B-2 Spirit Aerodynamic CFD Simulation

B-2 Spirit Aerodynamic CFD Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€220 Original price was: €220.€195Current price is: €195.

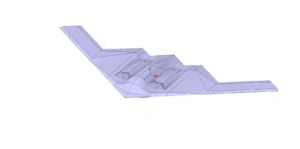

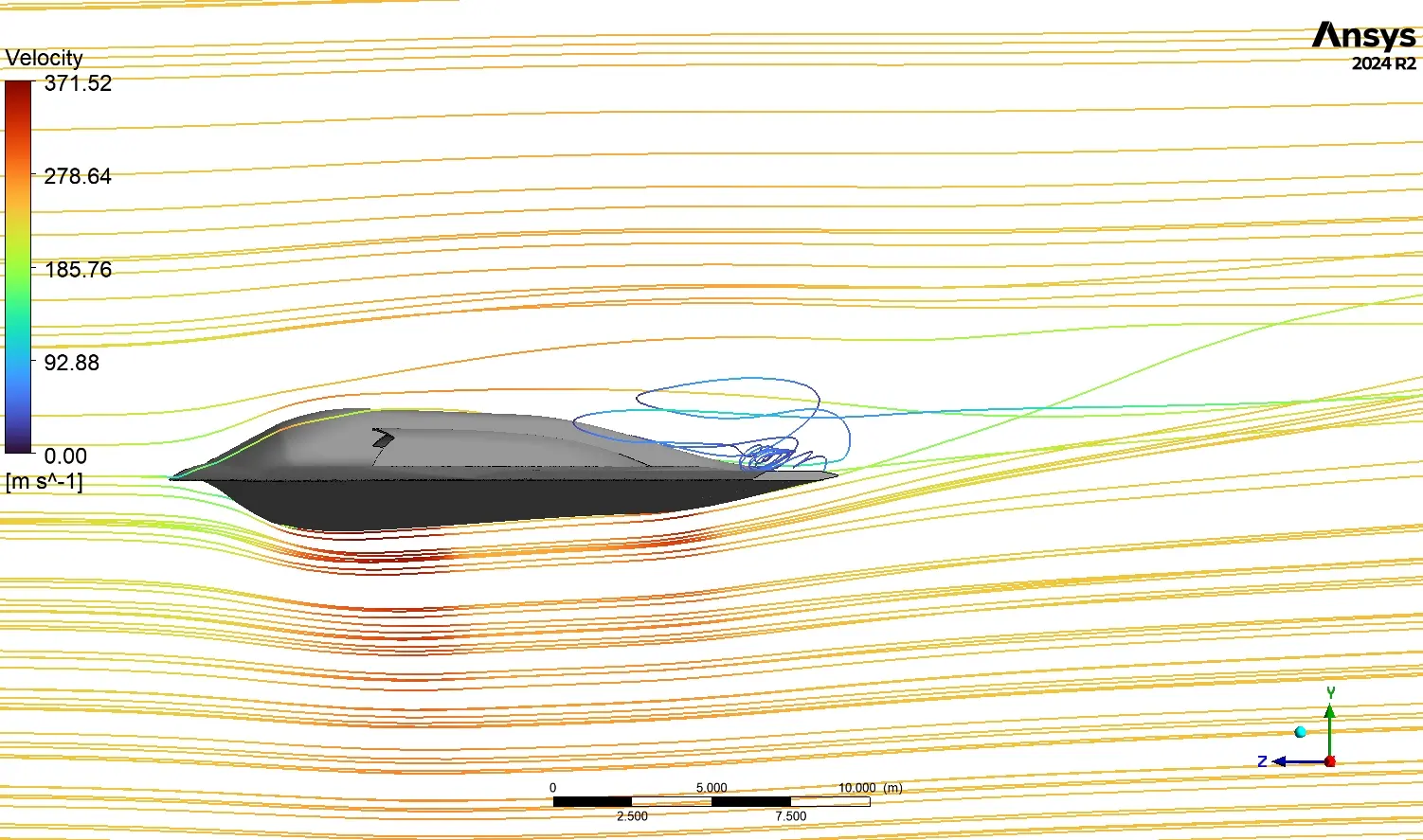

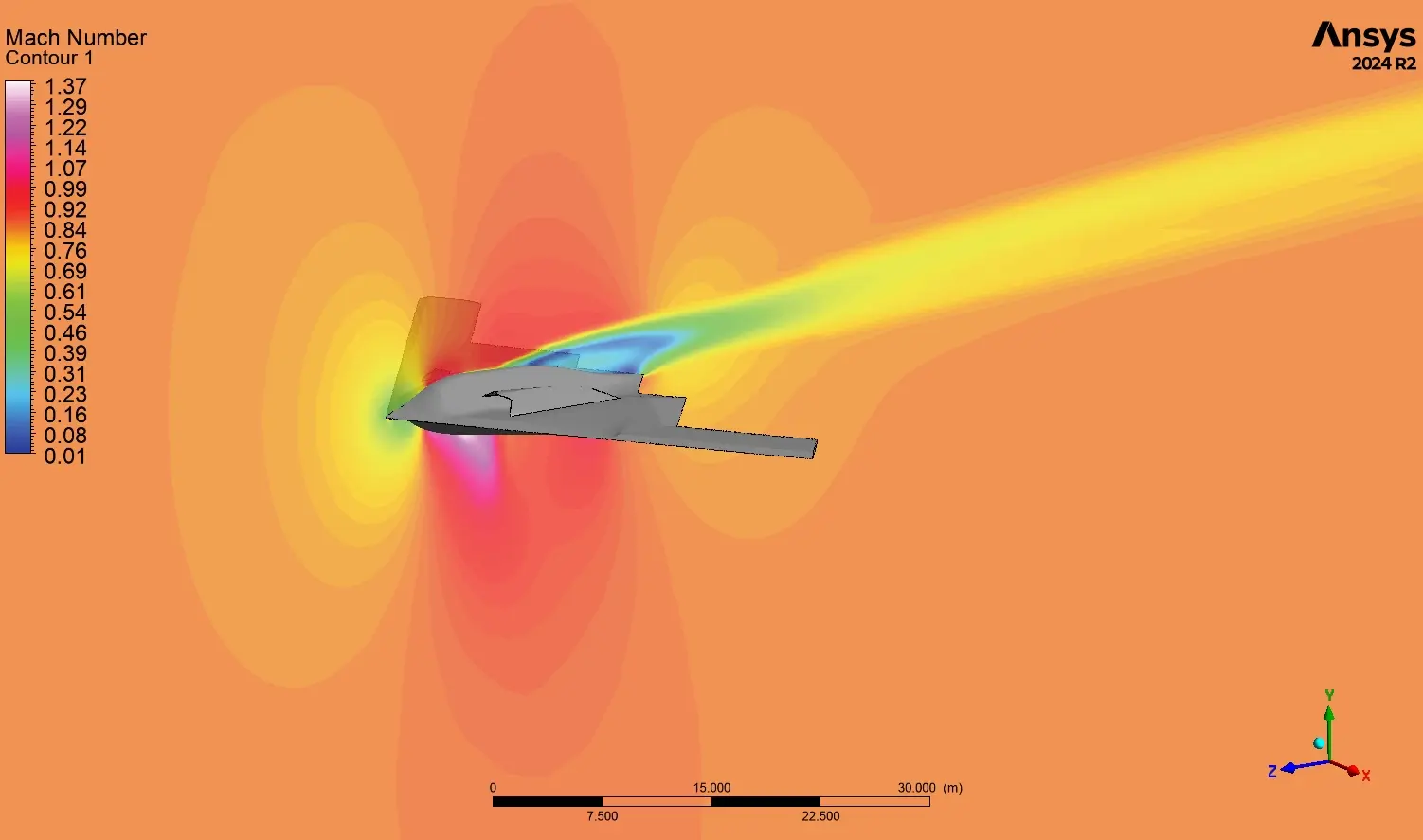

