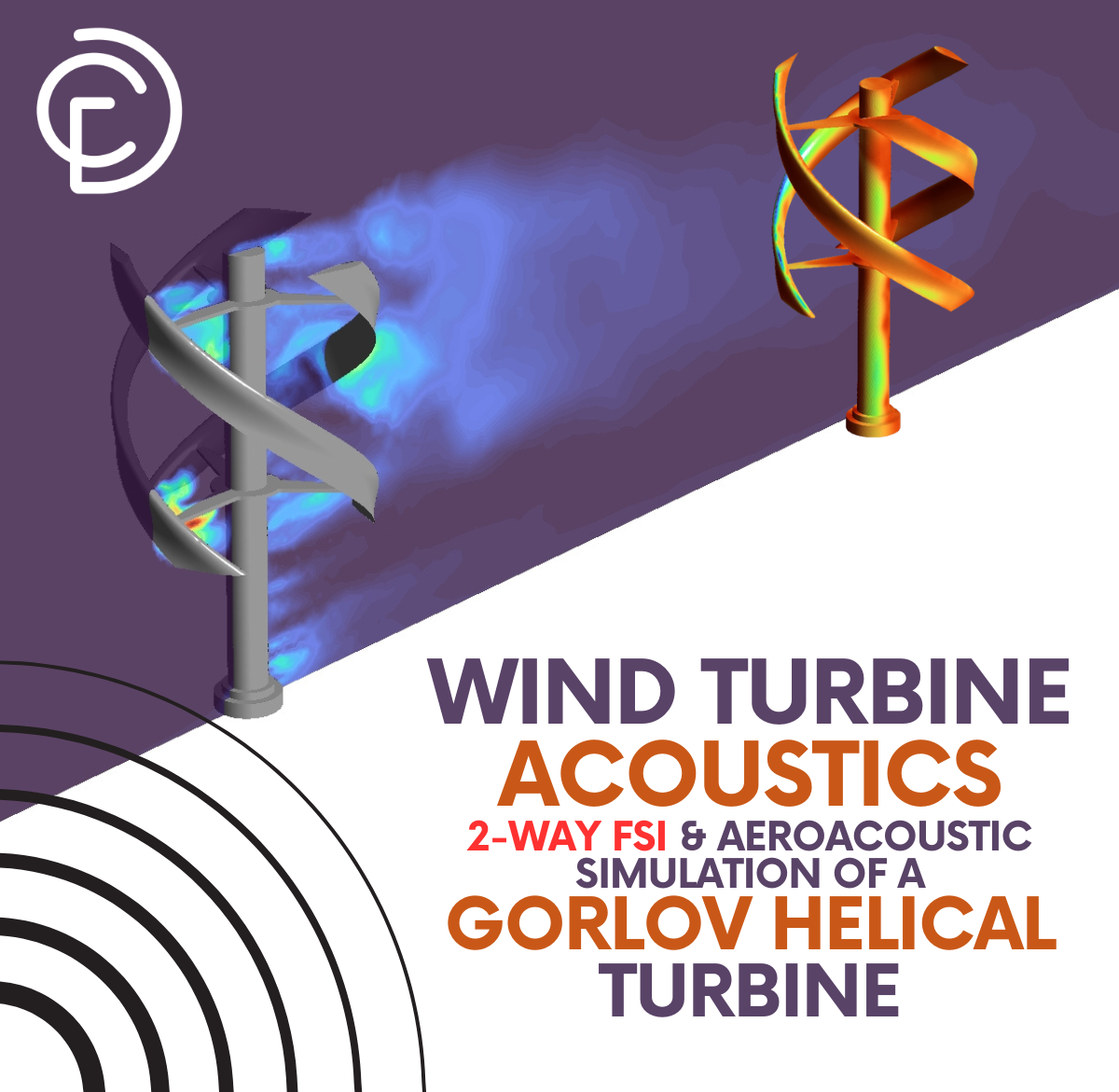

Wind Turbine Acoustics CFD: A 2-Way FSI and Aeroacoustic Simulation of a Gorlov Helical Turbine

Wind Turbine Acoustics CFD: A 2-Way FSI and Aeroacoustic Simulation of a Gorlov Helical Turbine

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170 Original price was: €170.€155Current price is: €155.

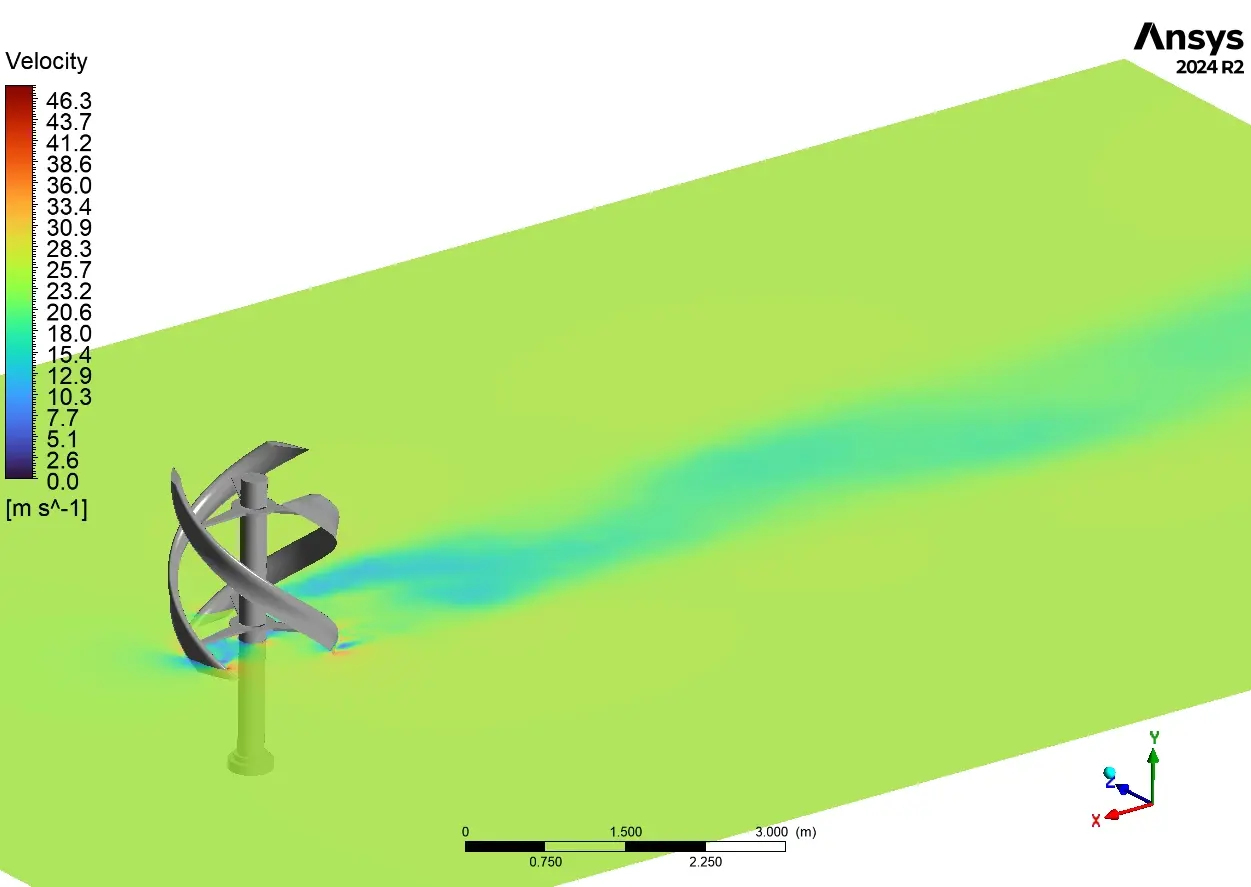

A Wind Turbine Acoustics CFD simulation is a vital computer analysis for developing modern renewable energy systems. The noise generated by rotating blades is a major design challenge. A Wind Turbine aeroAcoustics CFD Simulation using ANSYS Fluent allows engineers to predict this noise and understand its sources. This report details a study on a special Gorlov Helical Wind turbine, using an advanced method called Wind turbine FSI fluent analysis.

