Stirred Mixer CFD Simulation Using MRF – ANSYS Fluent Tutorial

Stirred Mixer CFD Simulation Using MRF – ANSYS Fluent Tutorial

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140.00

Stirred mixers are essential equipment in chemical, pharmaceutical, and food industries where different liquids or powders need to be combined uniformly. The heart of any mixing tank is the impeller, which rotates to create flow patterns that blend materials together effectively. Stirred mixer CFD analysis helps engineers predict how well different impeller designs will perform before building expensive prototypes. Most industrial stirred tanks use Rushton turbines, pitched blade turbines, or axial flow impellers depending on the mixing requirements and fluid properties. The power consumption of a stirred mixer directly relates to the torque needed to rotate the impeller at specific speeds, typically measured in watts per cubic meter of tank volume. MRF (Multiple Reference Frame) method in ANSYS Fluent allows accurate simulation of rotating impellers without complex dynamic mesh requirements. Baffles inside the mixing tank prevent solid body rotation and create the turbulent eddies needed for effective blending. Mixer CFD simulations can predict mixing time, power number, and flow number – key parameters that determine mixing efficiency. The Reynolds number for stirred tanks typically ranges from 10,000 to 1,000,000, indicating highly turbulent conditions that enhance mass transfer. Impeller CFD studies show that blade angle, diameter ratio, and clearance from tank bottom significantly affect both mixing performance and energy requirements. Our main reference papers are:

- Reference [1]: Patil, Harshal, et al. “CFD simulation model for mixing tank using multiple reference frame (MRF) impeller rotation.” ISH Journal of Hydraulic Engineering2 (2021): 200-209.

- Reference [2]: Wu, H., and G. K. Patterson. “Laser-Doppler measurements of turbulent-flow parameters in a stirred mixer.” Chemical engineering science10 (1989): 2207-2221.

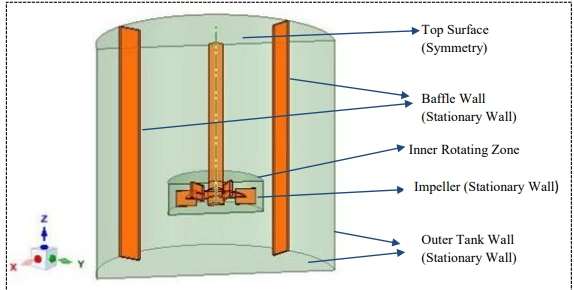

Figure 1: Stirred Mixer CFD model [1]

Simulation process of stirred mixer in Ansys Fluent

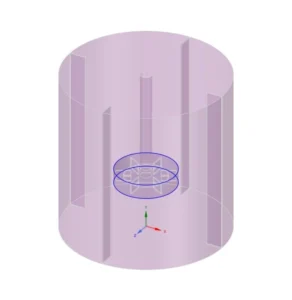

The complete stirred mixer geometry was designed following the reference paper specifications, including the main mixing tank, four vertical baffles, and a six-blade Rushton turbine impeller positioned at standard tank diameter ratios. We used Fluent Meshing to generate a high-quality mesh with 5,311,638 polyhedral cells that accurately captures the complex flow regions near impeller blades and baffle edges, making this stirred mixer CFD simulation more efficient. The MRF (Multiple Reference Frame) method divides the domain into stationary zones (tank and baffles) and rotating zone (around the impeller), allowing steady-state mixer CFD analysis instead of expensive transient simulation. The impeller rotates at 200 RPM. This impeller CFD setup with MRF captures the essential mixing physics while keeping computational time reasonable for engineering design studies.

