In this comprehensive guide, we’ll explore the Volume of Fluid (VOF) model – one of the most powerful approaches in Computational Fluid Dynamics (CFD) for modeling multiphase flows with clearly defined interfaces.

Contents

Toggle

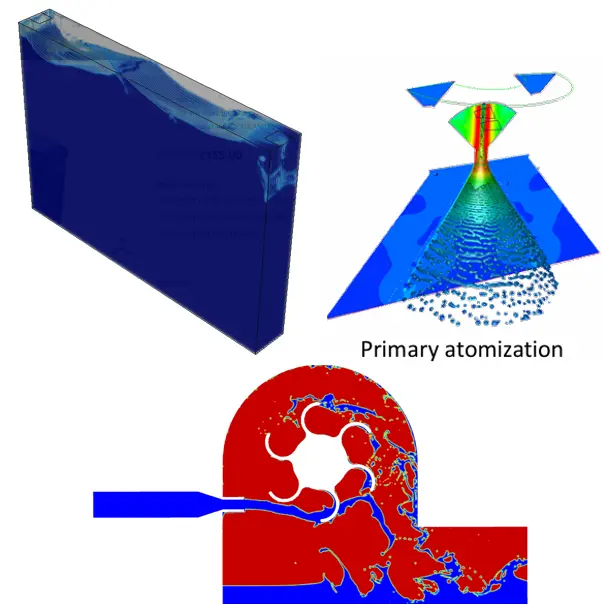

Figure 1: Application areas for VOF with visual examples

What is Multiphase Flow in CFD?

Multiphase flow refers to the simultaneous flow of materials with different states or phases. These could be combinations of:

- Gas-liquid flows (air bubbles in water)

- Liquid-liquid flows (oil and water)

- Solid-liquid flows (particles in fluid)

For a deeper understanding of different flow patterns, check our detailed blog on Different Regimes of Two-Phase Flow, where we explore various flow regimes including bubble flow, slug flow, annular flow, and more.

What is the VOF Model in CFD?

The Volume of Fluid (VOF) model is a surface-tracking technique that works on a fixed Eulerian mesh. It is designed for two or more immiscible fluids where the position of the interface between those fluids is of interest.

Key characteristics of the VOF method include:

- Single set of momentum equations shared by the fluids

- Volume fraction tracking throughout the computational domain

- Sharp interface representation between immiscible fluids

- Conservation of mass for each phase

Applicability of Volume of Fluid Model

The VOF model shines when working with specific types of multiphase flows. Understanding its applicability is crucial for selecting the right approach for your simulation needs.

When to Use VOF Model?

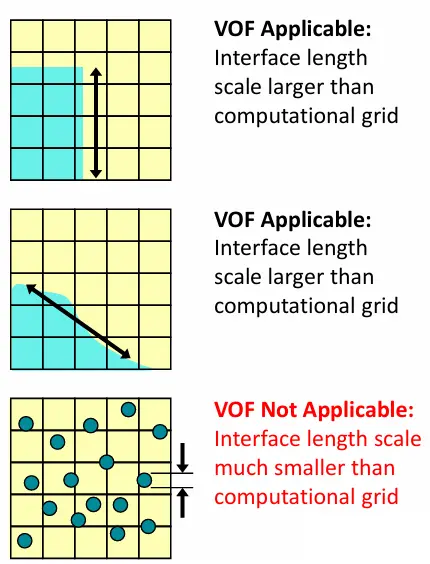

The Volume of Fluid model performs optimally when the interface length scale is larger than your computational grid. This is critical because VOF tracks the interface between phases using volume fractions in each cell. When interfaces are well-defined and span multiple cells, VOF can accurately capture their dynamics and shape.

However, VOF is not appropriate when the interface length is small compared to your computational grid. In these cases, the model struggles to accurately represent the interface physics. A key limitation occurs when modeling dispersed phases with many small bubbles or droplets. As the interface length scale approaches the grid scale, accuracy decreases significantly. For these scenarios, alternative approaches like Eulerian or mixture models often provide better results.

Additionally, VOF cannot model two gas phases since they mix at the molecular level rather than forming distinct interfaces.

Figure 2: Applicability of VOF multiphase model

Common Applications of VOF Model

The VOF model is used in many industrial applications. Some of the more famous applications include:

- Free surface flows such as in canals and open channels

- Sloshing phenomena in tanks and containers

- Prediction of water behavior in dam break simulations

- Bubble flow and motion of large bubbles in liquid

- Jet breakup and atomization processes

- Wave-structure interactions in marine engineering

- Liquid-liquid interfaces in oil and water separation

- Jet breakup scenarios where liquid streams disintegrate into droplets

- Motion of large bubbles rising through a liquid medium

- Dam break simulations tracking water movement after failure

- Steady or transient tracking of any liquid-gas interface

Want to see these applications in practice? Check our Multiphase CFD Simulation Tutorials for hands-on examples.