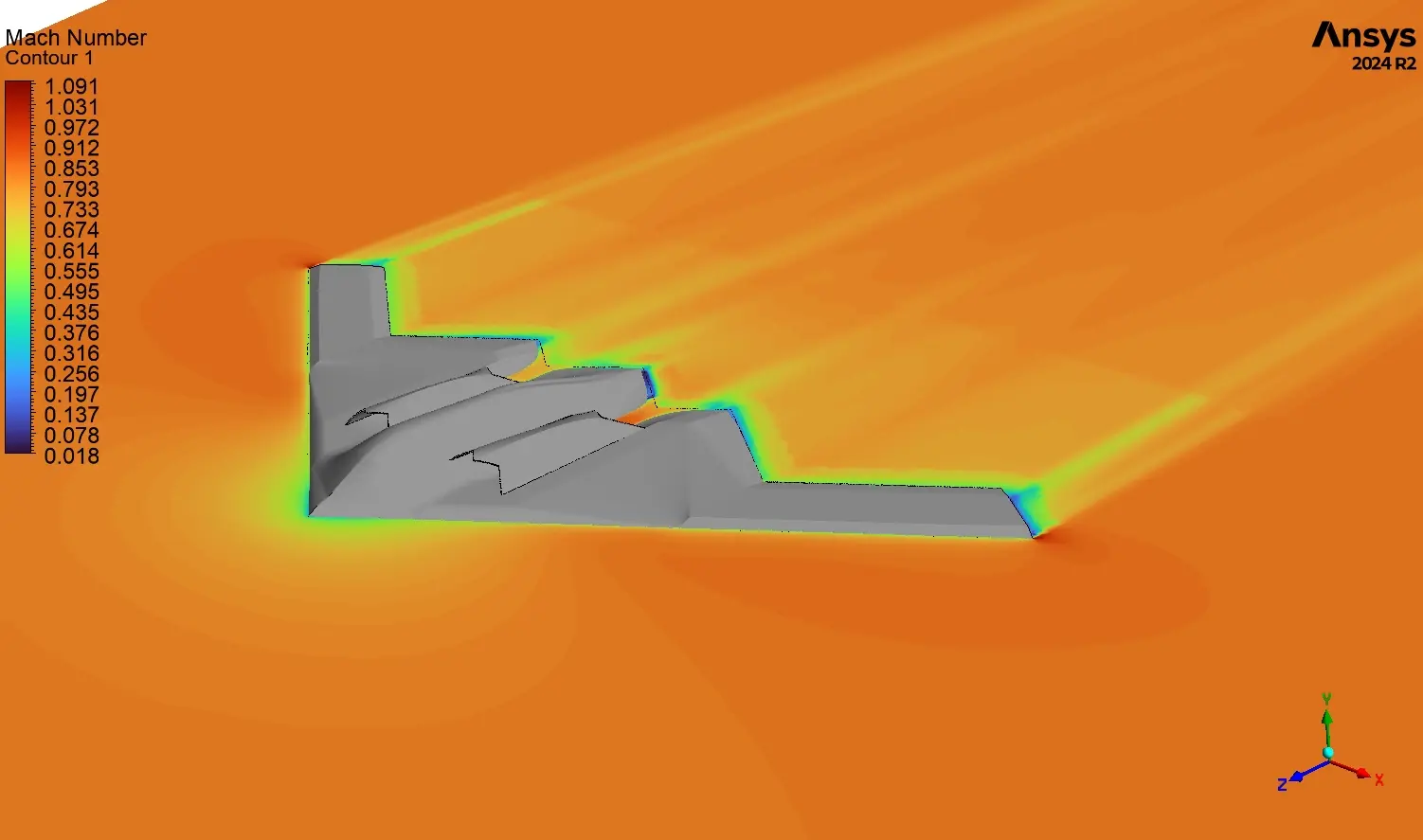

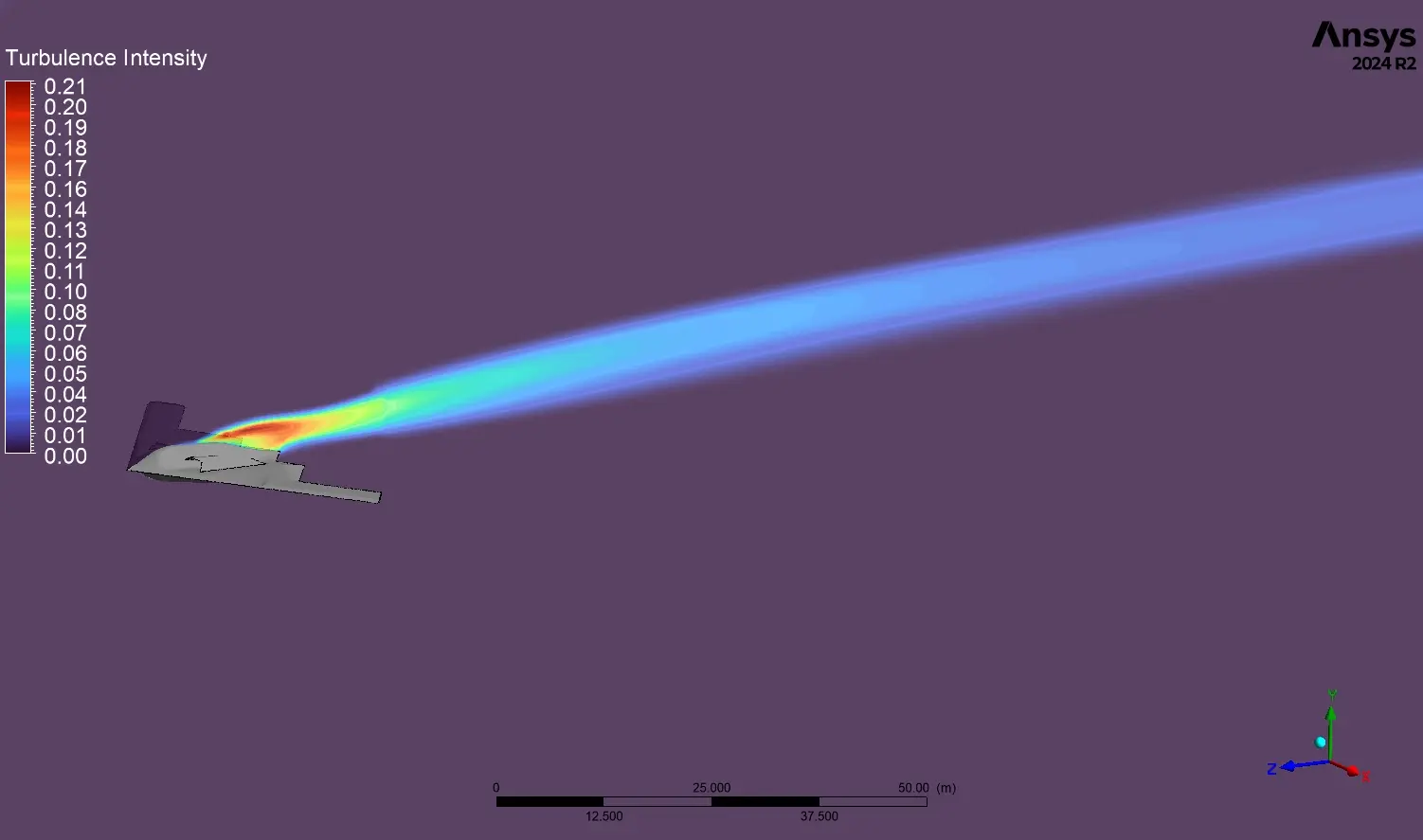

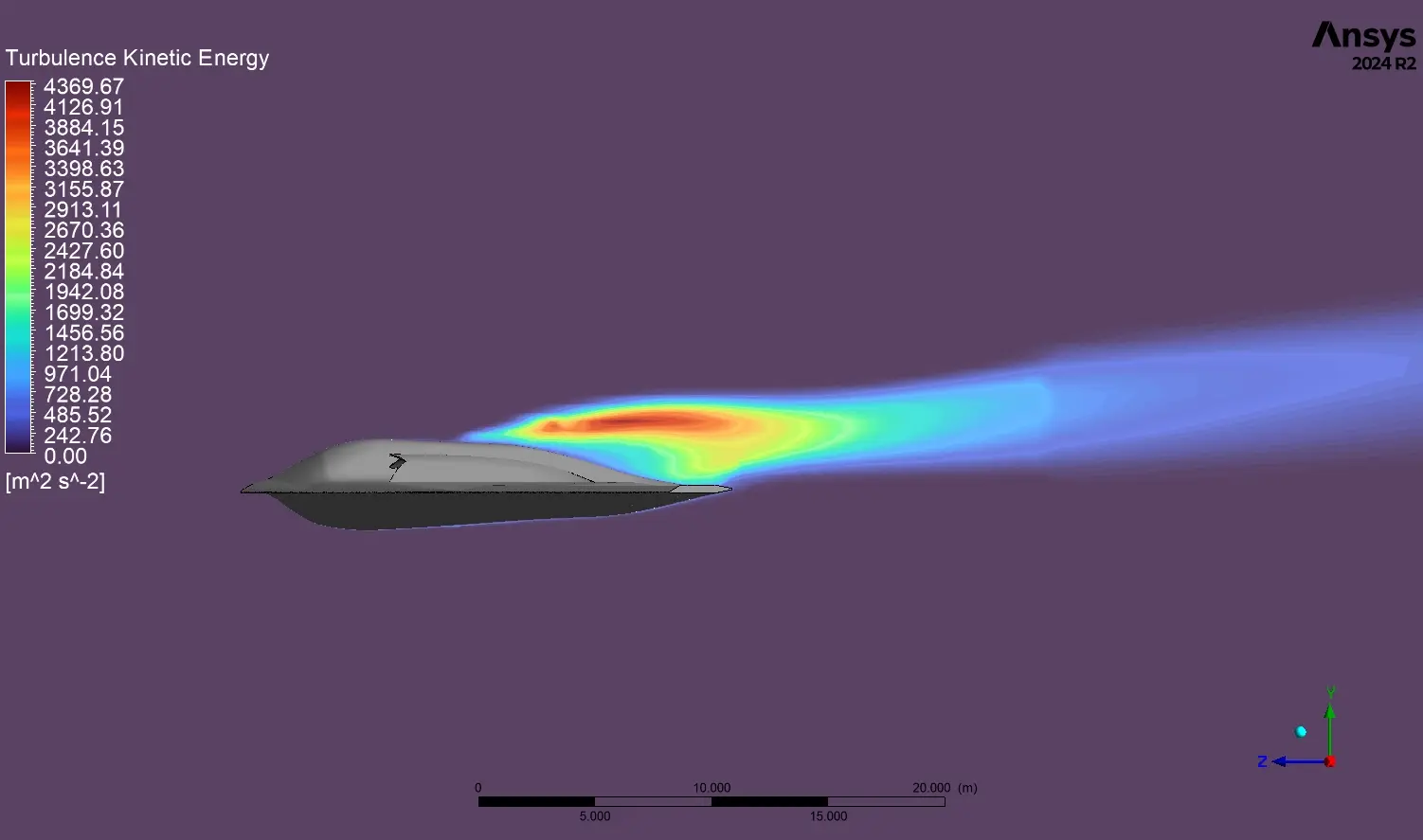

A B-2 Spirit Aerodynamic CFD simulation is a vital computer analysis that allows engineers to study the complex airflow around this unique stealth bomber. The B-2’s “flying wing” shape is excellent for avoiding radar, but it creates very special aerodynamic challenges. Using a B-2 Spirit Aerodynamic fluent simulation, we can see invisible flow patterns and forces. This B2 Bomber CFD Simulation is essential for understanding how the aircraft generates lift without a traditional tail.