This Wind turbine FSI CFD simulation combines fluid flow, structural mechanics, and acoustics. It shows how the wind makes the turbine spin, how the blades bend under the load, and how much noise is created. To predict the sound, the industry-standard Ffowcs Williams-Hawkings (FW-H) acoustic model was used. By analyzing the Starting wind turbine CFD behavior with a dynamic mesh fluent model, we can see the entire process. This complete analysis is essential for designers to create wind turbines that are not only efficient but also structurally safe and quiet. For more renewable energy CFD simulation tutorials and advanced acoustic CFD projects, visit: https://cfdland.com/product-category/engineering/renewable-energy-cfd-simulation/

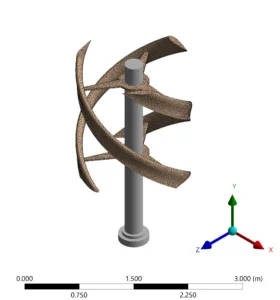

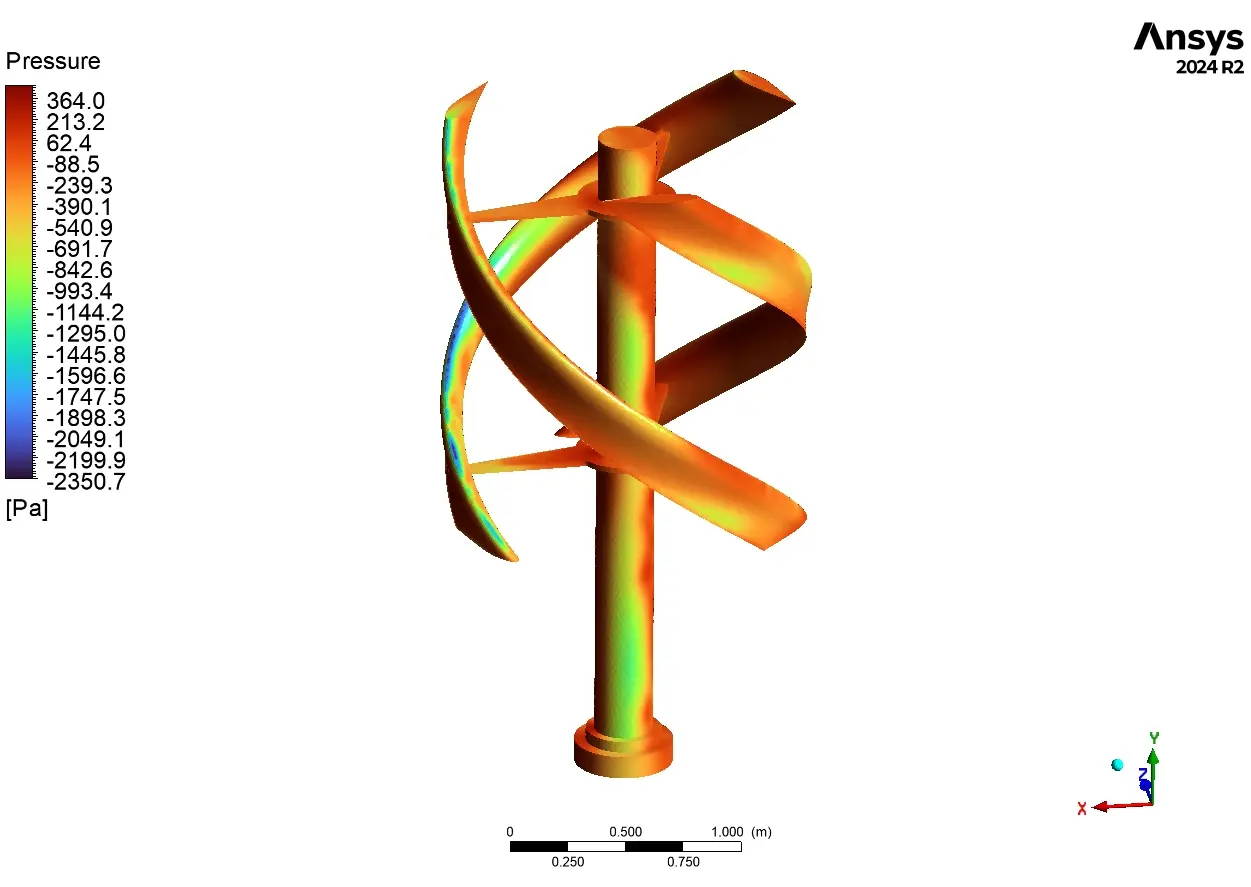

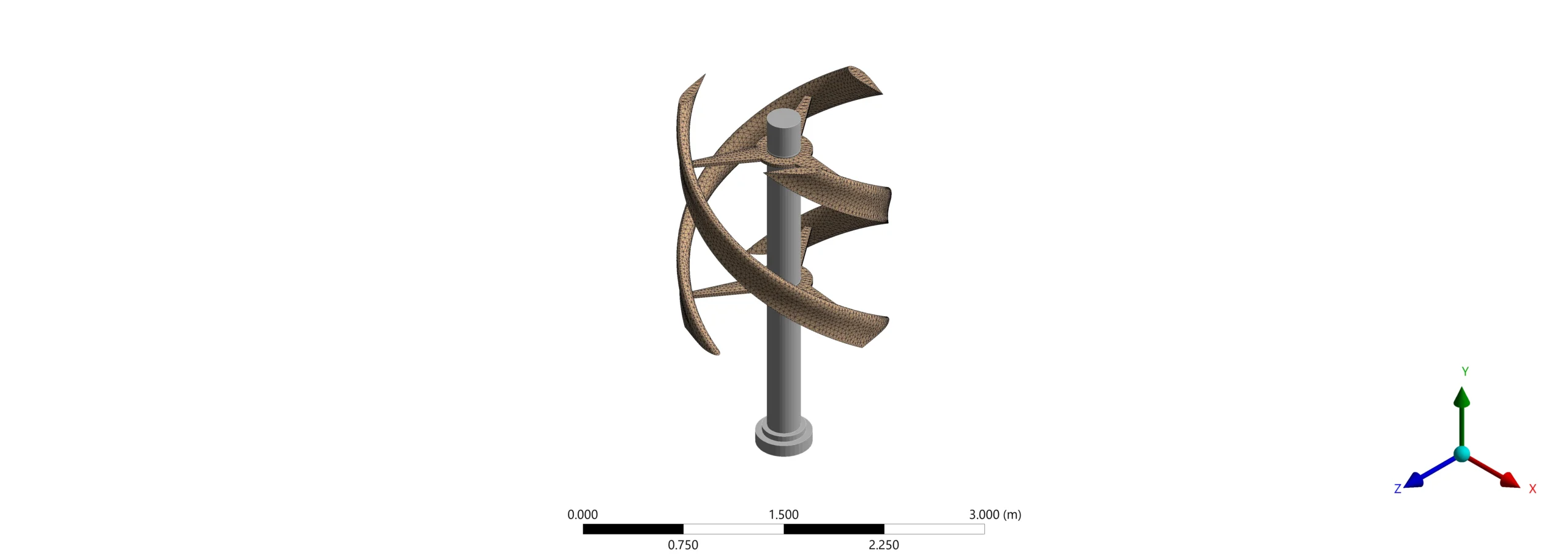

Figure 1: The 3D geometry of the Gorlov Helical Vertical Axis Wind Turbine (VAWT) used for the FSI and acoustic CFD simulation.

Simulation process: Fluent-CFD Setup, A Coupled FSI, Dynamic Mesh, and Wave Acoustic Model