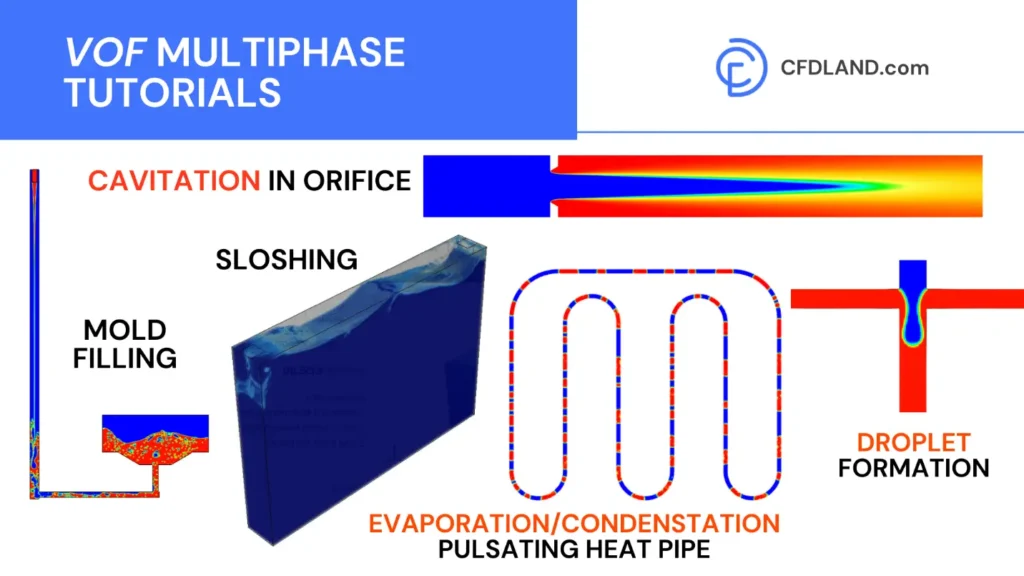

Figure 3: Some practical examples provided in our CFD SHOP about VOF Multiphase model CFD simulations

VOF Model Equations: One-Fluid Approach

The VOF model uses a single-fluid approach with shared properties weighted by the volume fraction. The governing equations include:

- Continuity equation for the mixture:

![]()

- Momentum equation for the mixture:

![]()

- Volume fraction equation:

![]()

Where:

- αq represents the volume fraction of phase q

- 0 ≤ αq ≤ 1 with Σαq = 1

- Properties like density and viscosity are weighted averages based on volume fraction

Interface Tracking in VOF

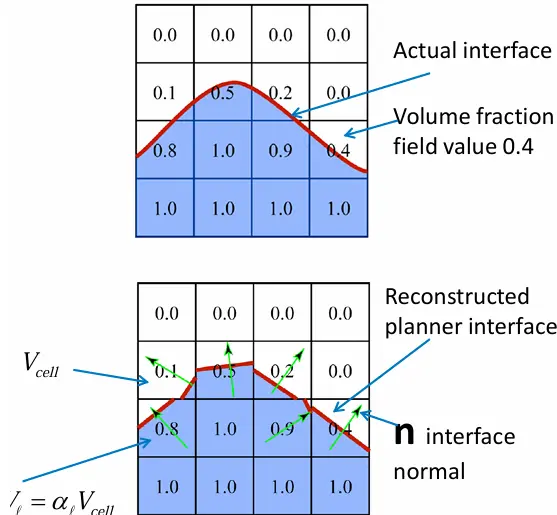

The Volume of Fluid method employs a sophisticated approach to tracking the interface between immiscible fluids. Unlike other multiphase flow models, VOF doesn’t track each interface explicitly, but instead uses a clever volume-based representation system.

In VOF CFD simulation, the phase interface is represented by the liquid volume fraction (αl) in each computational cell. As shown in the image, cells can contain varying amounts of each fluid, with volume fraction values between 0 and 1. A value of 0 indicates the cell contains only the secondary phase, while 1 means it contains only the primary phase.The actual interface (shown as a red curved line in the top diagram) passes through cells with intermediate volume fraction values. The interface tracking process follows three key steps:

- Representation: The model tracks the liquid volume fraction in each cell rather than explicitly tracking the interface location.

- Interface reconstruction: Once volume fractions are known, the model reconstructs the interface geometry. It calculates the normal direction to the interface using the gradient of the volume fraction field (∇αl). The interface is assumed to be planar within each cell, positioned to satisfy the known volume fraction.

- Interface movement: The interface evolves over time by solving the phase continuity equation that governs the convection of the liquid volume fraction field. This equation moves the volume fraction values based on the underlying fluid velocity.

The bottom diagram shows how the interface reconstruction creates a piecewise linear approximation (green lines) of the actual curved interface. This “stair-step” representation becomes smoother with finer mesh resolution. The normal vector (n) to each interface segment is crucial for accurate surface tension calculations and proper interface advection.

Figure 4: Interface tracking in VOF multiphase model

By using this approach, VOF simulations can deal with coalescence, complex interface deformations, and breakup without requiring any special treatments or connectivity. Free surface flows, droplet formation, and other applications with significant interface dynamics are ideal for VOF because the interface can freely evolve according to the underlying physics.

