Abrasive Flow Machining Multiphase CFD Simulation – ANSYS Fluent Tutorial

Abrasive Flow Machining Multiphase CFD Simulation – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€112

Abrasive Flow Machining (AFM) is a new kind of fine finishing method that has changed the way surfaces finish in complicated shapes and hard-to-reach places. A polymer carrier with abrasive particles suspended in it is used in this advanced method. It creates a semi-solid medium that runs under pressure through or across surfaces that need to be polished. Recent studies and real-world examples show that AFM multiphase simulation using Computational Fluid Dynamics (CFD) has become an important tool for improving this process without having to do a lot of actual testing. When AFM is used, solid abrasive particles are suspended in a viscous fluid medium. This creates unique modeling challenges that are well met by ANSYS Fluent’s mixture model method. According to Dash and Maity’s (2015) research [1], CFD simulation can accurately predict how much material will be removed and the quality of the finish on the surface. This simulation feature has been very useful in the aerospace, military, and automotive industries, where very tight tolerances on parts are necessary for performance and surface integrity is very important.

- Reference [1]: Dash, Rupalika, and Kalipada Maity. “Simulation of abrasive flow machining process for 2D and 3D mixture models.” Frontiers of Mechanical Engineering10 (2015): 424-432.

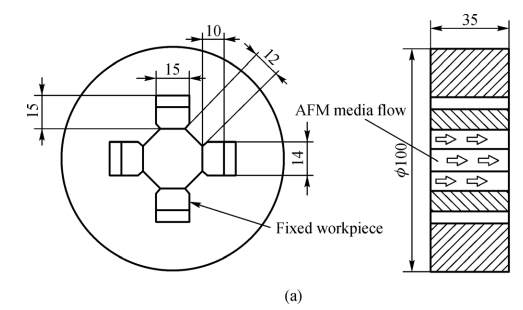

Figure 1: Arrangement of workpieces with fixtures [1]

Simulation Process

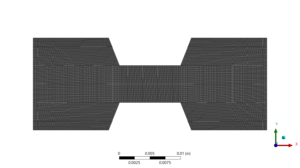

The Abrasive Flow Machining (AFM) multiphase simulation method uses ANSYS Fluent to analyze computational fluid dynamics in a 2D domain that is carefully built and has a structured grid with 42332 cells. This CFD simulation uses the mixture multiphase model with slip velocity to correctly show how the polymer medium (liquid phase) and silicon carbide abrasive particles (solid phase) interact with each other, which is necessary for a realistic representation of the AFM process. The simulation works in a laminar flow regime, which makes sense because the polymer transport medium has a high viscosity and the flow speeds aren’t very fast. Based on Dash and Maity’s method, the simulation treats the flow as Newtonian, in a steady state, and not compressible. The multiphase mixture model figures out the momentum, continuity, and energy equations for the mixed phases.

