In this article, we’ll look at how a heat exchanger works and why it’s so important in many places. First of all, heat exchangers are special devices that help move heat from one liquid or gas to another. So when you’re wondering how does the heat exchanger work, it’s actually quite simple – it allows heat to move from hot fluids to cold ones without letting them mix together. Also, there are many types of these devices, such as plate heat exchangers, and we’ll explain how does a plate heat exchanger work too. In addition, we’ll show you the different ways heat exchangers are used in homes, cars, and big factories. Furthermore, we’ll talk about how engineers use computer programs like ANSYS Fluent to test and improve heat exchanger designs before building them. If you want to learn more about this testing process, you can check out our helpful CFD tutorials about heat exchangers where we show these simulations step by step. Overall, heat exchangers are amazing devices that save energy and make many systems work better!

Contents

Toggle

What is a heat exchanger?

A heat exchanger is a special device that moves heat from one fluid to another. So, how does a heat exchanger work? Well, it’s actually quite simple! In a heat exchanger, hot fluid gives its heat to cold fluid without the two fluids mixing together. This happens because the fluids flow through separate spaces but are close enough for heat transfer to occur.

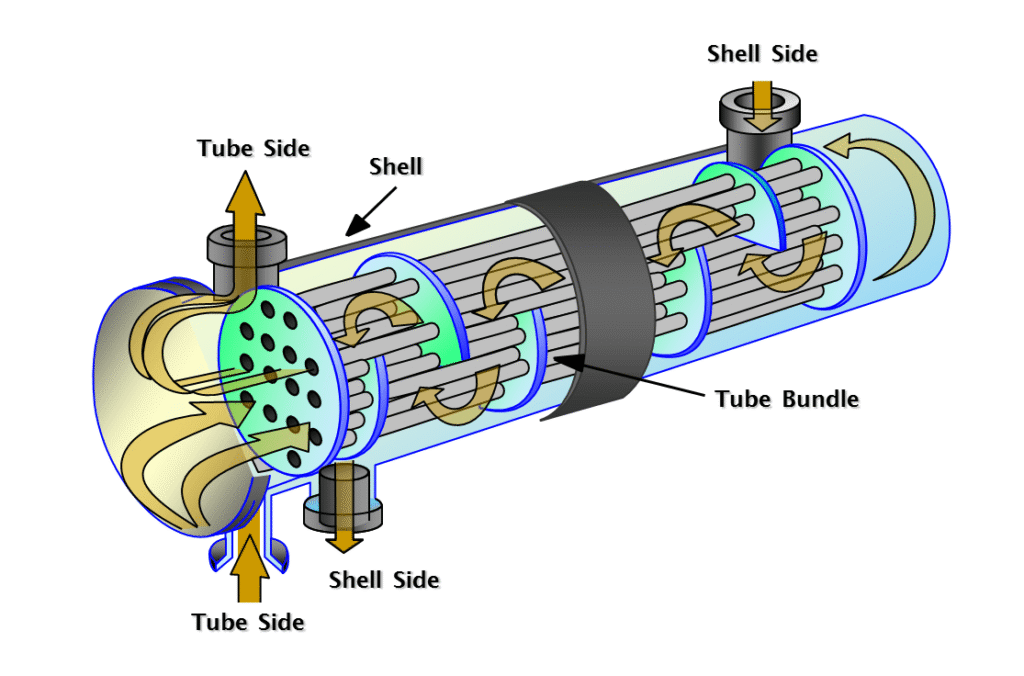

Figure 1: Schematic of shell & tube heat exchanger – how heat transfers

In the picture above, you can see a common type called a shell and tube heat exchanger. As you can see, it has two main parts – the shell (the outer container) and the tubes inside it. One fluid flows through the tubes (the “tube side”), and the other fluid flows around the tubes in the shell space (the “shell side”).

The working principle of heat exchangers is based on a simple fact – heat always moves from hot things to cold things. So, if you put a hot fluid and a cold fluid near each other (but not mixing), the heat will naturally move from the hot one to the cold one. This is exactly how the heat exchanger works in everyday applications!