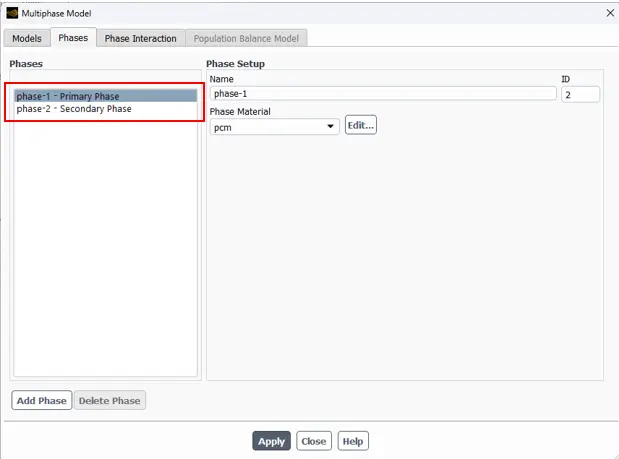

Defining Phases in VOF Simulation- ANSYS Fluent

For a successful VOF simulation, you must properly define:

- Primary and secondary phases (can generally be defined arbitrarily)

- Material properties for each phase

- Initial conditions for volume fractions

Figure 5: Primary & Secondary phases in VOF Multiphase panel

Tips for phase definition:

- Set the dispersed phase as the secondary phase

- Set compressible ideal gas (if any) as the primary phase for better solution stability

VOF Formulation

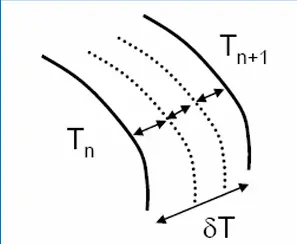

Explicit vs. Implicit Schemes for VOF

In this section, we’ll talk about the VOF specific settings and options. The first option that we will investigate here is the difference between volume fraction explicit or implicit formulation. The main difference between these two options is in fact in the way the volume fraction equation is discretized and solved. If the volume fraction’s value from the previous iteration is used in the equation for calculating the volume fraction in the current iteration, then the implicit method is used, while if the values from previous iterations are not used, then the explicit method is employed. Each of these methods have their own merits. For example, by using explicit method, the computational cost in each iteration is reduced. However, the time step size must be decreased. The opposite can be said about implicit method. This is one of the critical decisions in VOF modeling.

Explicit VOF Scheme

The explicit scheme offers:

- Superior interface sharpness through Geo-Reconstruct discretization

- Better numerical accuracy than implicit formulation

- Suitability for surface tension dominated flows

- Time step limitations based on Courant number stability criterion

- Only available when the transient solver is enabled

Figure 6: Explicit formulation in VOF multiphase panel – ANSYS Fluent

When using the explicit method, the physical time step defined by the user will be subdivided into multiple time steps to solve the volume fraction equation accurately. Now, each of these sub time steps must satisfy the courant number based time step size criterion to be deemed acceptable. By setting the courant number to less than unity, it is ensured that the interface will not cross more than one cell in each time step, and therefore you may be certain regarding the accuracy of your results. Moreover, if you are wondering how the sub time step sizes are calculated, you can take a look at the presented formula.

![]()

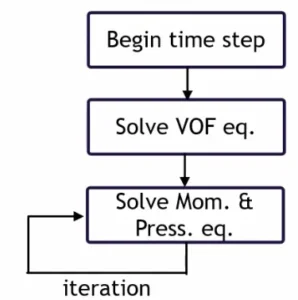

Figure 7: Interface location update during one time step – Explicit VOF formulation

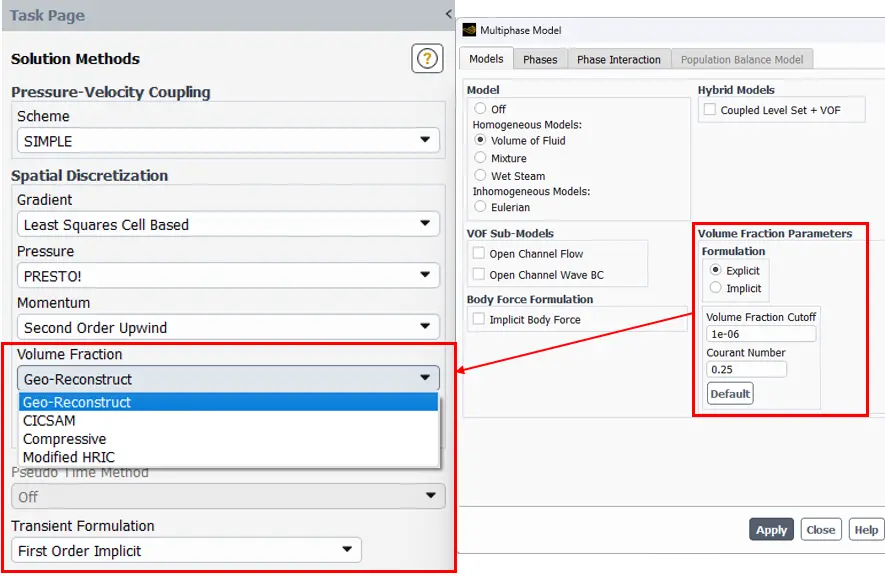

Implicit VOF Scheme

And finally, regarding the implicit formulation, this method solves phase continuity equation iteratively together with momentum and pressure.

