Non-premixed Combustion CFD, A Fluent DPM Tutorial for Fuel Droplet Injection

Non-premixed Combustion CFD, A Fluent DPM Tutorial for Fuel Droplet Injection

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€215 Original price was: €215.€145Current price is: €145.

Non-premixed Combustion is a fundamental process that powers a vast range of technologies, from diesel engines and aircraft gas turbines to industrial furnaces. In this type of combustion, the fuel and the oxidizer (typically air) are injected into the combustion chamber separately. They must mix before they can react, meaning the rate of combustion is controlled by the rate of mixing. When the fuel is a liquid, like pentane, the process becomes even more complex. The liquid fuel is injected as a spray of fine droplets, which must first heat up, evaporate into a vapor, and then mix with the surrounding air before ignition can occur.

Understanding this intricate interplay of droplet physics and chemical reaction is crucial for designing efficient and clean combustion systems. A Combustion with Fuel Droplets Injection CFD simulation is an indispensable tool for this purpose. It allows engineers to visualize the spray behavior, track evaporation rates, and analyze the resulting flame structure in detail. This project details a simulation of Non-premixed Combustion Fluent where liquid pentane droplets are injected into a combustion chamber. We use the Discrete Phase Model (DPM) to accurately track the fuel droplets and their interaction with the gas phase.

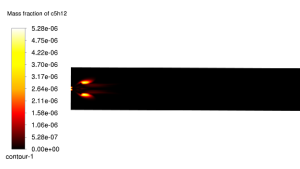

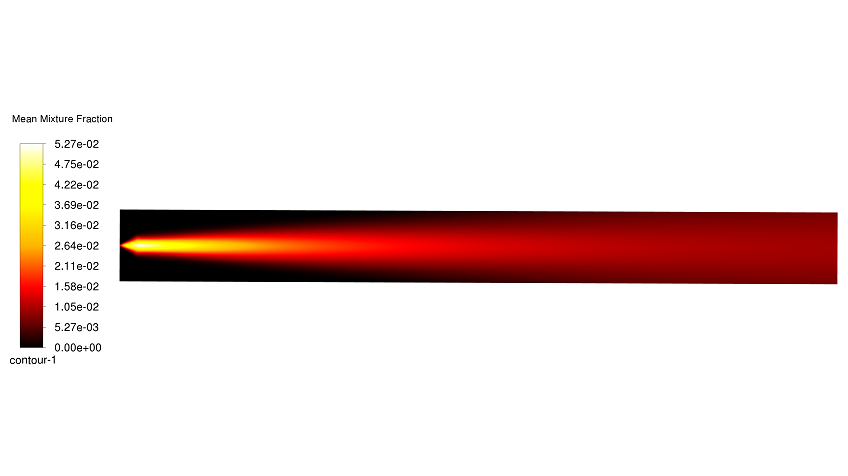

Figure 1: C5H12 spray combustion inside the chamber simulated using the DPM model in Fluent

Simulation Process: CFD Modeling of Fuel Droplets with DPM in Fluent

The simulation process began with the creation of a 2D axisymmetric geometry, modeling half of the combustion chamber to reduce computational cost. A high-quality structured mesh was then generated, consisting of 5200 cells, ensuring sufficient resolution to capture the key flow features.

The core of the simulation was configured within ANSYS Fluent. To model the reacting flow, the Non-premixed Combustion model was activated. This sophisticated model simplifies the complex chemistry by using a conserved scalar known as the mixture fraction. It calculates the thermochemical state based on a Probability Density Function (PDF) table, which effectively links the mixing of fuel and oxidizer to the resulting temperature and species concentrations. The most critical component for this project was the Discrete Phase Model (DPM). This Fuel Droplets DPM Fluent setup uses a Lagrangian approach to track the trajectory of each fuel droplet parcel. Importantly, two-way DPM coupling was enabled. This means the model accounts not only for how the gas flow affects the droplets but also how the evaporating droplets affect the gas phase by cooling it and adding fuel vapor mass.

Post-Processing: CFD Analysis of Fuel DPM Combustion

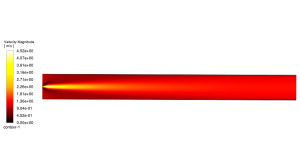

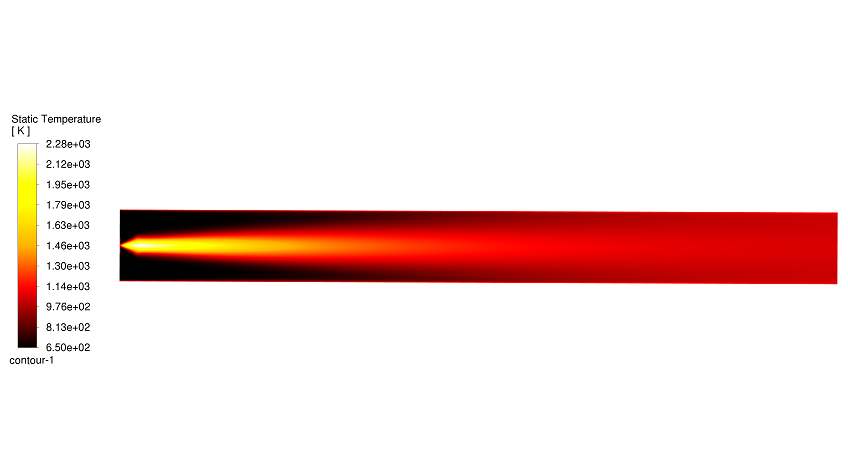

The temperature contour in Figure 2 provides a detailed map of the energy release within the chamber. The analysis reveals an intense reaction zone near the injector, where temperatures soar to a peak of 2280K. This high-temperature region corresponds to the area where the evaporated fuel vapor mixes with the air at a ratio close to stoichiometric, leading to the most vigorous combustion and heat release. As the hot gases flow downstream, the temperature gradually decreases due to heat diffusion and the completion of the reaction. This detailed thermal analysis, made possible by the Fuel Droplets DPM CFD model, is essential for predicting material temperatures and managing thermal stresses in a real combustor.