For example, in your car’s radiator (which is also a type of heat exchanger), hot coolant from the engine gives its heat to the cooler outside air. Similarly, in your refrigerator, a heat exchanger helps remove heat from inside the fridge to keep your food cool.

There are many types of heat exchangers besides the shell and tube design shown above. Some use plates instead of tubes, while others might use different arrangements. But they all work with the same basic principle – they help transfer heat from one fluid to another without letting the fluids mix together.

How does a heat exchanger work?

Heat exchangers work by moving heat from one fluid to another through a solid wall between them. First of all, it’s important to know that heat always travels from hot things to cold things. So, when a hot fluid and a cold fluid are kept apart by a thin metal wall, the heat naturally flows from the hot fluid to the cold one.

The main factor that determines how effectively a heat exchanger works is the overall heat transfer coefficient. This special number tells us how easily heat can pass through all the layers in the exchanger. If you want to understand this concept better, you can read our detailed article about the overall heat transfer coefficient and how it affects exchanger performance. Furthermore, most of the heat in these devices moves through convective heat transfer – this happens when fluid motion carries heat away from the surface. In fact, engineers carefully design the flow patterns to improve this process. To learn more about this important mechanism, check out our guide on convective heat transfer and its principles.

There are three main ways fluids can flow in a heat exchanger:

-

Parallel flow – Both fluids enter from the same end and flow in the same direction. In this design, the cold fluid never gets hotter than the exit temperature of the hot fluid.

-

Counterflow heat exchanger – The fluids flow in opposite directions. This arrangement is usually more efficient because it keeps a more even temperature difference throughout the entire exchanger.

-

Cross-flow heat exchanger – The fluids flow across each other at right angles. This is very common in car radiators and air conditioning systems. We’ve actually created a detailed parametric study on cross-flow heat exchangers using CFD simulation if you’re interested in seeing how these systems are analyzed.

Figure 2: Parametric study on cross-flow heat exchangers using CFD simulation

Additionally, heat transfer in exchangers happens through three main ways:

- Conduction (heat moving through the solid wall)

- Convection (heat carried by fluid movement)

- Sometimes radiation (though this usually isn’t as important)

The efficiency of a heat exchanger is also affected by problems like fouling (when dirt and deposits build up on surfaces) and the speed of the fluids. So, engineers carefully choose materials and flow rates to make sure the heat exchanger works as well as possible for its specific job!

Types of heat exchanger

There are many different types of heat exchangers that can be found in various applications. In fact, each type has special features that make it good for certain jobs. Let’s look at the main types of heat exchangers and understand how these heat exchangers work in different situations.

