Have you ever carried a full cup of coffee and had to walk carefully to stop it from spilling? That back-and-forth movement of the coffee is a simple example of sloshing. In engineering, sloshing is the movement of a liquid inside a container that is also moving. While it seems simple, this effect is a very important problem in multiphase flow systems.

Contents

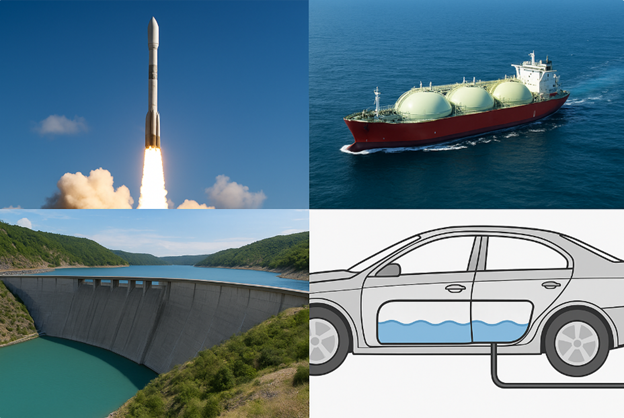

ToggleSo, why does sloshing matter so much? This movement can create powerful waves and high-impact forces that can damage the container or affect the stability of the entire system. This is a critical challenge in many industries:

- Aerospace: In rockets, propellant sloshing inside fuel tanks can change the rocket’s center of mass and interfere with its flight control.

- Marine: For large ships like oil tankers, the violent sloshing of liquid cargo can create huge forces on the tank walls and even affect the stability of the vessel in rough seas.

- Automotive: In cars, fuel sloshing can cause annoying noises and make fuel gauges inaccurate.

In the past, engineers had to build expensive physical models to study these effects. Today, we use Computational Fluid Dynamics (CFD). A sloshing CFD simulation lets us see exactly how the liquid will move, helping us design safer tanks and better control systems.

To show you the power of CFD in sloshing analysis, we will refer to some amazing simulations throughout this blog. We will see how to model these complex scenarios, including:

- A 3D sloshing tank using a dynamic mesh to capture large liquid movements.

- A sloshing simulation using a UDF for defining custom tank motions.

- An advanced two-way Fluid-Structure Interaction (FSI) analysis of an oil tanker, where the liquid and the tank structure affect each other.

Figure 1: Great sloshing CFD tutorials provided by CFDLAND

Physics of Sloshing: A Multiphase Perspective

To understand a sloshing simulation, we must first understand the physics. The movement of the liquid can seem random, but it follows clear rules. This section explains the basic science behind the sloshing phenomenon.

Free Surface Dynamics and Interface Tracking

In any multiphase sloshing problem, we have at least two fluids: a liquid (like water or oil) and a gas (like air). The line where these two fluids meet is called the free surface. Imagine a glass of water; the flat top of the water is the free surface. When sloshing happens, this surface is no longer flat. It moves, forms waves, and can even break apart. The main goal of a free surface flow CFD simulation is to accurately track the position and shape of this free surface over time. This is a big technical challenge, because the surface is constantly changing.

Forces and Mechanisms Driving Sloshing

Sloshing doesn’t happen by itself. It starts because of forces. When a tank moves or accelerates, the liquid inside wants to stay in its original position because of inertia. Think about when you are in a car that suddenly moves forward – you feel pushed back into your seat. The liquid feels the same push. This “push” from the tank’s movement is the main force that starts the sloshing. Gravity is the other key force. It always tries to pull the liquid back down, which is what creates the wave-like motion as the liquid moves back and forth. These two forces—the tank’s acceleration and gravity—are the primary drivers of liquid sloshing dynamics.

Key Parameters Affecting Sloshing Behavior

Several things can change how a liquid sloshes. The most important parameters are:

- Fill Level: A tank that is nearly full or nearly empty will have very little sloshing. The most violent sloshing usually happens when a tank is about half full.

- Tank Geometry: The shape of the tank has a big effect. Tanks with complex shapes or internal walls, called baffles, can reduce the amount of sloshing.

- Liquid Properties: The density and viscosity of the liquid are important. A thick liquid like honey will slosh much less than a thin liquid like water.

- Motion of the Tank: The speed and frequency of the tank’s movement are critical. Slow, gentle movements will cause small waves, while fast, jerky movements will cause large, violent waves.

Resonance and Natural Frequencies

Every tank has a natural frequency. This is the specific timing at which the liquid inside likes to slosh back and forth. Resonance is a dangerous situation that happens when the tank is shaken at exactly this natural frequency. When this happens, each new shake adds more energy to the wave, making it bigger and bigger. As noted, studying this resonance frequency is a key part of sloshing CFD simulation. Understanding and avoiding resonance is a primary goal of sloshing analysis because these huge waves can create very high sloshing impact pressure and damage the tank structure.

