Ventilated Wall CFD: Analyzing Particle Dispersion with DPM & Solar Load

Ventilated Wall CFD: Analyzing Particle Dispersion with DPM & Solar Load

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€240 Original price was: €240.€125Current price is: €125.

A Ventilated Brick Wall CFD simulation is a powerful tool for designing energy-efficient and healthy buildings. This innovative wall design features an air gap between the outer brick layer and the inner wall. As shown by Buratti et al. [1], this cavity uses natural airflow to reduce heat gain in the summer. At the same time, this airflow can impact indoor air quality by affecting the movement of dust and other airborne particles, a topic explored by Zhou et al. [2]. This report details a CFD simulation that investigates this dual function: how a ventilated wall can both manage heat and help remove particles from a room.

- Reference [1]: Buratti, Cinzia, et al. “Development and optimization of a new ventilated brick wall: CFD analysis and experimental validation.” Energy and Buildings168 (2018): 284-297.

- Reference [2]: Zhou, Yu, et al. “The effects of ventilation and floor heating systems on the dispersion and deposition of fine particles in an enclosed environment.” Building and Environment125 (2017): 192-205.

Figure 1: A prototype of the constructed ventilated brick wall in a laboratory setting [1].

Simulation Process: Modeling the Ventilated Brick Wall Fluent Simulation

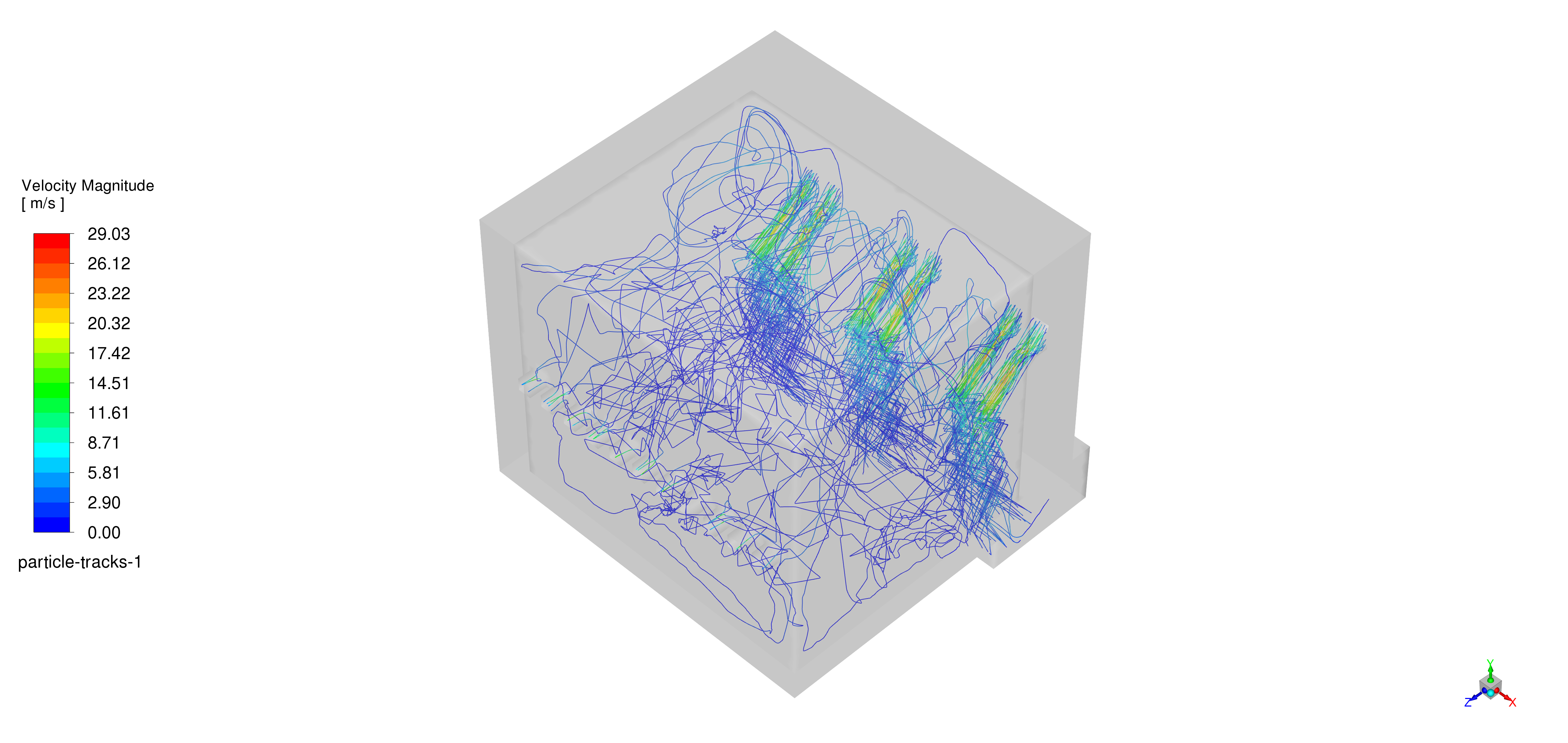

The simulation was performed in ANSYS Fluent using a 3D model of a room with a ventilated wall. To study the movement of dust, a multiphase approach was used. The air was modeled as a continuous fluid, while the dust particles were tracked individually using the Discrete Phase Model (DPM). This is also known as an Eulerian-Lagrangian approach.