Shell and tube heat exchanger

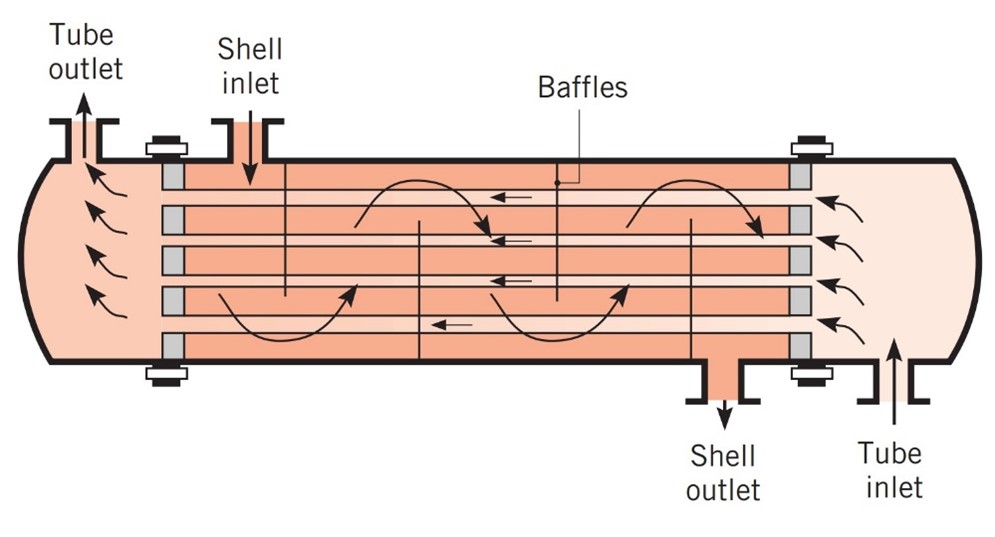

Shell and tube heat exchangers are very common and widely used in many industries. This type has a large outer container called a shell and many small tubes inside it. So, how does shell & tube heat exchanger work? Well, one fluid flows inside the small tubes, and another fluid flows around these tubes within the big shell. As the two fluids travel through the heat exchanger, heat moves from the hotter fluid to the cooler one through the walls of the tubes. This is the basic working principle of heat exchangers – heat naturally flows from hot areas to cold areas when they are close to each other. Shell and tube heat exchangers are very popular because they can handle really high pressures and temperatures. Also, they are strong and can be used for many years without major problems. Furthermore, they can be made from different materials like steel, copper, or even special alloys depending on what fluids will flow through them.

In addition, these heat exchangers come in different designs to solve specific problems. Some have fixed tube sheets where the tubes don’t move, while others have floating heads that allow the tubes to expand when they get hot. This flexibility makes shell and tube heat exchangers suitable for many jobs like cooling oil in refineries, generating steam in power plants, or processing chemicals.

Figure 3: Shell and tube heat exchanger with one shell pass and one tube pass, from Incropera et al., Fundamentals of Heat and Mass Transfer, 7th edition, Wiley.

