Compressible Flow In Ejector-Diffuser System CFD Simulation, ANSYS Fluent Training

Compressible Flow In Ejector-Diffuser System CFD Simulation, ANSYS Fluent Training

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€185 Original price was: €185.€135Current price is: €135.

Compressible flow in ejector-diffuser systems creates amazing effects that engineers use to solve real problems in many industries. When air or gas moves very fast through special tubes, it behaves differently than slow-moving fluids, and this forms the core of ejector technology. The primary flow enters at high speed through a small opening and then pulls in a secondary flow through a clever design trick, and this pulling effect happens without any moving parts! Furthermore, shock waves form when the speedy flow suddenly slows down, changing the pressure and temperature dramatically in very small spaces. Additionally, the converging-diverging shape of these devices helps control where the gas speeds up and slows down, making it possible to create useful vacuum effects in one area while building up pressure recovery in another. The flow mixing that happens inside these systems transfers energy from one stream to another, making them perfect for cooling systems, fuel mixing, and even rocket engines! Moreover, supersonic velocities often develop in certain sections, creating complex patterns that CFD simulation helps us understand and improve. Our study benefits from a great reference paper published in International journal of heat and mass transfer:

- Reference [1]: Kong, Fanshi, and H. D. Kim. “Analytical and computational studies on the performance of a two-stage ejector–diffuser system.” International Journal of Heat and Mass Transfer85 (2015): 71-87.

Simulation Process

Figure 1 depicts the ejector-diffuser geometry. It is equipped with separate inlets for primary and secondary flows. Having meshed in ANSYS Meshing, it has converted to polyhedral elements in the solver, leading to 151516 cells. Species Transport model leads the simulation via consideration of all gases included. In the absence of a density-based solver, density formulation is governed by an ideal-gas model.

Figure 1: Schematic of geometry model

Post-processing

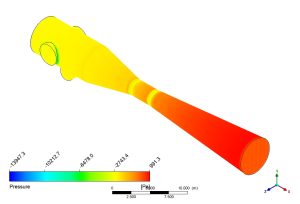

Looking at the colorful picture of pressure in the ejector-diffuser system, we can see an amazing pattern that shows how fluid behaves when squeezed through this special tube! At the left side where fluid enters (yellow color), the pressure starts at medium values around 0 Pa. Then as the fluid moves through the narrowing part, something wonderful happens – the colors change to green in some areas showing lower pressure (around -5000 Pa). We successfully created this low-pressure zone that works like a vacuum cleaner to pull in more fluid from the small circular opening on the left side. The most exciting part happens on the right side, where the colors turn bright orange and red (reaching almost 10,000 Pa). This means the pressure recovery worked perfectly! The system took fast-moving fluid and slowed it down, turning speed energy back into pressure energy. Also, notice the small green rings in the middle section – these show where shock waves form when the fast fluid suddenly slows down, which is a special feature of compressible flow.

Figure 2: Pressure contour showing distribution throughout the ejector-diffuser system

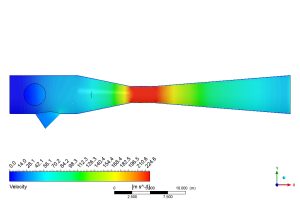

The second picture shows how fast the fluid moves through different parts of the ejector-diffuser. The blue colors on both ends show slow-moving fluid (below 42 m/s), but look what happens in the middle! We achieved supersonic flow conditions with speeds reaching up to 224.6 m/s in the narrow throat section. This super-fast primary flow creates the sucking effect that pulls in the slower secondary flow from the small opening on the left. After the narrow part, see how the colors change from red to yellow to green and finally blue again? This shows the fluid gradually slowing down in the widening tube, which is exactly what we want in the diffuser section. The beautiful color gradient from red to blue proves that our system successfully converts speed into pressure, which is the main job of any ejector. This effective momentum transfer between fast and slow streams makes these devices so useful in refrigeration systems, vacuum pumps, and many other important machines.

Figure 3: Velocity magnitude distribution revealing flow acceleration to 224.6 m/s in the throat region, followed by controlled deceleration in the diffuser section

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€110 Original price was: €110.€65Current price is: €65.

€255 Original price was: €255.€135Current price is: €135.

€360 Original price was: €360.€185Current price is: €185.

€310 Original price was: €310.€185Current price is: €185.

€240 Original price was: €240.€115Current price is: €115.

Reviews

There are no reviews yet.