Air Curtain Ventilation CFD: A Fluent Analysis of Ammonia Removal

Air Curtain Ventilation CFD: A Fluent Analysis of Ammonia Removal

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€110 Original price was: €110.€65Current price is: €65.

Managing hazardous gases like ammonia is a top priority for safety in industrial and laboratory settings. An Ammonia Removal By Air Curtain Ventilation CFD simulation is a powerful and cost-effective method for designing and validating safety systems. Instead of using physical walls, an air curtain uses high-velocity air streams to create invisible barriers. This technology is essential for containing and removing harmful gases from a specific zone, protecting workers and preventing contamination. This report details a CFD simulation using ANSYS Fluent to show exactly how an air curtain system effectively captures and removes ammonia gas.

Figure 1: An air curtain ventilation system installed in a laboratory for contaminant control.

Simulation Process: Modeling the Ammonia Removal Fluent Simulation

The simulation was performed in ANSYS Fluent using a 3D model of a workspace where ammonia is released from the floor. To model the mix of air and ammonia gas, the Species Transport model was activated. This is the key physics model that allows the simulation to track the concentration of ammonia throughout the room. The air curtain itself was modeled as a series of inlets on the ceiling, injecting clean air at high velocity. This creates the “curtain” effect. The entire simulation for this Air Curtain Ventilation CFD study was run to see how the system behaves once it reaches a stable, steady-state condition.

Post-processing: CFD Analysis, How Air Jet Momentum Creates Containment and Removal

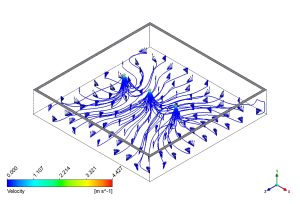

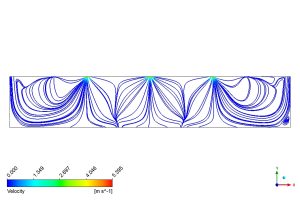

The simulation results provide a clear and fully substantiated story that begins with the air curtain jets, which are the “cause” of the entire process. The system works by injecting powerful, high-velocity jets of clean air downwards from the ceiling. This input of high momentum is the engine that drives both the containment and removal of the ammonia. The velocity streamlines in Figure 3 are the visual proof of this cause, showing the organized, fast-moving streams of air (reaching speeds of 4.4 m/s) that form the curtain.

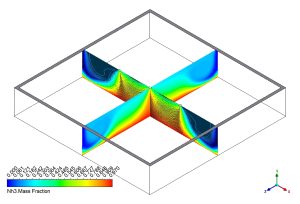

Figure 2: Ammonia mass fraction from the Ammonia Removal By Air Curtain Ventilation Fluent simulation, clearly showing the containment effect of the air barrier.

This directed momentum has a critical dual “effect” on the hazardous ammonia gas. First, the powerful jets act as invisible walls, physically blocking the ammonia from spreading outwards. The mass fraction contour in Figure 2 provides perfect evidence of this containment. It shows a sharp, clear boundary, with high concentrations of ammonia (red/yellow) trapped inside the curtained area and very low concentrations (blue) outside of it. Second, when the jets from different sides collide near the center, their momentum has nowhere to go but up, towards the exhaust vents. This creates a powerful, focused updraft. The streamlines in Figure 3 confirm this, showing all the air paths converging in the middle and flowing directly upwards. This updraft acts like a targeted chimney, capturing the contained ammonia and efficiently pulling it out of the building. The most significant achievement of this Ammonia Removal CFD analysis is the clear demonstration of how the high momentum of the air curtain jets (the cause) produces a powerful dual-action mechanism (the effect): a robust containment barrier and a focused central exhaust plume, which work together to guarantee the highly efficient and targeted removal of hazardous gases from a workspace.

Figure 3: Velocity streamlines illustrating how the Air Curtain Ventilation CFD simulation creates a focused upward flow to exhaust the contained ammonia.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€145Current price is: €145.

€210 Original price was: €210.€155Current price is: €155.

€135 Original price was: €135.€85Current price is: €85.

€120 Original price was: €120.€65Current price is: €65.

€160 Original price was: €160.€75Current price is: €75.

€240 Original price was: €240.€115Current price is: €115.

Reviews

There are no reviews yet.