Axial Fan Performance Over Time Using Sliding Mesh CFD Simulation, ANSYS Fluent Training

Axial Fan Performance Over Time Using Sliding Mesh CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€160 Original price was: €160.€135Current price is: €135.

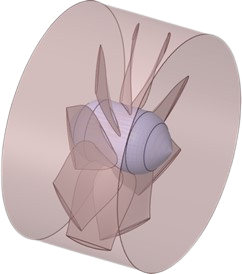

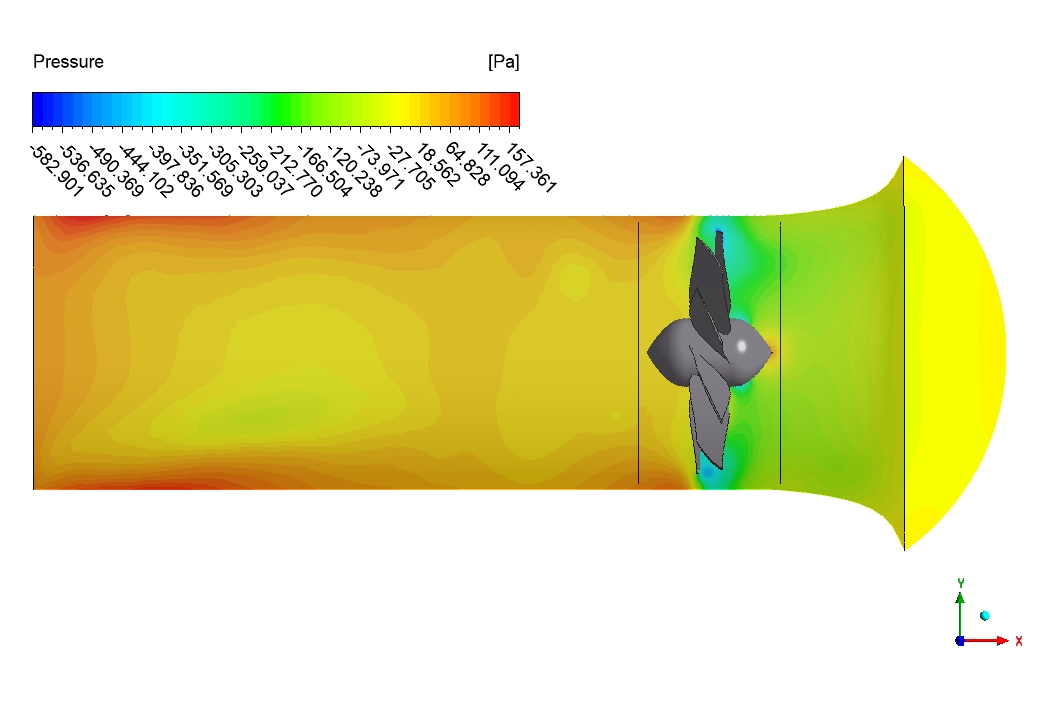

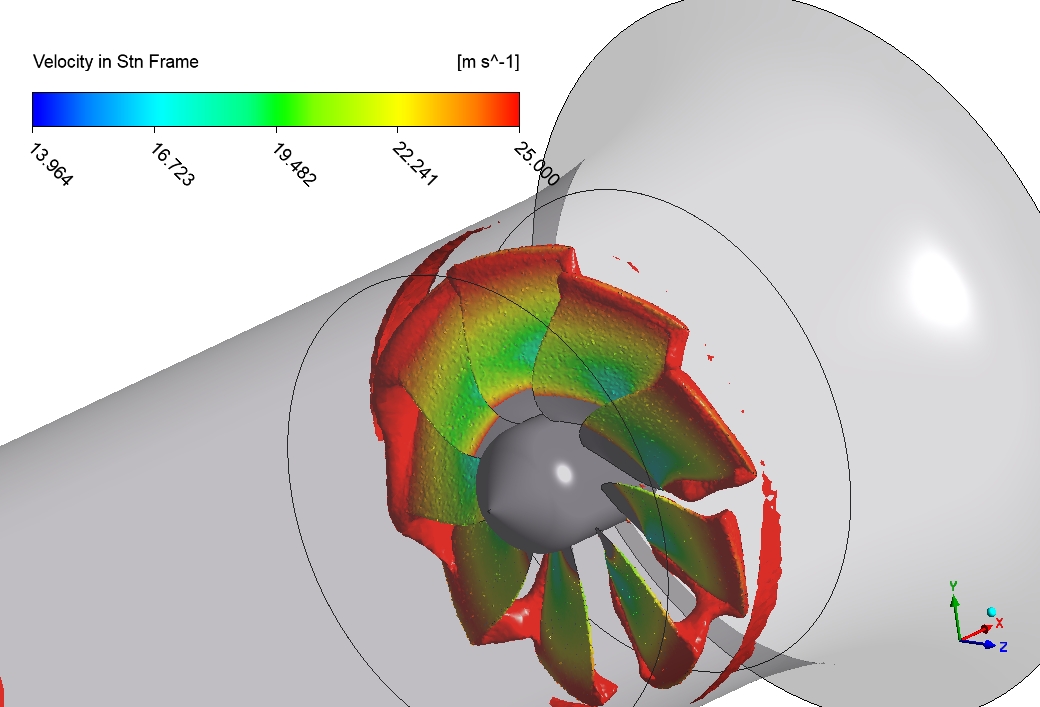

This report shows how we used computational fluid dynamics (CFD) to study an axial fan using the sliding mesh method in ANSYS Fluent. Axial fans are very common in cooling systems, ventilation, and many industrial applications. These fans have blades attached to a center hub and push air along the fan axis when they spin. Our transient simulation (which means it changes over time) helps us see how the fan performance changes as it rotates. We used a time-dependent analysis to track the airflow patterns, pressure distribution, and velocity field inside the duct. Our numerical simulation with 720 rpm rotation speed gives important information about pressure rise, flow separation, and how well the fan works in different conditions.

Figure 1- Axial Fan zone schematic

Simulation Process

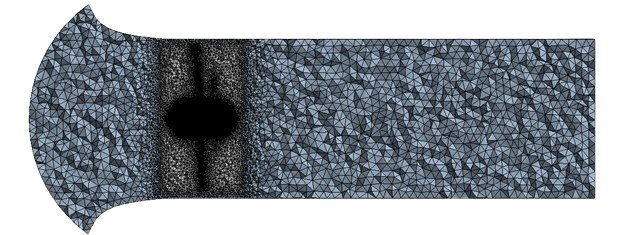

There are important points that have to be considered in the simulation`s initial steps. Using Sliding Mesh (Mesh Motion) module set a constraint to having two distinct regions. One stands for rotational and the other for stationary. Further, avoiding drastic changes in cell sizes, particularly around interfaces, is essential. As a result, 3330417 tetrahedral cells are produced. Axial fan is working with 720 rpm implemented in a duct. We seek the performance of axial fan over time, revealing a Transient ( unsteady) simulation.