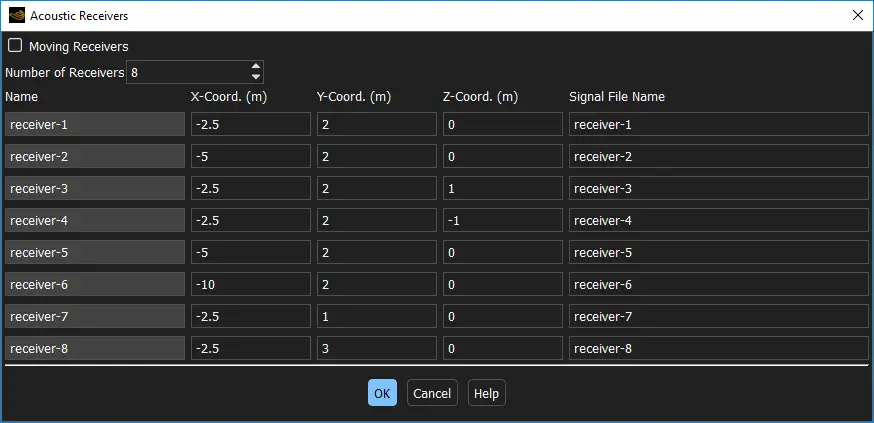

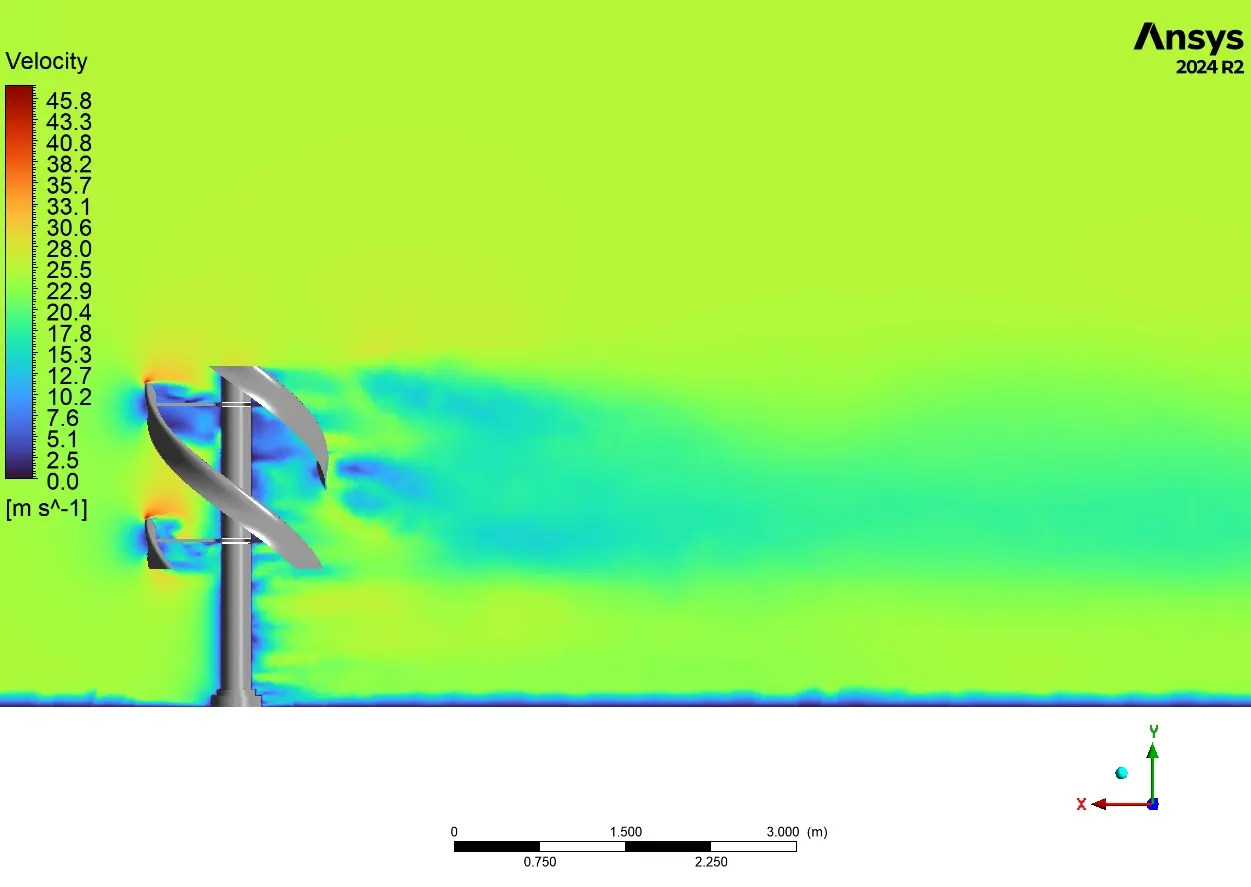

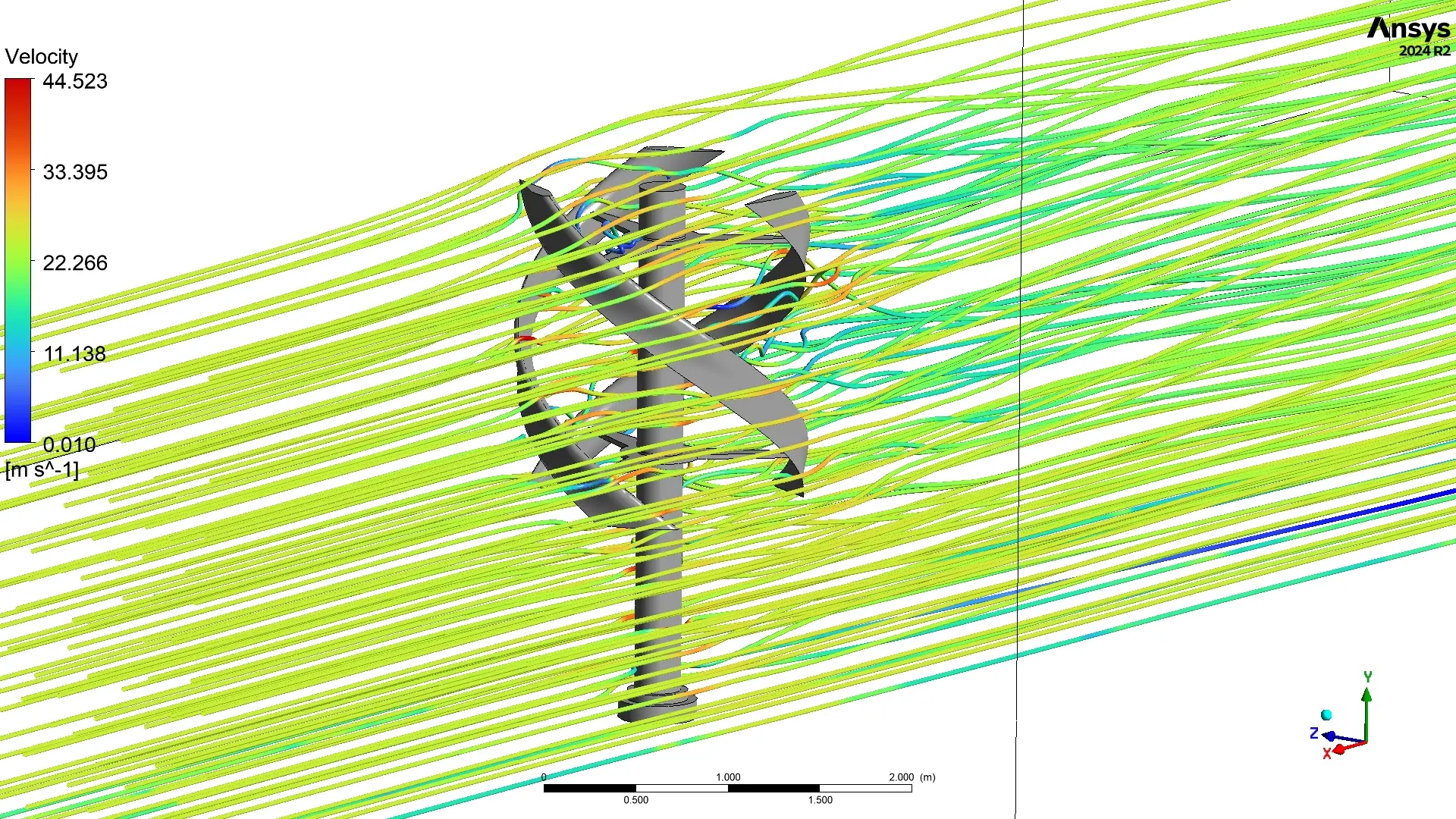

The simulation process for this Gorlov Helical Wind turbine CFD study began with the 3D geometry of the turbine. A high-quality computational grid was created for both the fluid domain (air) and the solid domain (the turbine structure). A critical part of this simulation was the setup of the 2-way Fluid-Structure Interaction (FSI) coupling. This means that two solvers, ANSYS Fluent for the fluid and ANSYS Mechanical for the structure, were linked to work together in real-time. The simulation was configured to analyze the turbine’s startup behavior. Initially, the turbine was stationary (zero rotational speed), and a wind of 25 m/s was applied. As the simulation started, the aerodynamic forces began to act on the blades. To handle the resulting rotation, the Dynamic Mesh module in Fluent was activated, using both smoothing and remeshing techniques to ensure the mesh quality remained high as the turbine moved. Simultaneously, the Ffowcs Williams-Hawkings (FW-H) Acoustics Model was enabled in Fluent. This specialized tool uses the pressure data from the unsteady flow on the blade surfaces to accurately predict the sound that travels away from the turbine. At every time step, the pressure and shear forces calculated by Fluent were sent to ANSYS Mechanical, which then calculated the resulting blade bending and displacement. This structural information was immediately sent back to Fluent to update the position of the dynamic mesh, creating a fully coupled and physically realistic simulation.

