Active Cooling Photovoltaic System CFD Validation: PVT Cooling Simulation in Fluent

Active Cooling Photovoltaic System CFD Validation: PVT Cooling Simulation in Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€245 Original price was: €245.€185Current price is: €185.

The efficiency of a Photovoltaic (PV) system drops significantly as it gets hotter. When a solar panel sits in the sun, it generates electricity, but it also absorbs a lot of heat. This heat increases the temperature of the cells, which reduces their electrical output and can damage the materials over time. This problem is even worse in High Concentrator Photovoltaic (HCPV) systems. To solve this, engineers use Active Cooling Photovoltaic Systems. This method involves pumping a fluid, usually water, through channels behind the panel to remove the waste heat.

This type of setup is often called a PVT system (Photovoltaic Thermal system) because it manages both electricity and heat. Designing these systems requires precise engineering. In this tutorial, we perform a PVT cooling system CFD analysis using ANSYS Fluent. This is a specific validation study aimed at proving the accuracy of our simulation against real-world data. We model a convergent-divergent microchannel heat sink to optimize thermal management. For more examples of sustainable energy simulations, please explore our Renewable energy tutorials. The results are validated against the experimental and numerical data from the paper by Ali et al. [1].

- Reference [1]: Ali, Abdallah YM, et al. “Thermal analysis of high concentrator photovoltaic module using convergent-divergent microchannel heat sink design.” Applied Thermal Engineering183 (2021): 116201.

Figure 1: The geometry and detailed dimensions of the photovoltaic and thermal assembly from the reference paper [1].

Simulation Process: CHT Modeling of PVT Systems in Fluent

The simulation process began with building the complex 3D geometry in ANSYS Design Modeler. The model is a multi-layer assembly. It includes the germanium solar cell, a ceramic substrate, and the copper and aluminum layers that form the heat sink. To capture the heat flow accurately, we generated a very fine structured mesh. The final grid contains 8,813,900 cells. This high cell count is necessary to resolve the tiny thermal gradients inside the microchannels of this Active Cooling PVT System.

The physics setup in ANSYS Fluent is based on Conjugate Heat Transfer (CHT). CHT is the term used when heat moves through solids and then into a moving fluid. The solar cell was defined as a solid zone with a constant heat source to represent the absorbed sunlight. The coolant is water, flowing through the microchannels in a laminar regime. By simulating this PVT cooling system, we can track exactly how heat travels from the solar cell, through the substrate, and into the water. This Active Cooling Photovoltaic System CFD setup allows us to test the cooling performance virtually before building a prototype.

Figure 2: A section of the high-density structured mesh used to accurately resolve thermal gradients.

Post-processing: Validating Solar Cell Temperature

The most critical part of this study is the validation. We compared our Active Cooling Photovoltaic System Fluent results with the reference paper [1] to ensure accuracy. The table below shows the comparison for the average solar cell temperature. The reference paper reported a temperature of 61°C at a mass flow rate of 0.0167 kg/s. Our CFD simulation predicted 60.2°C. This results in a very small error of only 1.3%. This excellent agreement validates our Active Cooling PVT System model. It proves that our mesh and physics settings in ANSYS Fluent are correct and reliable for designing high-efficiency solar cooling systems.

| Reference Paper | Present CFD Simulation | Error | |

| Average Solar Cell Temperature | 61°C | 60.2°C | 1.3% |

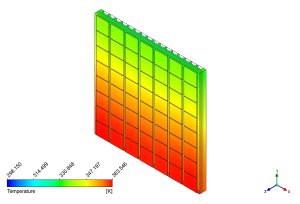

We can visualize this cooling process in Figure 3. The temperature contour shows the full range of temperatures in the module. The maximum temperature is 363.546K (90.4°C), which occurs at the bottom where the solar cell is generating heat. The top of the module is much cooler, reaching down to 298.15K (25°C). The gradient (change in color) shows the heat being pulled away by the water in the microchannels. This effective heat removal is the main goal of any PVT cooling system. By keeping the cell temperature lower (around 60°C instead of 90°C), the Active Cooling Photovoltaic System significantly increases the electrical efficiency and lifespan of the solar panel.

Figure 3: Temperature contour from the Active Cooling in Photovoltaic System CFD simulation, showing effective heat removal by the microchannel heat sink.

Key Takeaways & FAQ

- Q: What is an Active Cooling PVT System?

- A: A PVT (Photovoltaic Thermal) system generates electricity and captures heat simultaneously. “Active Cooling” means a fluid (like water or air) is pumped through the system to actively remove heat from the PV cells, preventing them from overheating and increasing their efficiency.

- Q: Why is Conjugate Heat Transfer (CHT) important in this simulation?

- A: CHT is essential because the heat must pass through different materials (Silicon, Copper, Aluminum) before reaching the water. A PVT cooling system CFD must solve the heat conduction in these solids and the heat convection in the fluid simultaneously to get accurate results.

- Q: How does cooling affect solar panel efficiency?

- A: Solar cells lose efficiency as they get hotter. For every degree rise in temperature, the power output drops. By using an Active Cooling Photovoltaic System to keep the temperature at 60.2°C instead of allowing it to rise higher, we maintain a higher electrical output.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€130 Original price was: €130.€85Current price is: €85.

€240 Original price was: €240.€175Current price is: €175.

€185 Original price was: €185.€135Current price is: €135.

€210 Original price was: €210.€155Current price is: €155.

€240 Original price was: €240.€115Current price is: €115.

€360 Original price was: €360.€180Current price is: €180.

Reviews

There are no reviews yet.