Plate heat exchanger

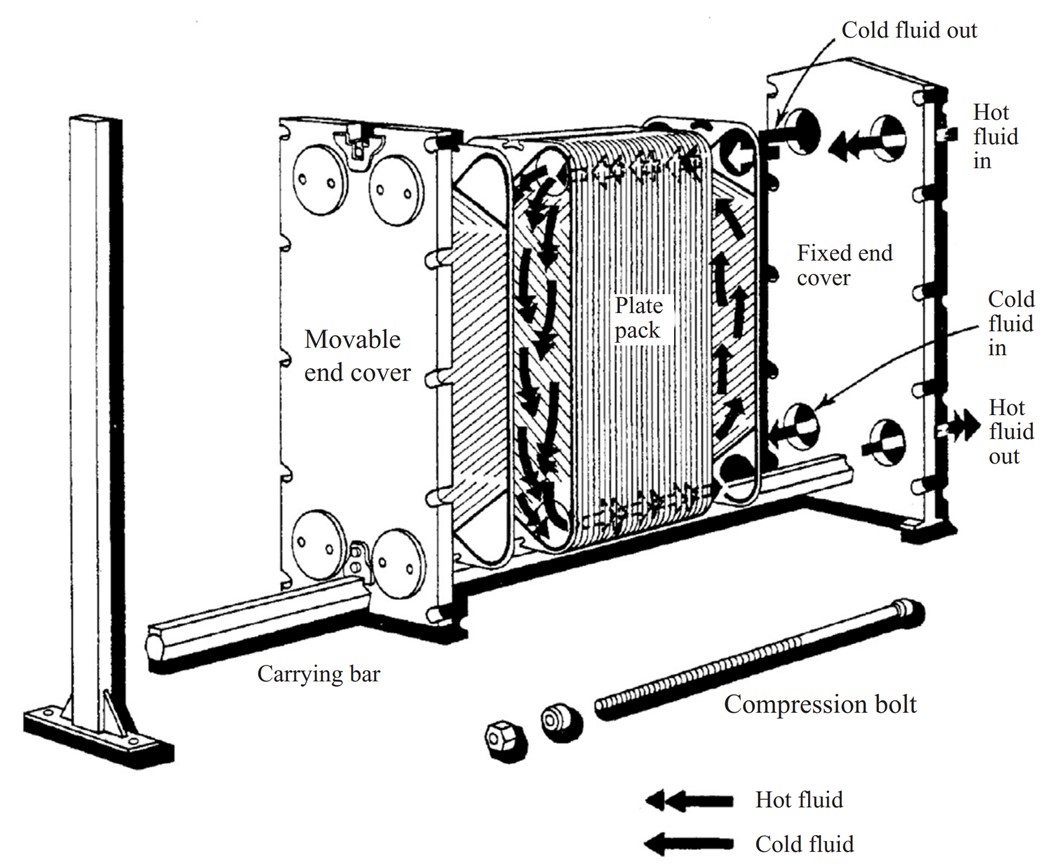

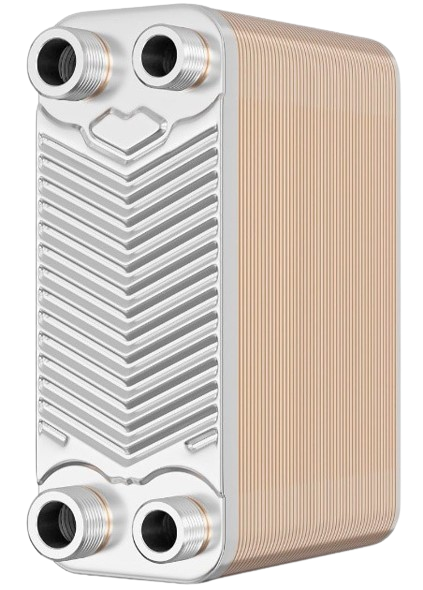

Plate heat exchangers work differently from shell and tube types. But how does a plate heat exchanger work? It uses many thin, metal plates stacked together with small gaps between them. These plates usually have a wavy or corrugated pattern to create turbulence in the fluid flow. In a plate heat exchanger, the hot and cold fluids flow through alternate spaces between these thin plates. So, the hot fluid might flow through spaces 1, 3, 5, and so on, while the cold fluid flows through spaces 2, 4, 6, and so on. As a result, each fluid is constantly in contact with both sides of the plates, which helps heat move quickly from one fluid to the other. One big advantage of plate heat exchangers is that they transfer heat very efficiently. This is because the thin plates provide a very large surface area where the fluids can exchange heat. Also, the corrugated pattern of the plates creates turbulence, which helps mix the fluids and improves heat transfer even more.

Moreover, plate heat exchangers are usually smaller than other types with the same heating or cooling power. They are also easy to clean – you can simply take apart the plates and clean each one separately. In fact, this makes them perfect for food and beverage processing where cleanliness is very important.

Figure 4: Sketch of plate heat exchanger, from Robinson et al., mass and heat transfer: analysis of mass contactors and heat exchangers