The implicit scheme provides:

- No Courant number limitation (can use larger time steps)

- Compatibility with both steady-state and transient calculations

- Less accuracy in interface representation due to numerical diffusion

- Better computational efficiency for many applications

Interface Tracking Schemes and Accuracy

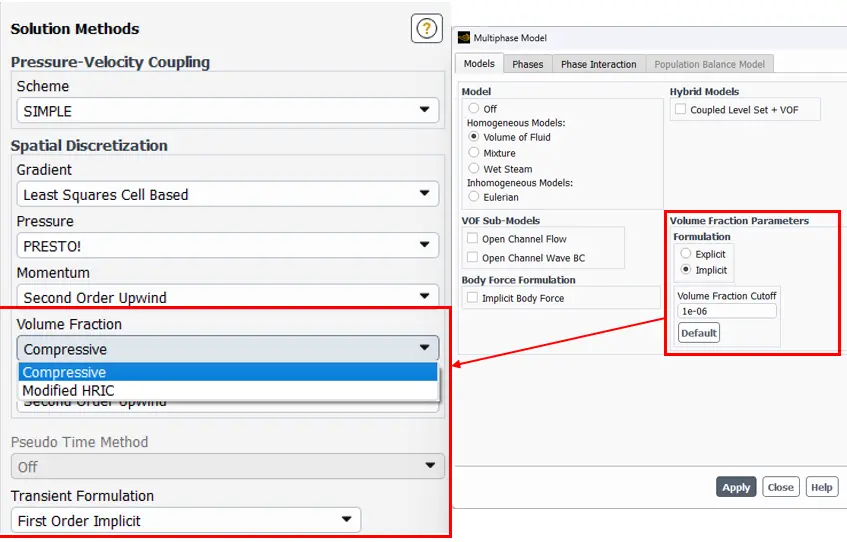

The accuracy of interface representation depends heavily on the chosen discretization scheme. The Volume fraction discretization methods provided in ANSYS Fluent for each explicit and implicit formulation are presented in the following figures:

Figure 8: Available volume fraction discretization methods provided in ANSYS Fluent for a) explicit b) implicit formulation

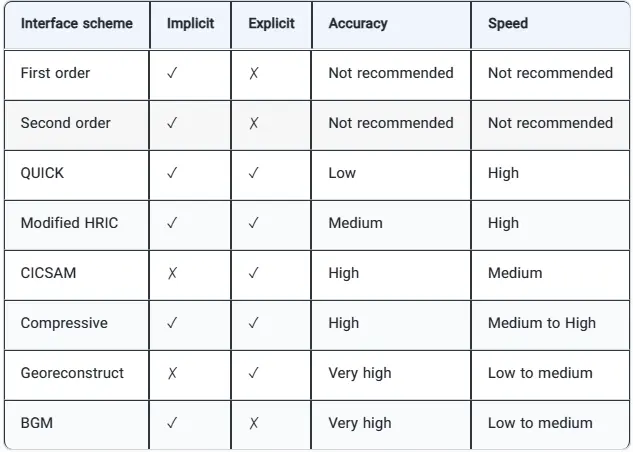

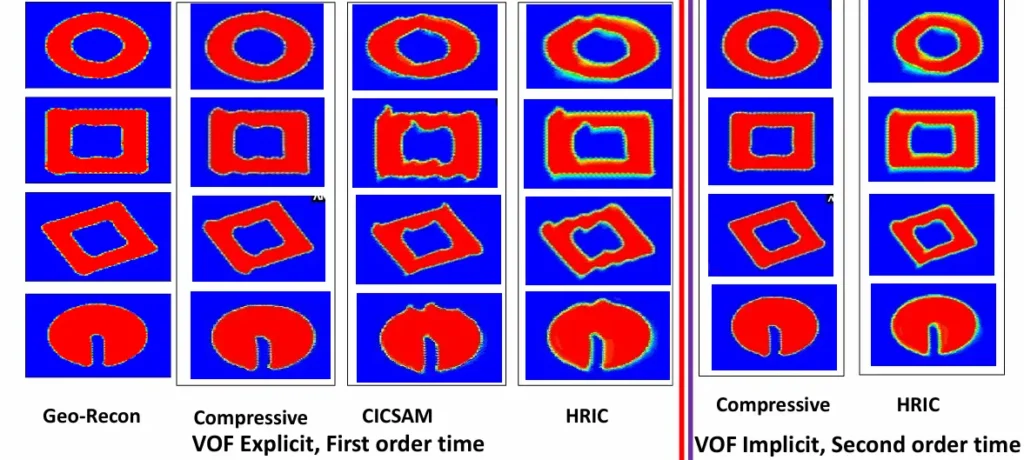

You can clearly see and understand the differences between each of the available methods. As shown in the following table provided by ANSYS.Inc, geo reconstruct and compressive methods provide great accuracy when explicit format is used, and compressive for the implicit method. However, their computational cost is greater compared with other methods. This table summarizes all features of each interface tracking schemes:

Figure 9: Interface tracking schemes provided in ANSYS Fluent – VOF multiphase modeling

As stated before, the choice of interface tracking scheme dramatically impacts the accuracy of your VOF simulation results. As shown in the visual comparison, the Geometric Reconstruction scheme delivers the sharpest interface representation across various test cases including circular interfaces, rectangular regions, and complex C-shaped geometries. For demanding multiphase flow applications where interface sharpness is critical, Geo-Reconstruct offers superior fidelity but requires the explicit VOF formulation. The Compressive scheme provides an excellent balance between accuracy and computational efficiency, working well in both explicit and implicit formulations. Meanwhile, CICSAM shows moderate interface smearing but handles complex shapes reasonably well, while HRIC offers faster solution times at the expense of some interface diffusion. Understanding these trade-offs is essential when selecting the appropriate scheme for your specific CFD multiphase flow application, whether you’re modeling free surface flows, bubble dynamics, or interfacial phenomena where capturing the exact interface shape is paramount.

Figure 10: Visual comparison between volume fraction discretization schemes – provided by ANSYS.Inc

Steady-state VOF schemes

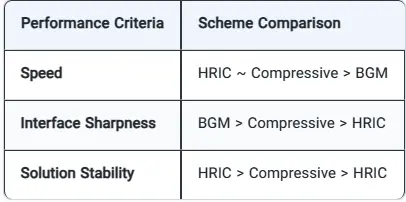

When conducting steady-state VOF simulations, the choice of interface discretization scheme significantly impacts both solution quality and computational performance. For engineers working on multiphase CFD projects where transient behavior isn’t the primary concern, understanding the tradeoffs between available steady-state schemes is essential for optimal results.

Figure 11: Steady state VOF discretization schemes comparison

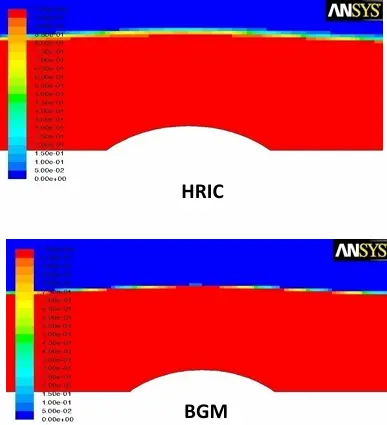

The table shows how the three main interface tracking schemes compare for steady-state VOF modeling. Modified HRIC runs fastest and is most stable, making it great for complex industrial problems. The Compressive scheme offers a good balance of speed, accuracy, and stability for most multiphase flow simulations. BGM (Bounded Gradient Maximization) creates the sharpest interfaces – almost as good as what you’d get from transient simulations – but takes longer to solve and might be less stable. When choosing a scheme for your multiphase CFD project, think about what matters most: speed, interface sharpness, or reliability. Each scheme has strengths that make it better suited for different types of multiphase flow problems.

The BGM scheme is introduced to obtain sharp interfaces with the VOF model, comparable to that obtained by geometric reconstruction scheme.

- Achieves sharp interfaces with 1-cell interface thickness

- Only available for steady-state solver

- Offers excellent interface sharpness compared to other schemes

Figure 12: BGM & HRIC visual comparison

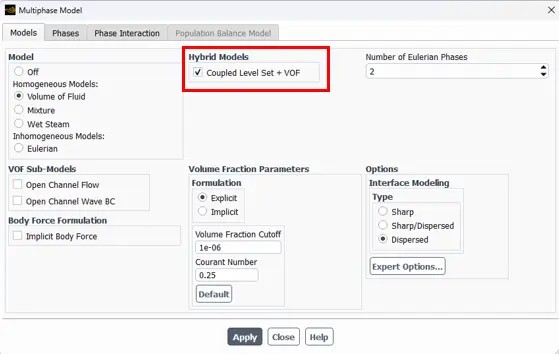

Coupled Level Set VOF Method

The Coupled Level Set VOF method combines two interface tracking approaches to leverage their strengths. Standard VOF excels at mass conservation but sometimes struggles with accurate interface curvature calculation. The Level Set method, in contrast, maintains a smooth function that makes interface normal and curvature calculations more accurate but can suffer from mass conservation issues. The coupled approach uses the Level Set function to compute accurate interface normals and curvature for surface tension calculations, while using the VOF method for fluid transport to maintain mass conservation. This hybrid technique is particularly valuable for applications where both accurate surface tension effects and strict mass conservation are critical, such as microfluidic devices, inkjet printing, or detailed bubble dynamics simulations where interface shape significantly affects the flow physics.