Two critical physics models were activated for this Ventilated Brick Wall Fluent simulation:

- The Discrete Ordinates (DO) radiation model was used to simulate the effect of sunlight heating the outer surface of the brick wall.

- Two-way DPM coupling was enabled, meaning that not only does the air move the particles, but the particles can also affect the airflow, which is important for realistic results.

Post-processing: CFD Analysis, How Solar Heat Creates a Natural Air Purifier

The simulation results provide a clear and fully substantiated story that begins with solar radiation, which is the primary “cause” of the system’s behavior. The DO radiation model simulates sunlight hitting the outer brick wall, causing it to heat up. This heat is transferred to the air inside the wall’s narrow cavity. As this pocket of air gets warmer, it becomes less dense and lighter than the surrounding air. This difference in density creates a powerful upward force called buoyancy. This buoyancy is the invisible engine that drives a continuous, upward flow of air through the cavity, creating a natural ventilation chimney effect.

Figure 2: Particle residence time, showing how the Ventilated Wall CFD system removes particles near it (yellow/green) while uncaptured particles remain for longer (red).

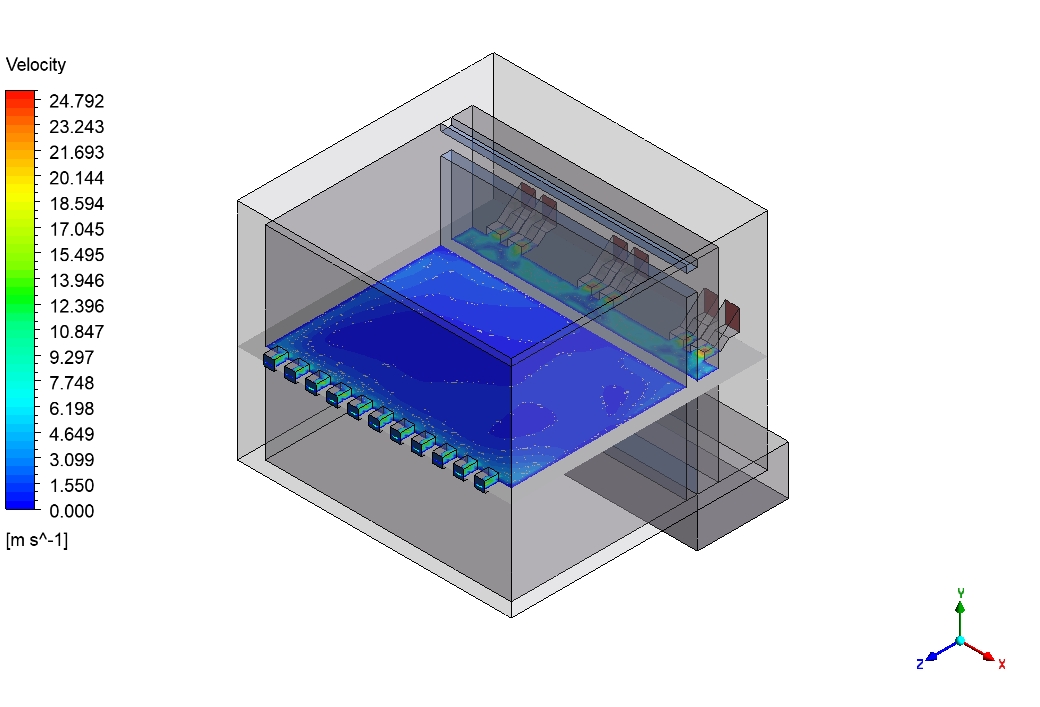

This buoyancy-driven airflow has a direct and highly beneficial “effect” on the room’s air quality. The upward draft in the wall cavity creates suction at the bottom vents, pulling particle-laden air from the room into the wall. The particle velocity plot in Figure 3 is the perfect visual proof of this effect. It shows particles being drawn from the floor level and accelerated to high speeds (yellow/green regions) as they are swept up and out through the wall’s ventilation channel. This process actively removes dust from the living space. The particle residence time in Figure 2 further supports this. Particles far from the wall that are not captured by the airflow settle and remain in the room for a long time (red tracks), while particles near the wall are quickly entrained and removed (shorter residence time, shown by yellow/green tracks). The most significant achievement of this study is the clear demonstration of how solar energy (the cause) is harnessed to create a natural, self-sustaining ventilation system (the effect) that not only improves thermal comfort but also acts as a continuous air purifier by actively capturing and removing harmful airborne particles from the indoor environment.

Figure 3: Velocity of discrete dust particles, showing them being accelerated up and into the ventilation cavity, proving the effectiveness of the Room Ventilation Fluent simulation.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€310 Original price was: €310.€170Current price is: €170.

€155 Original price was: €155.€95Current price is: €95.

€105 Original price was: €105.€65Current price is: €65.

€140 Original price was: €140.€65Current price is: €65.

€135 Original price was: €135.€65Current price is: €65.

€110 Original price was: €110.€65Current price is: €65.

Reviews

There are no reviews yet.