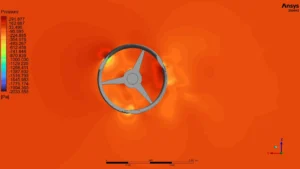

Figure 2: The computational mesh generated for the Wind Turbine in Ansys Mechanical

Post-processing: CFD Analysis of Performance, Stress, and Noise

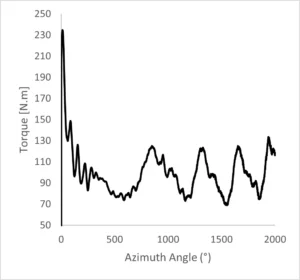

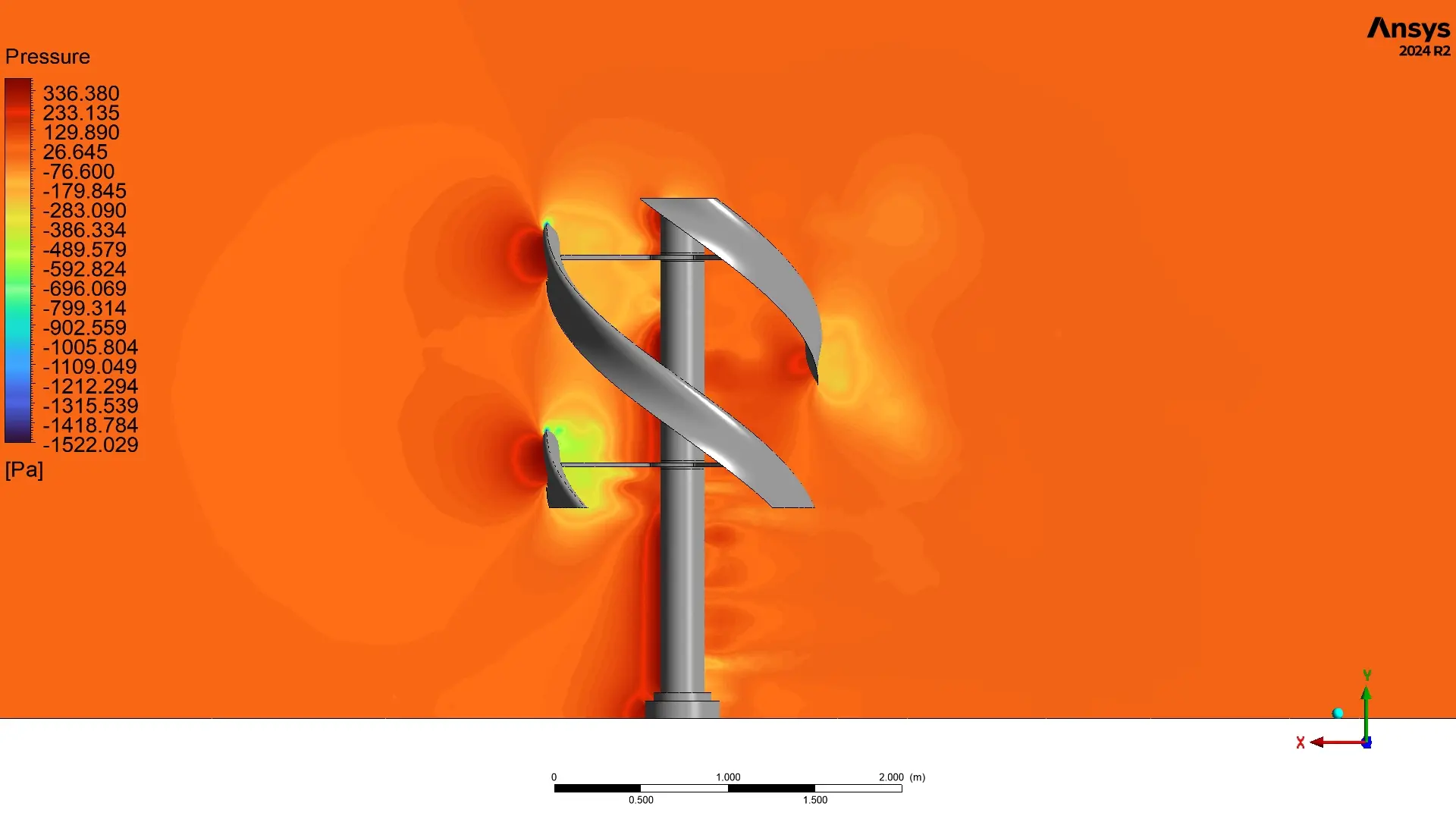

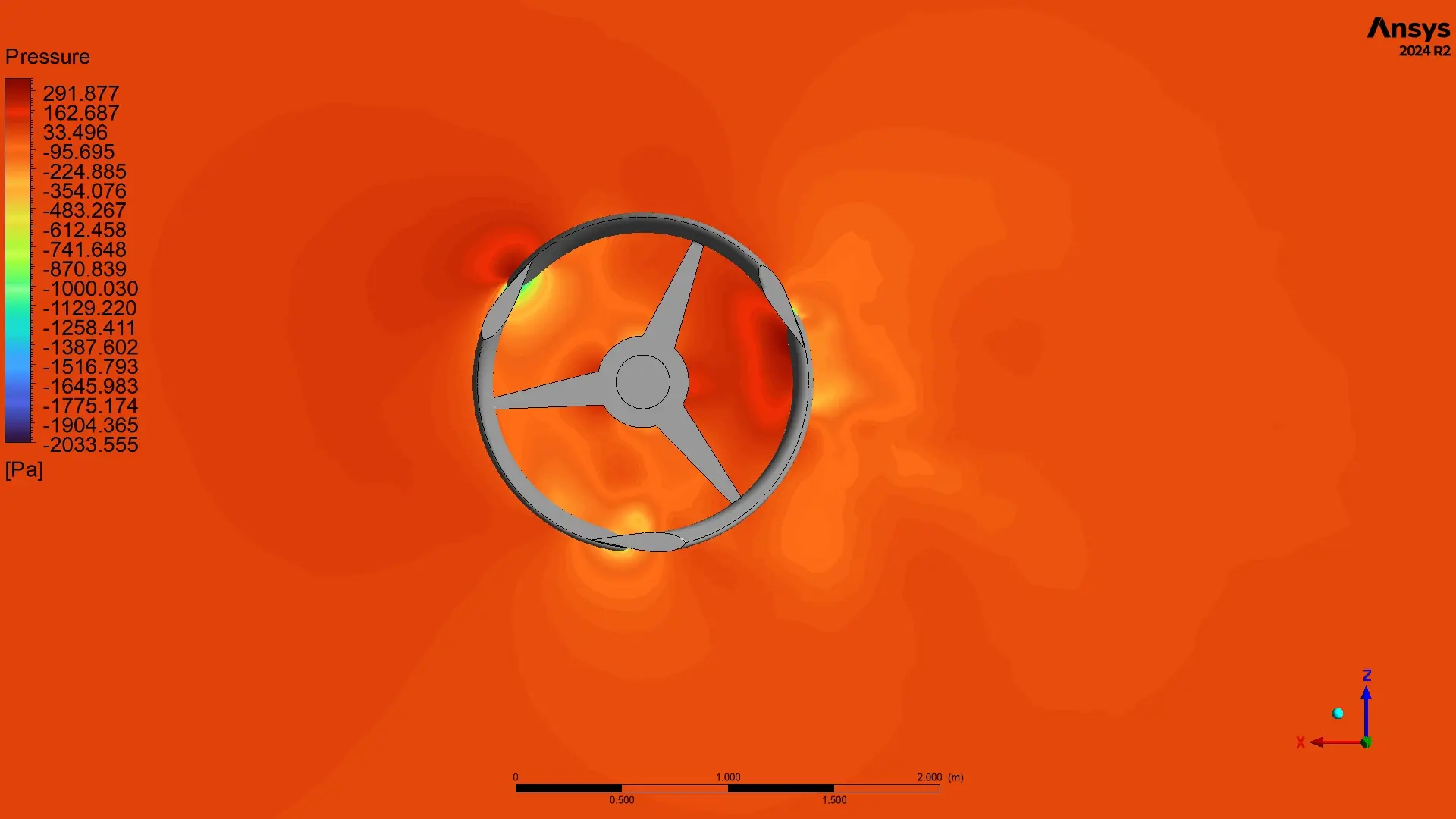

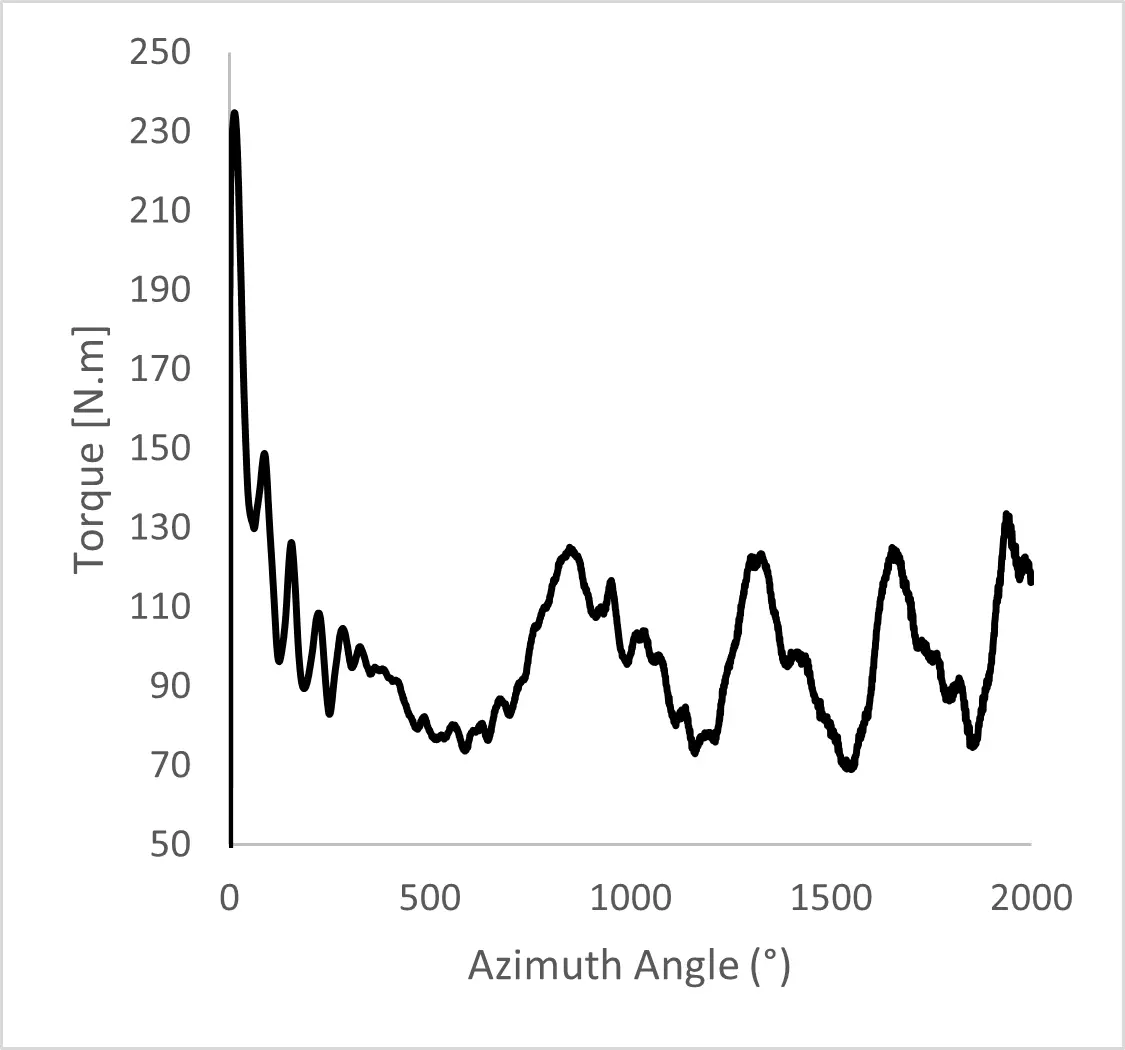

The simulation results provide a complete engineering story, connecting the aerodynamic forces that make the turbine spin, the resulting stress on its structure, and the acoustic noise it produces. The analysis starts with the fundamental driving force. The pressure contour in Figure 3 shows a large pressure difference across the helical blades, ranging from a high of +291 Pa on the front surfaces to a very low pressure of -2033 Pa on the back surfaces. From an engineering viewpoint, this pressure differential is the engine of the turbine. It creates the rotational force, or torque. The torque graph in Figure 6 shows this force in