Figure 13: Coupled level set + VOF hybrid model in ANSYS Fluent

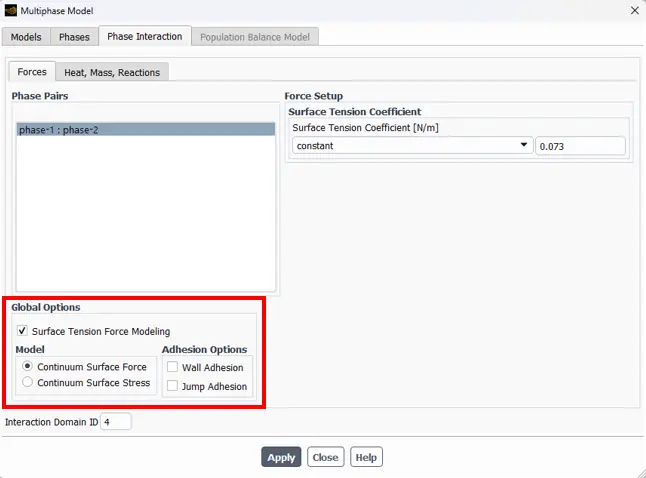

Surface Tension and Wall Adhesion Modeling

Surface Tension Models

Surface tension is critical for many multiphase applications, especially when:

- Capillary number (Ca) < 1 for flows with Re < 1

- Weber number (We) < 1 for flows with Re > 1

Figure 14: Surface tension modeling in ANSYS Fluent

ANSYS Fluent offers two different surface tension models for multiphase flow simulations

The first option is the Continuum Surface Force (CSF) Model, which uses a non-conservative approach. In this model, the interface forces are converted to volumetric forces that can be added to the momentum equations. CSF computes surface curvature directly from local gradients at the interface.

The second option is the Continuum Surface Stress (CSS) Model, which follows a conservative approach. This model doesn’t need to calculate curvature explicitly, making it perform better in areas with poor mesh resolution. CSS can also simulate Marangoni convection effects, which occur when surface tension varies across the interface.

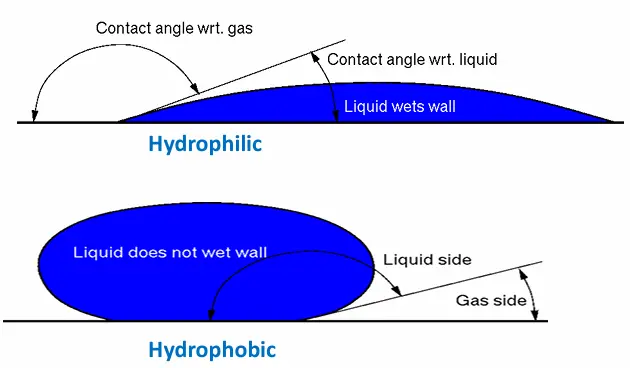

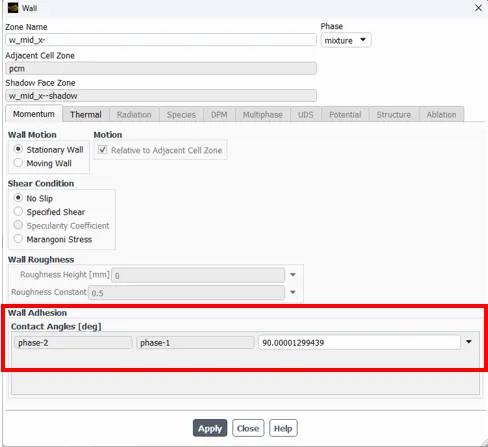

Wall Adhesion and Contact Angle Modeling

For accurate VOF simulations involving walls, proper wall adhesion modeling is essential. This feature helps create realistic meniscus shapes by accounting for wettability effects at solid boundaries. The contact angle implementation determines how fluids interact with walls, as shown in the diagram. This is particularly important for multiphase CFD applications where a liquid meets both a solid surface and a gas, creating either hydrophilic or hydrophobic behavior.

Using the right surface tension model in your VOF simulation significantly improves accuracy when modeling bubbles, droplets, or any flows where interfacial forces are important. The choice between CSF and CSS depends on your specific simulation requirements and mesh quality.

Figure 15: wall adhesion examples with hydrophobic and hydrophilic surfaces – Provided by ANSYS.Inc

Figure 16: Contact angle definition in ANSYS Fluent after activating wall adhesion

Boundary Conditions For VOF Modeling

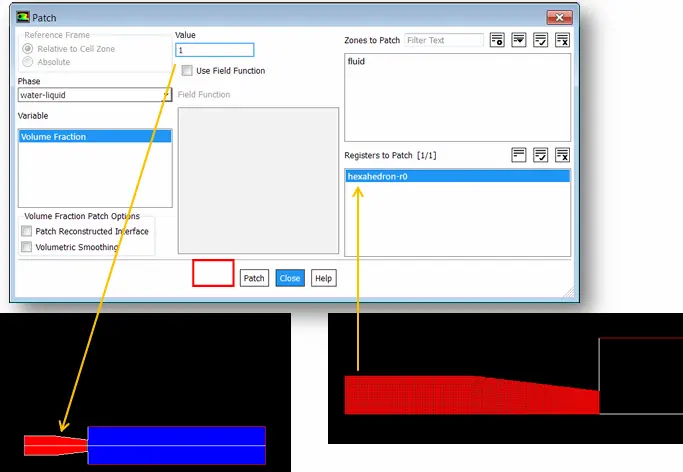

Setting up the right boundary conditions is essential for successful VOF simulations. When defining boundaries in your multiphase flow model, remember that only one fluid phase should enter or exit at any inlet or outlet. The volume fraction should be either 0 or 1 at these locations. For pressure inlets, you need to patch the volume fraction to 1 in the cells next to the boundary for the incoming phase. Always set proper backflow volume fraction values at outlets. Avoid using outflow boundary conditions when working with multiphase flows as they can cause convergence problems.