Figure 5: Hrale Stainless Steel plate Heat Exchanger

Double-pipe heat exchanger

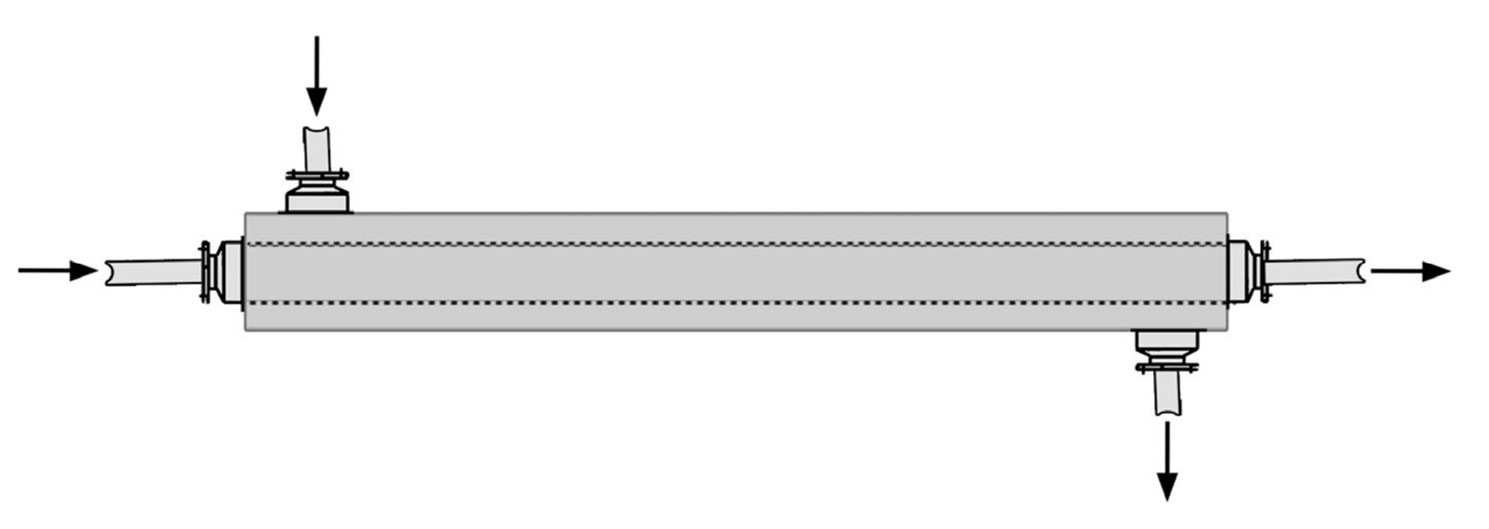

The double-pipe heat exchanger is the simplest type of all heat exchangers. So, how does this heat exchanger work? It’s basically just one pipe inside another larger pipe. One fluid flows through the inner pipe, and the other fluid flows through the space between the two pipes (called the annular space). This simple design makes double-pipe heat exchangers very easy to build and fix if something goes wrong. In fact, they’re often made from standard pipe sizes that are easy to find and replace. Also, this type can handle very high pressures, which makes it useful for certain jobs where safety is a big concern. However, double-pipe heat exchangers aren’t very space-efficient. They need a lot of floor space compared to other types that can transfer the same amount of heat. Furthermore, they’re usually only used when you don’t need to transfer large amounts of heat, such as in small processing plants or laboratory equipment. Despite these limitations, the simple and reliable nature of double-pipe heat exchangers makes them a good choice for specific applications. For instance, they work well in pilot plants (small test facilities) or in situations where you might need to frequently modify the system.

Figure 6: Double–pipe heat exchanger (cocurrent flow), from Robinson et al., mass and heat transfer: analysis of mass contactors and heat exchangers

