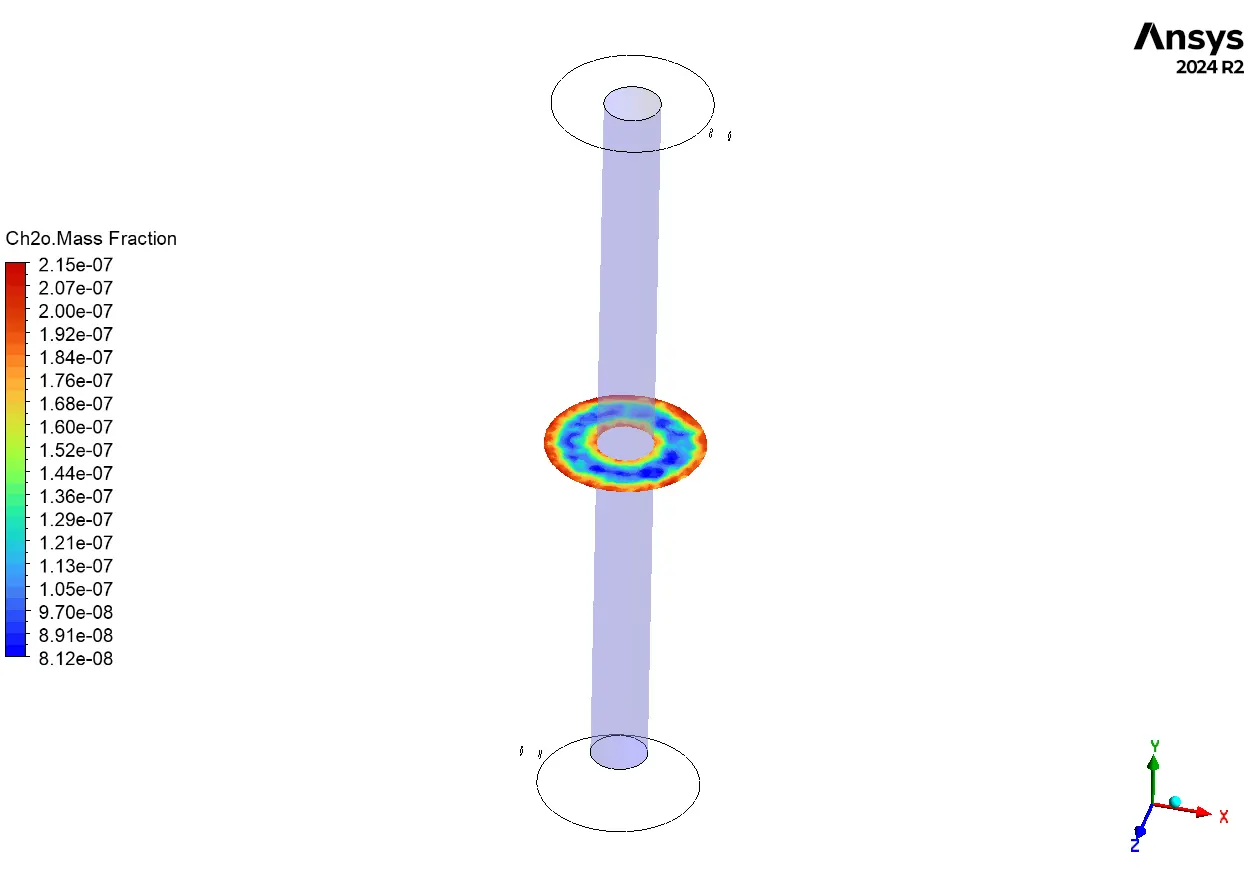

A detailed analysis of the results shows exactly how well the reactor cleans the water. The H2O2 concentration contour in Figure 3 reveals that the concentration drops from a high of 9.59 mol/m³ at the inlet to a low of 9.11 mol/m³ at the outlet. We can see a clear ring pattern around the central UV tube. This is the zone where the UV light is strongest, causing the H2O2 to break down most rapidly and create the pollutant-destroying radicals. The most significant achievement of this simulation is the calculation of the treatment efficiency. Based on the pollutant concentration at the inlet and outlet, the reactor achieves a 32.16% pollutant removal efficiency. This quantitative result proves the effectiveness of the design and the accuracy of our UV radiation CFD model.

Figure 3: H2O2 concentration, showing consumption around the UV tube and the overall treatment efficiency.