The initial conditions are just as important for VOF modeling. You can create proper starting conditions in three main ways. First, by patching flow variables directly into specific fluid zones. Second, by using volume registers that you create with the Adapt tool. Third, by using the “Patch Reconstructed Interface” option to get sharper fluid interfaces at the start of your simulation. Good initial setup helps your VOF simulation converge faster and produce more accurate results. When selecting solution strategies and time steps, pay attention to the specific needs of your multiphase flow problem to ensure stability throughout the calculation process.

Figure 17: Patching volume fraction in VOF modeling

Initial conditions can be generated by:

- Patching flow variables in specified fluid zones

- Using volume registers generated with the Adapt tool

- Utilizing the “Patch Reconstructed Interface” option for sharper initial interfaces

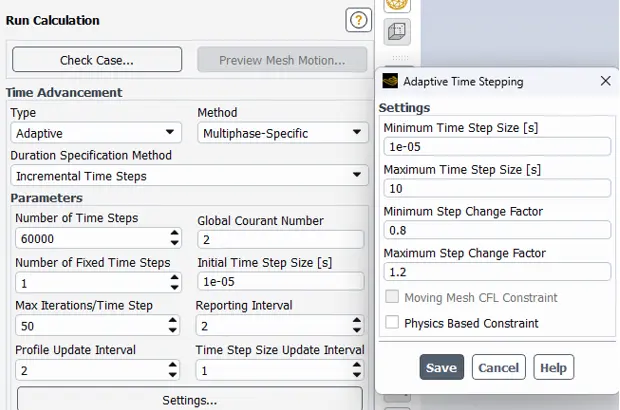

Time Step Selection for VOF

Appropriate time step selection is crucial for stable VOF simulations:

Time step can be estimated as:

![]()

Where:

- Vcell,min is the minimum cell volume (from Grid Check panel)

- U is the velocity scale of the problem (e.g., inlet velocity)

Tip: Start with smaller time step size for a few time steps, and then increase the time step size. If divergence persists, try switching off Skewness Neighbor Coupling in the Solution Controls panel.

Variable Time Stepping

For optimized simulation efficiency, you can employ variable time stepping technique. This automatically adjusts time step based on global Courant number. Plus, it allows setting maximum and minimum time step values witch optimizes computational effort, especially for explicit schemes.

Figure 18: Adaptive time stepping in ANSYS Fluent

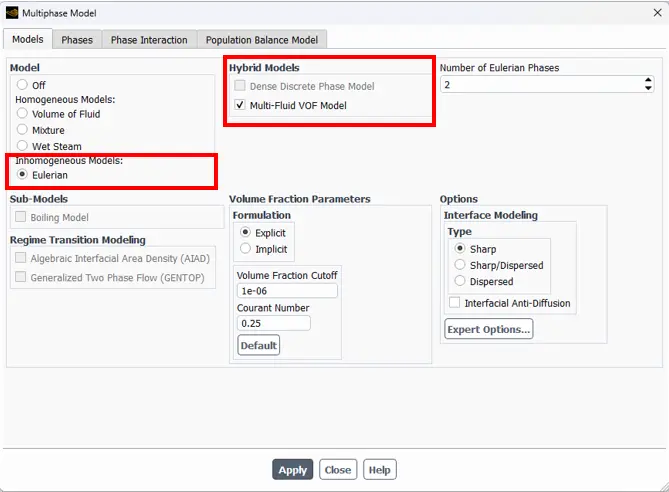

Multi-Fluid VOF Model

The Multi-Fluid VOF Model, which is a hybrid between VOF and Eulerian models, can be used for such cases where separate velocity fields for each phase are beneficial. Separate velocity and temperature fields solved for each phase. Interaction between phases is modeled via drag. It is particularly useful for bubble columns with head space.

Figure 19: Multi-fluid VOF model in ANSYS Fluent

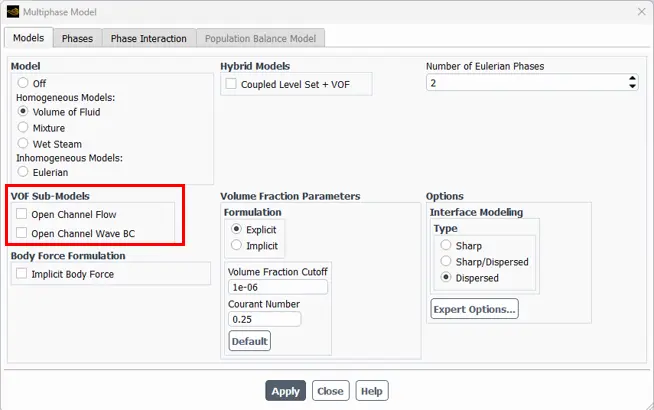

Open Channel Flow (VOF Sub-models)

When simulating rivers, spillways, or channels with a free surface, the Open Channel Flow option in VOF provides specialized boundary conditions. This feature helps model water flow with a clearly defined air-water interface. In the Open Channel settings, you can specify the free surface level, flow velocity, and volume fraction at boundaries. The model handles both subcritical and supercritical flows, allowing for proper wave propagation. This sub-model is particularly valuable for hydraulic engineering applications like dam spillways, floodplains, and irrigation channels. When combined with wave boundary conditions, it can simulate complex scenarios such as wave impact on coastal structures or offshore platforms, as shown in the example of wave interaction with floating structures. The Open Channel approach significantly improves convergence and accuracy for these types of simulations compared to standard VOF setups.