Figure 2: Structured grid over abrasive flow machining domain

Post-processing

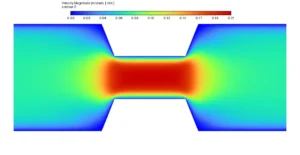

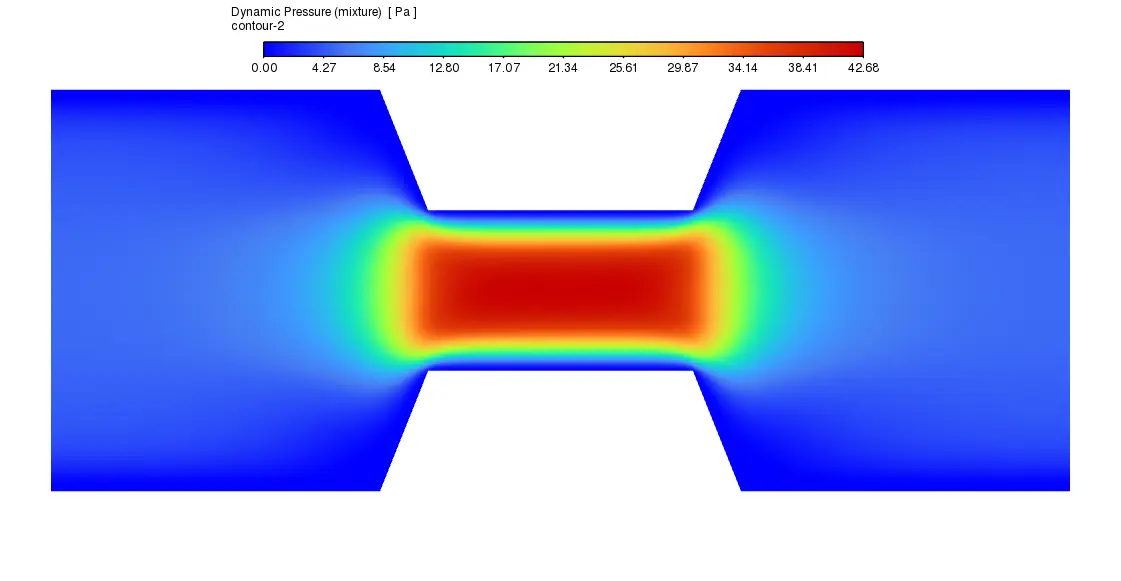

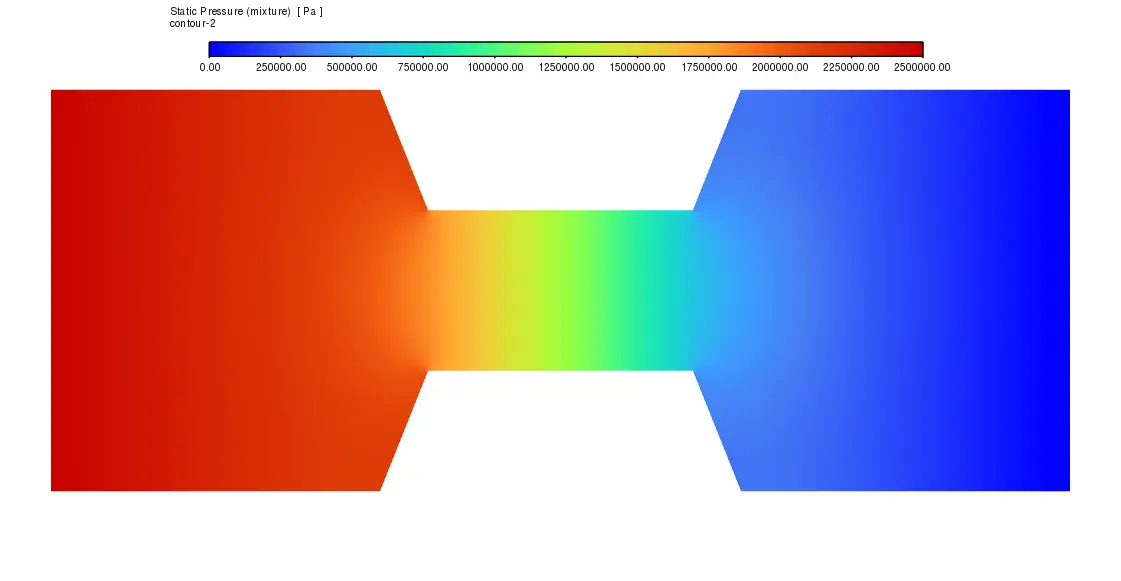

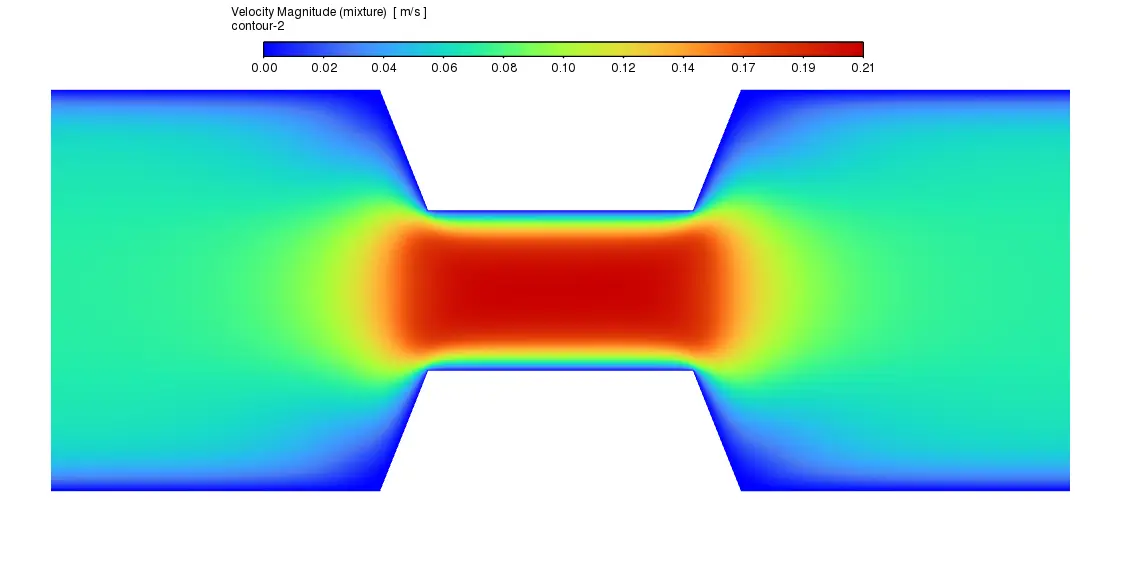

The velocity magnitude contour plot from the Abrasive Flow Machining Multiphase CFD Simulation shows that the flow is speeding up a lot in the narrowed section, with top speeds of about 0.21 m/s (red region) compared to only 0.02-0.04 m/s (blue-green regions) in the wider parts of the channel. This difference in velocity is very important for the AFM process because faster speeds in the narrowing create stronger shear forces that remove more material from the surface of the workpiece. The even spread of speed across the constriction shows that the finishing action will be the same all the way around, which is good for getting a consistent surface quality. It’s not sudden when the velocity profile changes from the wider parts to the constriction zone. This helps keep the flow from separating, which could cause uneven wear and uneven material removal.

