CFD Analysis of Laser-arc Hybrid Welding: A Fluent UDF Tutorial

CFD Analysis of Laser-arc Hybrid Welding: A Fluent UDF Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€210 Original price was: €210.€185Current price is: €185.

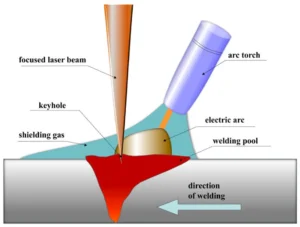

In this training guide, we explain the CFD Analysis of Laser-arc Hybrid Welding. This advanced manufacturing process uses a laser and an electric arc at the same time to join metals. The laser creates a deep, narrow weld at high speed, while the arc helps to fill wider gaps and stabilize the process. This combination is very effective, but the physics is extremely complex. Inside the tiny molten weld pool, the metal boils, flows rapidly, and solidifies in seconds. To prevent costly defects like cracks or voids in the final product, engineers need to understand and control this behavior. Because it is impossible to see inside the molten metal during a real weld, a Laser-arc Hybrid Welding fluent simulation is the best tool for design and analysis.

In this lesson, we show you how to perform a transient welding simulation in ANSYS Fluent. The main goal is to accurately predict the temperature and the flow of the liquid metal. This is achieved by using a custom code, or User-Defined Function (UDF), to model the unique heat sources. By following this guide, you will learn how to use a CFD Analysis of Laser-arc Hybrid Welding to improve weld quality and reduce the need for expensive physical testing. For more training on similar topics, please explore our Heat transfer tutorials.

Figure 1: Schematic diagram of the Laser-arc Hybrid Welding process, showing how the laser beam and electric arc work together on the workpiece.

Simulation Process: VOF and UDF Setup for Hybrid Heat Sources in ANSYS Fluent

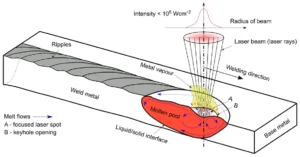

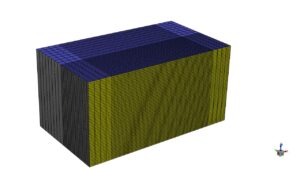

For this technical CFD – Laser-arc Hybrid Welding study, we first created the computational domain, which is a rectangular block representing the metal plate. A high-quality Structured Hexahedral Mesh was generated with exactly 197,120 cells. A structured grid was chosen because its cells are perfectly aligned with the direction of the welding torch. This alignment is critical for reducing numerical errors as the heat source moves across the domain. The core of the physics setup in ANSYS Fluent involved activating two key models. First, we used the Volume of Fluid (VOF) model to track the interface between the molten metal and the surrounding air. Second, we enabled the Solidification & Melting model, which uses the enthalpy-porosity technique to accurately handle the phase change from solid to liquid and back.

Standard heat source models in Fluent cannot represent this hybrid process. Therefore, the most critical part of this simulation was writing a custom User-Defined Function (UDF) in the C programming language. This UDF defines a moving heat source that combines two different mathematical models: a Gaussian profile for the laser to simulate its focused, deep energy, and a Double-Ellipsoid model for the arc to simulate its wider surface heating effect. The UDF was also programmed to calculate the powerful secondary forces that control the weld pool, including the Vapor Recoil Pressure (as the metal boils) and the Electromagnetic (Lorentz) Forces from the arc. The simulation was run in transient mode to capture the dynamic, second-by-second evolution of the weld pool.

Figure 2: 3D Geometry and Structured Mesh of the welding domain, showing the 197,120 hexahedral cells used for the accurate ANSYS Fluent simulation.

Post-processing: CFD Analysis of Laser-arc Hybrid Welding, Thermal Behavior, and Melt Pool Fluid Dynamics

