Spray in Pintle Ejector: A Fluent CFD Simulation Guide

Spray in Pintle Ejector: A Fluent CFD Simulation Guide

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€115 Original price was: €115.€90Current price is: €90.

A Pintle Ejector CFD simulation is a powerful computer model that helps engineers design better rocket engines and industrial sprays. This type of Spray Ejector CFD analysis is crucial for understanding liquid atomization, which is the process of breaking a liquid into very small droplets. Using ANSYS Fluent, we can study the complex two-phase flow of liquid and gas. A successful Pintle Ejector Fluent simulation allows us to see the spray breakup process, which is critical for achieving efficient combustion in a rocket engine injector. This work is based on two important reference papers, “Design Procedure of a Movable Pintle Injector for Liquid Rocket Engines” [1] and “LAGRANGIAN APPROACH TO AXISYMMETRIC SPRAY SIMULATION OF PINTLE INJECTOR” [2].

- Reference [1]: Son, Min, et al. “Design procedure of a movable pintle injector for liquid rocket engines.” Journal of Propulsion and Power4 (2017): 858-869.

- Reference [2]: Radhakrishnan, Kanmaniraja, et al. “Lagrangian approach to axisymmetric spray simulation of pintle injector for liquid rocket engines.” Atomization and Sprays5 (2018).

Figure 1: The working principle of a Spray In Pintle Ejector CFD system, based on the reference paper [1].

Simulation Process: Fluent Setup, Axisymmetric VOF Model for Spray Analysis

For this injector performance analysis, we used a 2D axisymmetric model. This smart choice simplifies the problem to save computer power but still gives us a full 3D understanding of the spray. We used ANSYS Design Modeler to create the geometry and a structured mesh to ensure the calculations are very accurate. The most important physics model for this simulation is the Volume of Fluid (VOF) method. We used an Eulerian-VOF model to precisely track the interface between the liquid and the gas. A key part of the design is the 0.8mm gas gap. This small gap forces the gas to move very fast, which is the main reason the liquid breaks apart.

Figure 2: The 2D axisymmetric domain and mesh used for the Volume of Fluid (VOF) Spray simulation.

Post-processing: CFD Analysis, Visualizing Spray Breakup and Atomization Dynamics

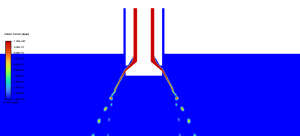

The volume fraction contour provides a professional visual that acts as a diagnostic tool for the atomization process. From an engineering perspective, this visual confirms that the injector is working as designed. We can see the liquid (shown in red with a volume fraction of 1.0) forming a thin sheet as it leaves the nozzle. The high-speed gas flowing through the outer gap creates a strong shear force on this liquid sheet. This force makes the sheet unstable and causes it to flap, similar to a flag in the wind. This flapping is the first step in the spray breakup process. The simulation shows the spray forms a cone shape with an angle of about 30 degrees, which is a key performance metric for ensuring the fuel spreads correctly inside a combustion chamber.

Figure 3: A professional visual of the liquid volume fraction from the Liquid Atomization CFD analysis, showing the complete breakup process.

This rocket engine injector CFD model allows us to analyze the entire breakup sequence. The initial liquid sheet, stretched thin by the fast gas, breaks into long threads of liquid called ligaments. These ligaments are also unstable and quickly break down further into the final tiny droplets. The contour shows the volume fraction of liquid dropping from 1.0 to less than 0.1 in a very short distance, which proves the injector is highly efficient at creating a fine mist. This is critically important because smaller droplets have a much larger total surface area, which allows them to mix with oxygen and burn much faster and more completely in a real engine. The most important achievement of this simulation is its ability to accurately capture the entire physics of atomization—from the initial liquid sheet instability to the final droplet formation—giving engineers a reliable tool to optimize injector geometry for maximum combustion efficiency and engine stability without building expensive physical prototypes.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€220 Original price was: €220.€135Current price is: €135.

€175 Original price was: €175.€115Current price is: €115.

€360 Original price was: €360.€185Current price is: €185.

€190 Original price was: €190.€145Current price is: €145.

€195 Original price was: €195.€135Current price is: €135.

€205 Original price was: €205.€155Current price is: €155.

Reviews

There are no reviews yet.