Tunnel Fire CFD: A Fluent Tutorial on Natural Ventilation & Smoke Propagation

Tunnel Fire CFD: A Fluent Tutorial on Natural Ventilation & Smoke Propagation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€255 Original price was: €255.€135Current price is: €135.

Tunnel fires are one of the most dangerous incidents that can happen underground, making smoke control and safety design essential. A Tunnel Fire CFD simulation is a powerful and safe way to study these events, allowing engineers to understand how smoke moves without conducting expensive and dangerous real-world tests. This report details a CFD simulation based on the reference paper, “Extended CFD models for numerical simulation of tunnel fire under natural ventilation: Comparative analysis and experimental verification” [1], to show how a fire behaves when only natural airflow is present.

- Reference [1]: Xu, Tong, et al. “Extended CFD models for numerical simulation of tunnel fire under natural ventilation: Comparative analysis and experimental verification.” Case Studies in Thermal Engineering31 (2022): 101815.

Figure 1: Schematic diagram of the physical tunnel model used for the simulation [1].

Simulation Process: Modeling the Tunnel Fire Fluent Simulation

The simulation was performed in ANSYS Fluent using a 3D model of a rectangular tunnel. A high-quality structured grid was created in ICEM software to ensure the calculations are accurate. The fire was modeled as a square ethanol pool fire located in the center of the tunnel floor. To accurately simulate the fire, two key models were used:

- The Eddy Dissipation combustion model was used to calculate how fast the fuel burns.

- The Species Transport model was used to track the movement of the fire’s products, like Carbon Dioxide (CO2), which we see as smoke. The entire simulation was run under Natural Ventilation Fluent conditions, meaning there were no fans, and air could only move due to the fire itself.

Figure 2: Illustration of AEM (mass sink and mass source) [1]

Post-Processing: CFD Analysis, How a Fire Creates a High-Speed Smoke Jet

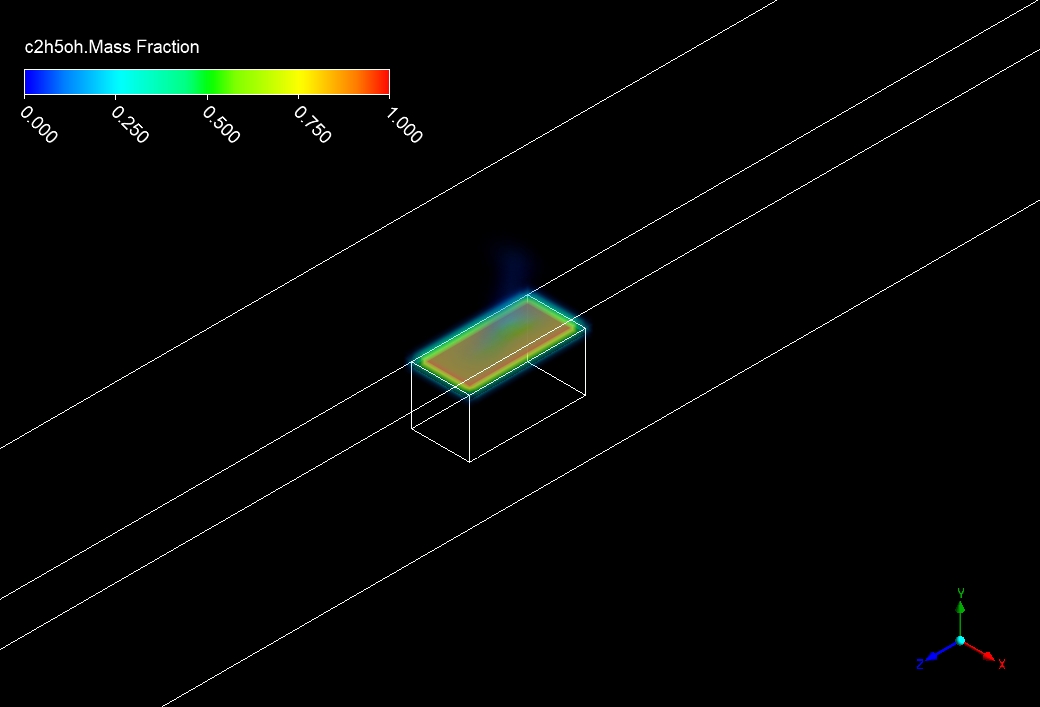

The simulation results provide a clear and fully substantiated story that begins with the fire itself, which is the “cause” of all air movement. The fire is a source of intense heat and combustion products. The chemical reaction releases hot gases, primarily CO2. The mass fraction contour in Figure 4 is the visual proof of this cause. It shows the highest concentration of CO2 (red, with a mass fraction of 0.171) located in a plume directly above the fire source. This intense heat makes the surrounding air and CO2 mixture extremely hot, and therefore much lighter and less dense than the cool air in the rest of the tunnel. This huge difference in density creates a powerful upward force called buoyancy, which acts as the engine driving the entire flow.

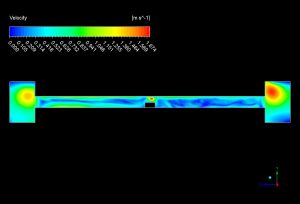

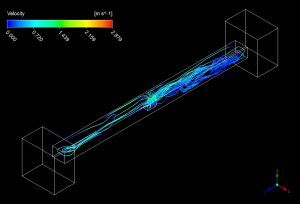

Figure 3: Velocity streamlines and contours from the Smoke Propagation CFD analysis, clearly showing the formation of the ceiling jet. Carbon Dioxide distribution after the fire, showing the highest concentration directly above the fire source, which drives the buoyancy-driven flow.

This powerful buoyancy force has a direct and dangerous “effect” on the flow inside the tunnel. The hot, light gas mixture shoots upwards until it hits the tunnel ceiling. Since it cannot go up any further, the flow is forced to turn and spread horizontally along the ceiling. This creates a fast-moving, concentrated layer of hot smoke and toxic gases known as a ceiling jet. The velocity contour in Figure 3 is the perfect visual proof of this effect. It shows the highest velocities (cyan to light green, reaching up to 2.88 m/s) are not at the fire itself, but are concentrated in a distinct layer just under the ceiling, moving away from the fire. This ceiling jet is the single most important factor in a tunnel fire, as it is the primary mechanism that transports deadly smoke and intense heat far from the fire source, creating hazardous conditions for anyone trying to escape. The most significant achievement of this Tunnel Fire CFD analysis is the clear demonstration of how the localized heat and mass release from the fire (the cause) generates a powerful, buoyancy-driven ceiling jet (the effect), which is the critical phenomenon that governs the speed and direction of smoke propagation and ultimately determines the safety conditions inside the tunnel.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€145Current price is: €145.

€195 Original price was: €195.€155Current price is: €155.

€310 Original price was: €310.€170Current price is: €170.

€330 Original price was: €330.€175Current price is: €175.

€185 Original price was: €185.€125Current price is: €125.

€160 Original price was: €160.€75Current price is: €75.

Reviews

There are no reviews yet.