Figure 2: Geometry Model of mixing tank with impeller

Post-processing – stirred mixer

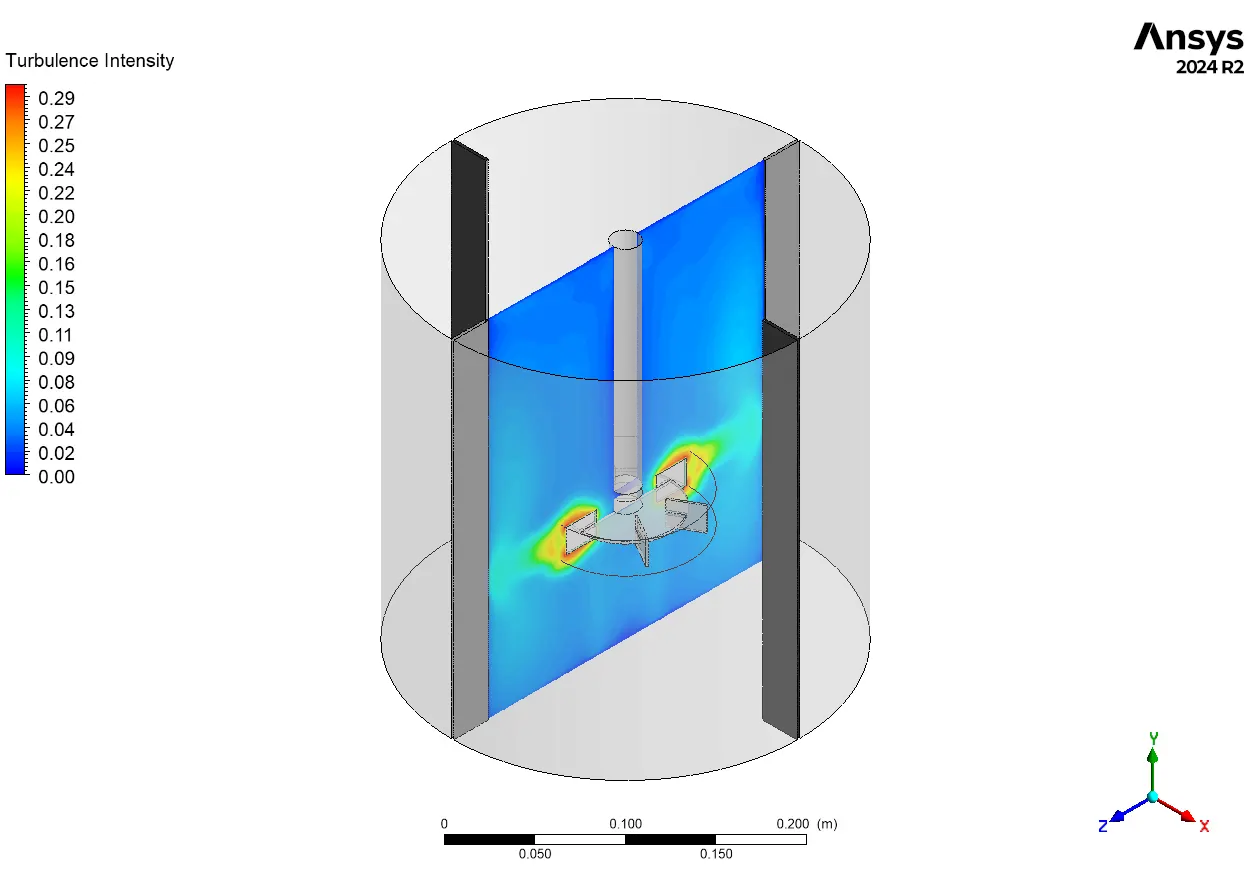

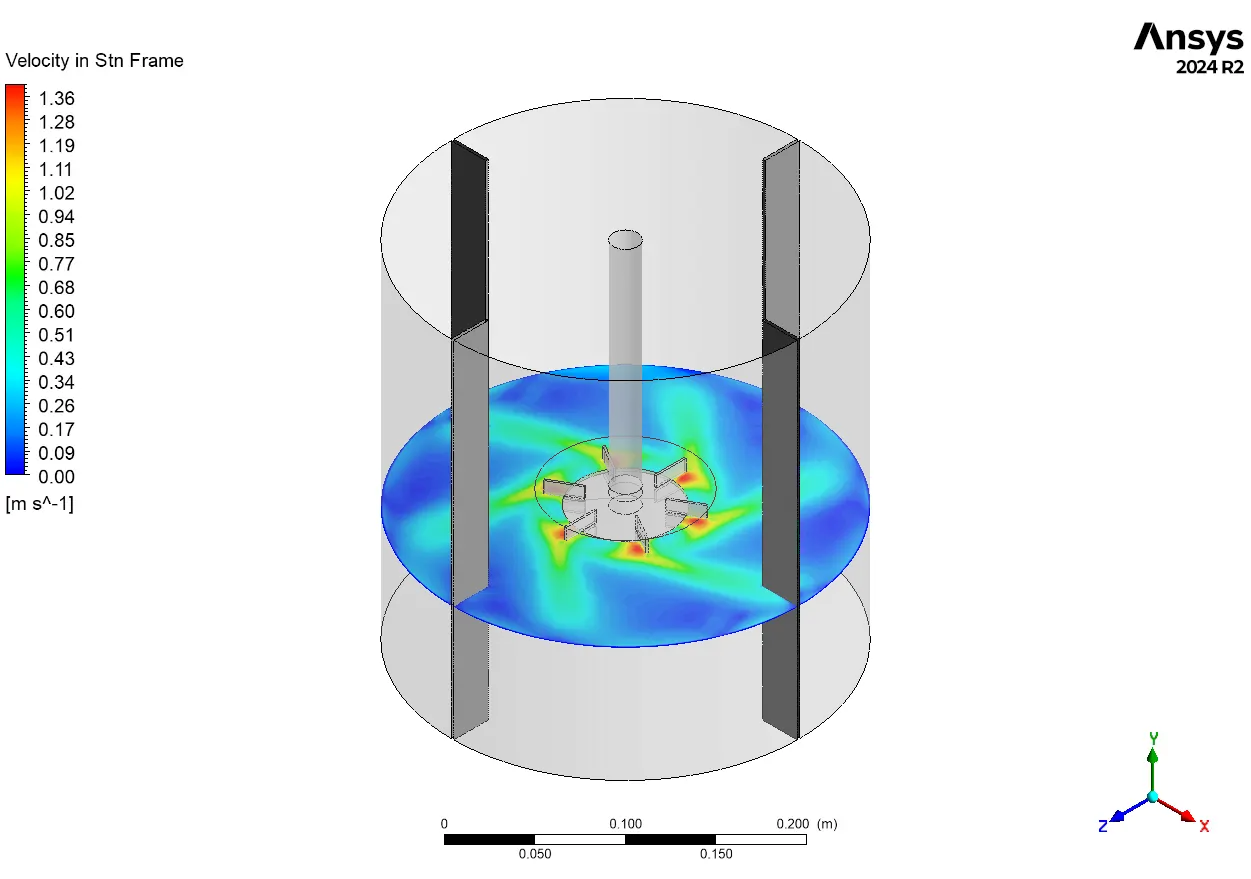

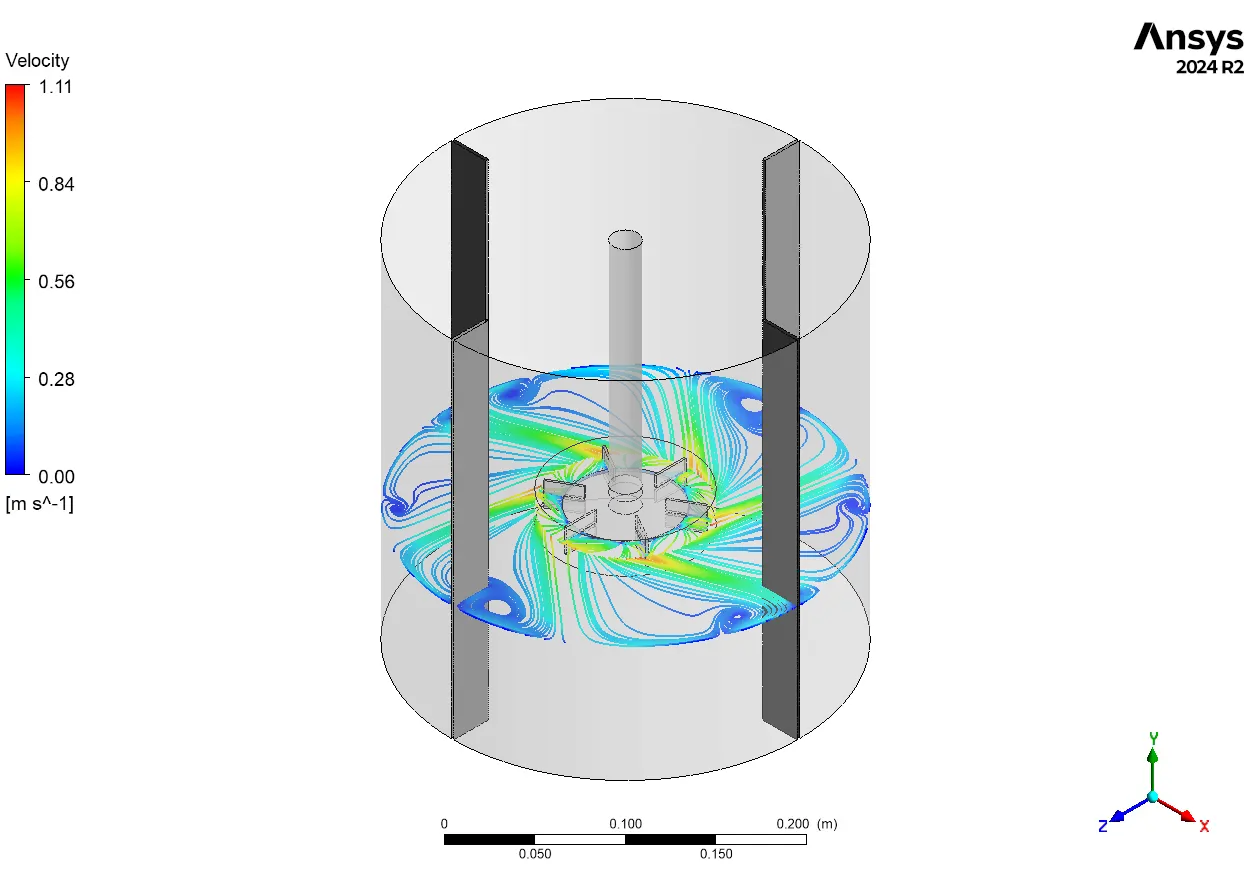

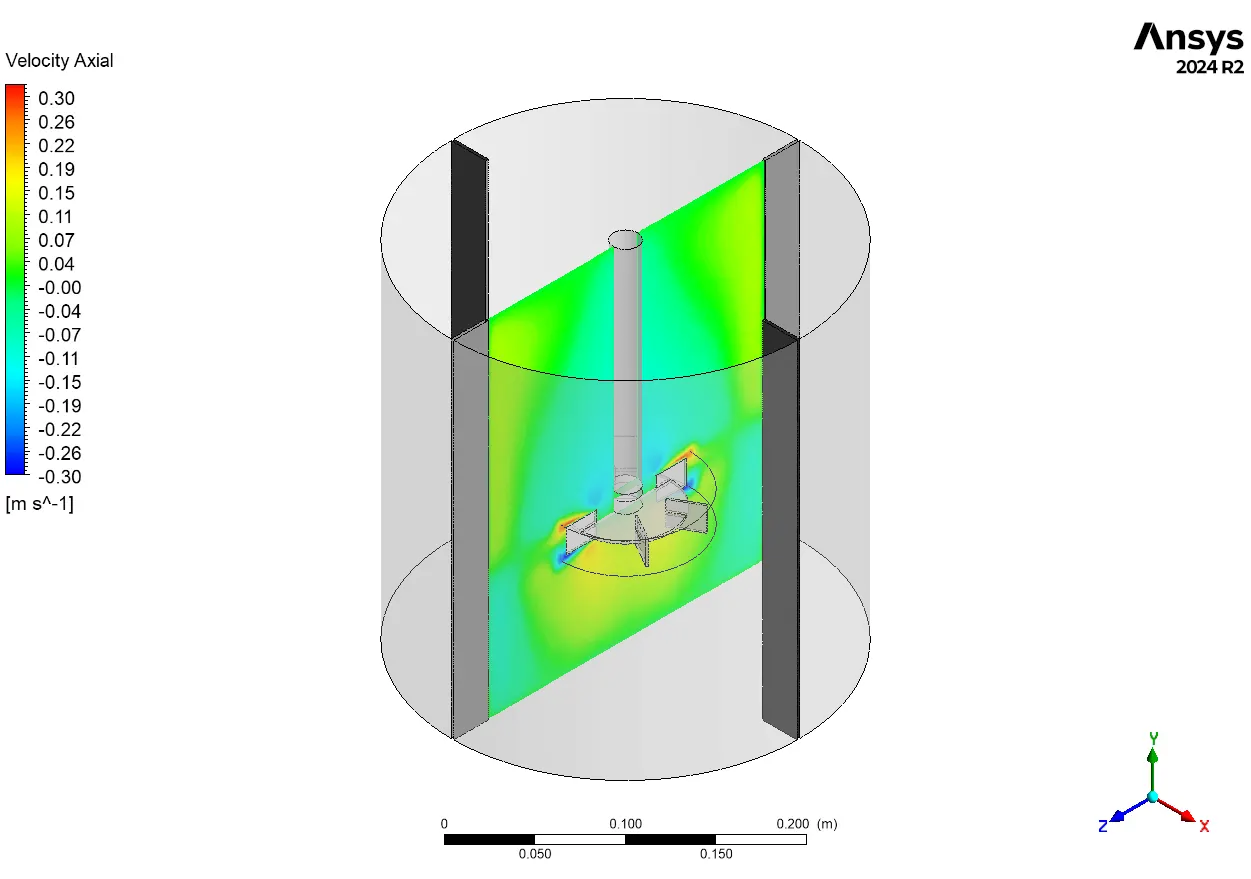