This report details a B2 Aerodynamics fluent analysis using ANSYS Fluent. The goal is to investigate the aircraft’s performance at a high-subsonic flight speed. By carefully modeling the air properties and using a very detailed mesh, this simulation provides the exact data designers need to balance the competing goals of stealth, lift, and drag, ensuring the B-2 can perform its mission effectively. For more detailed tutorials on aerodynamics and aerospace CFD simulation, visit our Aerodynamic CFD shop.

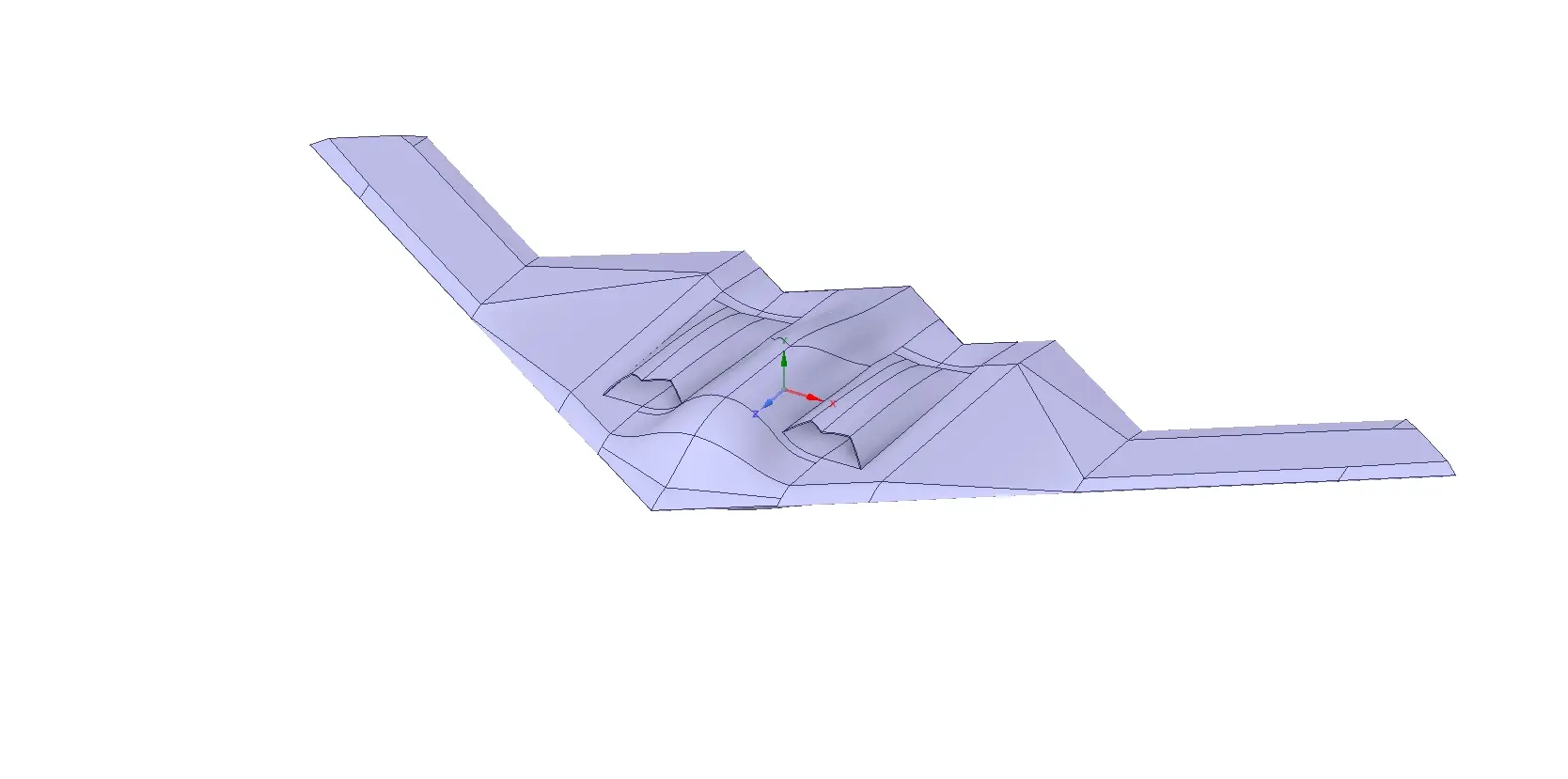

Figure 1: An overview of the B-2 Spirit geometry model for the B-2 Aerodynamic CFD simulation.

Simulation process: Fluent-CFD Setup, Adaptive Meshing for a High-Fidelity B-2 Model

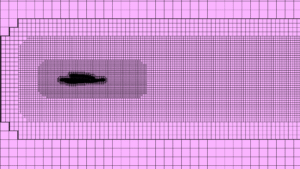

The simulation process for this B-2 Spirit CFD analysis began with the complex flying wing geometry. Creating a good mesh for this shape is very sensitive. The process was done in Fluent Meshing, starting with a careful calculation for the boundary layer. For the flight condition of Mach 0.835, the first cell height off the B-2’s surface was set to a tiny 0.00065 ft. This is critical to accurately capture the physics of the air right next to the skin. The overall computational domain was a large cone shape to correctly model the far-field air pressure. To save computer power while keeping the results accurate, two “bodies of influence” were used.

To model the air realistically, the Sutherland viscosity model and the ideal gas law were activated in ANSYS Fluent. After an initial simulation, a quality check was performed by measuring the y+ value across the entire aircraft surface. This check revealed areas where the mesh needed to be even finer. Using manual mesh adaptation, these specific regions were refined. This process of checking and refining resulted in a final, high-fidelity mesh of 38 million poly-hexcore elements, ensuring the simulation results are very accurate.

