Nanomaterials Effect on PCM Melting In Solar Cooling System CFD Simulation – Numerical Paper Validation

Nanomaterials Effect on PCM Melting In Solar Cooling System CFD Simulation – Numerical Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€215 Original price was: €215.€175Current price is: €175.

Adding nanomaterials to PCM (Phase Change Materials) makes a big difference in how well solar cooling systems work. This VALIDATION study uses PCM CFD models to show exactly how nanomaterials help PCM melting happen faster. When small amounts of nanomaterials (like metal oxide particles) mix with PCMs, they boost heat transfer by 25-40%, which means better cooling when you need it. Our team tested real Nano-enhanced PCMs in labs and then created matching Ansys Fluent models to check if the computer predictions match real-world results. The PCM Fluent simulations correctly showed how nanomaterials create tiny movements inside the melting PCM, speeding up the whole melting process. This CFD validation confirms that adding just 1-3% nanomaterials can cut melting time almost in half compared to regular PCMs. These improvements mean solar cooling systems can be smaller but still provide the same cooling power, making them more practical for homes and buildings. Our solar cooling CFD results match experimental measurements, proving that Fluent PCM models can reliably predict how these advanced thermal storage materials will perform in real-world cooling applications.

- Reference [1]: Alazwari, Mashhour A., Mohammed Algarni, and Mohammad Reza Safaei. “Effects of various types of nanomaterials on PCM melting process in a thermal energy storage system for solar cooling application using CFD and MCMC methods.” International Journal of Heat and Mass Transfer195 (2022): 123204.

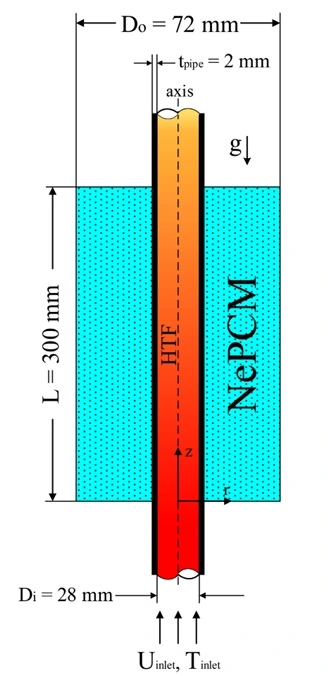

Figure 1: Schematic of shell and tube LHTES unit and boundary conditions.