Figure 2: Contours showing a) Temperature and b) Velocity patterns inside the chamber from the non-premixed combustion simulation.

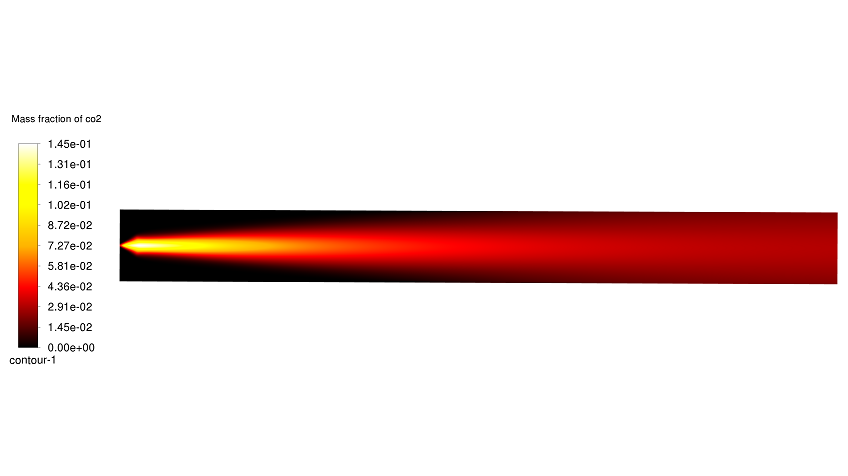

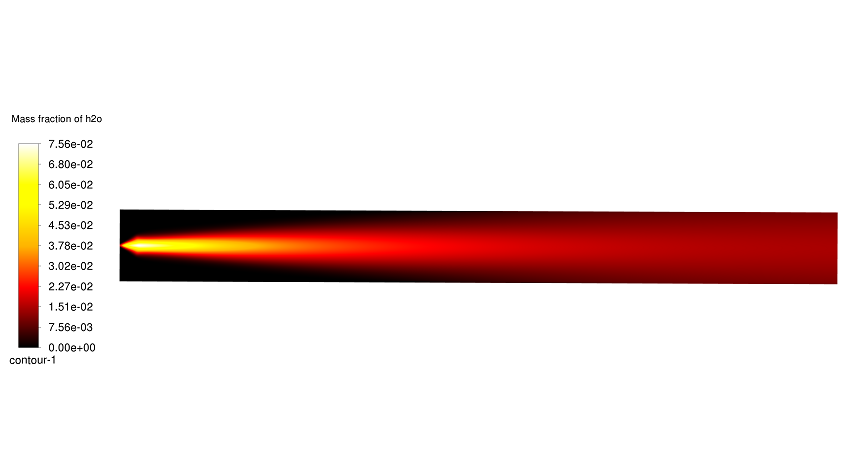

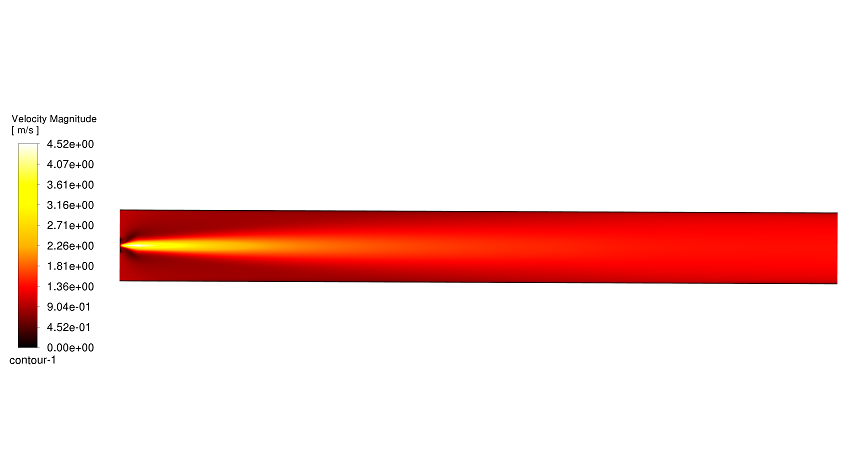

The simulation provides even deeper insight when we analyze the interaction between the droplets and the gas phase. The H2O mass fraction contour in Figure 3a, a primary product of combustion, shows a peak concentration of 7.56e-02, which aligns perfectly with the high-temperature flame zone. This validates that our combustion model is correctly predicting the chemical product formation. Figure 3b shows the DPM evaporation rate, which is the key to this entire process. The evaporation rate is highest in the hot, upstream region of the flame. The heat from the surrounding combustion provides the energy needed to turn the liquid pentane droplets into vapor. This demonstrates the critical two-way coupling: the hot gas evaporates the fuel, and the resulting fuel vapor sustains the flame that keeps the gas hot. This cyclic, self-sustaining process is the fundamental mechanism of spray combustion, and our simulation has successfully captured it.

Figure 3: Contours showing a) H2O Mass Fraction and b) DPM evaporation rate, highlighting the link between fuel evaporation and product formation.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€185 Original price was: €185.€155Current price is: €155.

€270 Original price was: €270.€190Current price is: €190.

€195 Original price was: €195.€135Current price is: €135.

€240 Original price was: €240.€125Current price is: €125.

€195 Original price was: €195.€135Current price is: €135.

€120 Original price was: €120.€75Current price is: €75.

Reviews

There are no reviews yet.