For Mach number 0.835 conditions, the speed of sound relationship becomes critical:

a=γRT

where γ is the specific heat ratio. The y+ calculations used the friction velocity formula:

uτ=U√Cf/2

The first cell height was determined using:

Δy=(y+×ν)/uτ

Figure 2: Generated grid poly-hexacore

Post-processing: CFD Analysis of Subsonic and Transonic Flow

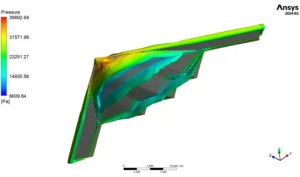

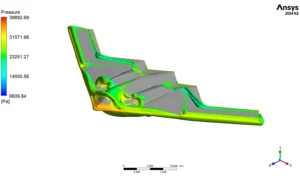

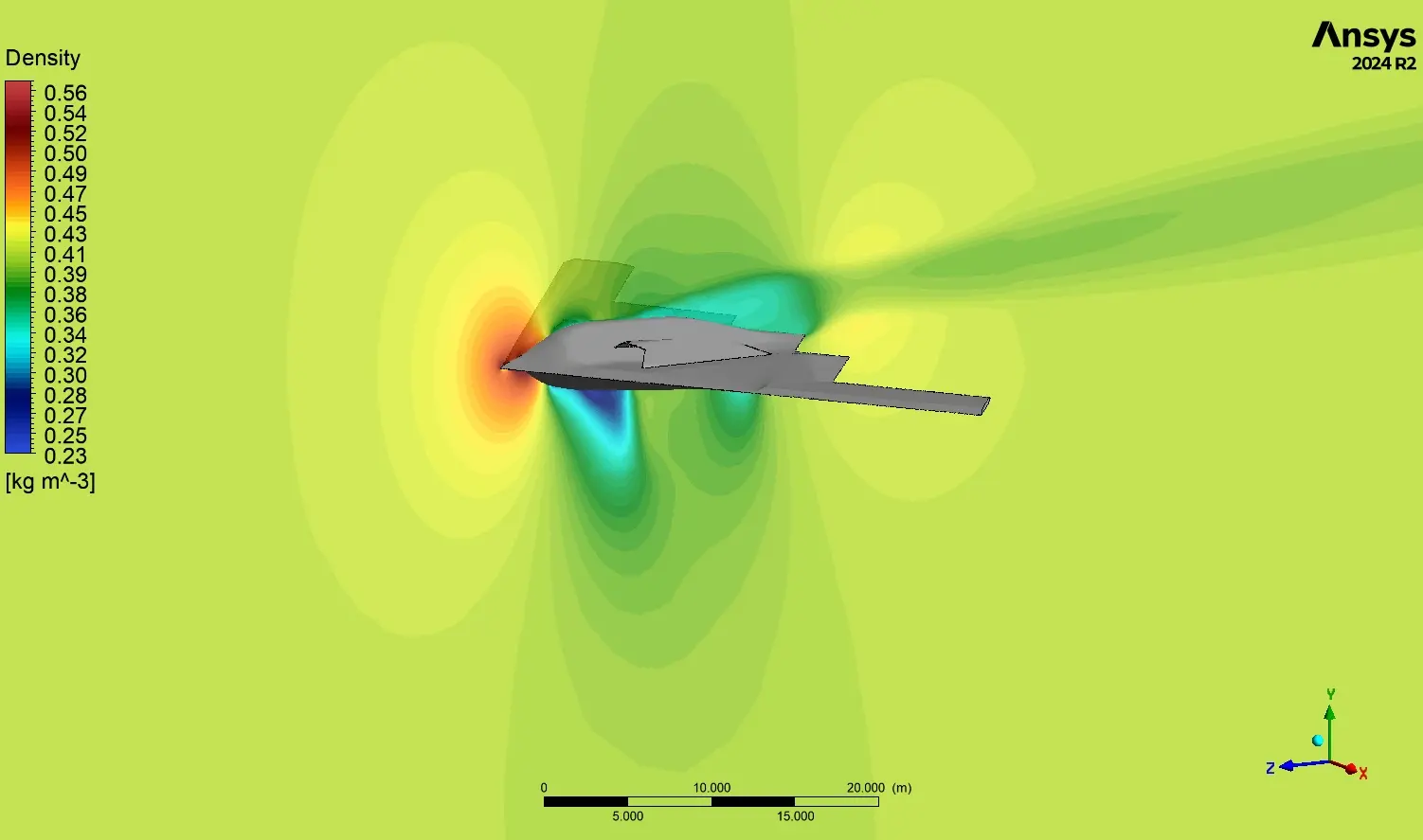

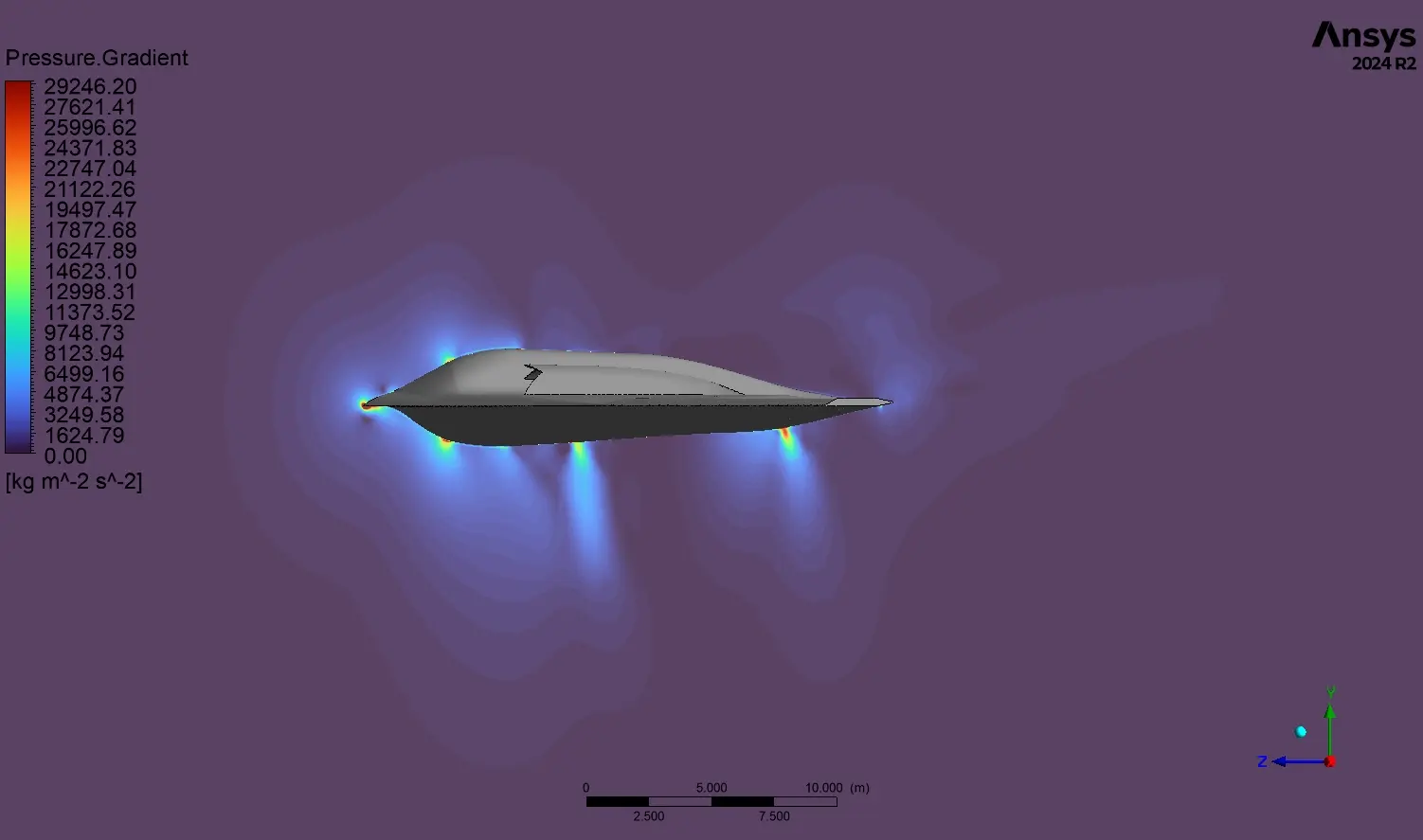