Figure 20: Open channel flow sub-model in VOF multiphase panel

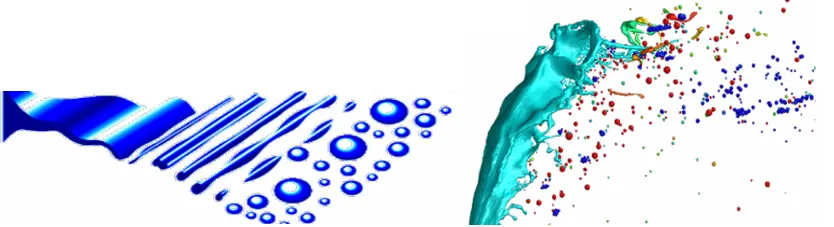

VOF to DPM Model Transition

The VOF to DPM transition offers a powerful hybrid approach for simulating liquid jet breakup in multiphase CFD. This method combines the strengths of both models to handle complex spray simulations efficiently. The process works in stages, starting with Volume of Fluid (VOF) to accurately capture the nozzle flow and initial droplet formation where interface tracking is critical. As simulation progresses, the model automatically detects when droplets become too small for effective mesh resolution in the VOF framework. These small droplets are then converted to Discrete Phase Model (DPM) particles, allowing the simulation to continue tracking their behavior without requiring extremely fine mesh everywhere. This smart transition saves significant computational resources while maintaining accuracy. The hybrid approach also supports modeling secondary breakup and heat/mass transfer effects in the DPM calculations, making it ideal for spray applications, fuel injection systems, and atomization processes. This technique is especially valuable when simulating complex systems where both the initial liquid jet dynamics and the resulting dispersed droplet behavior are important to capture.

Figure 21: VOF to DPM transition after primary injection

Want to learn how to set up similar simulations? Check our Multiphase CFD Tutorials for detailed guides.

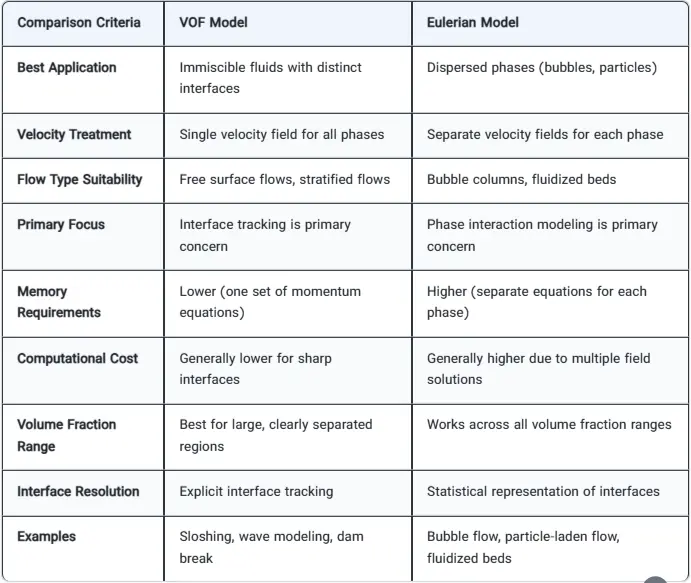

Difference between VOF and Eulerian Models

Understanding when to use VOF versus Eulerian approach is critical for successful multiphase simulations. The proper selection depends on the specific flow physics of your application.

Figure 22: Comparison between VOF and Eulerian multiphase models

Conclusion

Volume of Fluid (VOF) modeling offers engineers a powerful toolkit for simulating multiphase flows across diverse applications. We’ve explored the key aspects of this methodology, from interface capturing schemes (Modified HRIC, Compressive, and BGM) to specialized surface tension models (CSF and CSS) that account for crucial interfacial physics. Proper setup of boundary conditions and initial conditions significantly impacts simulation success, while advanced features like Open Channel Flow modeling, Body Force Formulation, Interface Modeling options, and the hybrid Coupled Level Set approach extend VOF capabilities to more complex scenarios. The VOF-to-DPM transition bridges the gap between continuous and discrete phase modeling for spray applications. Understanding when to use VOF versus Eulerian approaches helps engineers select the appropriate framework based on whether interface tracking or phase interaction dominates their specific multiphase CFD problem. By mastering these techniques and best practices, simulation engineers can achieve more accurate, efficient, and reliable results across industrial and research applications where multiple fluids interact in complex ways.