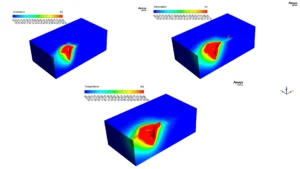

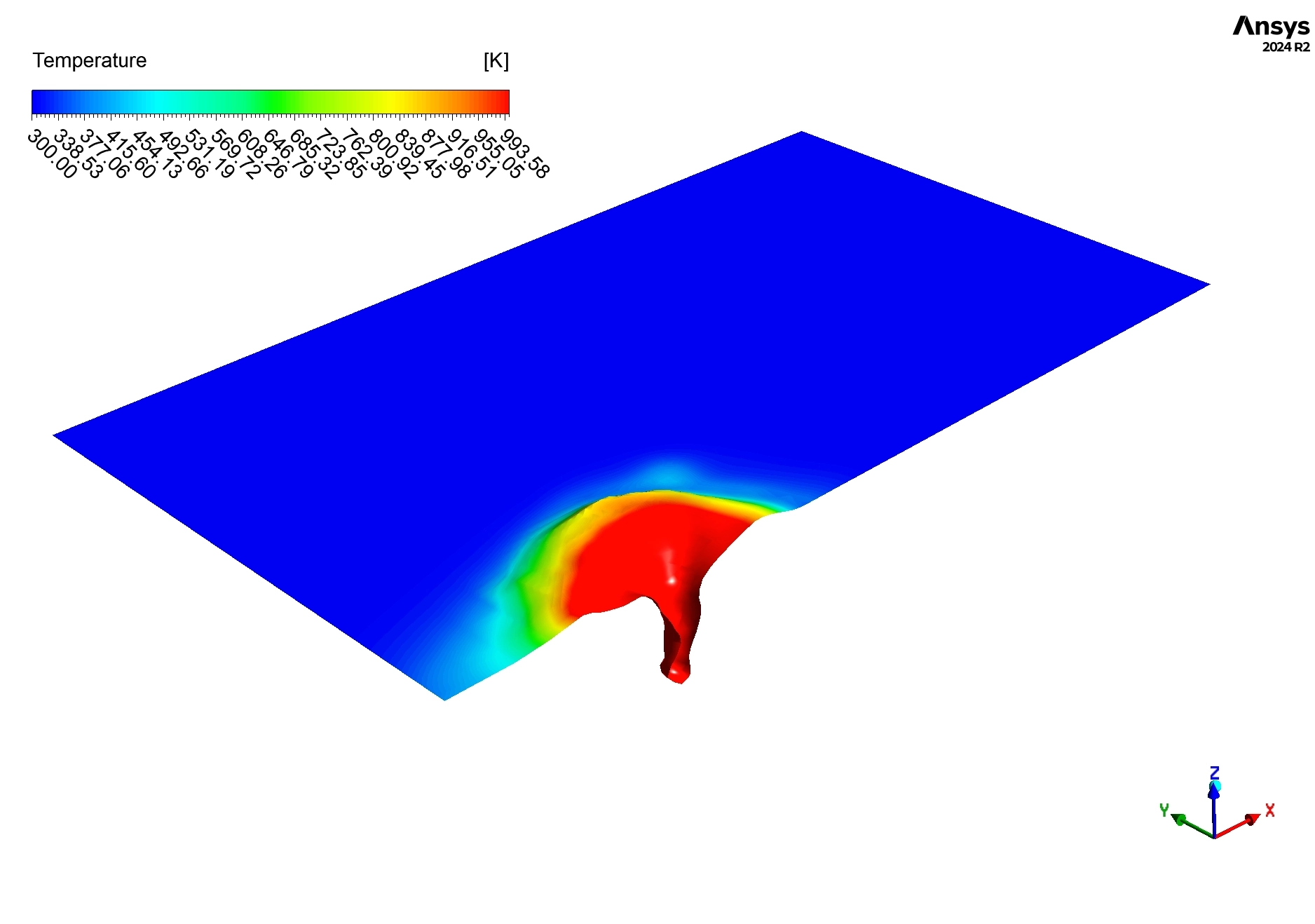

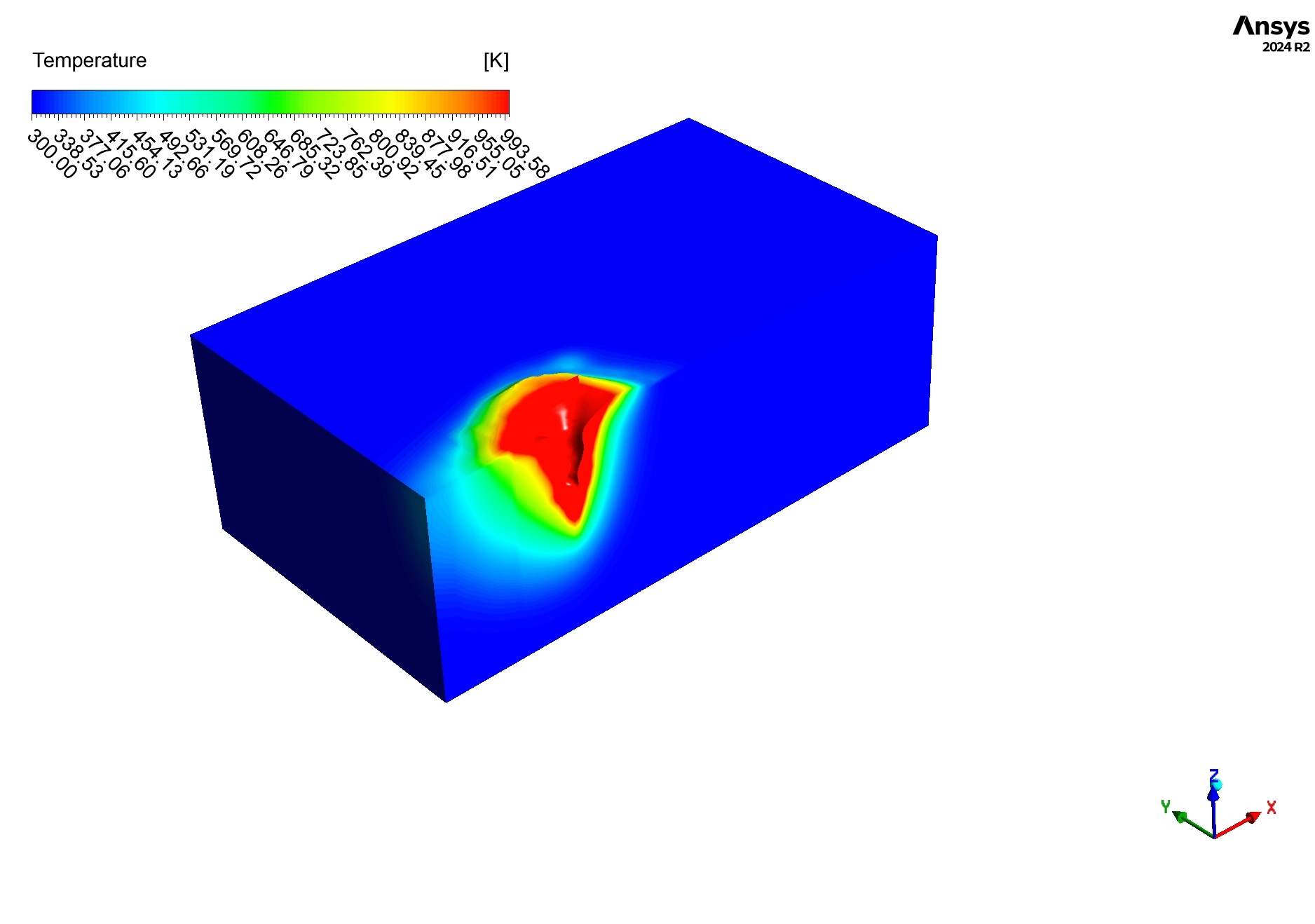

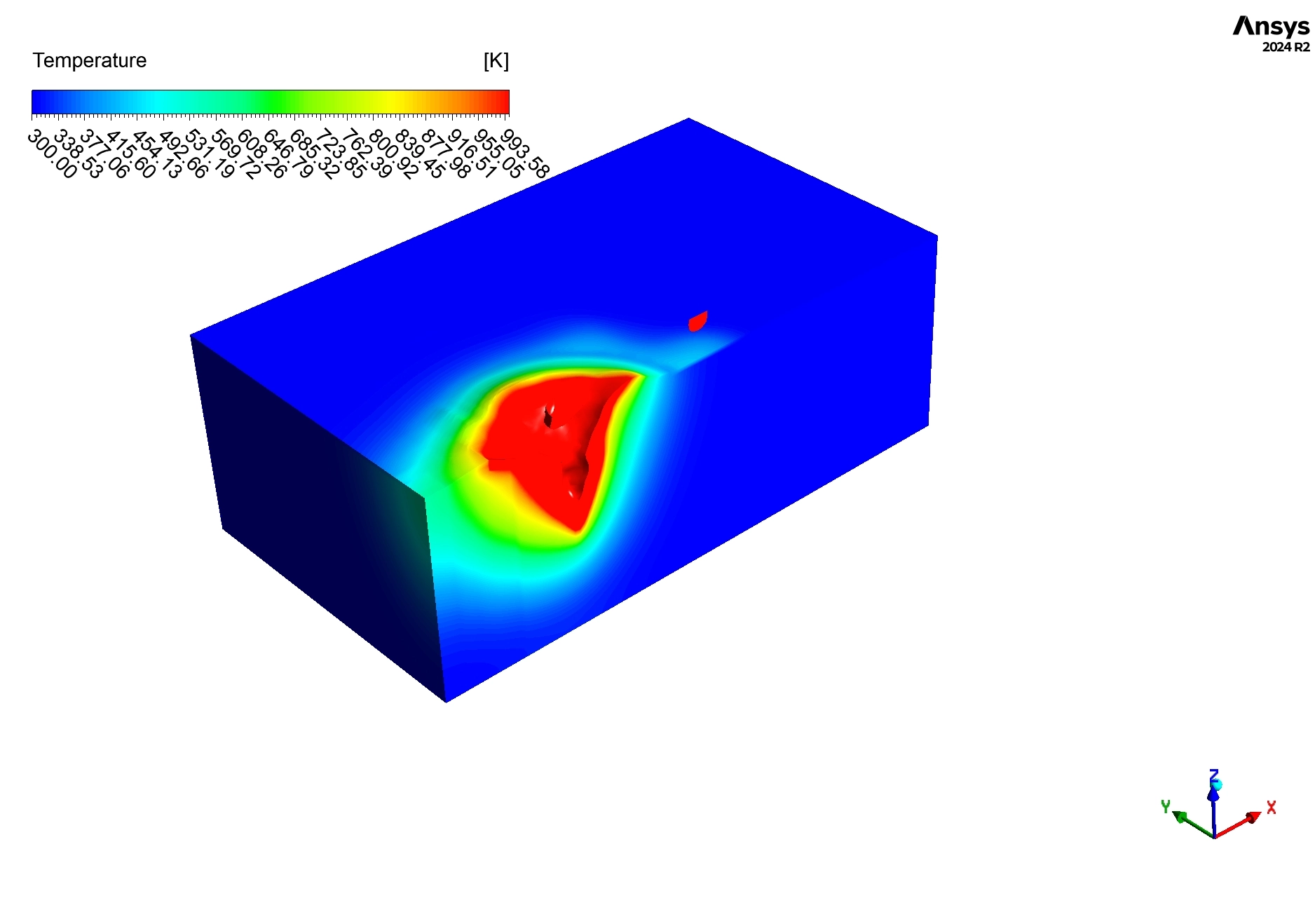

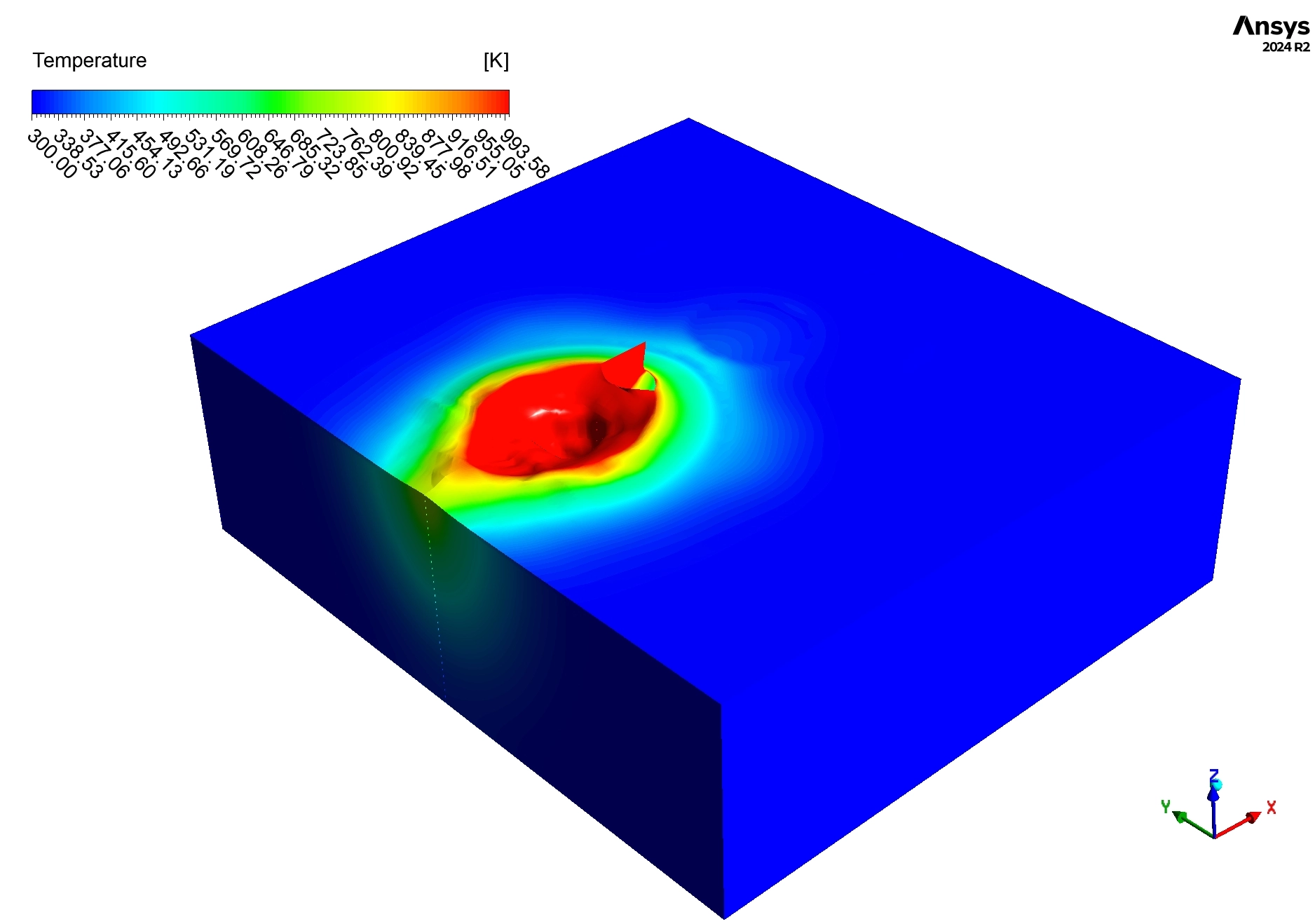

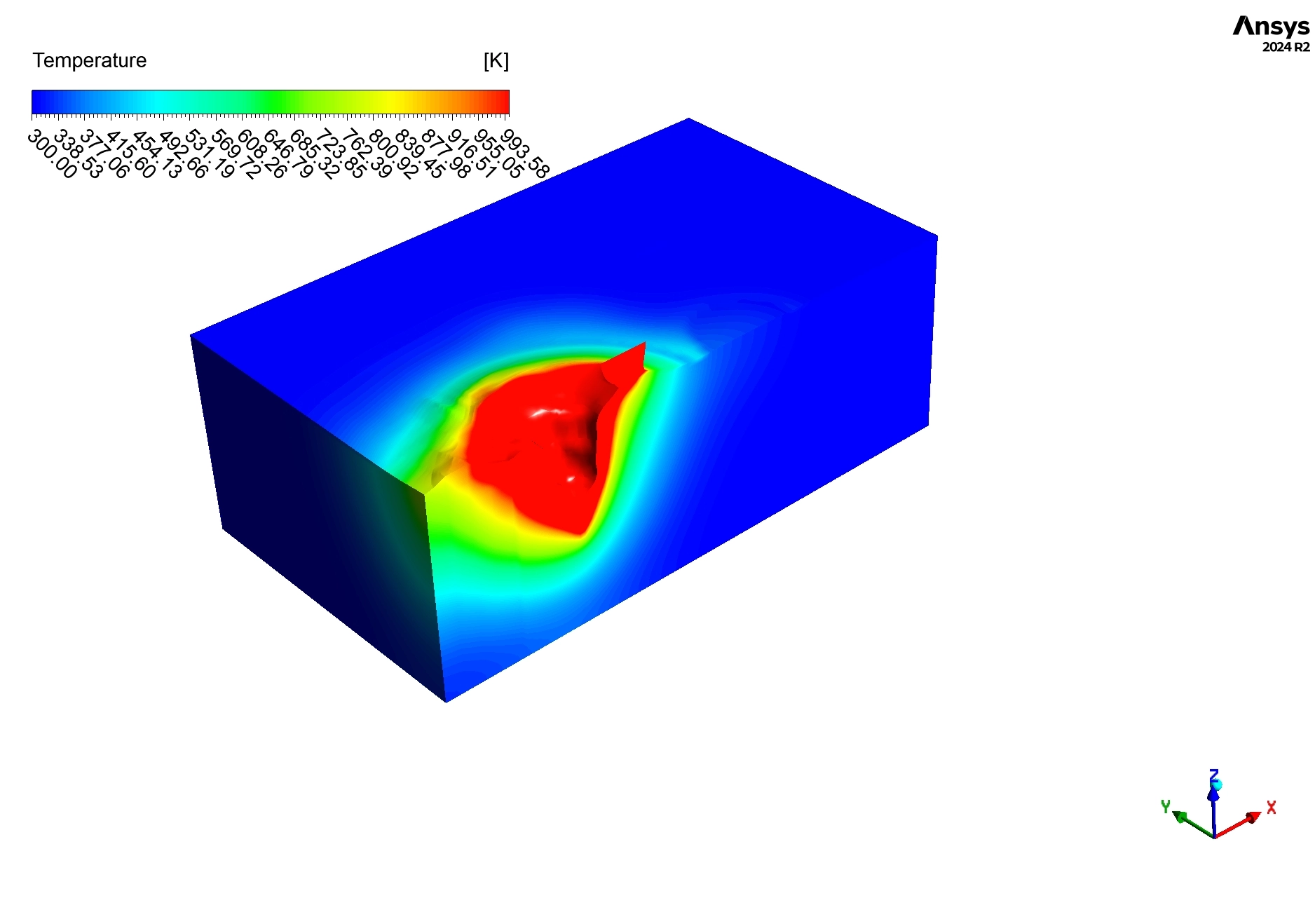

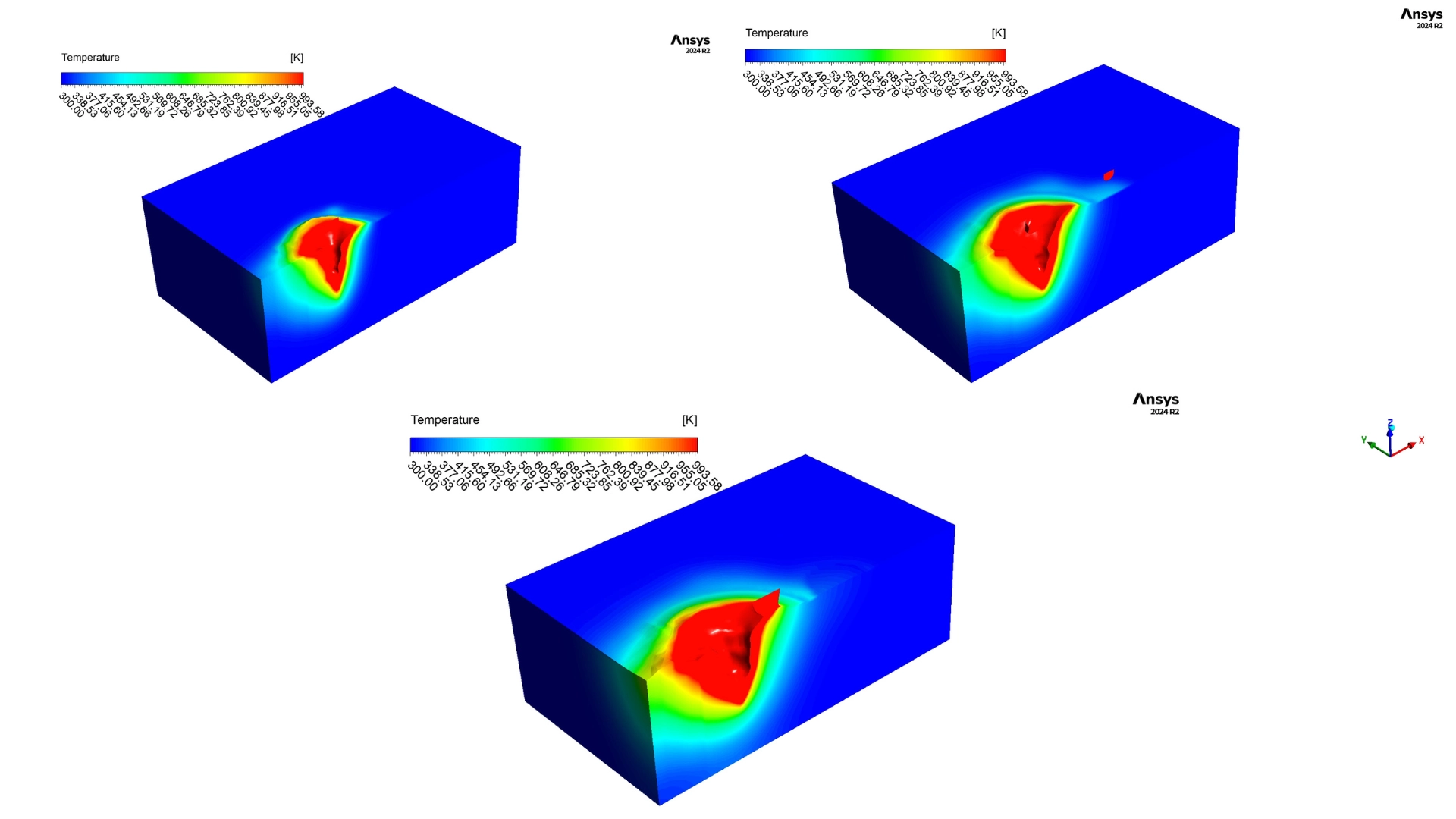

In this section, we provide a detailed engineering analysis of the simulation results. We interpret the contours to understand what is happening inside the weld and how it affects the final quality. First, we analyze the Temperature Distribution shown in Figure 3. The contour shows a snapshot in time, with the Red Zone indicating the active molten pool. The temperature in this zone exceeds 2700 K. This value is extremely important because it is close to the boiling point of steel. This confirms that the laser is powerful enough to create a keyhole, a deep vapor cavity that allows for deep penetration welding. The elongated shape of the heated region, with a long tail behind the heat source, is a direct result of Heat Accumulation. The metal does not cool instantly. This slow cooling rate behind the torch is a critical factor for manufacturers, as it influences the final grain structure (metallurgy) of the metal and can help prevent solidification cracking.

Figure 3: Temperature Contours showing the formation of the high-temperature molten pool (Red Zone, >2700 K) and the heat-affected zone in the welding simulation.