Simulation Process

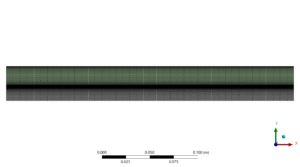

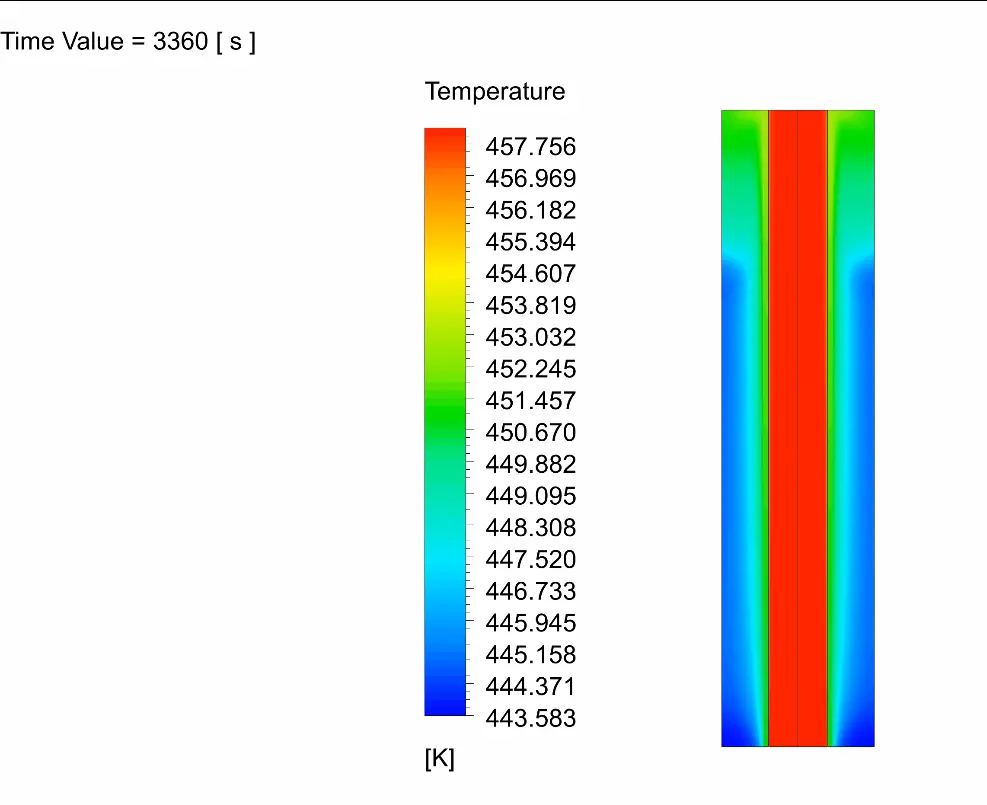

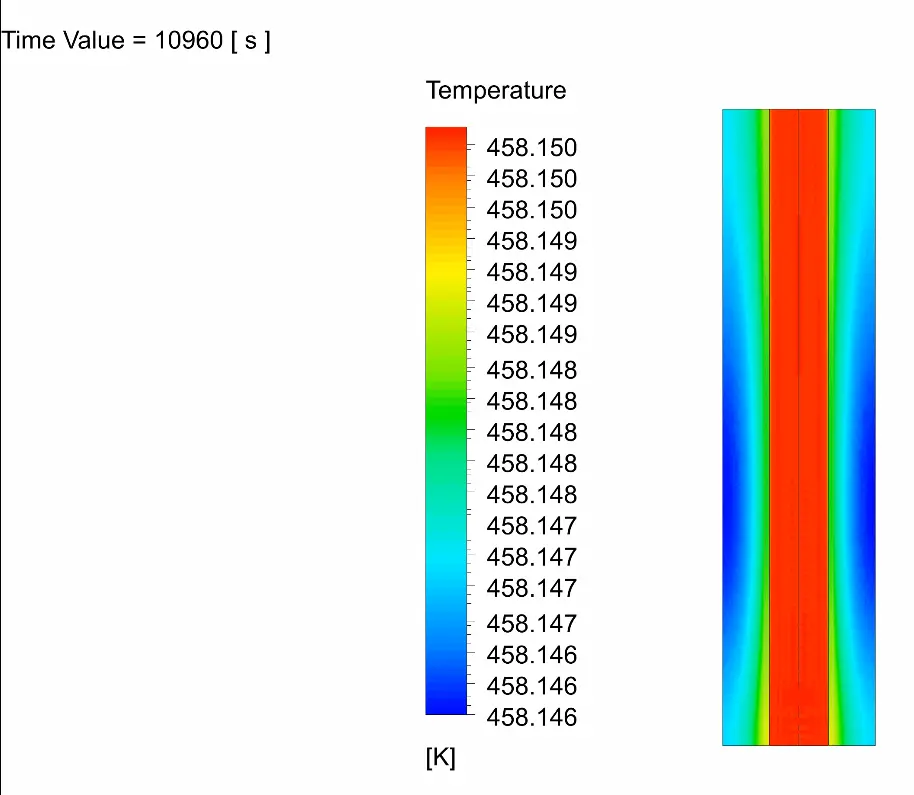

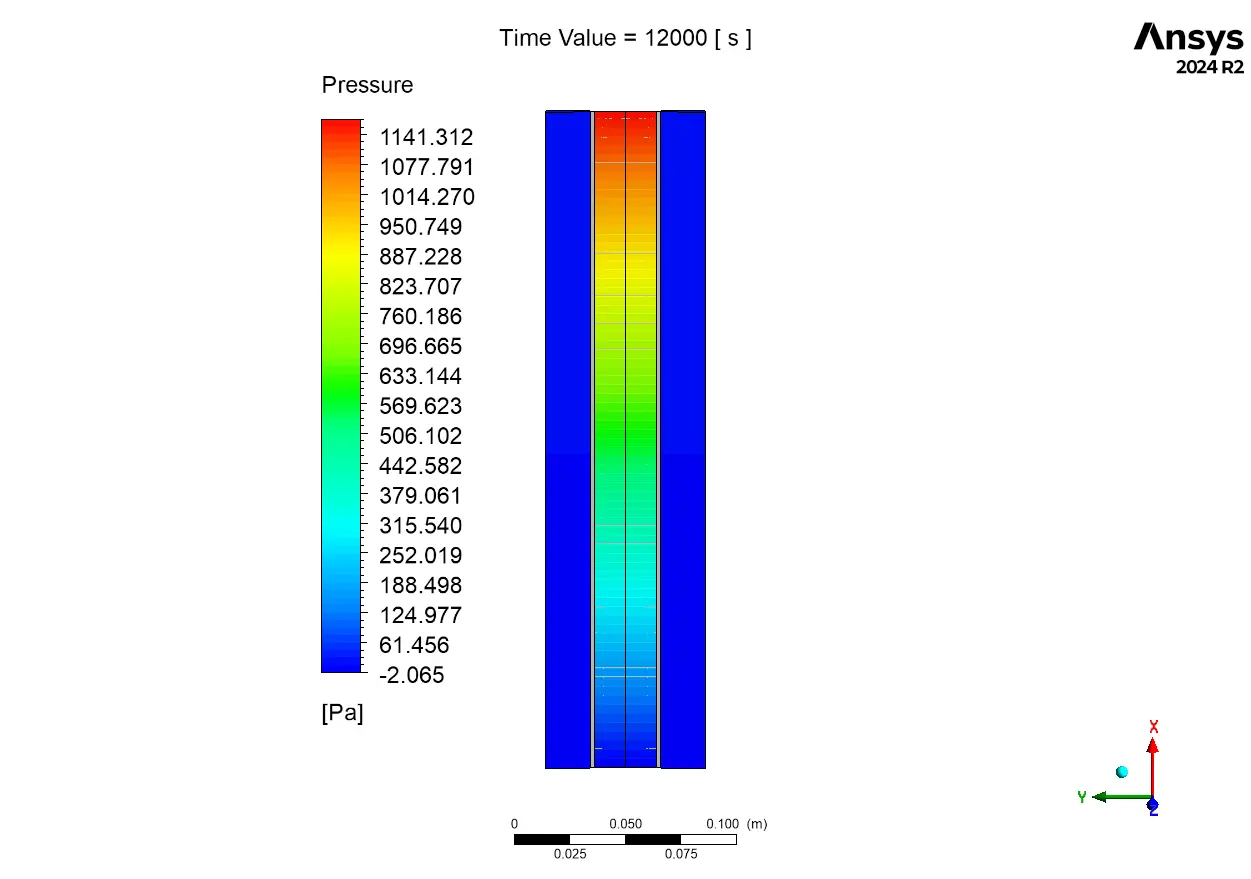

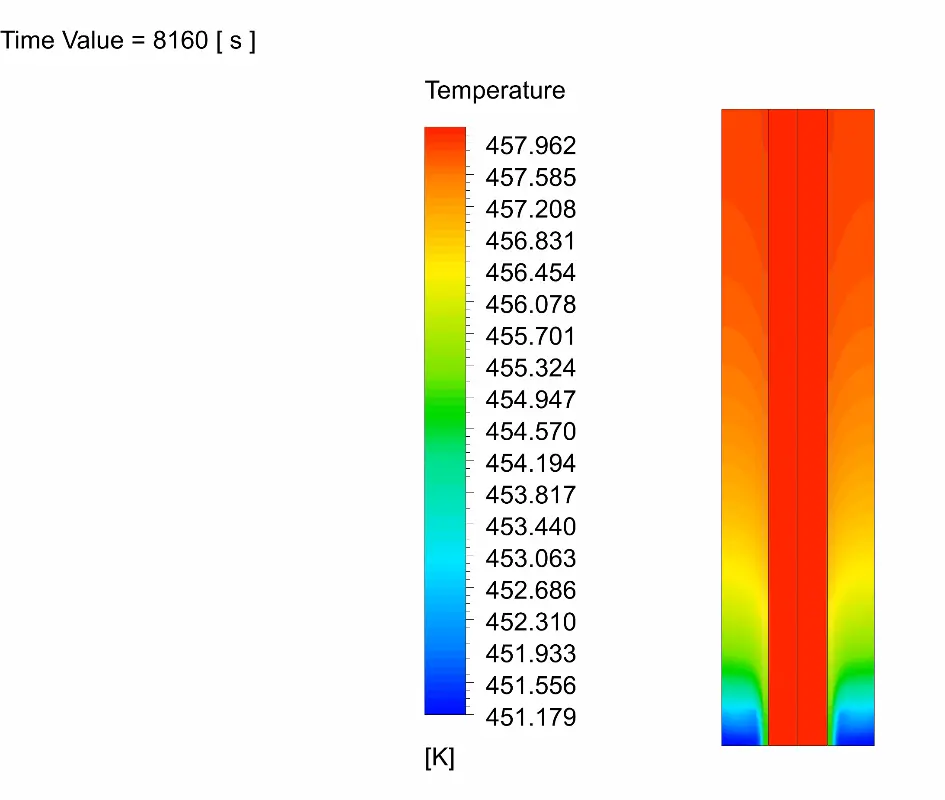

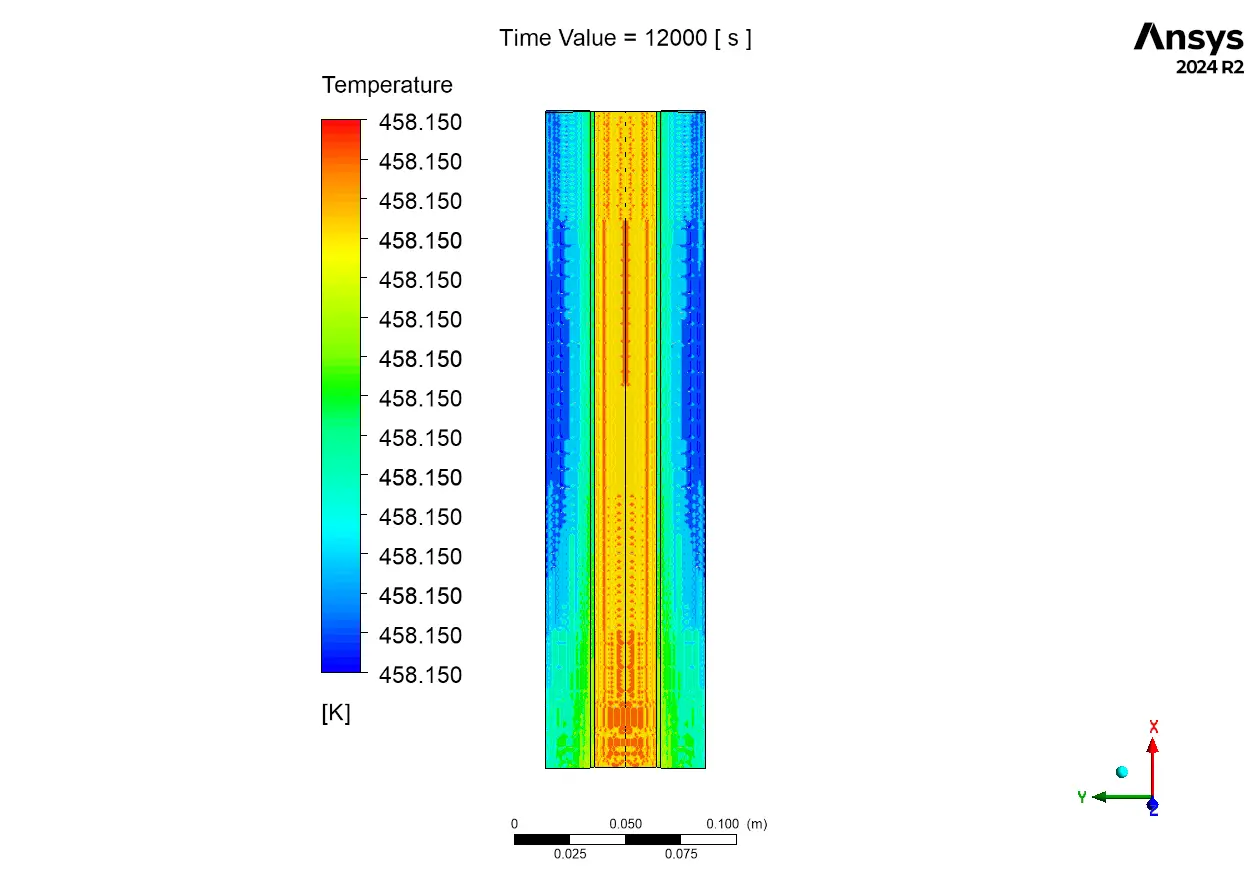

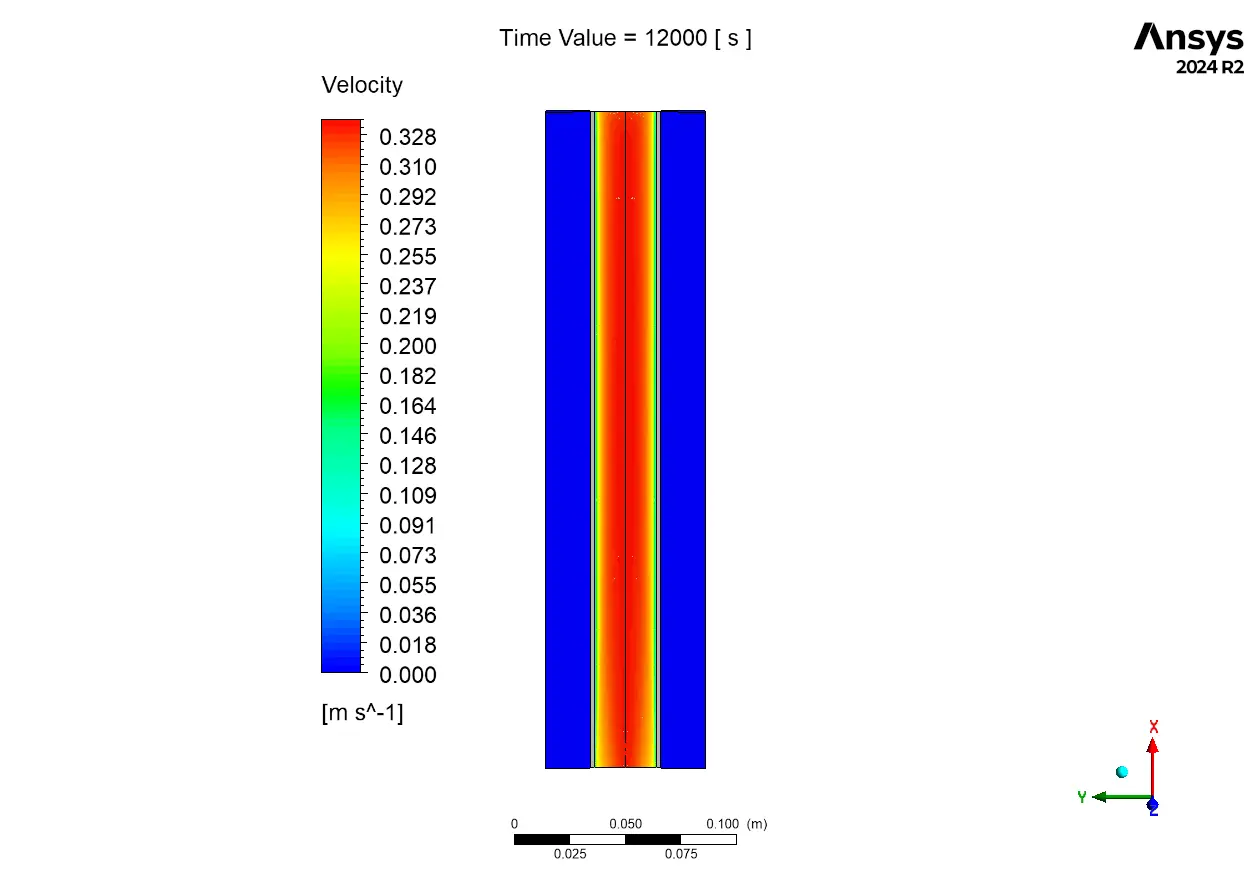

Our validation methodology begins with creating an exact geometric model based on the reference paper’s specifications for a vertical shell-tube thermal energy storage unit. We developed a structured grid with refined mesh density near walls to accurately capture the steep temperature gradients and boundary layer phenomena. The Fluent PCM simulation utilizes the Solidification & Melting module which implements the enthalpy-porosity approach for tracking the phase change interface without explicit front tracking. A custom User Defined Function (UDF) applies precise inlet velocity profiles to match boundary conditions for the heat transfer fluid. We implemented a single-phase nanofluid approach that treats the Nano-enhanced PCM as a continuous medium with modified thermo-physical properties calculated using validated mixing models. Real-time monitoring of liquid fraction and temperature distribution enables direct comparison with experimental benchmarks.