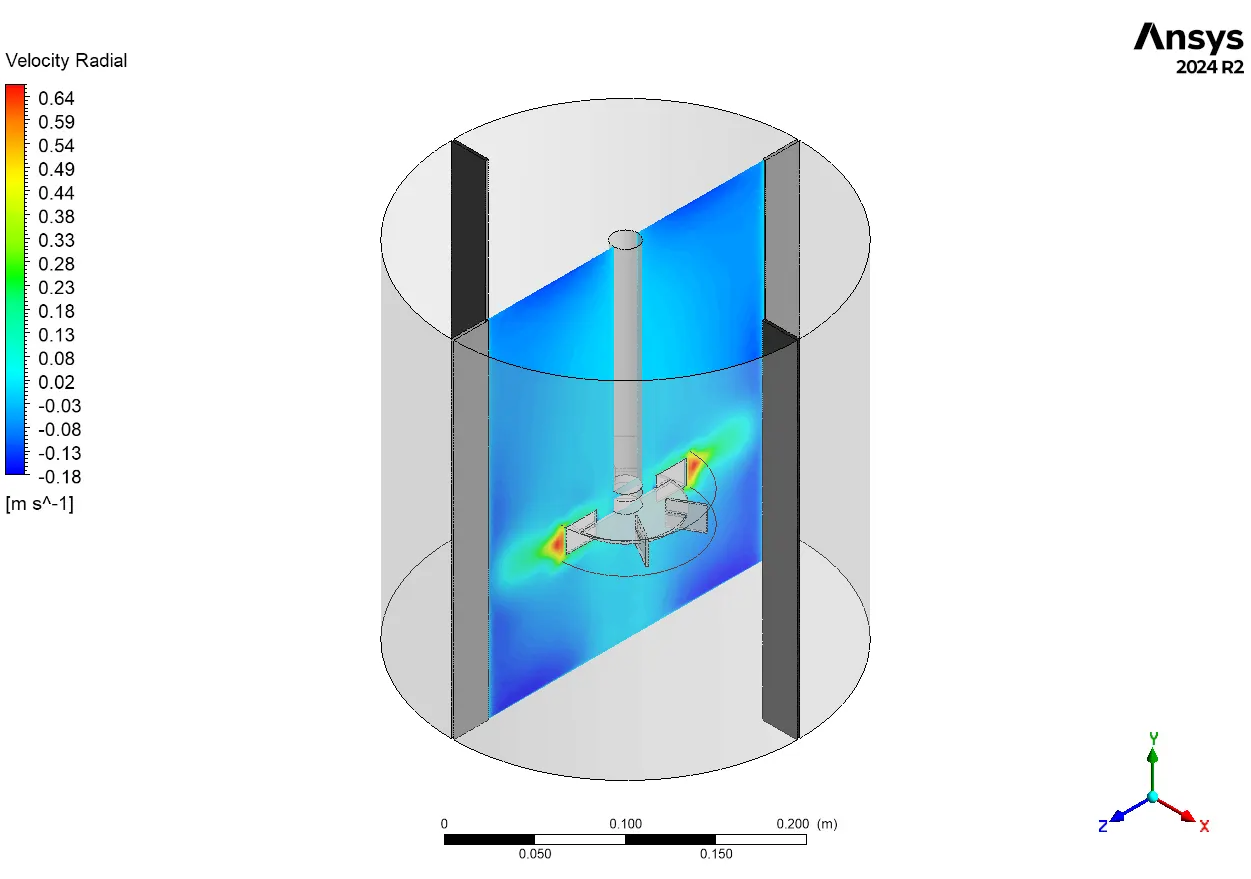

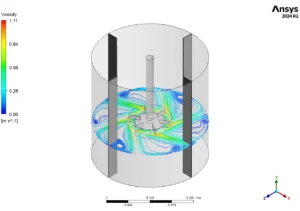

The velocity streamlines inside the stirred mixer create beautiful spiral patterns that explain how mixing happens at the molecular level. Maximum velocity reaches 1.11 m/s right at the impeller blade tips, where rotating blades push fluid radially outward toward the mixing tank walls. These high-speed jets hit the baffles and split into upward and downward flow streams, creating the essential circulation loops needed for effective blending. The Rushton turbine impeller generates strong radial flow patterns that extend from the center to the tank walls, ensuring every drop of fluid gets pulled into the mixing action. Baffles prevent the entire fluid mass from spinning as one solid body, instead forcing it to tumble and create the turbulent eddies that make stirred mixers so effective. This impeller CFD analysis confirms that MRF method in ANSYS Fluent accurately captures the complex flow circulation without expensive transient calculations.