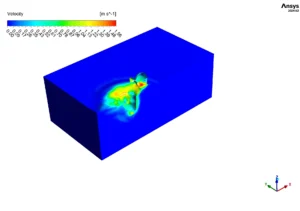

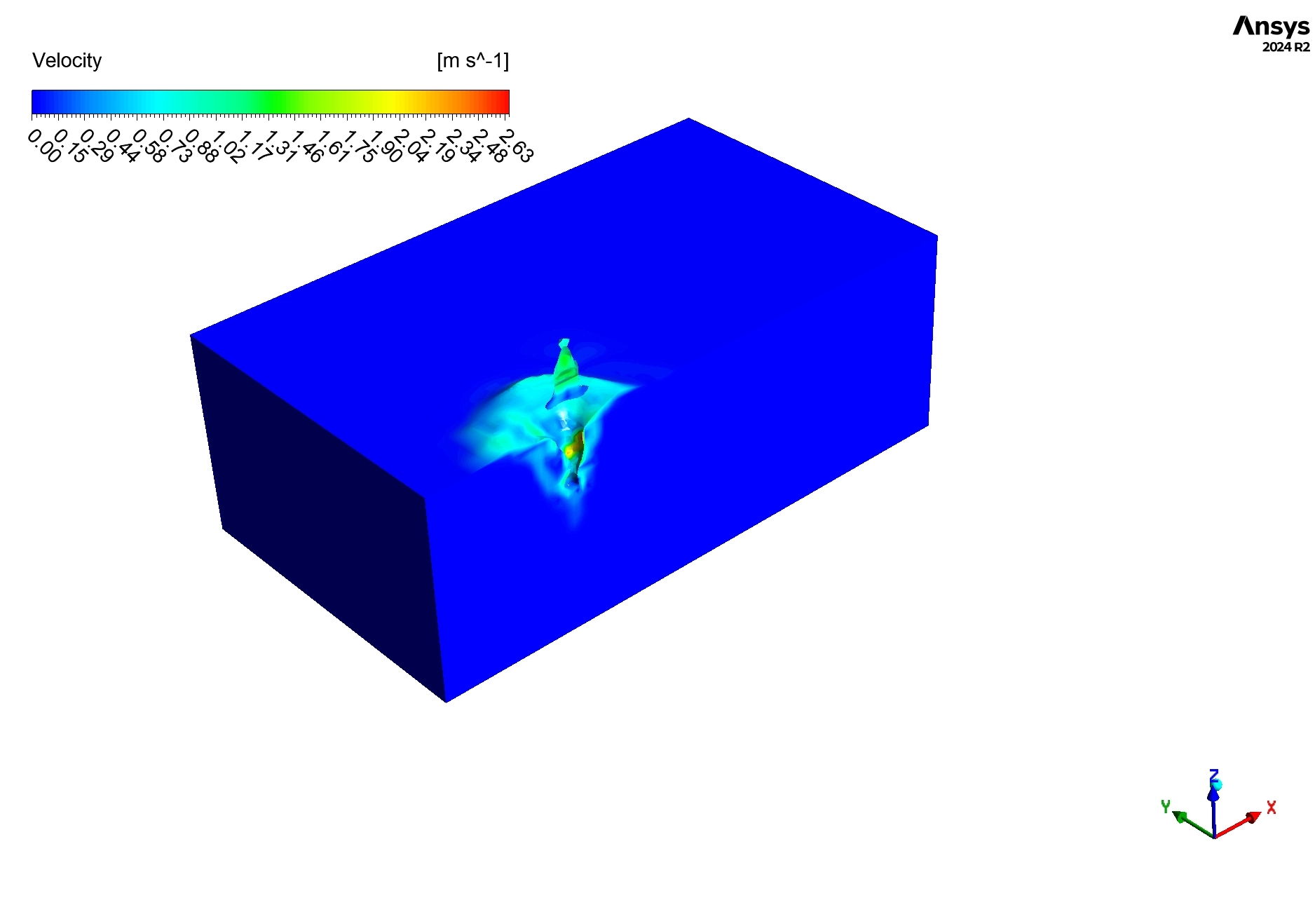

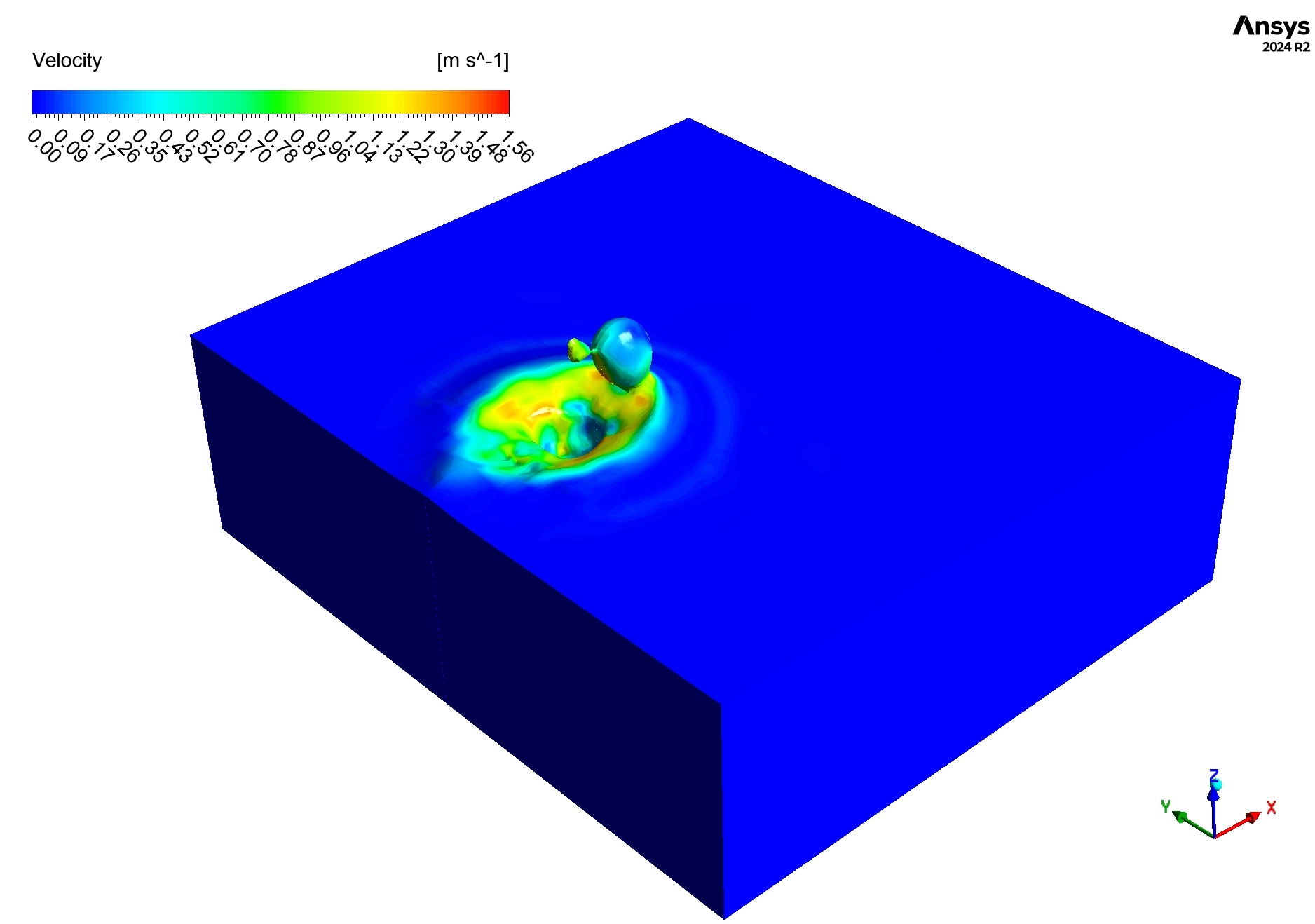

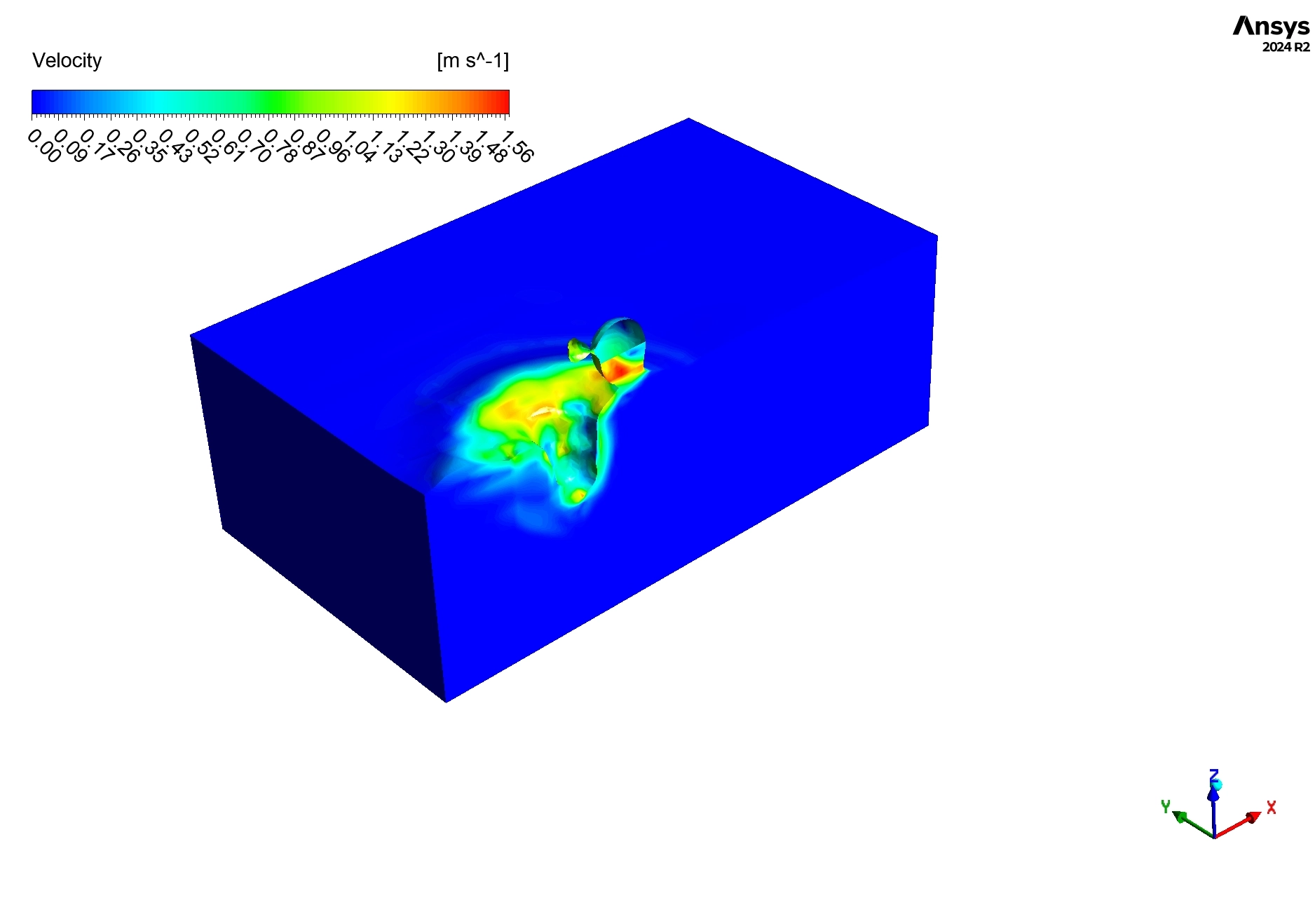

Next, we examine the Velocity Field inside the molten pool in Figure 4. While the solid metal is stationary, the liquid metal is moving very fast, reaching a Maximum Velocity of 0.9 m/s. This high speed is not caused by the torch’s movement; it is driven by powerful internal forces. The primary forces are Marangoni Convection, caused by temperature-driven changes in surface tension, and the recoil pressure from the vaporizing metal. The arrows in the velocity plot show a strong backward flow, where liquid metal is pushed from the front of the keyhole to the rear of the pool. From an engineering standpoint, this circulation is the key to a successful weld. This rapid mixing distributes heat evenly and helps the filler material (if used) mix properly, preventing defects. The high velocity of 0.9 m/s confirms that the weld pool is dynamic and unstable, which is characteristic of high-energy hybrid welding. This CFD Analysis of Laser-arc Hybrid Welding proves that the UDF is correctly capturing the dominant forces that create a strong, deep, and well-mixed joint.

Figure 4: Velocity Magnitude Contours inside the weld pool, highlighting the complex fluid dynamics with peak velocities of 0.9 m/s driven by Marangoni and recoil forces.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€75Current price is: €75.

€130 Original price was: €130.€85Current price is: €85.

€240 Original price was: €240.€125Current price is: €125.

€360 Original price was: €360.€185Current price is: €185.

€200 Original price was: €200.€125Current price is: €125.

€280 Original price was: €280.€145Current price is: €145.

Reviews

There are no reviews yet.