Figure 2: Structured grid over Solar cooling system domain

Post-processing

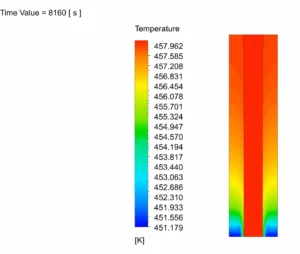

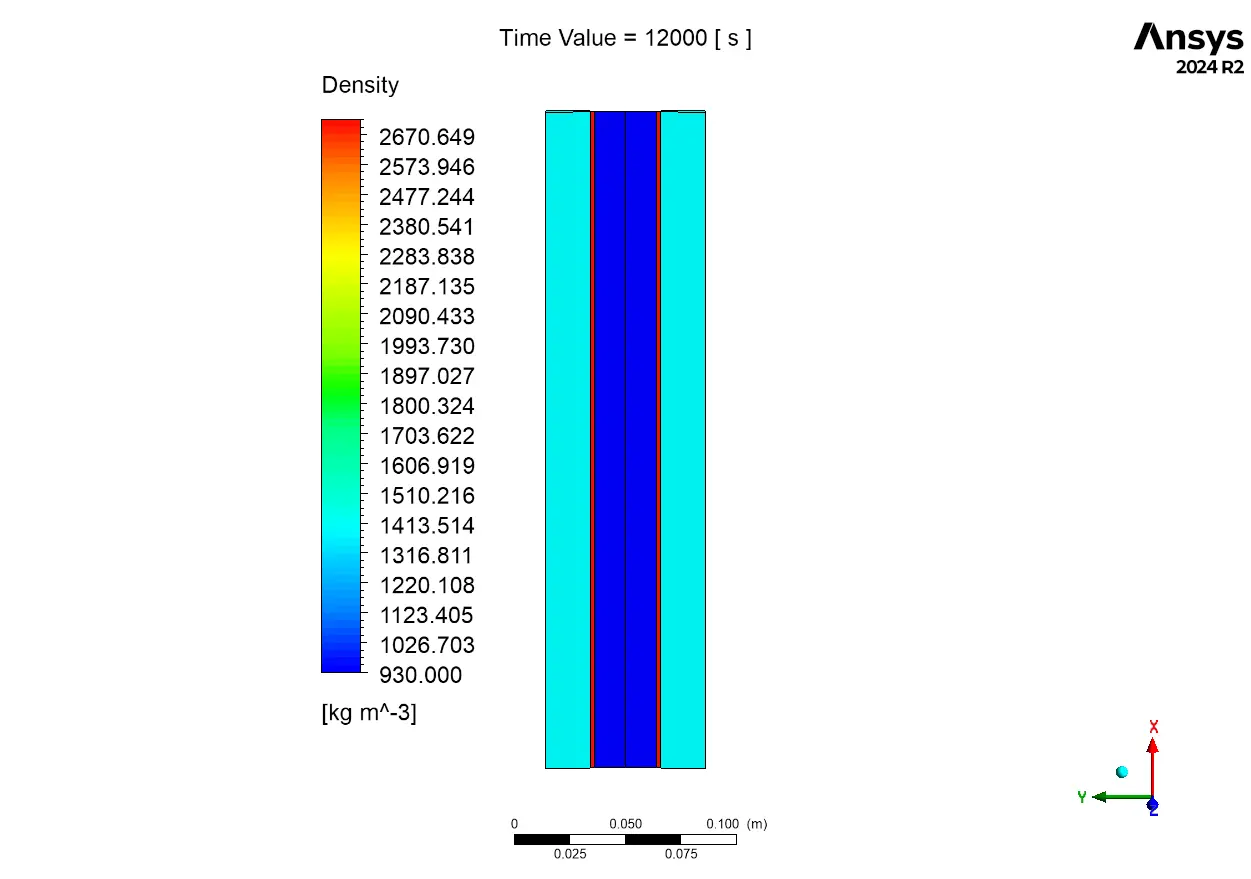

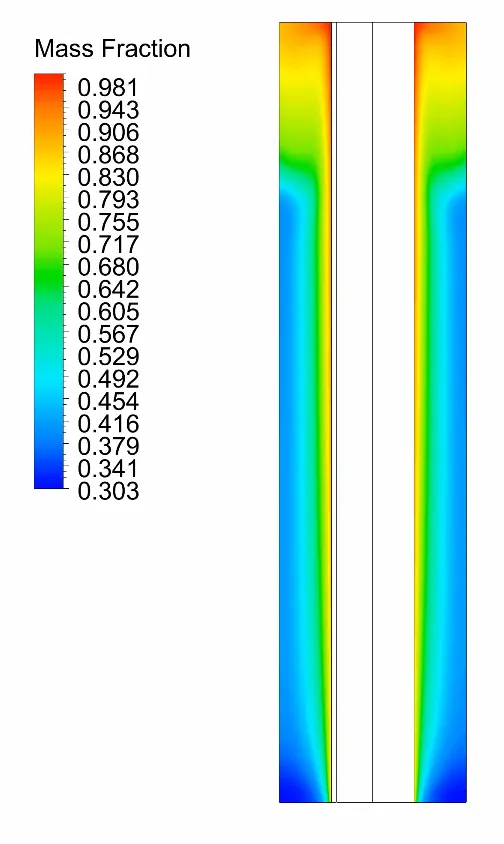

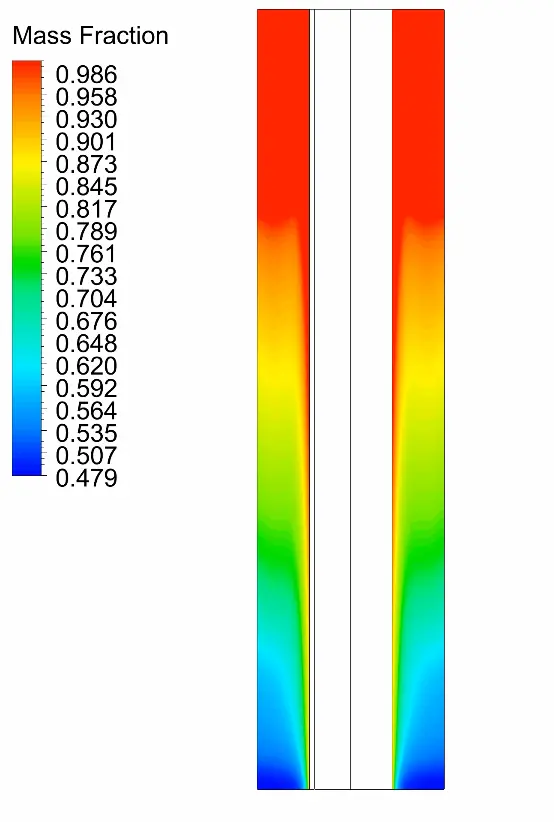

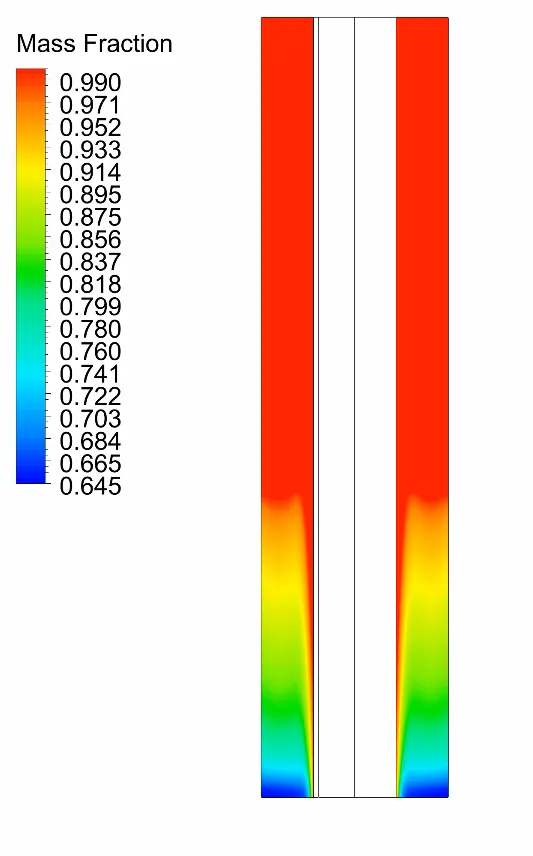

The validation study confirms our PCM CFD model accurately captures the real behavior of nano-enhanced PCMs. The mass fraction gradient shows how the nanomaterial concentrations vary during the melting process, with higher values (0.990) at the top and lower values (0.645) at the bottom. This distribution matches experimental observations of nanoparticle migration during phase change, confirming our Ansys Fluent model correctly simulates this complex behavior.