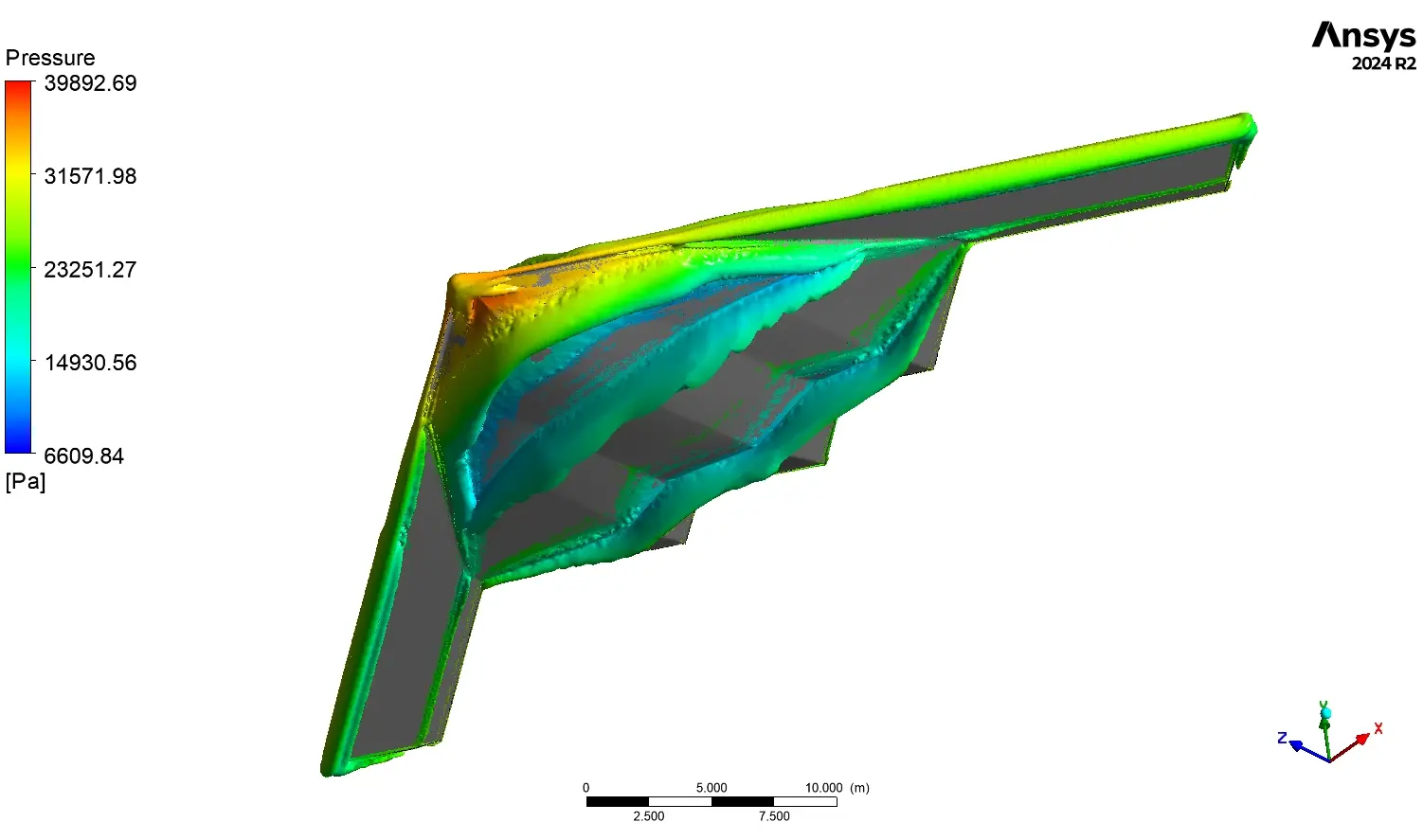

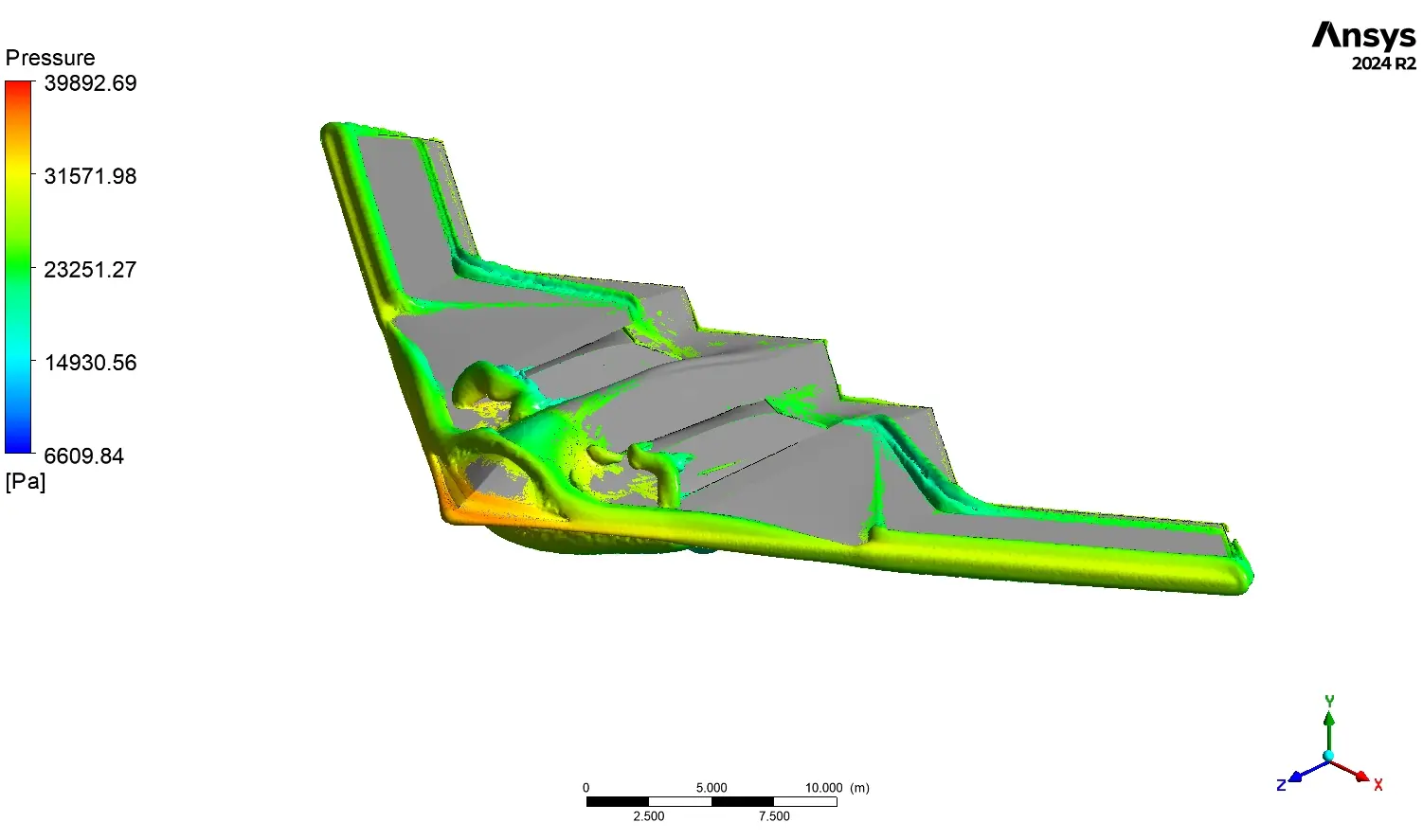

The simulation results provide a complete engineering story, revealing the complex balance of forces that allows the B-2 to fly effectively while maintaining its stealth characteristics. From an engineering viewpoint, the analysis begins with how the aircraft generates lift. The pressure gradient contours in Figure 3 clearly show a region of very high pressure on the front leading edges, with a maximum value of 39,892 Pa. This is the stagnation point, where the air directly impacts the aircraft. The contours also show large areas of low pressure across the upper surfaces. It is this pressure difference between the high-pressure bottom and low-pressure top that generates the necessary lift. However, this pressure also creates a significant drag force that the engines must overcome.

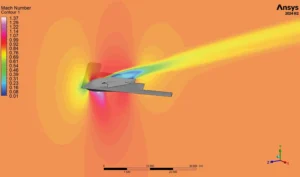

Figure 3: B2 Spirit pressure gradient contour and iso-value pressure gradient colored by pressure showing high pressure zones on aircraft surfaces

