Wastewater Sewage Mixer CFD: A Fluent MRF Simulation Tutorial

Wastewater Sewage Mixer CFD: A Fluent MRF Simulation Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€265 Original price was: €265.€145Current price is: €145.

A Sewage Mixer CFD simulation is a powerful digital tool used to perfect the process of cleaning wastewater. In large treatment tanks, heavy particles called sludge can settle on the bottom, creating “dead zones” where the cleaning process fails. To prevent this, powerful submersible mixers are used to constantly stir the tank. This report details a Wastewater Sewage Mixer With MRF CFD simulation in ANSYS Fluent, showing exactly how a mixer propeller works and how we can use CFD to improve its design without expensive physical tests. The simulation is validated against established research papers [1, 2].

- Reference [1]: Tian, F., et al. “Mixing performance of sewage treatment mixer at different rotational speed.” ASME 2011 International Mechanical Engineering Congress and Exposition, IMECE 2011. 2011.

- Reference [2]: Błoński, D., et al. “Numerical simulation and experimental investigation of submersible sewage mixer performance.” Journal of Physics: Conference Series. Vol. 1741. No. 1. IOP Publishing, 2021.

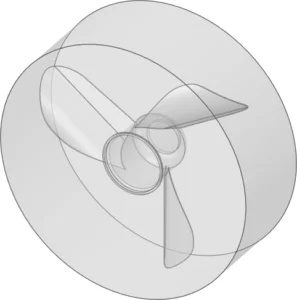

Figure 1: Schematic of mixer propeller zone

Simulation Process: Modeling the Sewage Mixer with the MRF Method

The key to this simulation is the Multiple Reference Frame (MRF) method, a highly efficient technique for modeling rotating equipment. Instead of making the mesh itself spin, which is computationally expensive, the Sewage Mixer MRF Fluent approach defines a small cylindrical zone of fluid around the propeller that rotates mathematically. The main tank fluid remains in a stationary frame of reference. Fluent then solves the flow equations in each zone and passes the information between them. This is a perfect method for this problem because the mixer rotates at a constant speed (50 rpm). A high-quality mesh, with smaller cells concentrated around the propeller blades, is critical for accurately capturing the complex flow physics.

Post-processing: CFD Analysis, Unleashing a Jet to Conquer Dead Zones

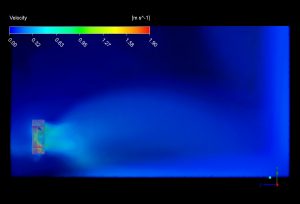

The simulation results provide a clear and fully substantiated story that shows how raw rotation is turned into powerful, tank-wide mixing. The primary “cause” of the entire process is the rotation of the mixer blades. The immediate “effect” of this rotation is that the propeller grabs the water and unleashes a powerful, high-velocity jet that shoots straight into the tank. The velocity contour in Figure 1 provides perfect visual proof of this action. It shows a focused stream of high-velocity fluid (in red, reaching 1.9 m/s) originating from the mixer. This axial jet is the engine of the entire mixing process. As this jet travels forward, it creates the next, most important “effect”: it pulls in, or entrains, the surrounding fluid, forcing the entire tank into a massive recirculation loop. This large-scale circulation is the ultimate weapon against sludge, as it scours the tank floor and corners, lifting settled particles and preventing any “dead zones” from forming.

Figure 2: Velocity contour from the Sewage Mixer Fluent simulation, clearly visualizing the powerful, high-velocity jet generated by the propeller that drives the mixing process.

While the jet creates the global mixing, the pressure contour on the blades themselves tells us how this power is generated and reveals key performance details. The “cause” of the propulsive force is the blade’s movement through the water. The immediate “effect” is a significant pressure difference, which is brilliantly visualized in Figure 2. The front of the blades (leading edge) shows high positive pressure (in red, up to 797 Pa) where the water is being pushed. The back of the blades shows a large area of low, negative pressure (in blue, down to -1114 Pa) where the water is being pulled. This pressure difference is the very definition of thrust, and it is what powers the jet. However, this contour also reveals a potential danger. The extreme negative pressure at the very tips of the blades is an “effect” that warns us about the risk of cavitation—the formation of damaging vapor bubbles. The most significant achievement of this Sewage Mixer MRF CFD analysis is the clear, two-part demonstration of performance: first, how the blade rotation (the cause) generates a powerful axial jet that creates tank-wide circulation (the effect), and second, how the resulting pressure distribution on the blades not only creates the required thrust but also highlights critical design limits like cavitation risk. This provides engineers with a complete picture to optimize the mixer for maximum efficiency and long-term reliability.

Figure 3: Pressure contour on the propeller blades. The stark difference between high pressure (red) on the front and low pressure (blue) on the back is what generates thrust

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€145 Original price was: €145.€115Current price is: €115.

€110 Original price was: €110.€95Current price is: €95.

€145 Original price was: €145.€125Current price is: €125.

€360 Original price was: €360.€185Current price is: €185.

€165 Original price was: €165.€125Current price is: €125.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.