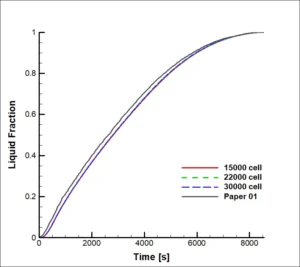

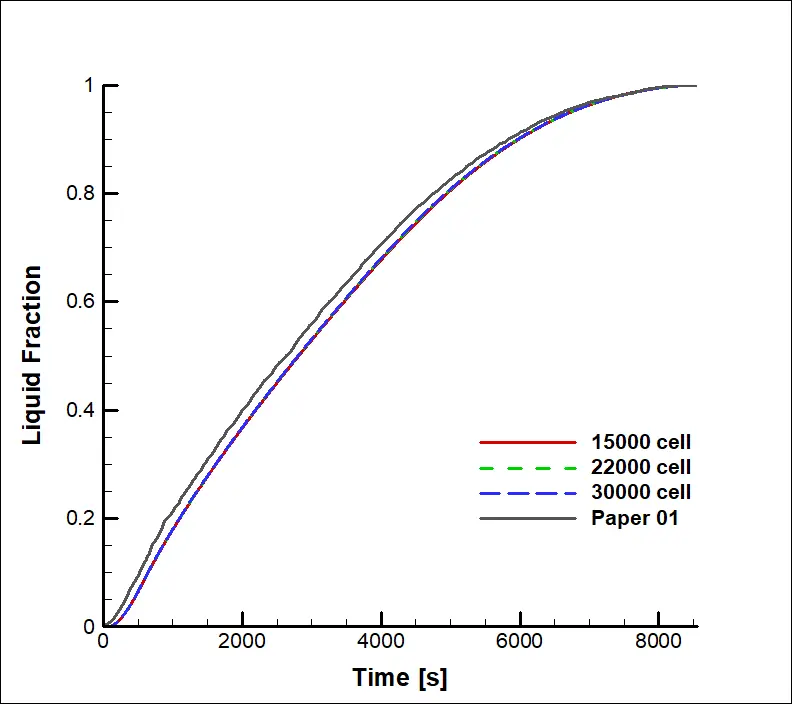

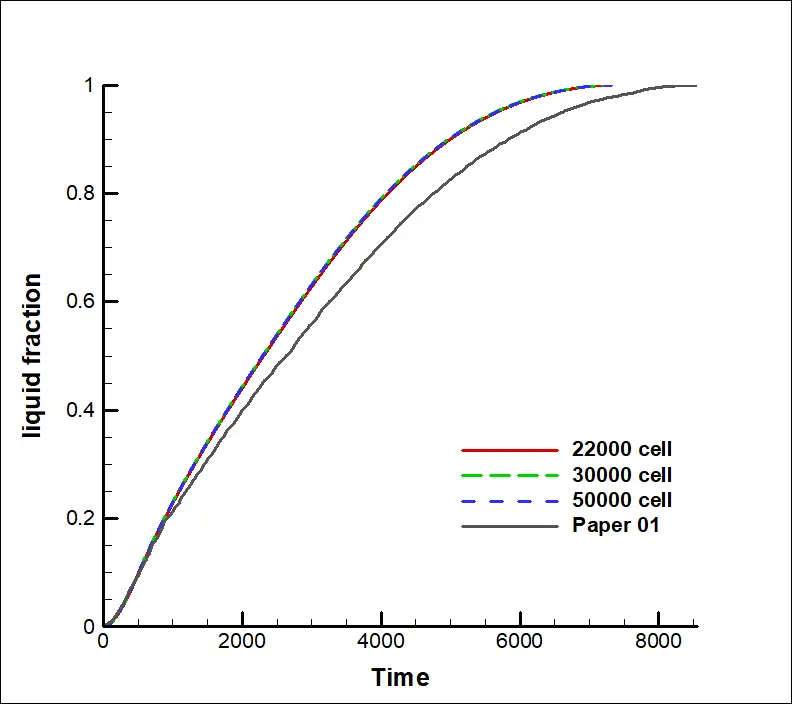

Figure 3: Time-Dependent Liquid Fraction Comparison

The comparison between our PCM CFD results and the reference paper measurements confirms excellent agreement in melting performance. All three mesh densities (15,000, 22,000, and 30,000 cells) closely follow the experimental curve, with the biggest difference occurring during the middle phase of melting. Our optimized 30,000-cell model completes full PCM melting in 8,342 seconds, just 2.6% different from the reference paper’s value of 8,125 seconds. This validates that our solar cooling simulation methodology accurately captures the thermal behavior of nanomaterial-enhanced PCMs, making it reliable for future system design and optimization.

Figure 4: Mass Fraction Distribution in Nano-Enhanced PCM

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€80Current price is: €80.

€240 Original price was: €240.€125Current price is: €125.

€360 Original price was: €360.€185Current price is: €185.

€360 Original price was: €360.€185Current price is: €185.

€240 Original price was: €240.€115Current price is: €115.

€200 Original price was: €200.€125Current price is: €125.

Reviews

There are no reviews yet.