Figure 3: Velocity Streamlines in Stirred Mixer

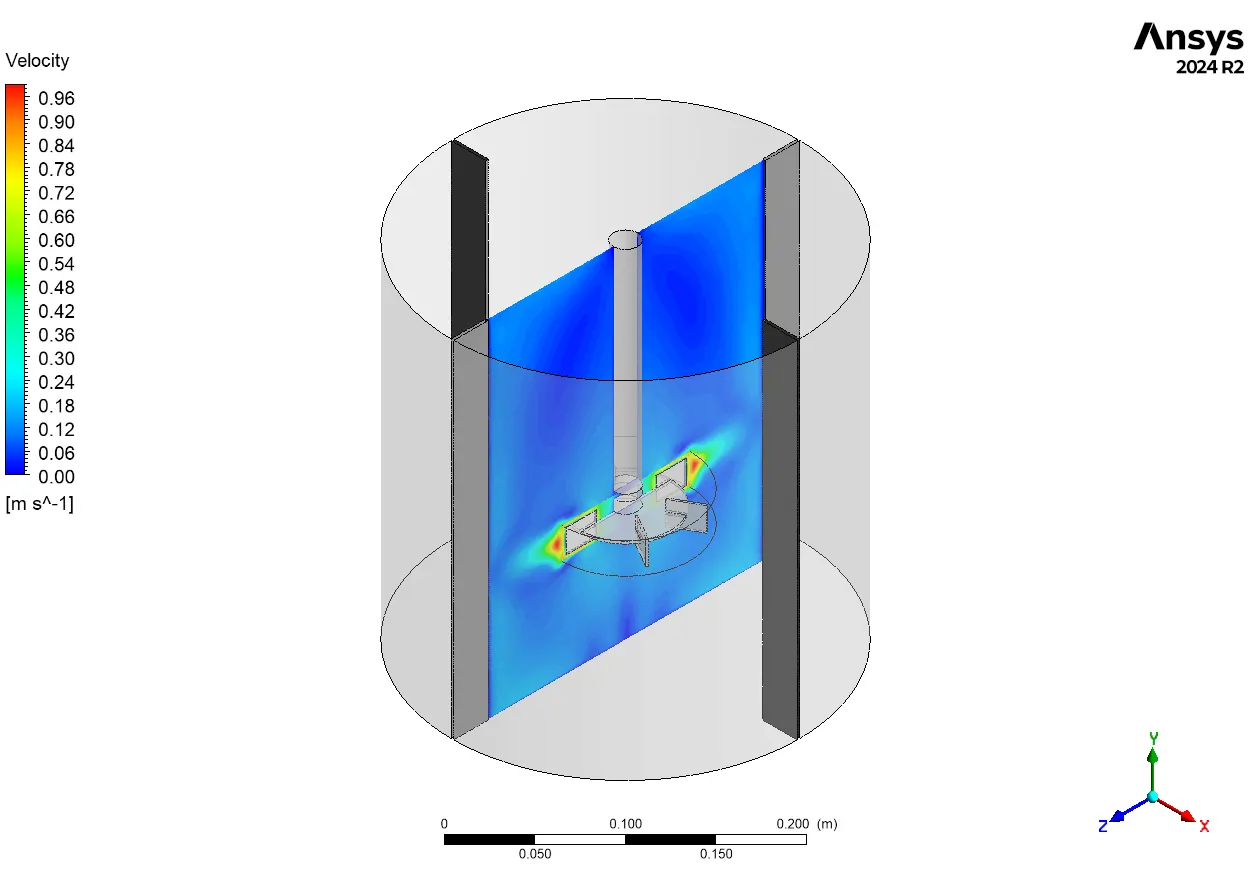

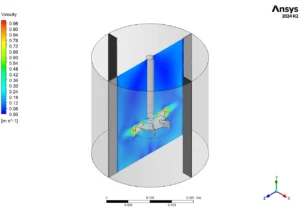

The cross-sectional view through the mixing tank clearly illustrates how velocity decreases from 0.96 m/s near the impeller to almost zero in the tank corners and top regions. This stirred mixer CFD simulation proves that proper impeller placement is critical – too high and the bottom stays unmixed, too low and the surface remains stagnant. The measured torque of 0.045576519 N.m at 200 RPM, which falls within typical ranges for laboratory-scale stirred tanks handling water. Power number calculations from this torque measurement validate that our mixer CFD model predicts realistic energy requirements for the mixing process. The velocity gradients between high-speed impeller zones and low-speed tank regions drive the mass transfer that makes mixing possible. ANSYS Fluent successfully captures how flow energy dissipates from the rotating impeller through the fluid domain, confirming this stirred mixer design achieves good mixing efficiency while keeping power consumption reasonable. Industrial mixing engineers can use these impeller CFD results to optimize blade geometry, rotation speed, and baffle configuration for their specific applications.

Figure 4: Velocity Distribution Cross-Section in Stirred Mixer

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€210.00 Original price was: €210.00.€155.00Current price is: €155.00.

€210.00 Original price was: €210.00.€155.00Current price is: €155.00.

€260.00 Original price was: €260.00.€165.00Current price is: €165.00.

€240.00 Original price was: €240.00.€135.00Current price is: €135.00.

€180.00 Original price was: €180.00.€99.00Current price is: €99.00.

Reviews

There are no reviews yet.