Centrifugal Blood Pump CFD Simulation, ANSYS Fluent Training

Centrifugal Blood Pump CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€290.00 Original price was: €290.00.€175.00Current price is: €175.00.

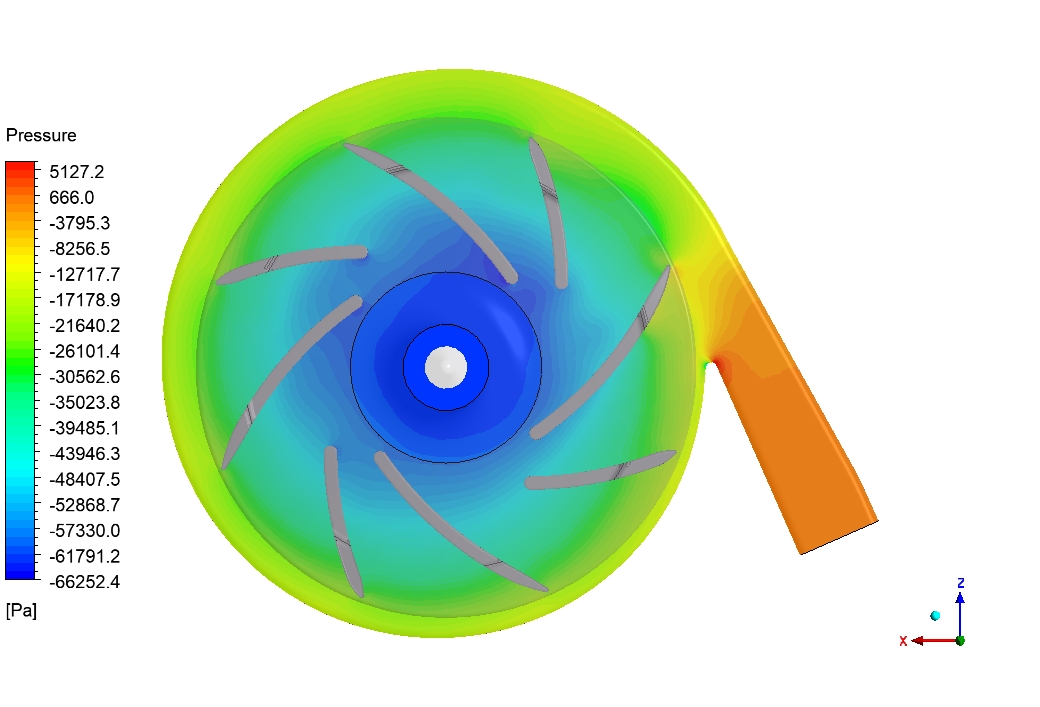

CFD simulation is essential for designing and optimizing centrifugal blood pumps. Engineers and researchers can view and evaluate complex pump flow patterns, pressure distributions, and shear stresses without physical prototypes using this advanced modeling technique. The current CFD study features from the guidance of the reference paper entitled “ On the Optimization of a Centrifugal Maglev Blood Pump Through Design Variations”.

Figure 1: Schematic of the maglev blood pump mode from reference paper

Simulation Process

The baseline design was based on a previously developed maglev blood pump. The main design parameters of the impeller (as shown in Figure 1) were determined accordingly and are shown in Table 1 (reference paper). 9495864 tetrahedral elements establish the computational zone. The Frame Motion module, known as Multi-Reference Frame (MRF), applies 3500 rpm impeller motion.

Figure 2: Section view of produced grid

Post-processing

The pump is made up of a circular impeller with curved blades that is enclosed in a casing with a central intake and an outlet.

The velocity distributions reveal higher velocities toward the impeller’s outer edges, with speeds reaching up to 11.7 m/s in the stationary frame. This is compatible with the pump’s centrifugal operation. The flow patterns show the fluid’s swirling motion as it is driven outward by the rotating impeller blades. Regarding the wall shear stress distribution, with the highest stresses (up to 489.8 Pa) occurring around the blade tips and casing walls, where velocity gradients are steepest.

With a pressure head of 6.017m, it appears that this pump design can generate enough pressure for blood circulation applications. However, the very high velocities and shear stresses found indicate that careful consideration may be required to avoid potential blood injury or hemolysis.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175.00 Original price was: €175.00.€115.00Current price is: €115.00.

€280.00 Original price was: €280.00.€145.00Current price is: €145.00.

€140.00 Original price was: €140.00.€85.00Current price is: €85.00.

€265.00 Original price was: €265.00.€135.00Current price is: €135.00.

€240.00 Original price was: €240.00.€135.00Current price is: €135.00.

€180.00 Original price was: €180.00.€99.00Current price is: €99.00.

Reviews

There are no reviews yet.