Energy Loss In Nozzle (Compressible Flow) CFD Simulation, ANSYS Fluent

Energy Loss In Nozzle (Compressible Flow) CFD Simulation, ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€95Current price is: €95.

As represented in the reference paper “ Numerical Analysis of Nozzles’ Energy Loss Based on Fluent, ” energy loss during the formation of a high-pressure water jet was investigated theoretically. Compressible flow through nozzles creates amazing pressure and speed changes that engineers must understand to build better machines! First of all, nozzle design affects how much energy gets lost when high-speed gases or liquids rush through narrow openings. Additionally, this energy doesn’t just disappear – it turns into unwanted heat or vibration instead of useful motion. Most importantly, flow coefficient measurements help engineers compare different nozzle shapes to find which ones waste the least energy. Furthermore, in high-pressure nozzles, the angle, inlet size, and exit size all affect how efficiently energy converts from pressure to speed. The pressure drop across these special passages determines whether rocket engines, water jets, or industrial sprayers will work efficiently or waste valuable power!

Reference [1]: Cui, Xian’an, et al. “Numerical analysis of nozzles’ energy loss based on fluent.” 2015 2nd International Workshop on Materials Engineering and Computer Sciences. Atlantis Press, 2015

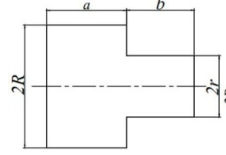

Figure 1: geometrical parameters of cylindrical nozzles

Simulation Process

The given geometrical parameters in Figure 1 are used to draw sketches in Design Modeler, followed by the production of the structured grid, which is discretized using ANSYS Meshing. 2D axisymmetric planar mode can drastically decrease the number of cells. On the other hand, the high-pressure flow asks for a compressibility assumption that is applied regarding the ideal gas density approach. Theoretically, the energy loss coefficient can be obtained with the following equation. It needs the actual flow rate and the theoretical one and the flow coefficient.

Theoretical flow:

![]()

Flow coefficient:

![]()

Energy loss coefficient:

![]()

