Three-Phase Separator CFD Simulation: Oil-Water-Air Analysis in Fluent

Three-Phase Separator CFD Simulation: Oil-Water-Air Analysis in Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€240 Original price was: €240.€155Current price is: €155.

In the oil and gas industry, fluids never come out of the ground purely. They are usually a messy mixture of crude oil, water, and natural gas. Before this mixture can be sold or processed, it must be separated into its three individual parts. The machine used for this is called a Three-Phase Separator. It is a large vessel that uses gravity to pull heavy water down and let light gas float up. Designing these vessels is difficult because the flow inside is very complex.

This project is a Three-Phase Separator CFD simulation designed to visualize this internal behavior. We use ANSYS Fluent to virtually look inside the tank and see how the Oil-Water-Air Separation happens. For more learning resources on industrial separation, please visit our Separators tutorials. Our simulation setup is guided by the methodology found in the research by Le et al. [1].

- Reference [1]: Le, Thuy Thi, et al. “Three-phase Eulerian computational fluid dynamics of air–water–oil separator under off-shore operation.” Journal of Petroleum Science and Engineering171 (2018): 731-747.

Figure 1: Schematic showing the basic principle of the Three-Phase Separator geometry.

Simulation Process: Eulerian Multiphase Setup in Fluent

To start this Three-Phase Separator Fluent tutorial, we first built a 3D model of the vessel. Since the tank is symmetrical, we only modeled half of it to save simulation time. The geometry includes a special inlet cap to stop the incoming fluid from splashing and a bucket to help calm the liquid. We then generated a mesh containing 200,664 tetrahedral cells. A mesh of this size is necessary to capture the boundaries between the different fluids accurately.

In the ANSYS Fluent setup, we selected the Eulerian Multiphase model. This is the most advanced model for this type of Three-Phase Separator ANSYS Fluent study because it solves equations for each phase (air, oil, water) separately but allows them to interact. We also included Drag and Surface Tension forces, which are critical for predicting how oil droplets rise through water or how water droplets settle out of oil. The goal is to simulate the physical settling process driven by density differences.

Figure 2: The geometry and mesh for the Oil-Water-Air Separator CFD simulation.

Post-processing: Analysis of Gravity Separation and Residence Time

A real analysis of the simulation results, based on the provided contours and geometry, explains exactly how the mechanical design forces the fluids to separate. The process begins at the inlet, where the high-speed mixture hits the Inlet Diverter Cap. The simulation shows that this simple plate plays a massive role. It absorbs the kinetic energy of the incoming jet, slowing the fluid down immediately. Without this cap, the jet would shoot straight to the bottom, churning the water and preventing any separation. Once the flow is calmed, Gravity Separation takes over.

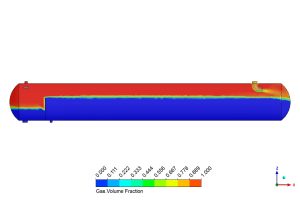

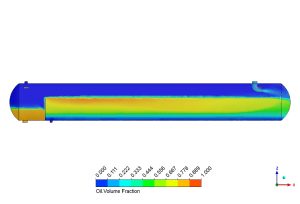

The contours reveal two distinct separation speeds. The air separates almost instantly. Because gas is very light (low density), buoyancy forces pull it straight to the top of the vessel. The Air Volume Fraction contour confirms this, showing a clean blue layer of gas collecting at the very top, ready to exit through the porous zone. However, the separation of oil and water is much slower because their densities are similar (oil is only slightly lighter than water). This is where the Bucket becomes the hero of the design. The bucket acts as a barrier that holds the liquid in the main chamber, increasing the “residence time.” Residence time is the amount of time the fluid stays in the tank. By forcing the liquid to stay longer in a calm state, the heavy water droplets have enough time to sink to the bottom, and the oil droplets have enough time to float up. The Oil Volume Fraction contour clearly shows this stratification: a defined yellow-green oil layer forms comfortably on top of the water layer, sandwiched below the gas. This Three-Phase Separator ANSYS Fluent analysis proves that the combination of the inlet diverter (to stop turbulence) and the bucket (to increase time) is what makes efficient separation possible.

Figure 3: Volume fraction contours showing the clear separation of Air (top), Oil (middle), and Water (bottom).

Key Takeaways & FAQ

- Q: Why do we use the Eulerian model for this simulation?

- A: The Eulerian multiphase model is used in ANSYS Fluent because it is the most accurate way to simulate high-volume fractions of multiple fluids (Oil, Water, Air) mixing and separating simultaneously.

- Q: What is the purpose of the Inlet Diverter Cap?

- A: As shown in this Three-Phase Separator CFD simulation, the inlet cap blocks the high-speed incoming fluid. It dissipates the momentum, preventing turbulence that would mix the oil and water back together.

- Q: What is residence time and why does the bucket help?

- A: Residence time is how long fluid stays in the tank. The bucket prevents the liquid from flowing directly to the outlet. It creates a pool where the liquid sits quietly, giving gravity enough time to pull the oil and water apart.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€170 Original price was: €170.€155Current price is: €155.

€205 Original price was: €205.€165Current price is: €165.

€175 Original price was: €175.€115Current price is: €115.

€195 Original price was: €195.€135Current price is: €135.

€205 Original price was: €205.€155Current price is: €155.

€330 Original price was: €330.€199Current price is: €199.

Reviews

There are no reviews yet.