action. As the turbine starts from rest, the torque quickly rises to a peak of 237 N.m, demonstrating the turbine’s strong self-starting capability in a 25 m/s wind. The torque then fluctuates between 70 N.m and 240 N.m as the turbine rotates.

Figure 3: Pressure contours from the Wind Turbine FSI CFD simulation, illustrating the pressure difference between the front and back of the blades that generates rotational torque.

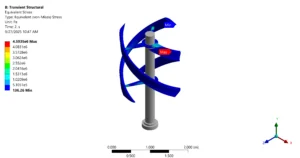

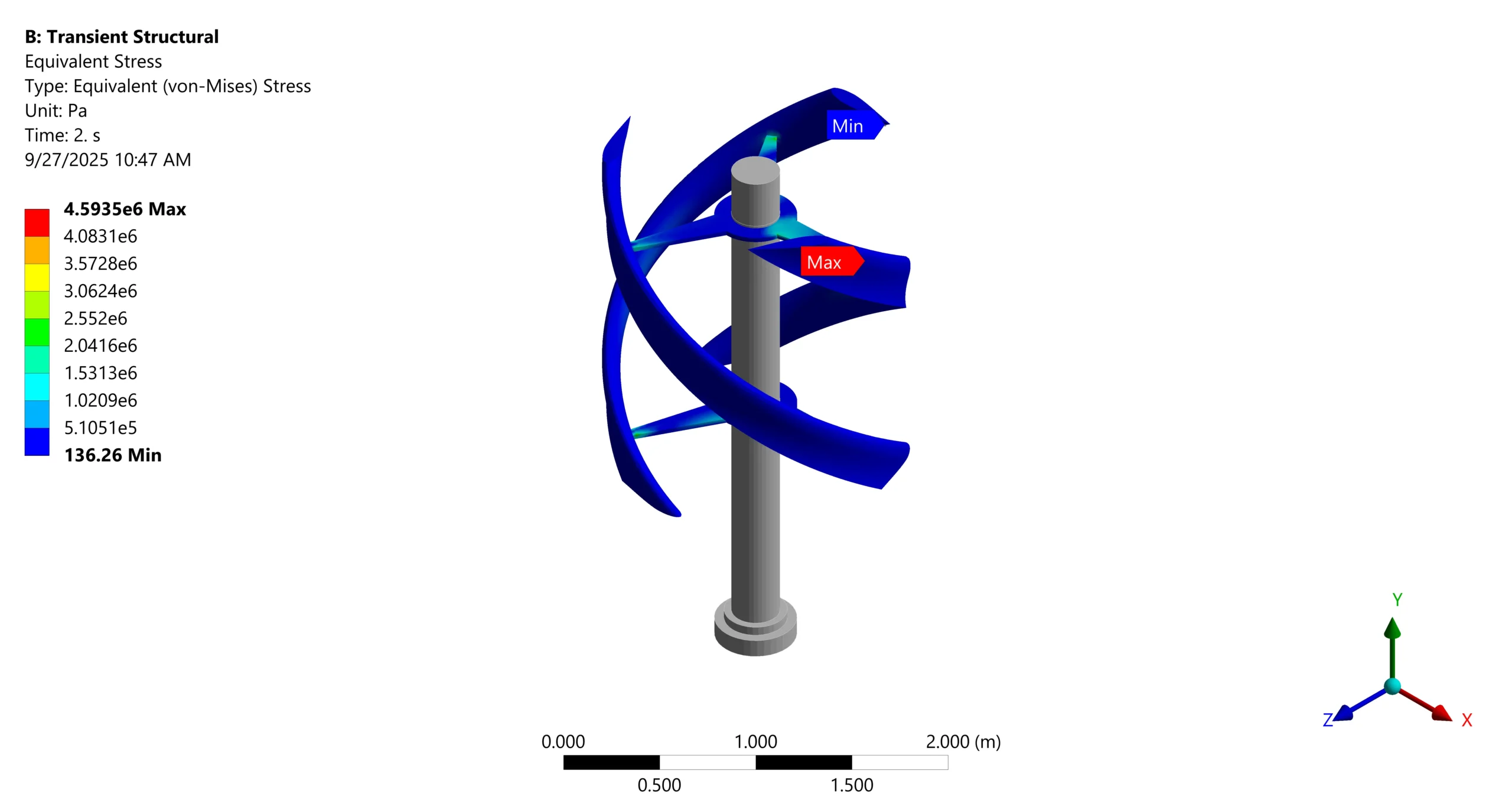

This powerful aerodynamic loading has a direct structural consequence. The 2-way FSI coupling allows us to see this in the equivalent stress contour in Figure 5. The maximum stress on the blades reaches 4.59 MPa. Crucially, the simulation shows that this highest stress is concentrated at the blade-hub connection points. This is the most important structural finding; it identifies the most likely point of failure due to fatigue and tells designers exactly where reinforcement is needed.