Finned-Tube Heat Exchanger

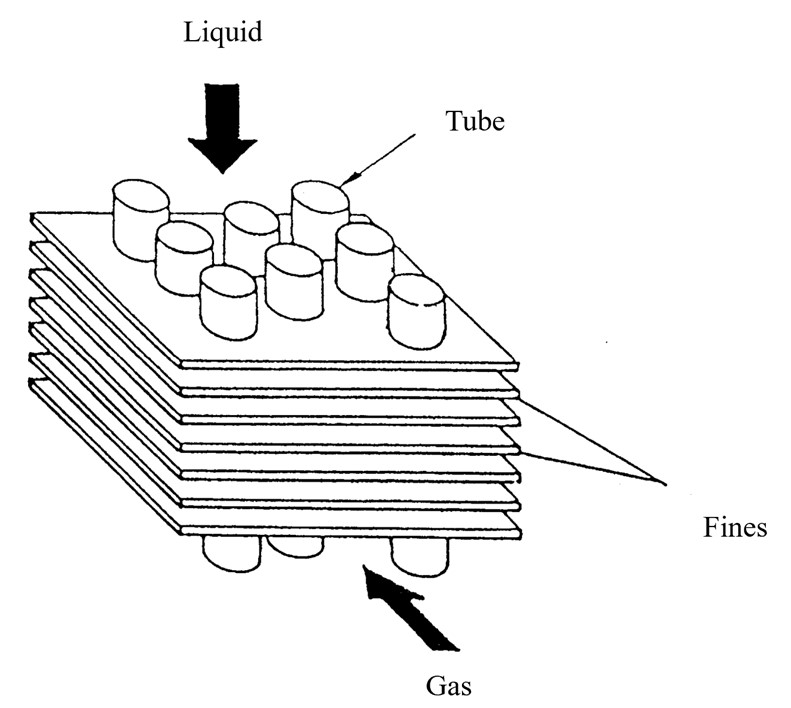

Finned-tube heat exchangers are specially designed for situations where one fluid is a gas (usually air) and the other is a liquid. But how does a finned-tube heat exchanger work? These have thin metal fins attached to the outside of the tubes to create more surface area. The reason for adding these fins is simple – gases like air aren’t very good at transferring heat compared to liquids. This is because gas molecules are far apart from each other and don’t carry heat as well as liquid molecules that are close together. So, the fins help by creating more surface area where the gas can touch and pick up or give off heat.

You can easily see finned-tube heat exchangers in everyday items. For example, the radiator in your car is a finned-tube heat exchanger where hot coolant flows through tubes while air passes across the finned surfaces. Similarly, the coils on the back of your refrigerator and the indoor unit of your air conditioner are also finned-tube heat exchangers. Additionally, the fins can come in different shapes and sizes depending on the specific needs. Some have straight fins, while others have wavy or spiral patterns to create more turbulence in the airflow. As a result, engineers can customize finned-tube heat exchangers to work efficiently in many different situations.

Figure 7: Schematic representation of core region of a fin–tube heat exchanger, from heat transfer enhancement in cross-flow heat exchangers using oval tubes and multiple delta winglets by S. Tiwari et al.

In conclusion, understanding these different types of heat exchangers helps engineers choose the right one for each specific job. Each type has advantages and limitations, so knowing how heat exchangers work allows us to use them effectively in everything from home appliances to massive industrial processes.

Heat exchangers applications

Heat exchangers have many important uses in our daily lives and in industry. In fact, these devices are all around us, even if we don’t always notice them. Let’s look at the various applications of heat exchangers in different fields.

- HVAC Systems: Heat exchangers are a key part of heating, ventilation, and air conditioning (HVAC) systems. For example, in your home air conditioner, a heat exchanger works by transferring heat from inside your house to the outside air. Also, in heating systems, they help move heat from a furnace or boiler to the air that circulates through your home.

Furthermore, modern HVAC systems often use special heat recovery exchangers. These smart devices capture heat from outgoing stale air and transfer it to incoming fresh air. As a result, buildings can save a lot of energy while still getting plenty of fresh air. Additionally, how heat exchangers work in HVAC systems affects how comfortable and energy-efficient buildings can be. In fact, engineers carefully choose the right type and size of heat exchanger to make sure buildings stay at just the right temperature without wasting energy.

- Power plants: Heat exchangers serve a critical function in power generation, playing essential roles in various types of power plants. In fossil fuel power plants, they convert thermal energy from burning fuel into steam, which subsequently drives turbines to produce electricity. Additionally, condensers, another type of heat exchanger, are employed to convert exhaust steam back into water, creating closed-loop systems. These components are pivotal not only in fossil fuel power plants but also in nuclear power plants and renewable energy systems like solar thermal power plants, where they facilitate the transfer of heat to water or steam, enabling the generation of electricity through turbine-driven processes.

Figure 8: Application of heat exchanger in power plants : Geothermal Heat Exchanger CFD Simulation, ANSYS Fluent Training

- Food processing: Heat exchangers are extensively utilized in diverse food processing applications to ensure product safety and quality. They play crucial roles in pasteurization, sterilization, cooking, drying, and cooling processes within the food and beverage production industry. By efficiently transferring heat, heat exchangers aid in heating liquids to kill bacteria during pasteurization, sterilizing food products, and facilitating the cooling process to maintain freshness and preserve product integrity.

