Oil Desalination Hydrocyclone: A Fluent CFD Simulation

Oil Desalination Hydrocyclone: A Fluent CFD Simulation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€175 Original price was: €175.€145Current price is: €145.

Crude oil desalting is a very important step in a refinery. It removes salt and water from the oil to stop machines from rusting. A Hydrocyclone CFD simulation is a computer model of a special separation device. Using this Oil Desalination Hydrocyclone Fluent analysis, we can see how the hydrocyclone uses spinning force to separate oil from water because they have different weights. This multiphase flow CFD is key to making the refinery process simulation more efficient. This Oil Desalination CFD work is based on the methods from the research papers, “Crude oil desalting using hydrocyclones” [1] and “Experimental investigation of de-oiling hydrocyclone” [2].

- Reference [1]: Bai, Z-S., and H-L. Wang. “Crude oil desalting using hydrocyclones.” Chemical Engineering Research and Design12 (2007): 1586-1590.

- Reference [2]: Pratarn, Wongsarivej, Srirahong Kanawut, and Sawasdisevi Thanit. “Experimental investigation of de-oiling hydrocyclone.” Key Engineering Materials545 (2013): 230-235.

Figure 1: The principle of fluid flow in a Liquid-Liquid Hydrocyclone [1].

Simulation process: Fluent Setup, Eulerian-RSM Model for Multiphase Separation

For this Centrifugal Separator Simulation, we modeled the geometry based on the reference paper [1]. We then used Fluent Meshing to create a high-quality grid of 1,063,687 polyhedra cells. In ANSYS Fluent, we set up the simulation using the Eulerian multiphase model. This model is perfect for analyzing two fluids, in this case, a primary phase of oil and a secondary phase of water with a droplet diameter of 7.5e-05 meters. To accurately capture the strong swirling flow, which is the most important part of this device, we activated the Reynolds Stress Model (RSM) with 7 equations. This advanced turbulence model is needed for high-swirl flows.

Post-processing: CFD Analysis, Swirl Dynamics and Separation Mechanism

The velocity contours and streamlines provide a professional visual that acts as a diagnostic map of the hydrocyclone’s performance. From an engineering standpoint, this professional visual shows the creation of a powerful swirl field. The mixture enters the side inlet, and the water phase quickly accelerates to a maximum speed of 10.87 m/s along the wall, while the oil reaches speeds of up to 6.90 m/s. This high-speed rotation creates a strong centrifugal force. This force is the engine of separation, pushing the heavier water droplets toward the outer wall. The streamlines clearly show the water forming a tight downward spiral that leads directly to the underflow outlet, where waste is removed.

Figure 2: Oil Velocity Distribution and Flow Patterns

This Eulerian Multiphase Fluent simulation allows us to confirm the device’s design effectiveness. While the heavy water is pushed out and down, the lighter oil is forced into a low-pressure zone at the center of the spinning vortex. This creates an upward-flowing oil core, seen in the simulation as an axial velocity of up to -2.68 m/s. This “reverse” flow is exactly what engineers want to see, as it proves a clean stream of oil is moving toward the overflow outlet at the top. This separation happens in a very compact space, making hydrocyclones very efficient. The most important achievement of this simulation is its ability to visualize and quantify the two distinct flow paths inside the device—the downward helical flow of water and the upward axial flow of oil—providing clear proof that the geometry and flow conditions create efficient separation and giving engineers a validated tool to optimize refinery operations.

Figure 3: A professional visual combining oil velocity and water streamlines from the Oil-Water Separation CFD analysis.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€220 Original price was: €220.€155Current price is: €155.

€175 Original price was: €175.€125Current price is: €125.

€195 Original price was: €195.€150Current price is: €150.

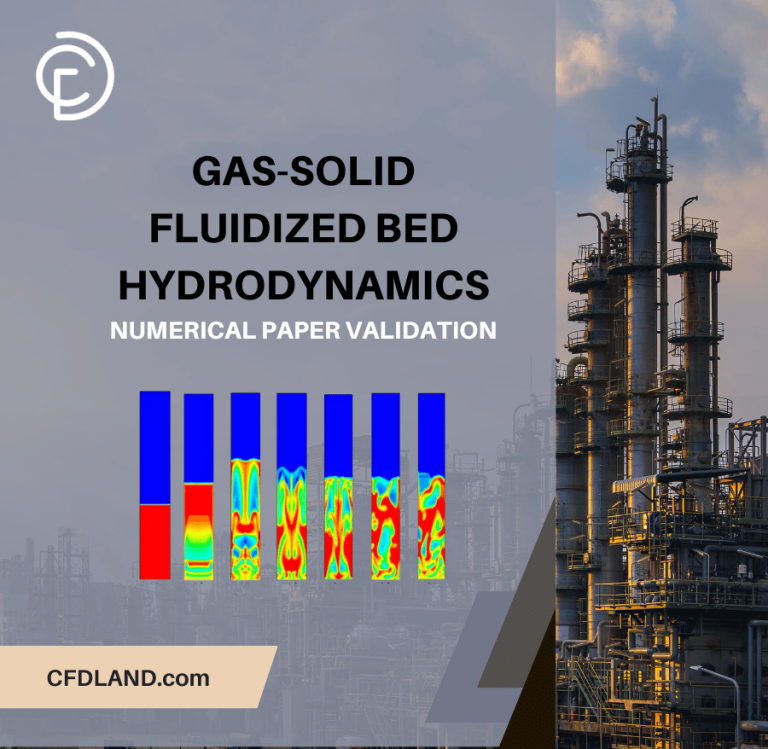

€360 Original price was: €360.€185Current price is: €185.

€205 Original price was: €205.€155Current price is: €155.

€330 Original price was: €330.€199Current price is: €199.

Reviews

There are no reviews yet.