Vortex Shedding of a Grooved Cylinder: A Fluent CFD Analysis

Vortex Shedding of a Grooved Cylinder: A Fluent CFD Analysis

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140 Original price was: €140.€85Current price is: €85.

When a fluid like air or water flows past a cylinder, it can create a repeating pattern of swirling vortices. This is called vortex shedding. A Vortex Shedding CFD simulation is a computer model that helps engineers study this effect. The famous von Kármán vortex street pattern can cause large structures like bridges and chimneys to shake. A Grooved Cylinder CFD analysis is a type of passive flow control used to change this flow and reduce forces. Using ANSYS Fluent for an unsteady flow simulation, we can perform a Vortex Shedding Fluent analysis to see how grooves affect the flow separation and the resulting lift and drag coefficients.

Simulation Process: Fluent Setup, Unsteady Laminar Flow for Bluff Body Analysis

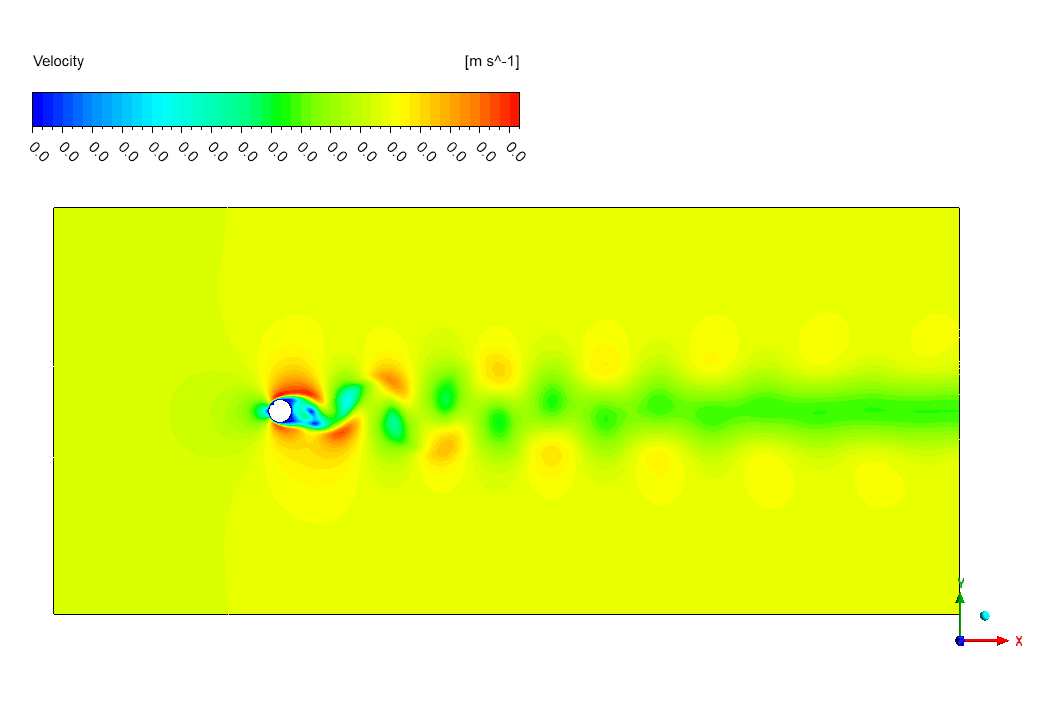

To perform this Grooved Cylinder Fluent simulation, we first created the geometry of both a smooth and a grooved cylinder in ANSYS Design Modeler. A high-quality, structured grid was then generated using ANSYS Meshing. This fine mesh is critical for accurately capturing the flow details in the boundary layer right next to the cylinder’s surface. In ANSYS Fluent, we set up an unsteady, or transient, simulation because vortex shedding is a time-dependent event. The flow was defined as laminar. We also set up monitors to calculate the forces on the cylinder, specifically the lift and drag coefficients, throughout the simulation.

Figure 1: The computational domain for the Flow Around a Cylinder CFD simulation.

Post-processing: CFD Analysis, Flow Separation Dynamics and Force Coefficients

This simulation allows us to precisely quantify the effect of the grooves. The calculated drag coefficient for the grooved cylinder was 1.286, a small but measurable improvement over the smooth cylinder’s drag coefficient of 1.3. This proves the grooves provide a slight drag reduction. The oscillating lift coefficient was found to be 0.0394 for both cylinder types, indicating that while the drag was slightly reduced, the fundamental instability causing the side-to-side forces remains. This is critical information for an engineer, as the frequency of this lift force oscillation (known as the Strouhal number) is often more important for predicting vibrations than the magnitude of the drag itself. The most important achievement of this simulation is its ability to precisely measure the minor 0.98% drag reduction caused by the grooves while confirming that the magnitude of the lift oscillations remains unchanged, providing engineers with the exact quantitative data needed to evaluate the effectiveness of this passive flow control method for real-world applications.

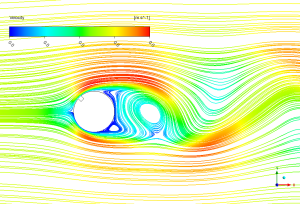

Figure 2: Velocity streamlines from the Vortex Shedding of Grooved Cylinder CFD analysis, visualizing the flow pattern.

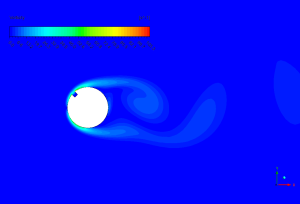

The vorticity contour provides a professional visual that acts as a diagnostic tool for the flow structure. From an engineering standpoint, this visual confirms the formation of the von Kármán vortex street behind the cylinder. We can analyze how vortices are shed alternately from the top and bottom surfaces of the cylinder. This periodic shedding is the direct cause of the oscillating forces that can lead to dangerous structural vibrations. The grooves on the cylinder surface act as a passive flow control device. They subtly alter the point where the flow separates from the cylinder’s body, which in turn changes the size and shape of the low-pressure wake region behind it.

Figure 3: A vorticity contour from the Flow Separation Analysis, showing the classic von Kármán vortex street.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€180 Original price was: €180.€150Current price is: €150.

€220 Original price was: €220.€115Current price is: €115.

Reviews

There are no reviews yet.