Figure 2- Generated mesh for axial fan inside a duct

Post-processing

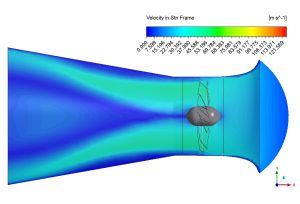

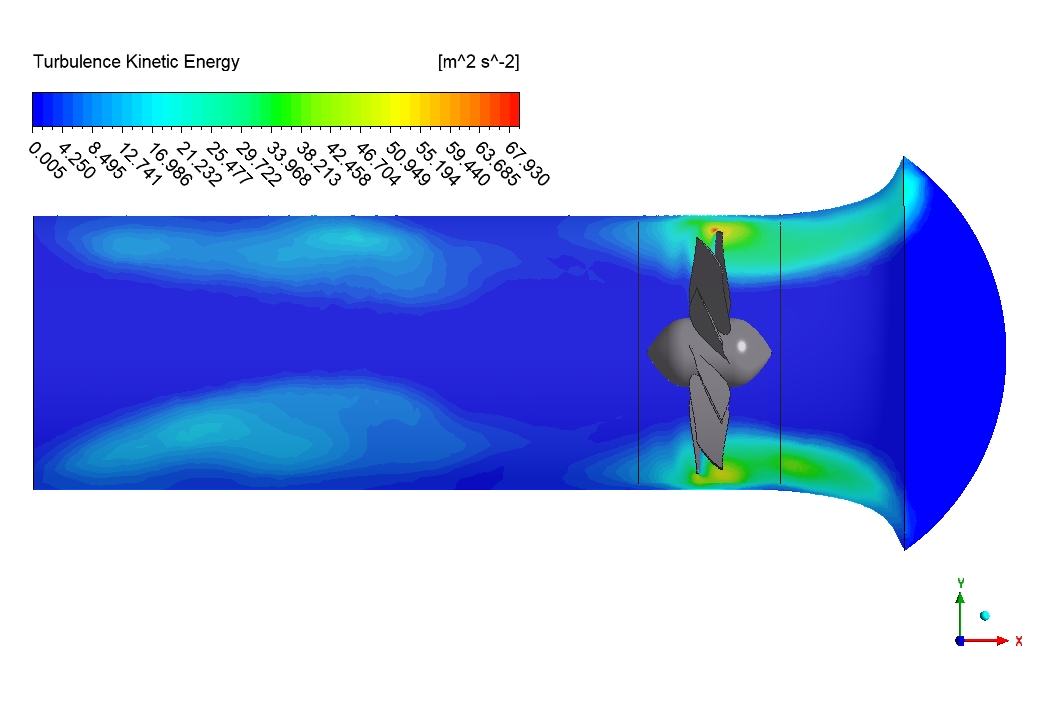

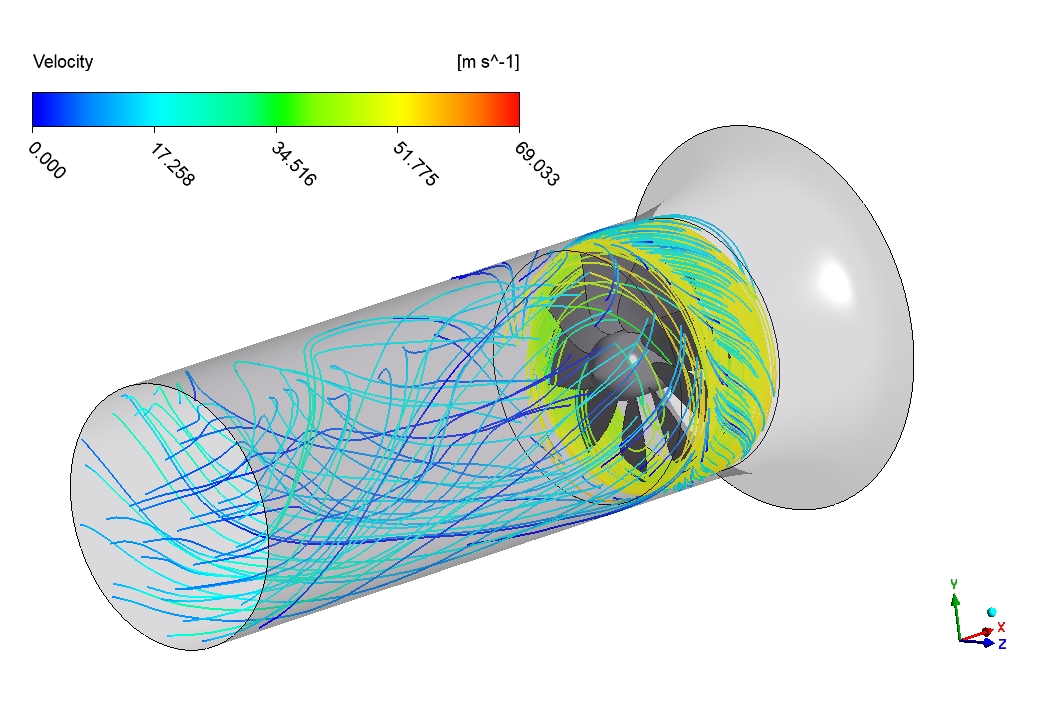

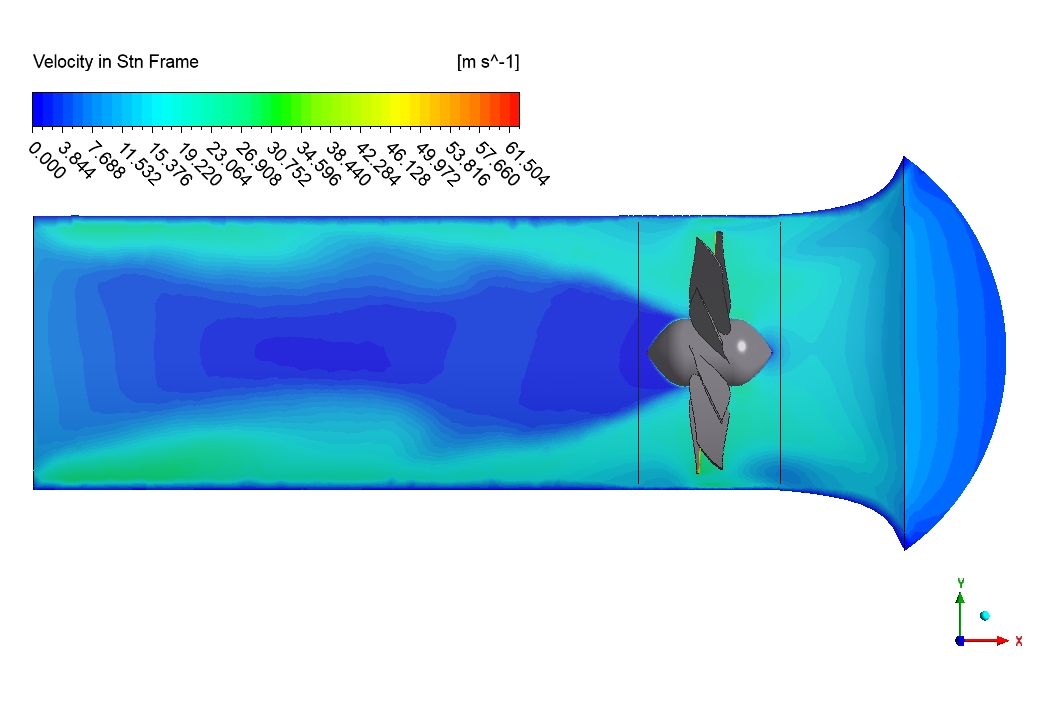

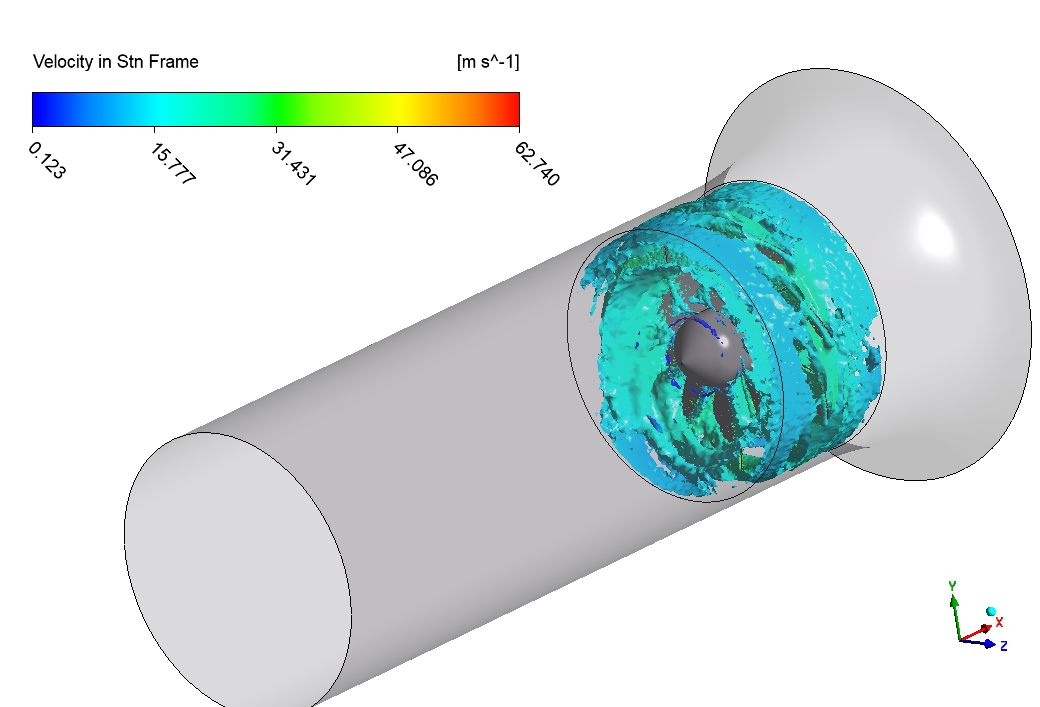

The velocity results in Figures 3 reveal the flow acceleration pattern through the system. In the stationary frame view (Figure 2), the flow starts slow (dark blue, 3-7 m/s) at the inlet, stays relatively slow through most of the duct, then speeds up slightly (light blue, 15-23 m/s) after passing the propeller. The streamline visualization in Figure 4 tells the complete story by showing how air actually moves. The streamlines start organized at the inlet (blue lines, 0-17 m/s), then get twisted as they pass through the rotating propeller blades, reaching speeds of 34-51 m/s (green-yellow). What’s really interesting is how the streamlines straighten out after passing through the fan instead of continuing to spin. This means the duct is doing a good job straightening the flow and converting rotational energy into useful forward thrust. The cone-shaped outlet helps the high-speed flow (yellow streamlines) gradually slow down and spread out, which improves overall propulsion efficiency. Without this expanding section, we’d waste a lot of energy as turbulence and swirling motion.

Figure 4: Velocity contour & Streamline visualization showing the flow paths and velocity magnitudes

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€120 Original price was: €120.€95Current price is: €95.

€195 Original price was: €195.€165Current price is: €165.

€235 Original price was: €235.€155Current price is: €155.

€280 Original price was: €280.€199Current price is: €199.

€155 Original price was: €155.€95Current price is: €95.

Reviews

There are no reviews yet.