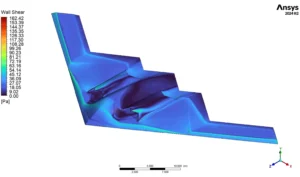

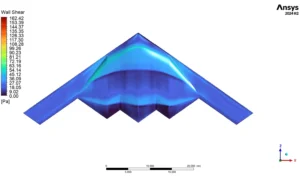

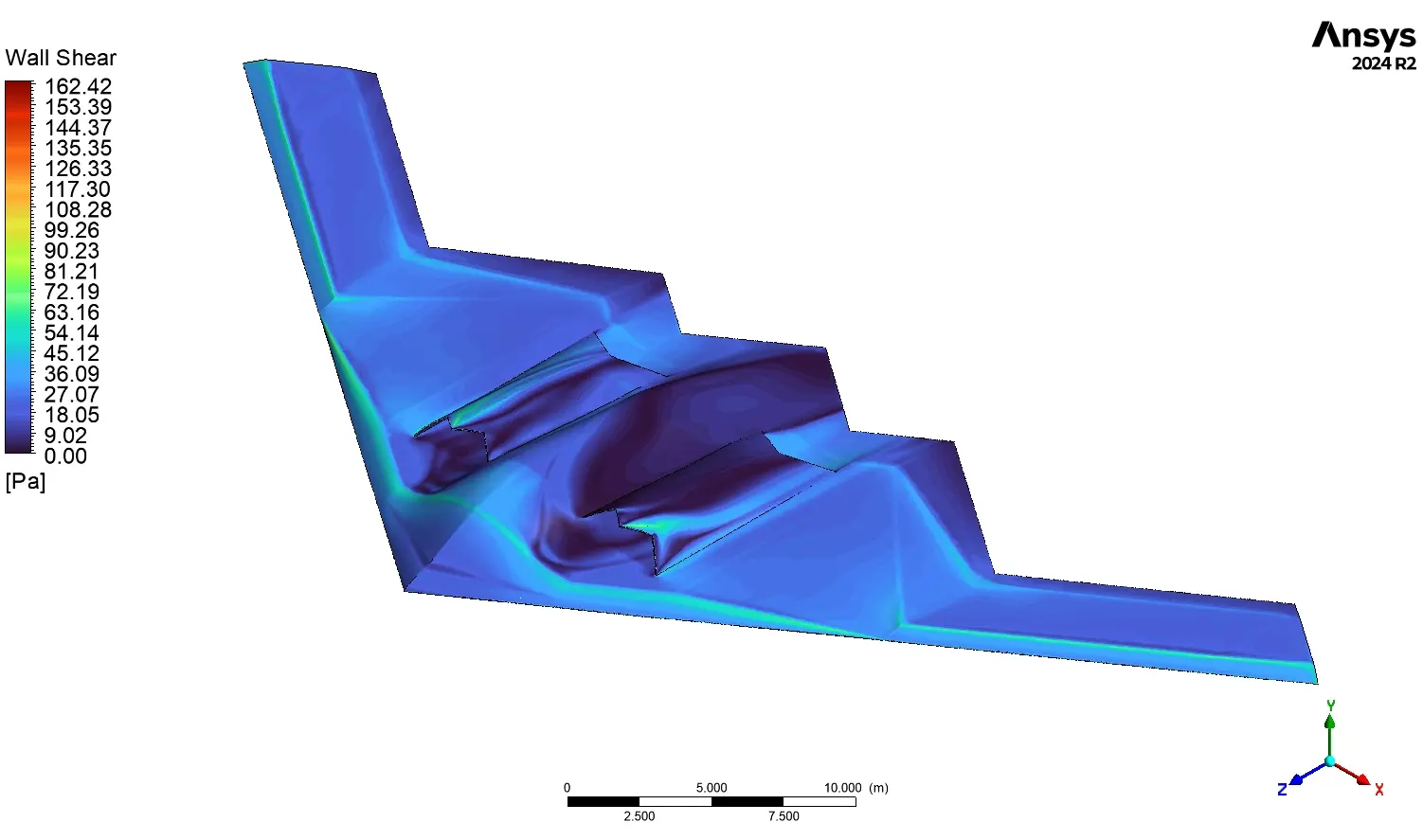

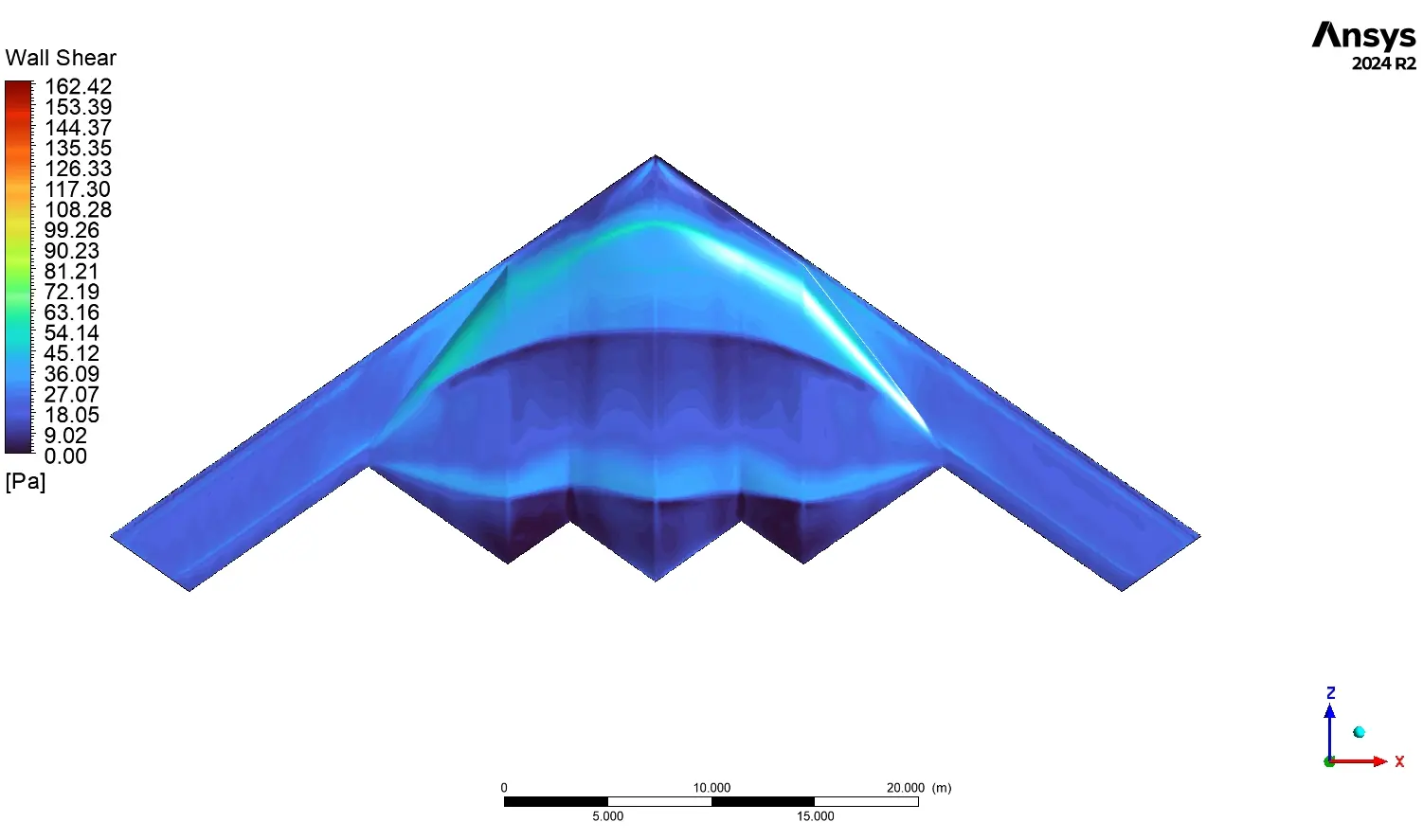

The wall shear stress contour in Figure 4 tells the other half of the drag story: friction. This contour shows where the air is “rubbing” against the skin of the B-2. The simulation calculates a maximum stress of 162.42 Pa in specific areas. For designers, knowing the location of these high-stress areas is critical for understanding aerodynamic heating and material fatigue over the aircraft’s lifetime. The most critical finding of this simulation is shown in the Mach number contours in Figure 5. Even though the B-2 is flying at a subsonic speed of Mach 0.835, the air must accelerate as it flows over the curved upper surfaces. This acceleration causes the local airflow to reach supersonic speeds (Mach > 1.0) in several pockets. When this supersonic flow slows back down to subsonic, it creates a weak shock wave.

Figure 4: Wall shear stress distribution on B2 Spirit surfaces showing boundary layer effects

Figure 5: Mach number contours around B2 Spirit showing supersonic flow regions and shock wave formation

The most important achievement of this simulation is the successful capture and visualization of these localized shock waves. For a stealth aircraft designer, this is the most important challenge to solve. Shock waves are a major source of aerodynamic drag (called wave drag) and, even more critically, they can create a very large radar reflection, compromising the aircraft’s stealth. This B2 Aerodynamics fluent analysis gives designers the precise information they need: it shows them exactly where these shock waves form and how strong they are. This allows them to make tiny, millimeter-level changes to the aircraft’s shape to minimize the strength of these shocks, thereby balancing the need for lift against the absolute requirement for minimum drag and maximum stealth.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€85Current price is: €85.

€250 Original price was: €250.€195Current price is: €195.

€180 Original price was: €180.€135Current price is: €135.

€155 Original price was: €155.€95Current price is: €95.

€380 Original price was: €380.€185Current price is: €185.

€140 Original price was: €140.€125Current price is: €125.

Reviews

There are no reviews yet.