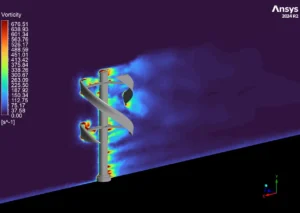

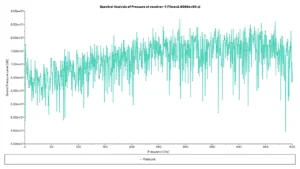

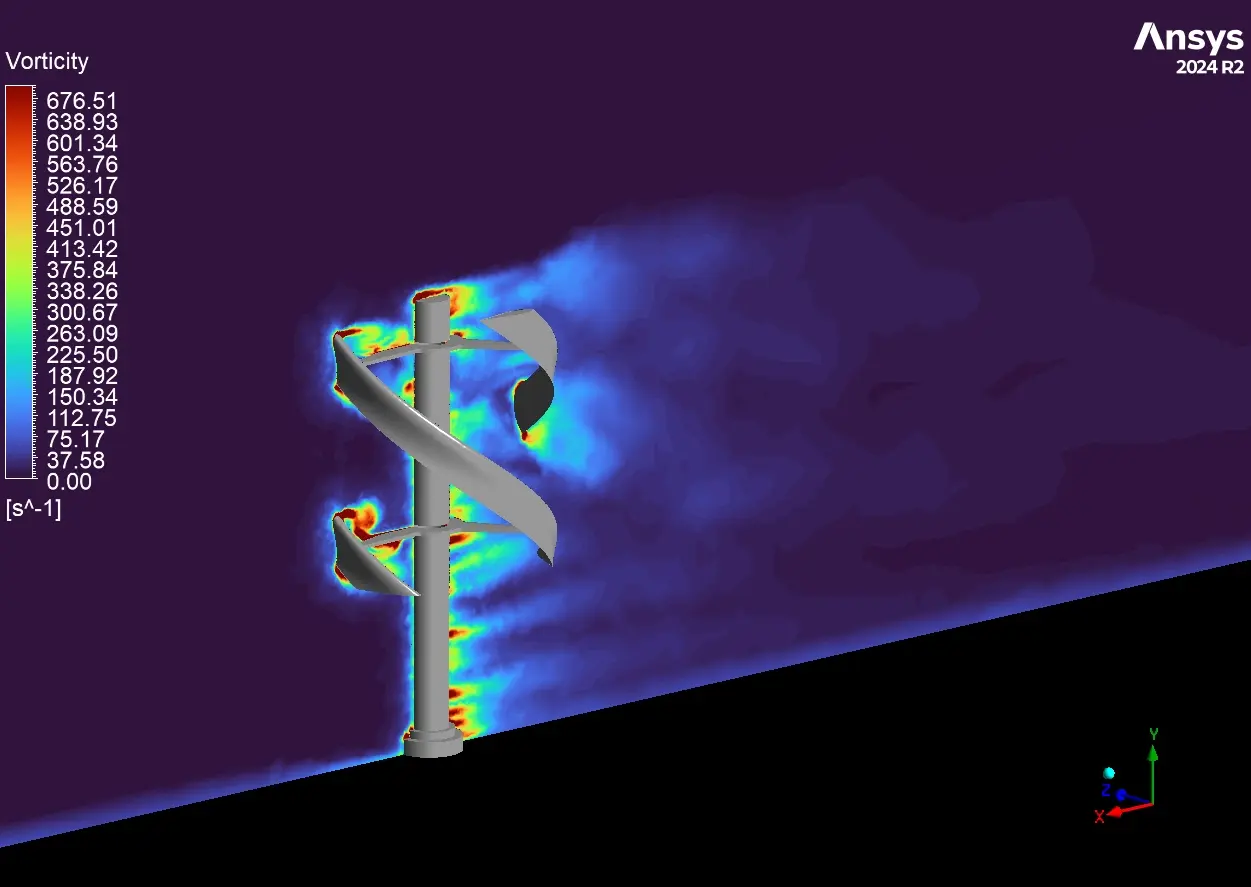

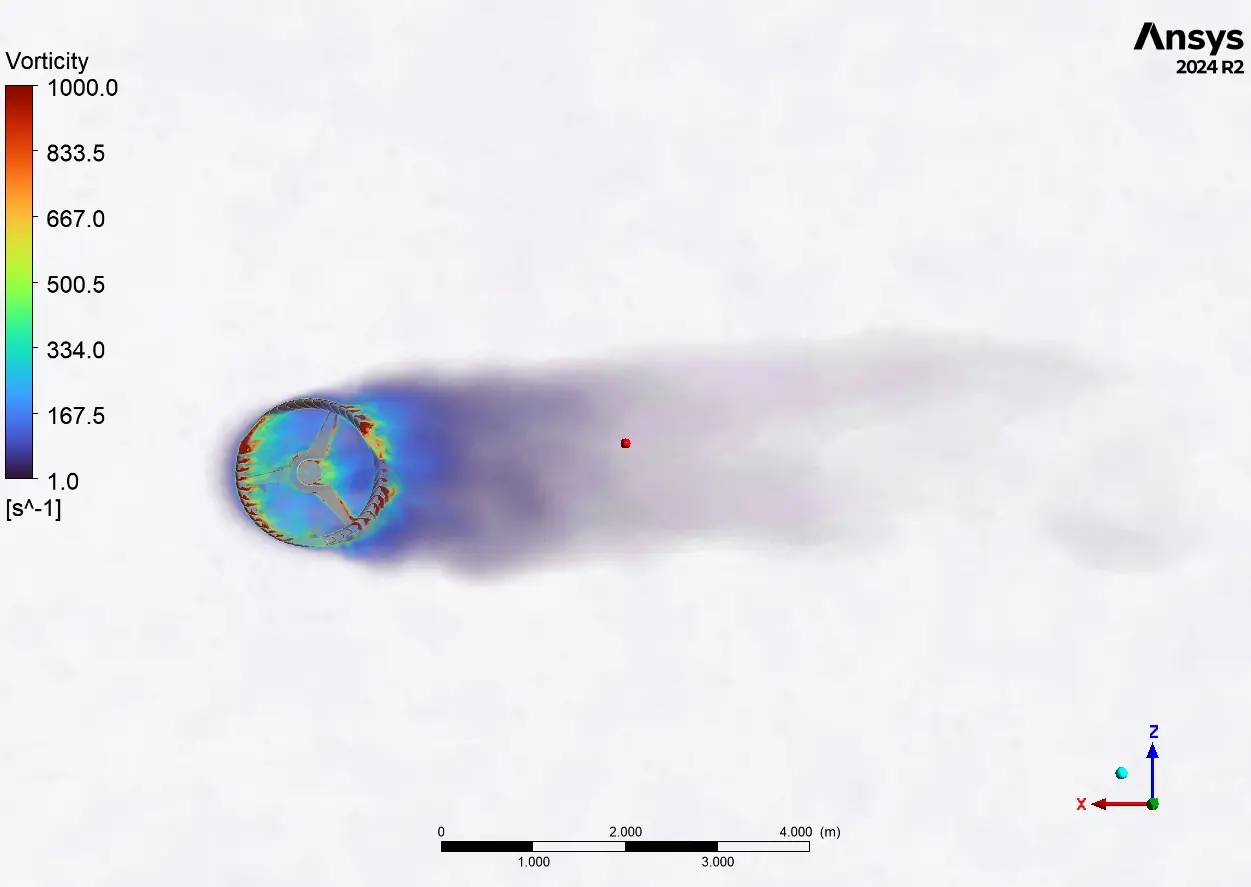

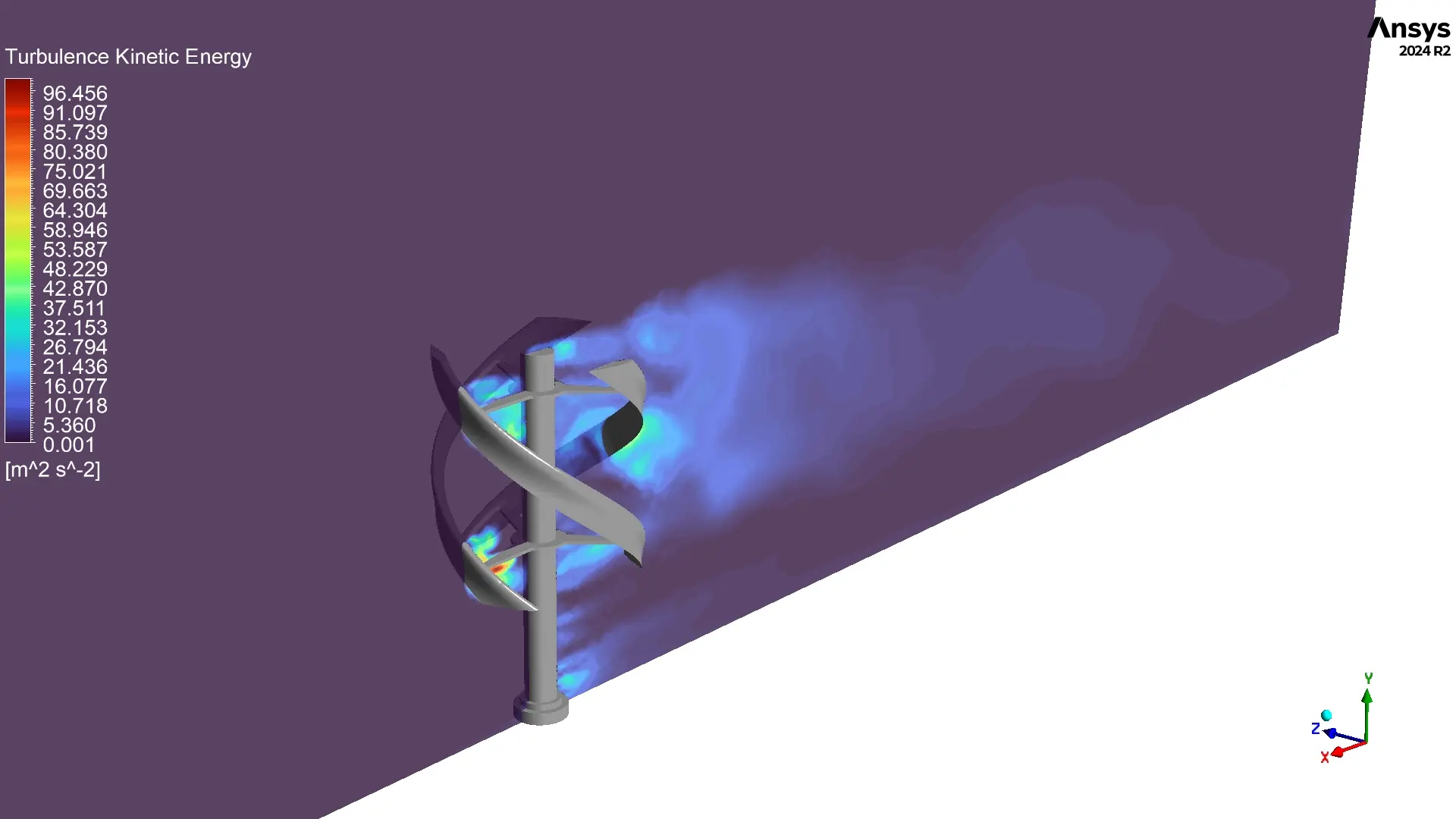

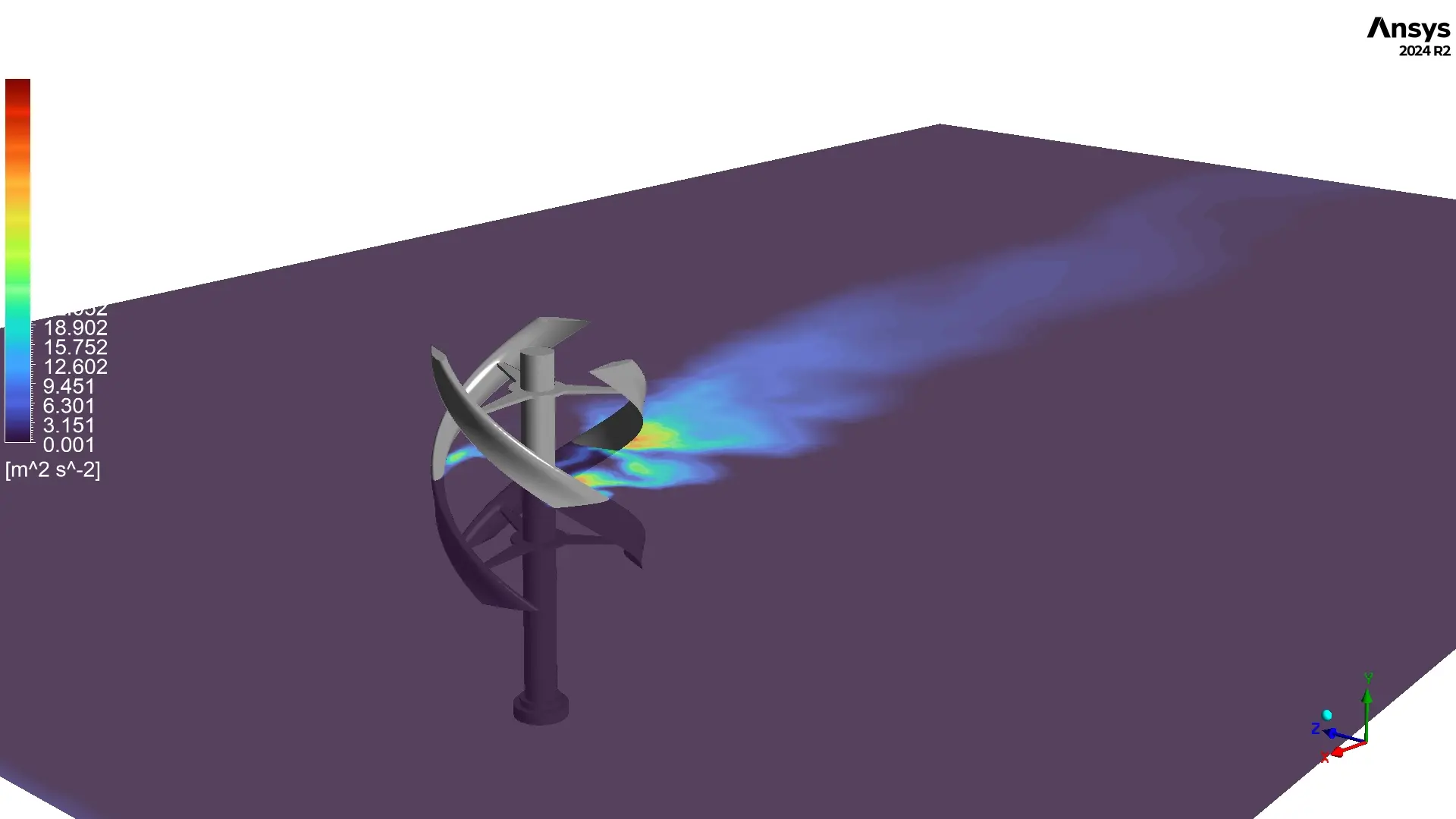

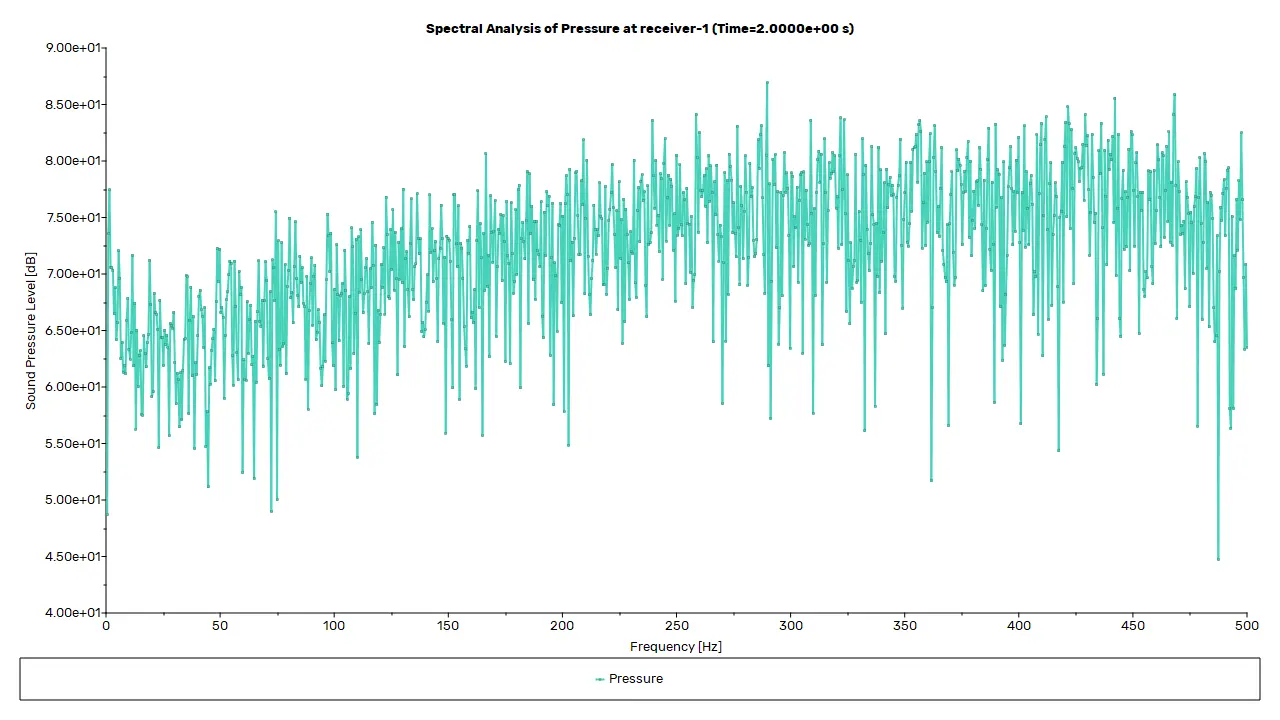

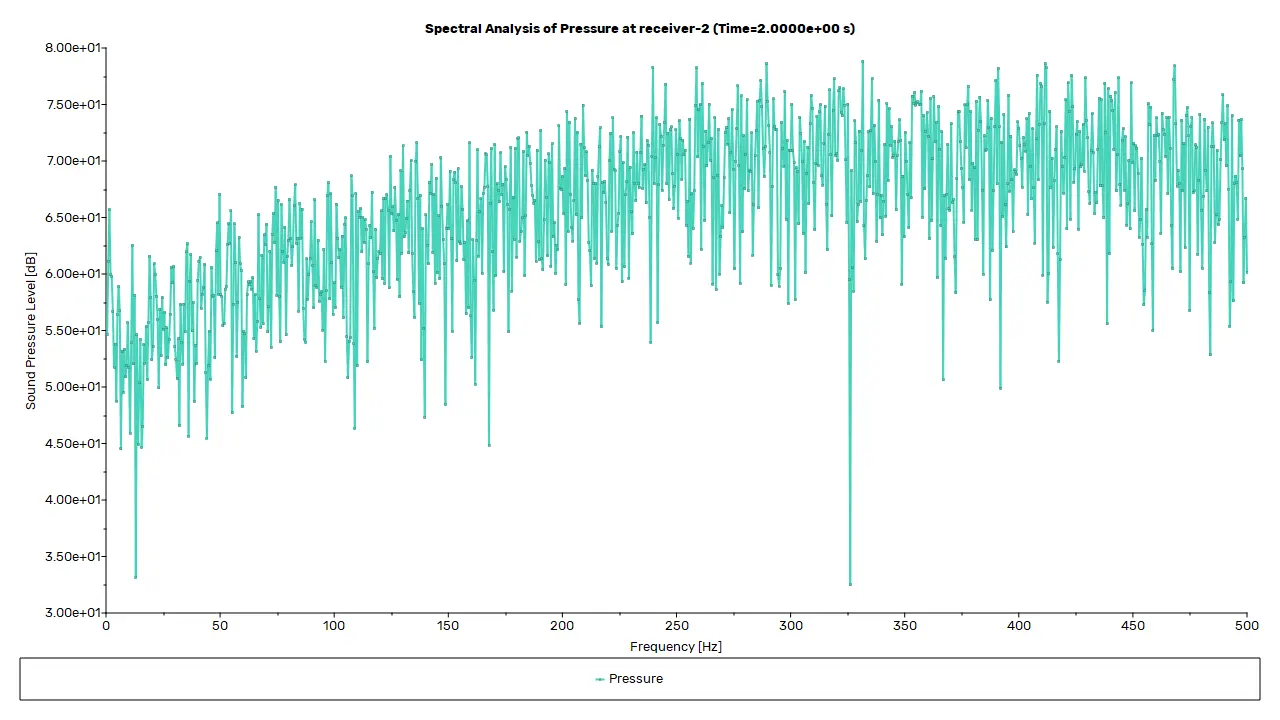

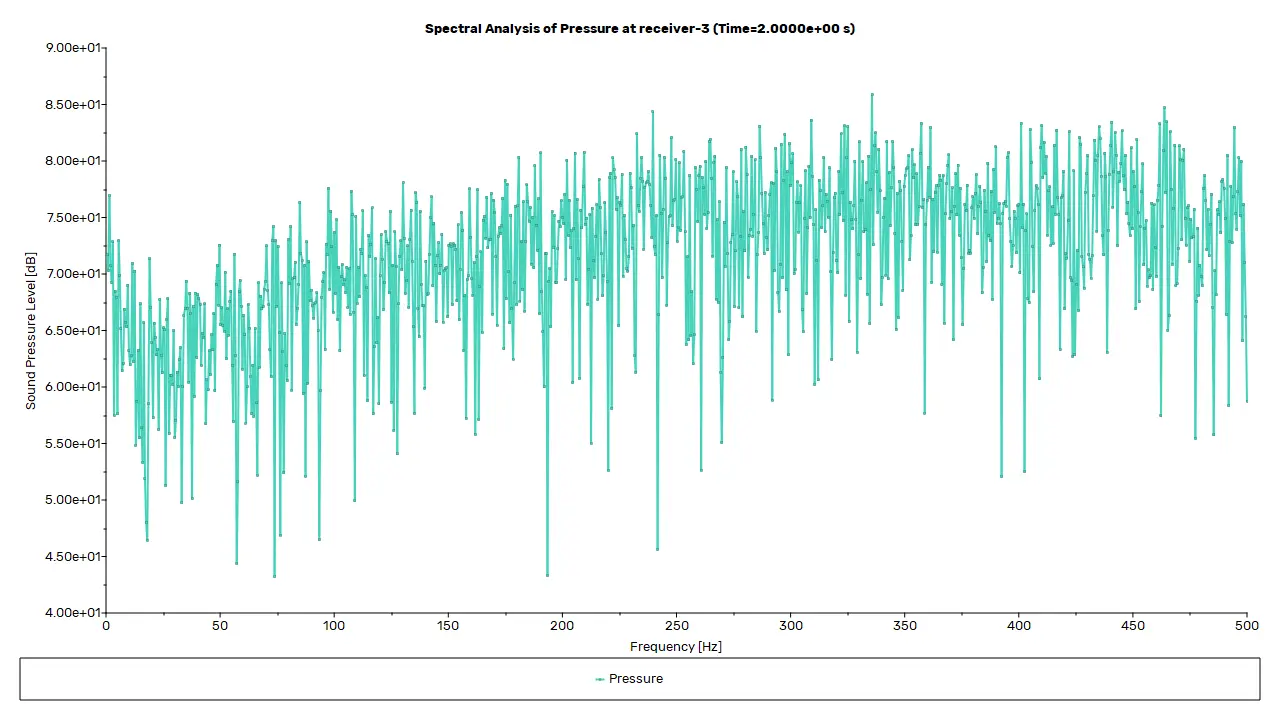

The aerodynamic forces not only create power and stress, but also noise. The vorticity contour in Figure 4 reveals the source of this noise. The regions of high vorticity, reaching up to 676.51 s⁻¹, show where the air becomes highly turbulent and forms swirling vortices, especially as it leaves the blade’s trailing edges. These turbulent structures create rapid pressure fluctuations, which travel through the air as sound waves. The FW-H acoustic analysis in Figure 7 captures this sound. The spectral plot shows that the noise is broadband, as expected from turbulence, with sound levels ranging from 45 dB to a peak of approximately 87 dB. The simulation precisely identifies the

