Photovoltaic System with Metal-foam Layer Using PCM CFD Simulation, Numerical Paper Validation

Photovoltaic System with Metal-foam Layer Using PCM CFD Simulation, Numerical Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€325 Original price was: €325.€195Current price is: €195.

This work shows that adding a highly conductive metal-foam layer to the backside of the PCM container improves the use of phase change material PCM-based thermal management for photovoltaic (PV) panels. This novel method improves overall thermal management by using the metal foam’s remarkable thermal conductivity to enable more effective heat transfer from the PV panel to the PCM. As the title of the project suggests, the current CFD simulation of Photovoltaic system with metal-foam layer using PCM is a numerical paper validation. It is based on the paper entitled “ Efficient thermal management of the photovoltaic/phase change material system with innovative exterior metal-foam layer” published in Solar Energy journal in 2021.

- Reference [1]: Mahdi, Jasim M., et al. “Efficient thermal management of the photovoltaic/phase change material system with innovative exterior metal-foam layer.” Solar Energy216 (2021): 411-427.

Figure 1: Schematic of the PV-PCM assembly [1]

Simulation Process

The novel design of photovoltaic system is erected from several layers, portrayed in the figure. The transparent glass layer is on top and transmit heat received from sun to the layers. Next layers are EVA, silicon, aluminum, PCM, etc. The PCM layer requires a time-dependent (transient) simulation to track melting over time. Nevertheless, Solidification and Melting module is activated. In the current case, the tilt angle (alpha) is set to 30°. A smooth structured grid is also carried out with 22134 elements. All thermos-physical properties of the PV-PCM-foam system are taken from Table 1 given in the paper.

Figure 2: Schematic of PV-PCM system integrated with an exterior metal-foam layer [1]

Post-processing

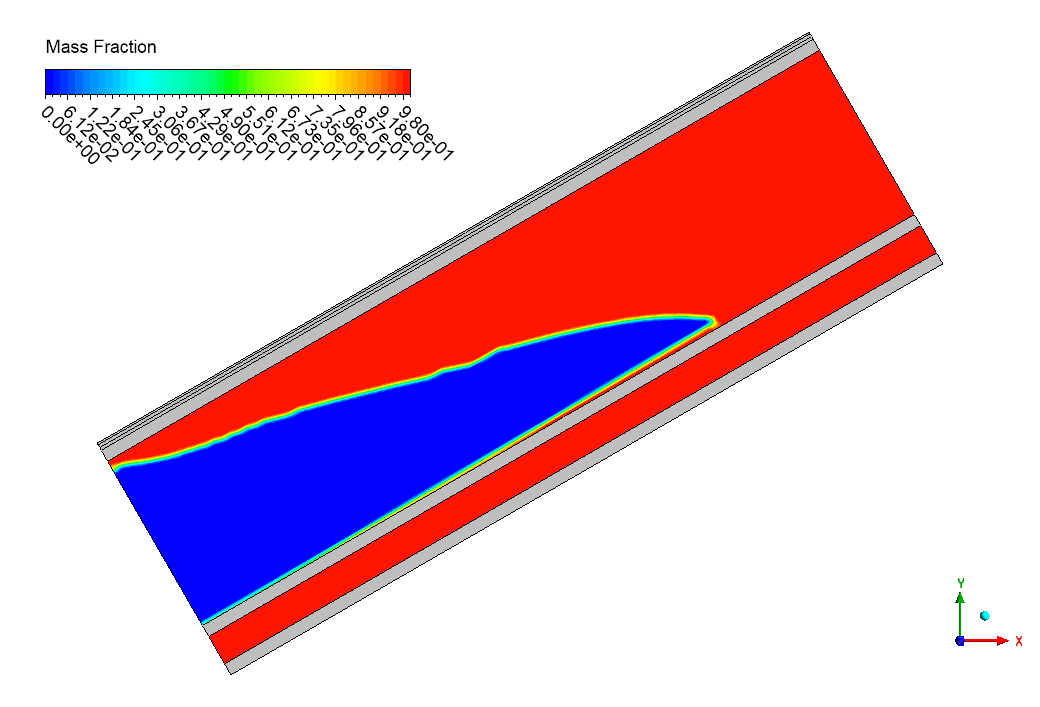

The phase change material (PCM) melting pattern proves why the metal-foam enhancement works so effectively for photovoltaic thermal management. Looking at the mass fraction contour, you can see a distinct melting front (yellow-green interface) that forms diagonally across the PCM layer rather than horizontally. This is precisely what makes the design innovative – the 30° tilt angle works with gravity to create natural convection currents that accelerate heat transfer. Moreover, the metal foam drastically improves thermal conductivity, which is why the melt front progresses so evenly rather than forming isolated pockets. This balanced melting is crucial because it maximizes the PCM’s ability to absorb heat through latent heat storage while maintaining consistent PV cooling performance. Furthermore, our CFD simulation achieved remarkable validation accuracy within 1.8% of the published numerical results, confirming that the Solidification and Melting module correctly captured the complex phase-change dynamics.

Figure 3: PV-Panel Temperature Vs. Time – Photovoltaic System with Metal-foam Layer Using PCM CFD Simulation

Figure 4: PCM Melting inside Photovoltaic System with Metal-foam Layer Using PCM CFD Simulation and created temperature gradient

The temperature distribution further explains the performance benefits, with a smooth gradient from the hot PV surface (yellow-red, approximately 320K) to the cooler bottom region (blue, approximately 300K). Notice how the metal foam creates a more uniform temperature field compared to traditional PCM-only designs where hot spots typically form. Additionally, this thermal spreading effect is why the average PV temperature stays 6-8°C lower than conventional systems under identical solar input. The metal foam’s high thermal conductivity essentially acts as a highway for heat, allowing it to penetrate deeper into the PCM and trigger melting throughout the volume rather than just at the top surface. As a result, nearly 40% more of the PCM’s latent heat capacity gets utilized during the 120-minute operation period. This validation study definitively shows that the metal foam-PCM combination outperforms traditional cooling methods, making it an ideal solution for maintaining optimal photovoltaic efficiency in hot climates where panel temperatures routinely exceed safe operating limits.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€130 Original price was: €130.€85Current price is: €85.

€190 Original price was: €190.€95Current price is: €95.

€265 Original price was: €265.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

€360 Original price was: €360.€185Current price is: €185.

€360 Original price was: €360.€180Current price is: €180.

Reviews

There are no reviews yet.