- Oil and Gas Industry: Heat exchangers are pivotal in oil refineries and natural gas plants, facilitating heating, cooling, and condensing of hydrocarbons and process fluids. They aid in crude oil distillation, gas purification, and product condensation, ensuring efficient processing and product quality in these industries.

How does a heat exchanger work in a boiler?

In a boiler, high-temperature gases are produced by the combustion process. Pipes pass inside the boiler, carrying the desired fluid, usually water. The gases transfer their heat to this fluid, raising its temperature and possibly changing its phase to steam. Increasing the number of tubes, optimizing their arrangement, and adding fins can enhance heat transfer. Boilers are used in many industries, including fossil fuel power plants and some HVAC systems.

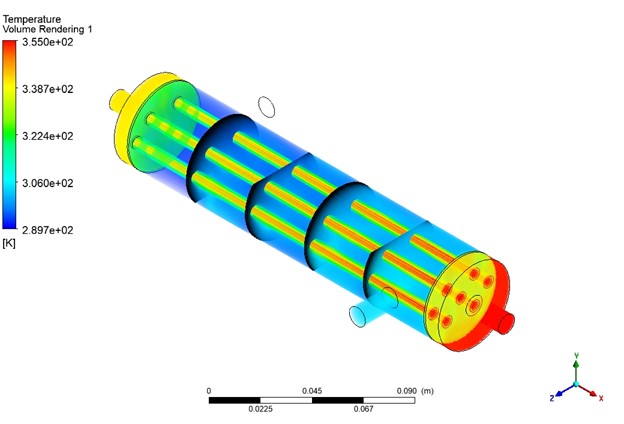

Simulation of heat exchangers by ANSYS Fluent

ANSYS Fluent is known for its ability to simulate a wide range of heat exchanger models across diverse industrial applications. The software allows users to create detailed models of complex geometries and provides various meshing methods for accurate simulations. With ANSYS Fluent, users can effectively simulate turbulent flow regimes, a crucial aspect of many heat exchanger applications.

In addition, the software offers advanced post-processing capabilities, enabling users to extract comprehensive performance data from the simulations. As a result, ANSYS Fluent serves as a valuable tool for analyzing and optimizing heat exchanger performance. However, it is essential for users to ensure the accuracy of their simulations by validating the results against experimental data or established benchmarks.

At CFDLAND, we have completed numerous Heat exchanger projects using ANSYS Fluent, all of which can be viewed in our CFD shop. Additionally, you can submit your CFD projects through the Order Project section. Trust our team of CFD experts to handle even the most complex simulations with proficiency and precision.

Figure 9: Temperature contour of a heat exchanger based on ANSYS Fluent simulation, from “Performance Improvement of Shell & Tube Heat Exchanger with Baffle CFD Simulation”

Related Blogs

Want to learn more about the science behind heat exchangers? Check out these related articles:

• Energy Conservation Equation – Discover the fundamental principle that governs all heat transfer processes and helps engineers design better heat exchangers.

• What is Boiling Heat Transfer? – Learn about this highly efficient heat transfer mechanism that occurs in many industrial heat exchangers and power generation systems.

• Conjugate Heat Transfer (CHT) – Understand how heat moves through both solid materials and fluids in heat exchangers and why this matters for design.

• Natural Convection: Understanding Heat Transfer in Fluid Systems – Explore how fluids move naturally due to temperature differences and how this affects heat exchanger performance.

Conclusion

In conclusion, heat exchangers stand as indispensable components across industries, enabling efficient heat transfer for myriad applications. From HVAC systems to power generation and food processing, their versatility and effectiveness drive innovation and sustainability. With advanced simulation tools like ANSYS Fluent, engineers can continue to refine heat exchanger designs, optimizing performance and contributing to a more energy-efficient future.