Figure 3: Velocity field – Abrasive Flow Machining Multiphase CFD Simulation

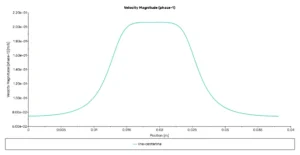

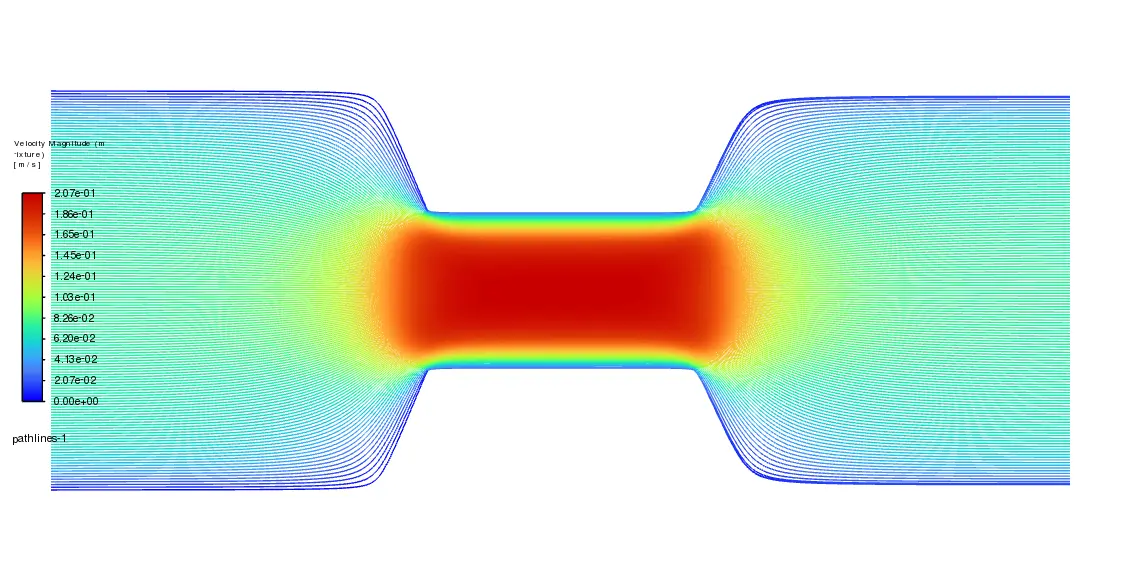

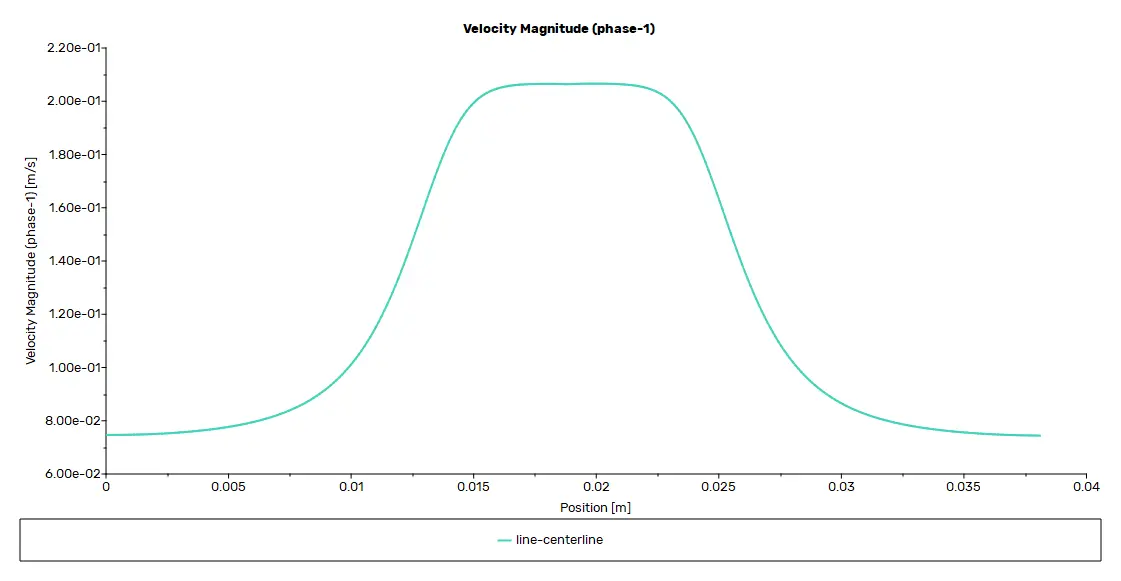

The dynamic pressure contour and centerline velocity curves show that the Abrasive Flow Machining process works well in this configuration. There is a pressure gradient that pushes abrasive particles toward the workpiece surface. The dynamic pressure distribution shows a high value of about 42.68 Pa in the middle of the constriction. The difference in pressure is very important to the AFM’s performance because it affects both the path of the particles and the force they use to stick to the walls of the object. According to the centerline velocity profile graph, the flow speeds up from about 0.075 m/s at the entry to a plateau of 0.205 m/s through the constriction zone (between 0.015 m and 0.025 m) and then slows down at the exit. This speed behavior shows that the abrasive particles will keep up their finishing action along the whole narrowing length, not just at the entrance and exit. This is how AFM can remove material at the same rate in hard-to-reach places. The modeling results show that geometric restrictions in AFM tools can be planned in a way that controls the flow of speed and pressure, making the finishing process better for complicated parts.

Figure 4: Mixture velocity plot on the centerline – Abrasive Flow Machining Multiphase CFD Simulation

Figure 5: Dynamic pressure contour – Abrasive Flow Machining Multiphase CFD Simulation

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€235 Original price was: €235.€175Current price is: €175.

€190 Original price was: €190.€165Current price is: €165.

€175 Original price was: €175.€115Current price is: €115.

€195 Original price was: €195.€145Current price is: €145.

€195 Original price was: €195.€150Current price is: €150.

€210 Original price was: €210.€155Current price is: €155.

Reviews

There are no reviews yet.