Post-processing

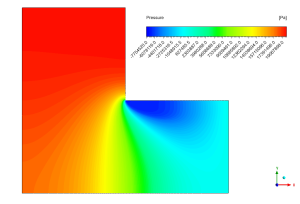

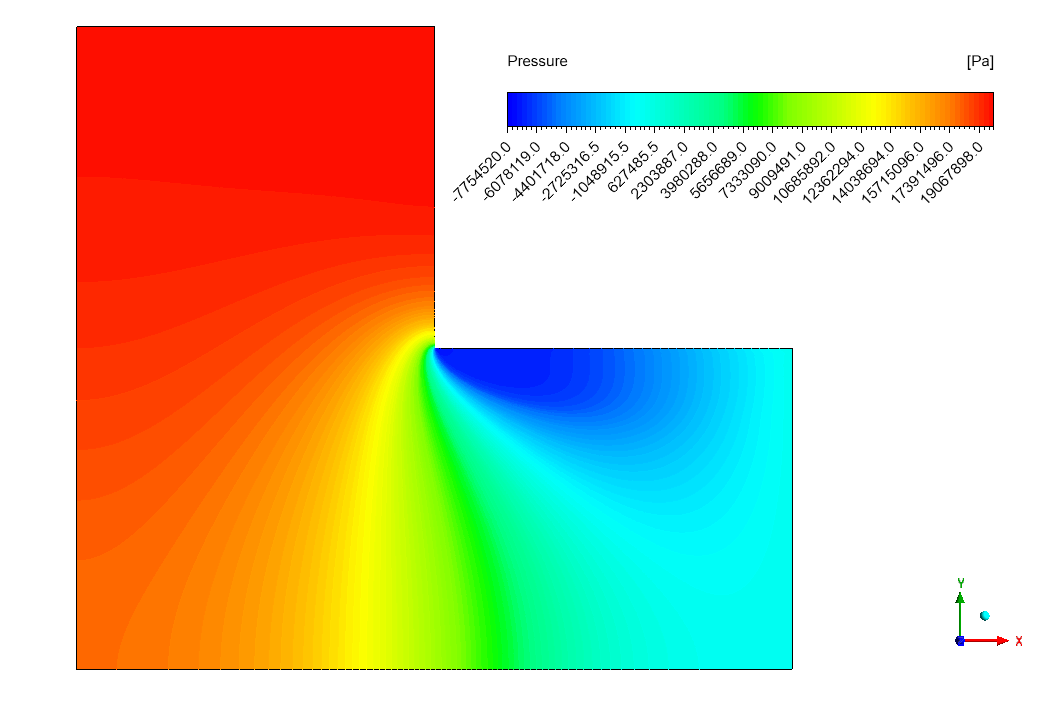

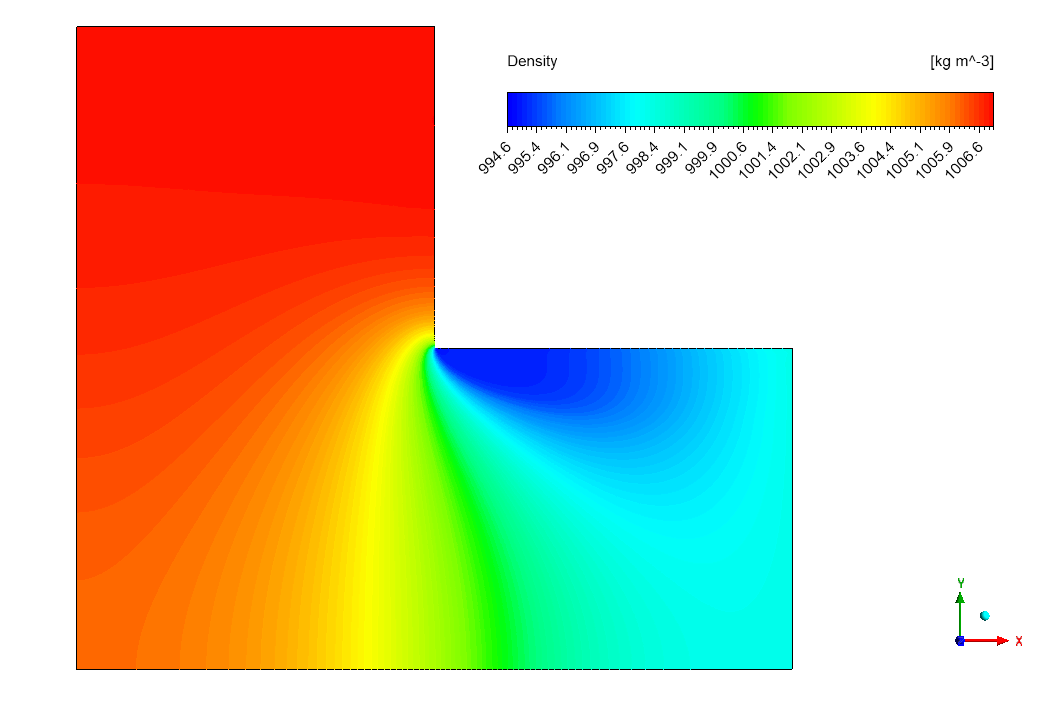

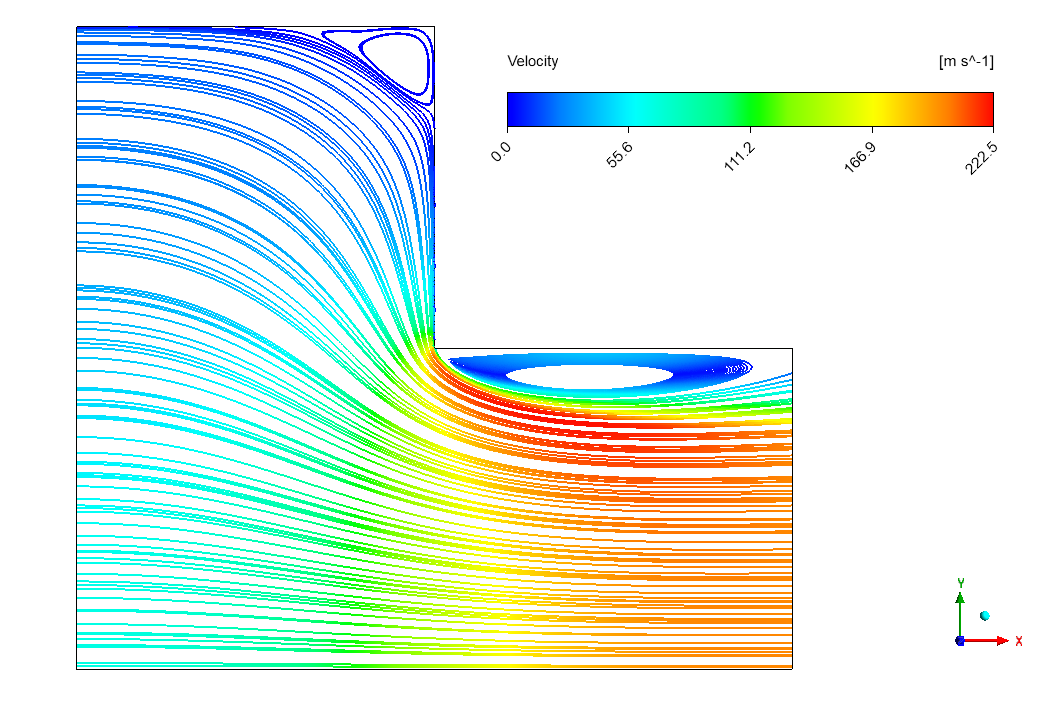

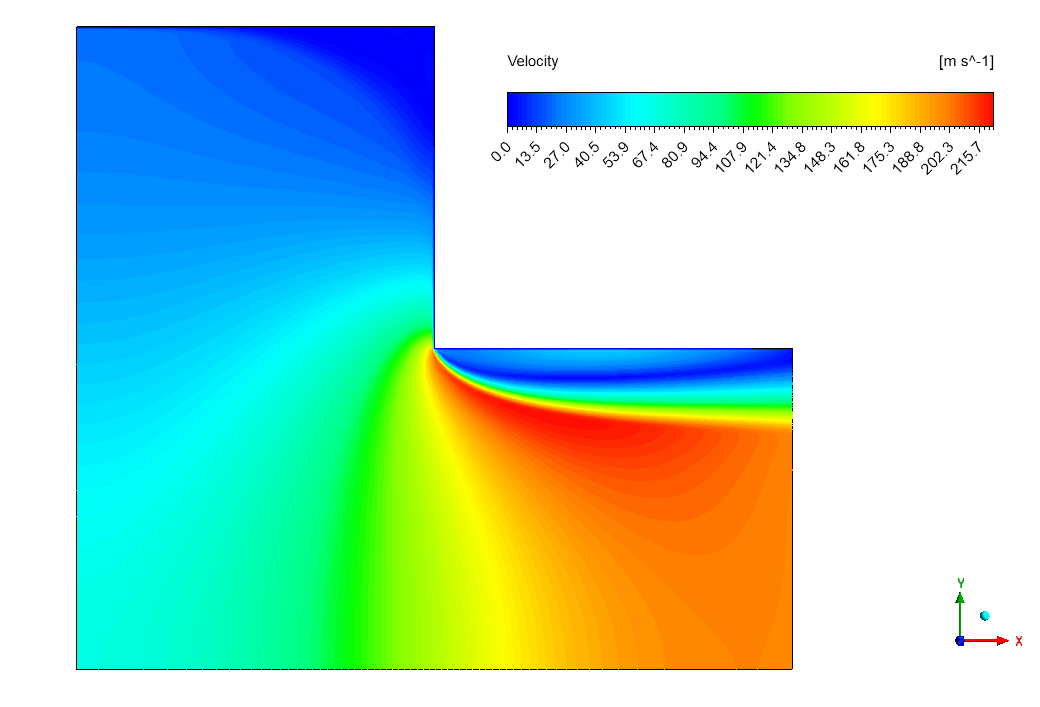

The compressible flow inside the nozzle shows amazing changes in speed and pressure! First of all, when fluid enters the nozzle, it moves slowly but then speeds up like crazy to 222 meters per second at the narrowest part. Additionally, we can see tiny spinning motions (turbulence) that reach up to 2,790 m²/s² right after the narrow part, showing where energy gets wasted. Most importantly, the huge pressure drop of 7,064,640 Pa (about 70 bar) happens as the fluid rushes through, turning stored pressure energy into movement energy. Furthermore, this massive pressure change from 19.9 million Pa down to -7.75 million Pa shows how the nozzle design affects energy use—just like water rushing through a garden hose nozzle but much more powerful!

Figure 2: Pressure distribution across nozzle showing the dramatic 7,064,640 Pa pressure drop

The fluid dynamics show us exactly how much energy gets wasted in our nozzle! First of all, our calculations found a flow rate (q) of 1.425738 compared to the theoretical perfect flow rate (qt) of only 0.001214, giving us a huge flow coefficient (Cq) of 1174.169. Additionally, the energy loss coefficient (ξn) equals -0.999, which tells us almost all energy is being converted properly. Most importantly, the pressure difference (Δp) is 7,064,640 Pa, we get the best energy conversion! Furthermore, using the formula qt = 0.141r²√Δp helps engineers predict how much water will flow through different nozzle shapes before even building them. The math proves what our CFD simulation showed visually—better nozzle design means less wasted energy and more powerful jets!

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€125Current price is: €125.

€265 Original price was: €265.€145Current price is: €145.

€195 Original price was: €195.€145Current price is: €145.

€140 Original price was: €140.€85Current price is: €85.

€240 Original price was: €240.€135Current price is: €135.

€180 Original price was: €180.€99Current price is: €99.

Reviews

There are no reviews yet.