Figure 3: Resonance occurs when the tank’s motion matches the liquid’s natural frequency, causing wave height to grow dangerously large

Multiphase Modeling Approaches for Sloshing

To perform a sloshing CFD simulation, you need the right tools inside the software. Choosing the correct models is the most important step for getting accurate results. This section explains the best approaches for a sloshing ANSYS Fluent simulation.

Volume of Fluid (VOF) Method for Free Surface Flows

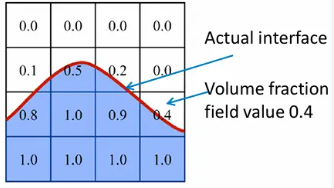

First, we need a way to track the free surface. The best tool for this is the Volume of Fluid (VOF) model. The Sloshing VOF Model works by giving each cell in the mesh a number between 0 and 1.

- If a cell’s value is 0, it is 100% full of gas (like air).

- If a cell’s value is 1, it is 100% full of liquid (like water).

- If the value is between 0 and 1, it means the free surface passes through that cell.

The VOF model is the recommended multiphase model for sloshing. This method is very good at capturing the sharp, clear interface between the liquid and the gas. You can read more about VOF multiphase model here.

Figure 4: Volume of Fluid (VOF) model tracks the free surface by calculating the liquid fraction in every mesh cell

Variable Gravity vs. Moving Dynamic Mesh Approaches

Next, we need to make the tank move. There are two main ways to do this in a CFD sloshing simulation:

- Variable Gravity Approach: In this method, the tank and its mesh stay still. Instead of moving the tank, we change the direction of gravity using a User-Defined Function (UDF). It’s like tricking the liquid into thinking it’s being moved. This method is simpler and often faster to compute.

- Moving Dynamic Mesh Approach: This is a more direct method. The mesh of the tank actually moves, rotates, or shakes, just like it would in the real world. This approach is very powerful for simulating complex motions and is often more intuitive. A perfect example of this is a 3D sloshing tank CFD simulation using dynamic mesh, which accurately captures the violent motion of the liquid. Often, the exact motion of the tank is programmed using a sloshing tank UDF.

Choosing between these two approaches depends on your specific problem, but the Moving Dynamic Mesh is generally used for more complex, large-scale motions.

Turbulence Modeling at the Interface

When sloshing is violent, the flow at the free surface can become very messy and chaotic. This is called turbulence. To capture this effect accurately, we need to use a turbulence model. As recommended, good choices for sloshing problems are the SST K-omega or Realizable K-Epsilon models. These models help the simulation predict the energy loss and mixing that happens at the interface.

Surface Tension and Wall Adhesion Effects

Surface tension is the force that makes a liquid’s surface act like a thin, stretched skin. Wall adhesion is how the liquid “sticks” to the tank walls. These forces are usually small in large tanks. However, as noted in references, these effects “may be important” for smaller tanks or for liquids with very high surface tension. Including these effects can make your sloshing simulation more accurate in those specific cases.

Applications and Industry Solutions

The sloshing phenomenon is a critical challenge in many fields, and CFD simulations are the best way to solve it. In the aerospace industry, propellant sloshing inside a rocket’s fuel tank can affect its stability during flight. A sloshing analysis using ANSYS Fluent helps engineers design control systems that can handle these movements, ensuring the mission is successful. This type of sloshing CFD work is essential for the safety and reliability of space travel.

In the marine industry, the scale of the problem is massive. On large ships carrying Liquefied Natural Gas (LNG) or oil, violent sloshing can create huge sloshing impact forces on the tank walls. These forces can damage the structure and even risk the stability of the entire vessel. Engineers use CFD simulations to design internal walls called baffles that reduce wave heights and control these forces. The most advanced studies even use Fluid-Structure Interaction (FSI), like in this two-way FSI analysis of an oil tanker, to see how the liquid and the tank structure affect each other in real-time.

The applications are also relevant to our daily lives. In the automotive sector, fuel tank sloshing can cause annoying noises and make fuel gauges inaccurate. A sloshing simulation helps engineers design quieter, more efficient fuel tanks. Finally, in civil engineering, a seismic sloshing analysis is used to understand how water in large storage tanks or dams will behave during an earthquake. This analysis is vital for ensuring these structures are safe and can withstand natural disasters.

Figure 5: From ensuring rocket stability to designing safer ships and cars, sloshing analysis is a critical part of modern engineering across many industries

Conclusion

In this article, we explored the world of the sloshing phenomenon. We saw how the movement of liquids in a container is a critical design challenge in major industries like aerospace, marine, and automotive. Understanding the physics of the free surface, the danger of resonance, and the impact forces is essential for creating safe and efficient products. Computational Fluid Dynamics (CFD) provides a powerful and accurate way to study and predict these complex liquid motions.

Using tools like the VOF model and dynamic mesh in ANSYS Fluent, engineers can perform detailed sloshing simulations that save time and money by reducing the need for physical testing. From designing stable rockets to ensuring the structural safety of large ships, sloshing CFD is an indispensable part of modern engineering.

If you have a project involving sloshing or any multiphase problem, our experts are here to help. For professional consultation and simulation services, you can contact our experts for ordering the project via the LINK.