Figure 4: Vorticity contours from the Fluent simulation, visualizing the turbulent wake and vortex shedding structures that are the primary sources of Wind Turbine AeroAcoustics.

Figure 5: Equivalent stress contours from ANSYS Mechanical, showing the structural response of the blades calculated through the 2-way FSI coupling.

Figure 6: The torque generation graph, which is a key result for analyzing the Starting wind turbine CFD performance from a stationary position..

Figure 7: The spectral analysis plot from the FW-H acoustic model in Fluent, showing the predicted Sound Pressure Level (SPL) and dominant noise frequencies at a specific receiver location.

The most important achievement of this simulation is the successful integration of fluid dynamics, structural response, and aeroacoustics into a single, comprehensive analysis. For a designer or manufacturer, this data is invaluable. It provides a complete performance picture, allowing them to:

- Optimize Power: Modify the blade shape to maximize the pressure difference and increase the average torque.

- Ensure Safety: Strengthen the blade-hub connection identified as a high-stress area to guarantee a long operational life.

- Reduce Noise: Redesign the blade tips and trailing edges to change the vortex shedding patterns (seen in Figure 4), which will directly reduce the 87 dB noise peaks (seen in Figure 7), leading to quieter and more community-friendly turbines.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€180 Original price was: €180.€150Current price is: €150.

€195 Original price was: €195.€165Current price is: €165.

€180 Original price was: €180.€135Current price is: €135.

€155 Original price was: €155.€95Current price is: €95.

Reviews

There are no reviews yet.