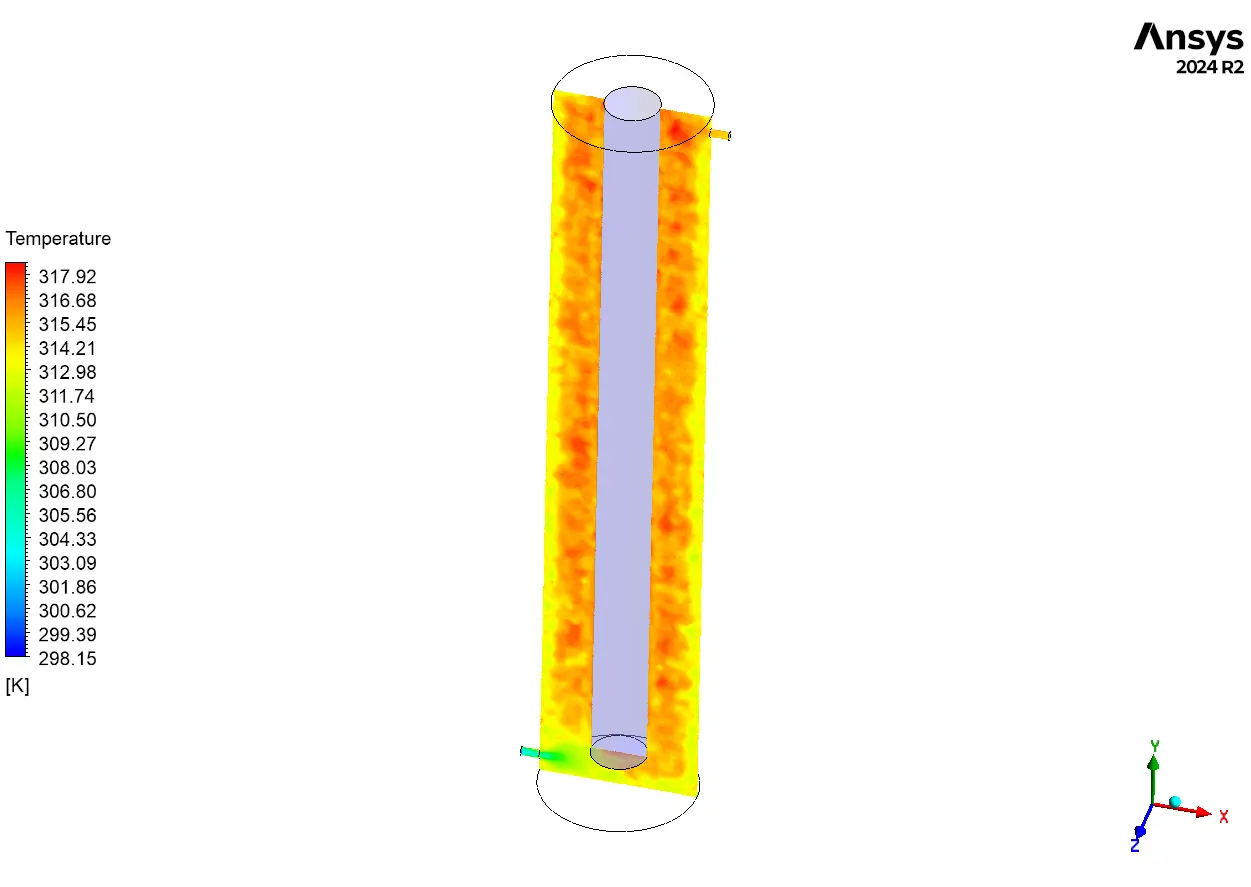

Furthermore, the temperature contour in Figure 4 gives us important information about the heat generated during the process. The temperature increases from 298.15 K at the inlet to a maximum of 317.92 K in the areas right next to the UV tubes. This heating happens because both the UV light and the chemical reactions release energy. Understanding this temperature distribution is critical for designing a reliable system. High temperatures can affect the chemical reactions and potentially damage the equipment. The rotating flow in the reactor helps to mix the fluid and distribute this heat more evenly, preventing dangerous hot spots. This thermal analysis is a key part of optimizing the performance and safety of a Rotating Flow Reactor.

Figure 4: Temperature distribution inside the reactor, highlighting the heat generated by the UV lamps and reactions.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€145Current price is: €145.

€280 Original price was: €280.€145Current price is: €145.

€240 Original price was: €240.€135Current price is: €135.

€245 Original price was: €245.€185Current price is: €185.

€180 Original price was: €180.€115Current price is: €115.

€240 Original price was: €240.€135Current price is: €135.

Reviews

There are no reviews yet.